Section of rear floor 5D

| Section of rear floor 5D |

| 1. |

Position the car in an aligning bench and cross-measure if necessary.

|

|

| 2. |

Remove the rear plate.

|

|

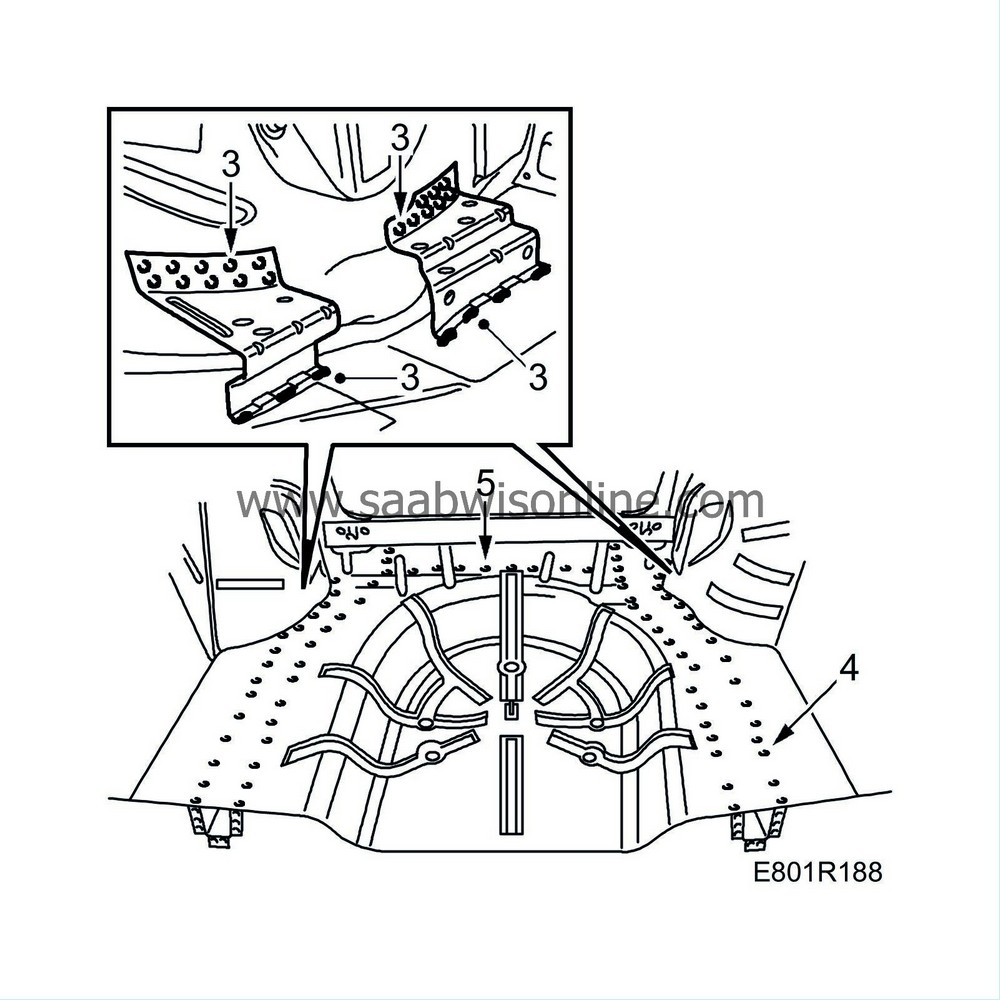

| 3. |

Drill out the spot welds and grind down the seam welds for the luggage compartment reinforcements.

Lift away the reinforcements. |

|

| 4. |

Drill out the spot-welds that secure the floor to the frame members.

|

|

| 5. |

Drill out the rear spot-welds in the cross-member.

|

|

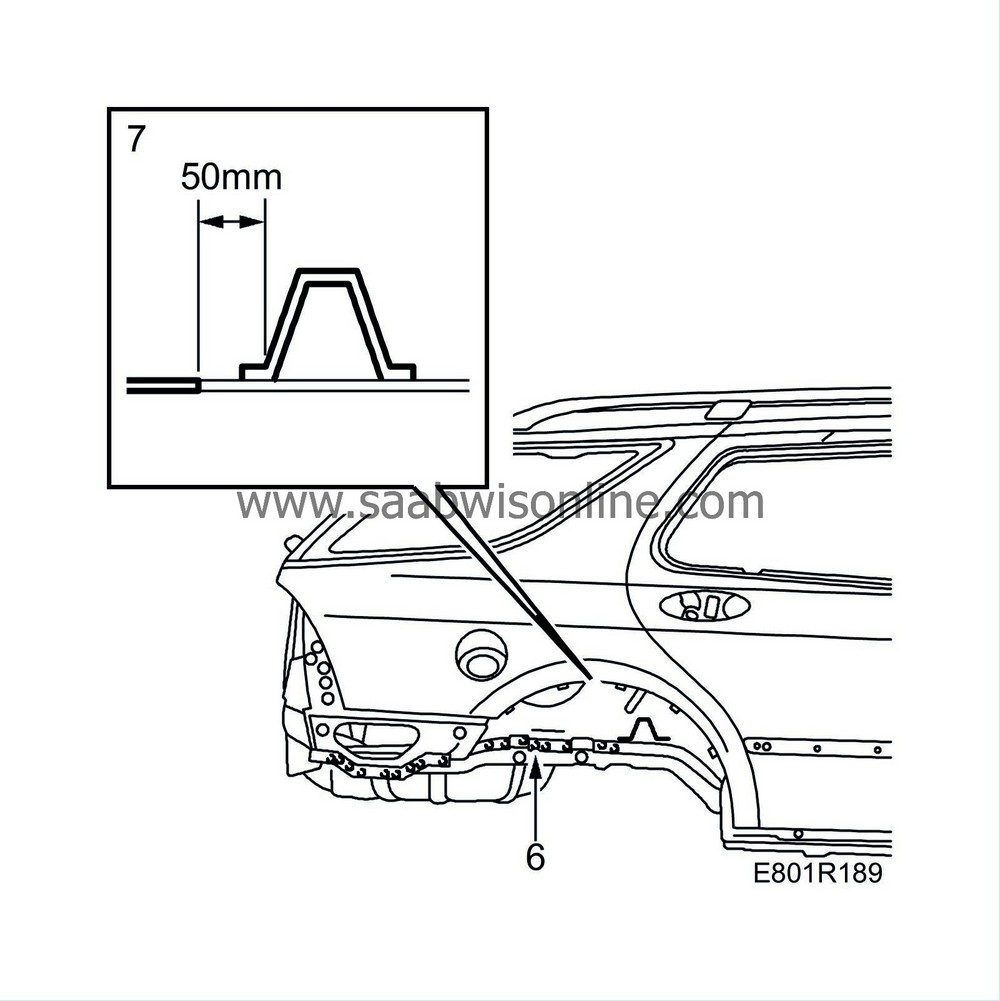

| 6. |

Drill out the spot-welds holding the sides of the floor.

|

|

| 7. |

Measure 50 mm from the cross-member where the floor is to be cut.

|

|

| 8. |

Cut away the rear floor and remove it.

|

|

| 9. |

Align any deformed sheet metal or panels.

|

|

| Fitting |

| 1. |

Cut the floor so that it fits against the flange on the cross-member.

|

|

| 2. |

Grind all the surfaces that are to be welded.

|

|

| 3. |

Position the floor and mark it by scribing where the frame members are located.

|

|

| 4. |

Remove the floor and drill holes for plug-welding.

|

|

| 5. |

Cut out the corners above the frame members so that they fit against the existing floor.

|

|

| 6. |

Apply welding primer to all surfaces to be plug or spot-welded.

|

|

| 7. |

Fit the floor and fixate with a few welding clamps.

|

|

| 8. |

Plug-weld the floor.

|

|

| 9. |

Seam-weld the corners that have been cut out.

|

|

| 10. |

Spot-weld the floor to the wheel housing.

|

|

| 11. |

Fit the rear plate.

|

|

| 13. |

Smooth off the welds.

|

|

| 14. |

Remove any remaining welding primer. Welding primer reduces adhesion of paint, filler and sealant.

|

|

| 15. |

Apply primer to all bare metal surfaces.

|

|

| 16. |

Seal joints and seams with sealant.

|

|

| 17. |

Apply PVC substitute on the underside of the floor.

|

|

| 18. |

Apply a thin coating of anti-corrosion agent in members and cavities after painting.

|

|