Grinding (turning) a brake disc, removed

| Grinding (turning) a brake disc, removed |

Lathe “VBG 600” and the “accessory 26” connecting plate were used in the development of this method.

| 1. |

Remove the brake disk. Refer to

To remove

for the front wheels and

To remove

for the rear wheels.

|

|

| 2. |

Measure the disc. Refer to

Checking for lateral runout and variation in thickness, front wheels

and

Checking for lateral runout and variation in thickness, rear wheels

.

|

|

| 3. |

Clean the mating surface.

|

|

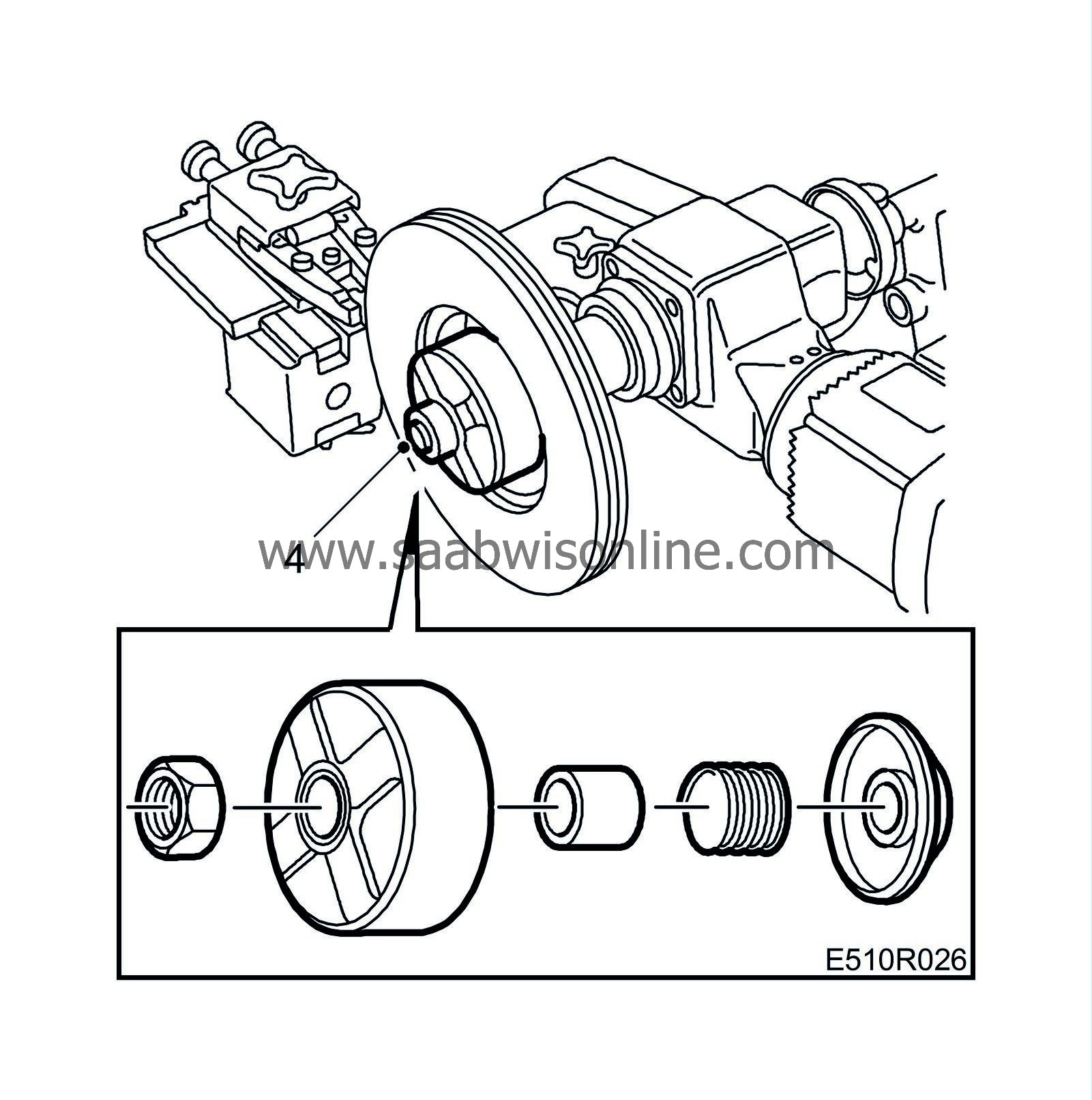

| 4. |

Fit the connecting plate on the lathe.

|

|

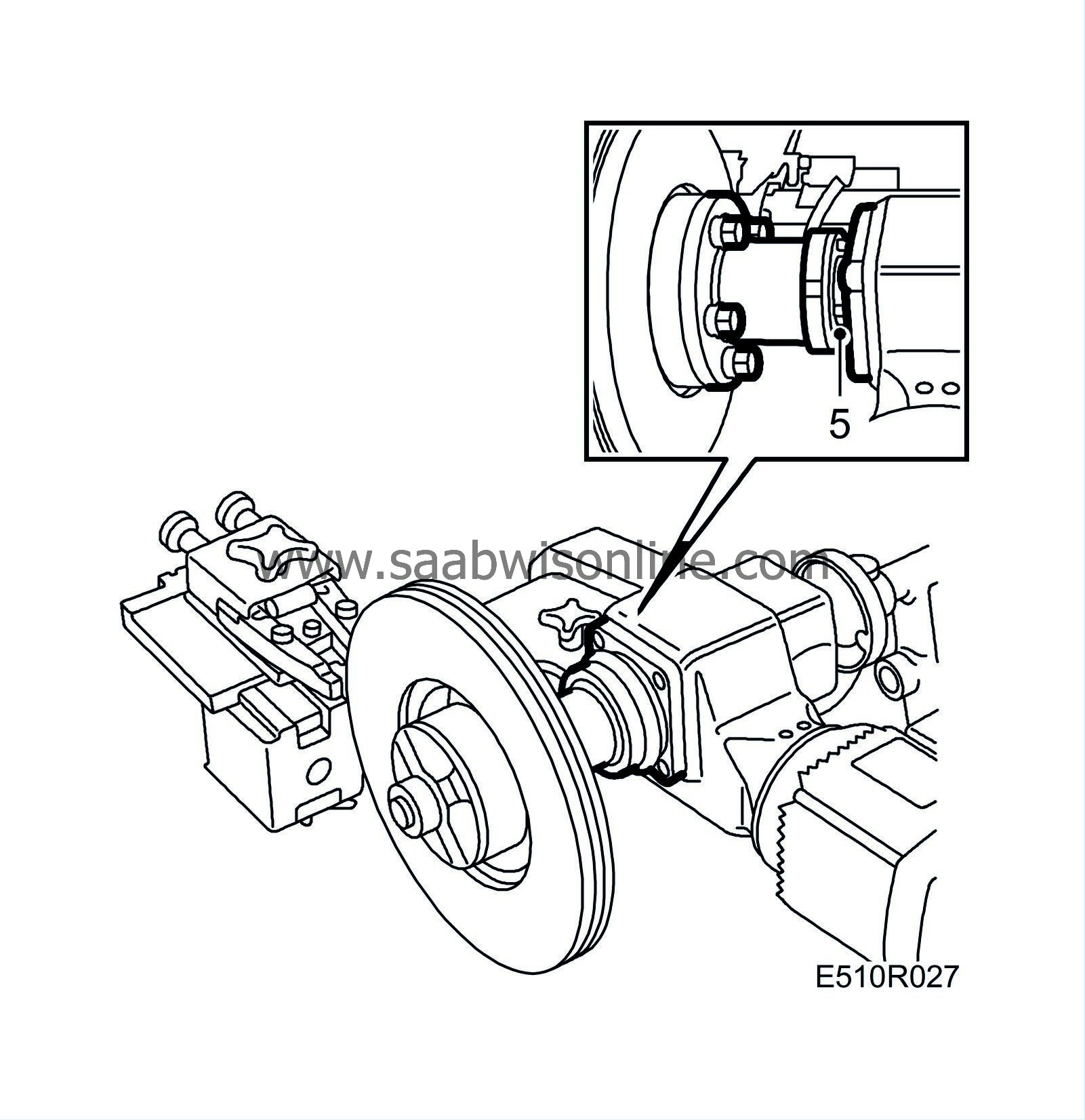

| 5. |

Back off the adjusting screws.

Clean the connecting surface and fit the brake disc to the connecting plate, connect the lathe. |

|

| 6. |

Adjust the turning tools against the disc with the tool holder. Remove the locking screw and move the holder.

|

|

| 7. |

Set the automatic stop.

|

|

| 8. |

Feed out the tool holder and manually grind off the outer and inner rusty edges.

|

|

| 9. |

Set the turning depth and switch on automatic operation.

|

|

| 10. |

Check the brake disc.

|

|

| 11. |

Remove the brake disc from the lathe.

|

|

| 12. |

Remove the brake disc from the lathe and fit it to the car. Refer to

To remove

for front wheels and

To remove

for rear wheels.

|

|