Checking and adjusting basic charging pressure

|

|

Checking and adjusting basic charging pressure

|

|

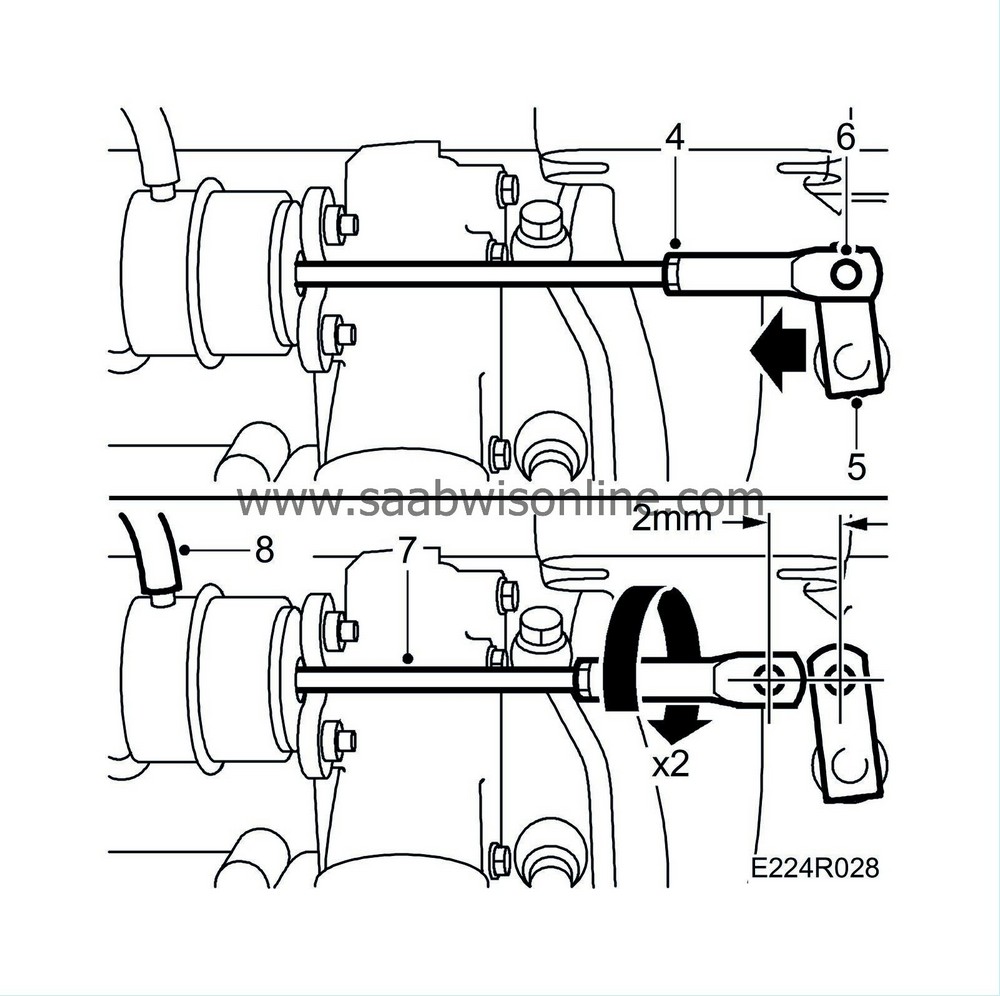

1.

|

Remove the bypass pipe with valve, 1 bolt on the turbocharger intake pipe and 1 hose clip on the turbocharger delivery pipe.

|

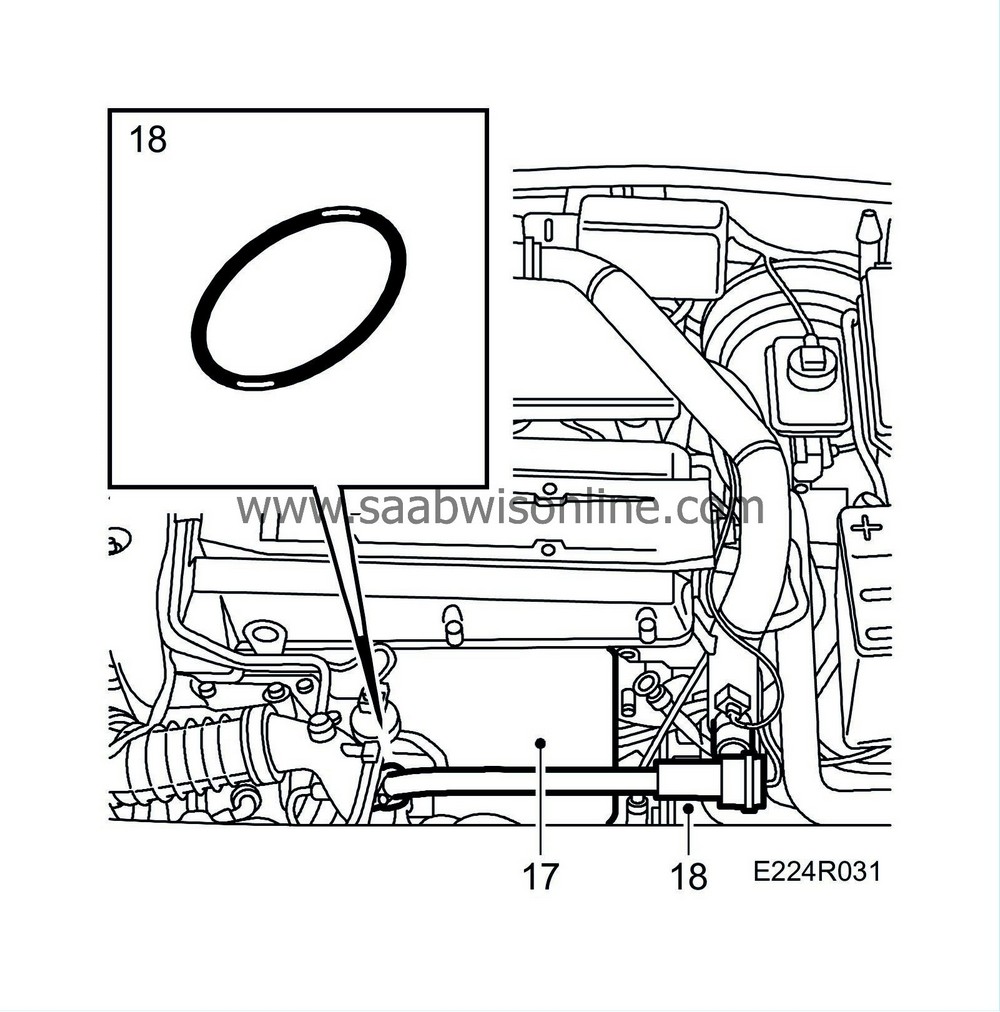

Note

|

|

There is an O-ring in the bypass pipe mounting on the compressor inlet.

|

|

|

2.

|

Remove the exhaust manifold heat shield. The heat shield is attached with a nut and two clips on the underside.

|

|

5.

|

Hold the operating arm and remove the pushrod from it. Secure the operating arm as it might otherwise “overcentre”.

|

|

6.

|

Move the operating arm on the boost pressure control valve to the “Closed” position and adjust the end piece so that the pushrod can easily be fitted on the operating arm pin.

|

|

7.

|

Detach the pushrod from the operating arm pin. Turn the end piece clockwise about 2 turns so that a prestress of 2 mm is obtained. Attach the pushrod to the operating arm pin. Fit the retaining ring.

|

|

8.

|

Detach the hose marked “W” from the diaphragm unit.

|

|

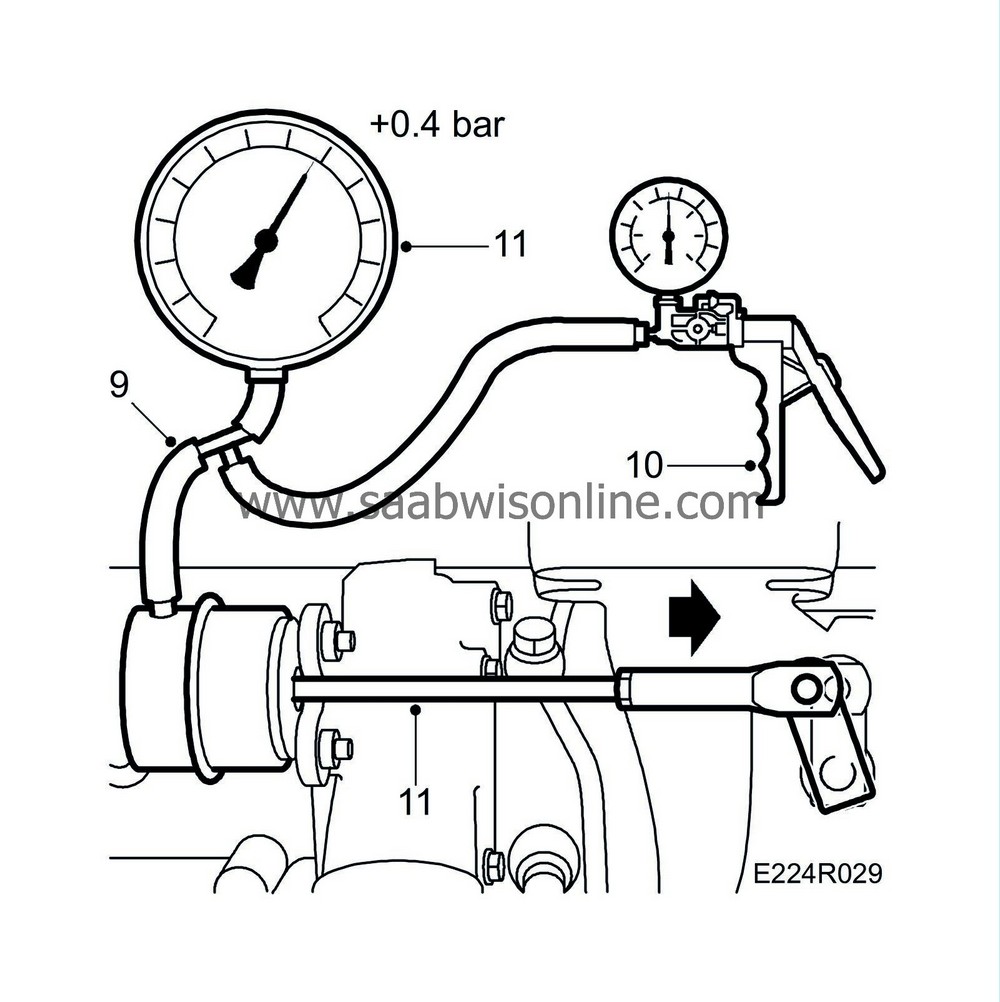

10.

|

Carefully pump up the pressure so that the control rod moves and regulates the boost pressure.

|

|

11.

|

Just as the control rod starts to move, read off the pressure on the pressure gauge dial. The pressure should be 0.4 bar for the Garrett GT17 turbo unit (B205E / B235E) and 0.45 bar for the Mitsubishi TO04 turbo unit (B235R).

|

|

12.

|

Shorten the rod even more if the pressure is lower than 0.4 and 0.45 bar respectively.

|

|

13.

|

Remove the control rod and coat the pin on the operating arm sparingly with Molykote 1000 (part no. 30 20 271) or the equivalent.

|

|

14.

|

Fit the control rod and clip, grip the control rod to prevent it from moving and lock the nut.

|

|

15.

|

Disconnect the pressure gauge and pump.

|

|

16.

|

Reconnect the hose to the diaphragm unit.

|

|

17.

|

Fit the heat shield, coat its stud with Molykote 1000 (part no. 30 20 271) or the equivalent and screw on the nut.

Tightening torque, lock nut 20 Nm (15 lbf ft)

|

|

18.

|

Grease the O-ring with non-acidic vaseline and fit the bypass pipe.

Tightening torque 8 Nm (6 lbf ft)

|

|

19.

|

Carry out charge air adaptation:

|

|

|

19.a.

|

Drive the car until the engine is warm.

|

|

|

19.b.

|

Give full throttle a few times from 2000 rpm. The time during which the engine speed is within the range 2400 - 4000 should exceed 2 seconds.

|

Note

|

|

Charge air adaptation should be carried out in the highest gear possible. The customer should be informed of the fact that the engine torque may vary slightly during the first occurrences of hard acceleration if charge air adaptation has not been carried out.

|

|