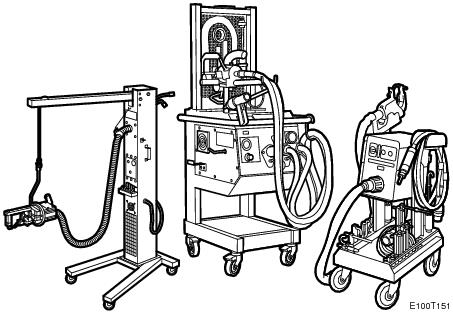

Welding unit

| Welding unit |

The technique of using welded attachment components has extremely good anti-corrosion properties. The welding unit should also be able to handle the welding of attachment components such as T rivets and screw rivets as well as studs or washers that can be used during body alignment.

The placement of attachment components on the car requires easy-to-handle equipment with a flexible welding gun.

It should be possible to convert the welding unit from normal resistance welding and welding of studs/washers used during body alignment.

In general, trial and error is required to develop a good welding result prior to actually welding on the car. Test pieces of the metal are welded with different current strength and welding time until the result is satisfactory. For spot welding, the electrodes should have a diameter of max 6 mm. The spot weld core should have a diameter of 5 mm to ensure strength.

| Technical performance |

| • |

Determining welding time

|

|

| • |

Setting welding energy

|

|

| • |

Handle spot welding min 0.5-2.5 mm plate

|

|

| • |

Welding of T rivets, screw rivets and washers

|

|

| • |

Crimping

|

|

Compare with the following equipment:

| • |

Tecna 3450

|

|

| • |

Prospot PR10

Internet address: www.prospot.com |

|

| • |

Car-O-Liner CR510

Internet address: www.car-o-liner.se |

|

| • |

Elektron Multispot M80, M83, M90

|

|

| • |

Midispot QSVM9000

Internet address: www.celette.com www.elmatech.com |

|