Suspension arm bush, rear

|

|

Suspension arm bush, rear

|

|

1.

|

Raise the car. If a jack is used, safety stands should be placed under the car.

|

|

2.

|

Remove the front wheel on the same side as the suspension arm that is to be removed.

|

|

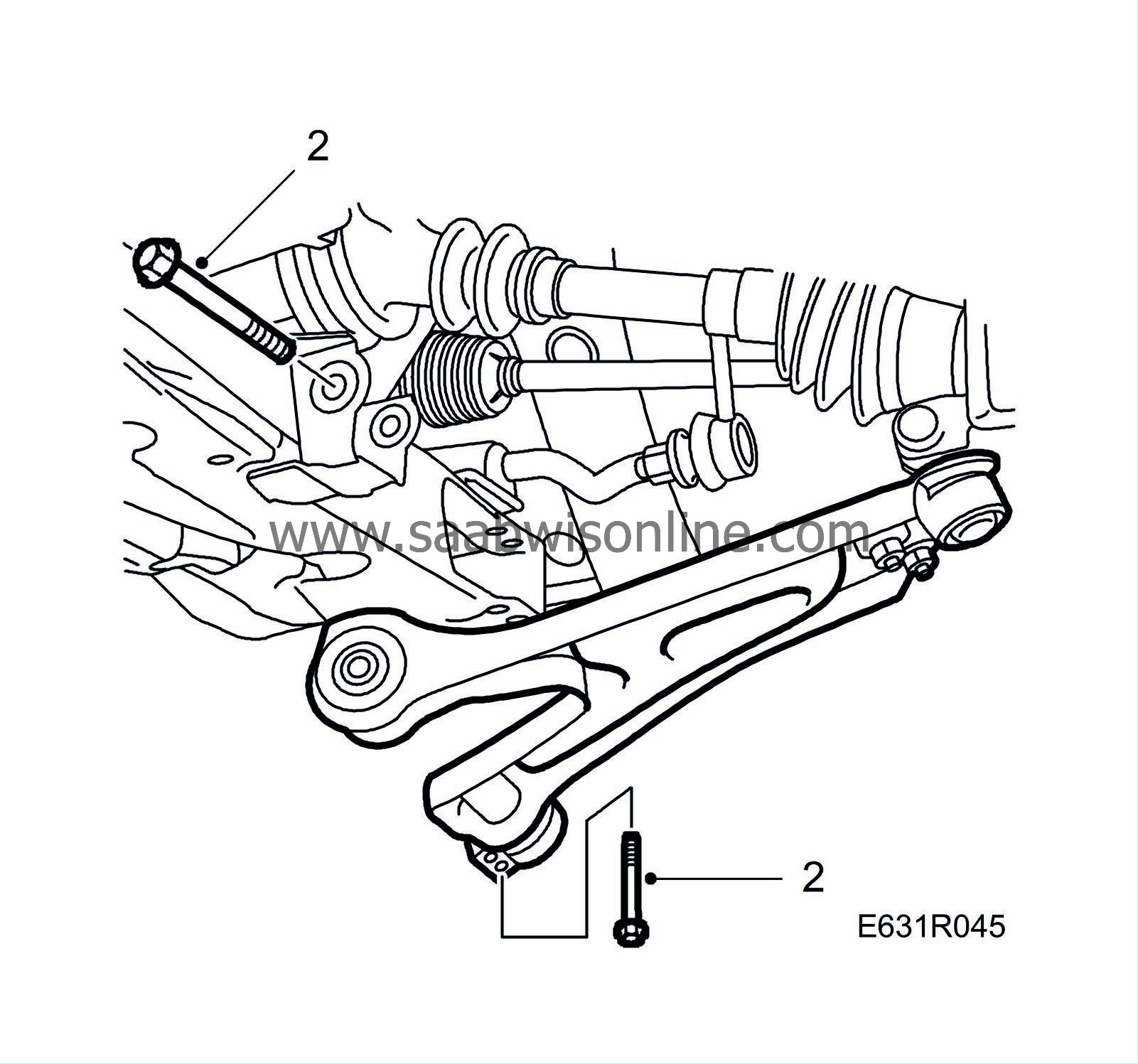

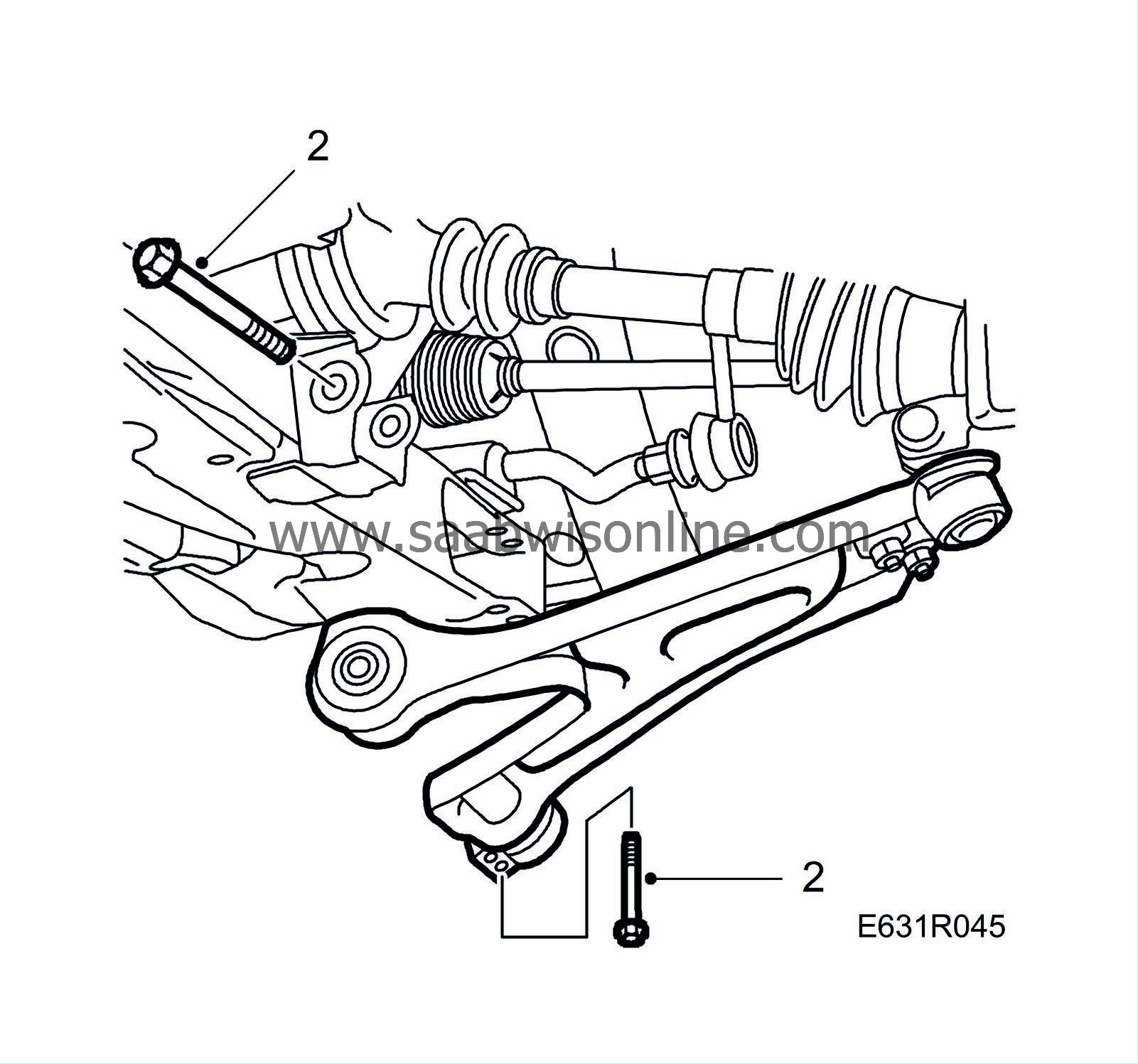

3.

|

Unbolt the suspension arm from the subframe at the rear attachment point.

|

|

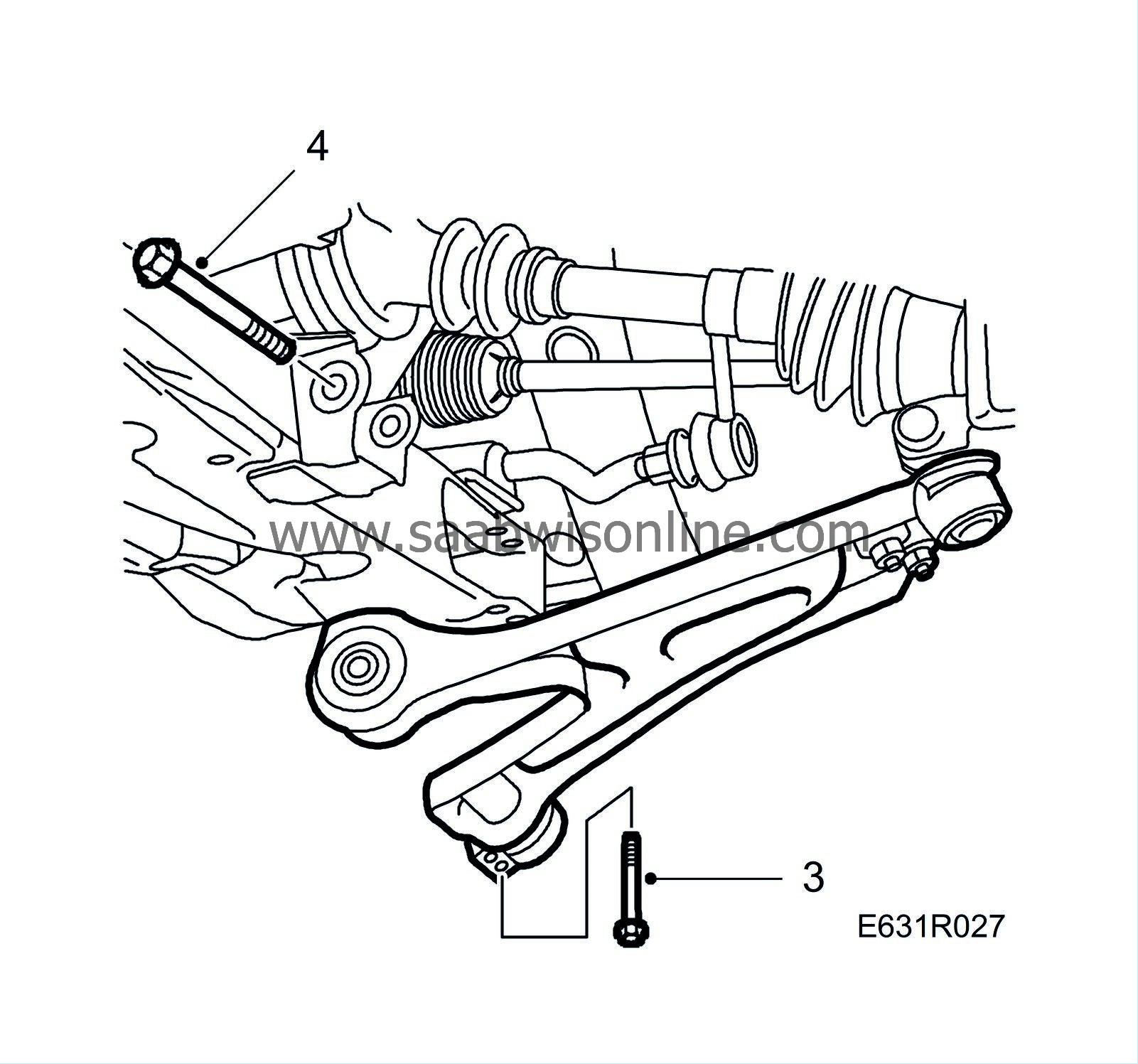

4.

|

Remove the bolt securing the suspension arm at the rear attachment point and swing down the suspension arm.

|

|

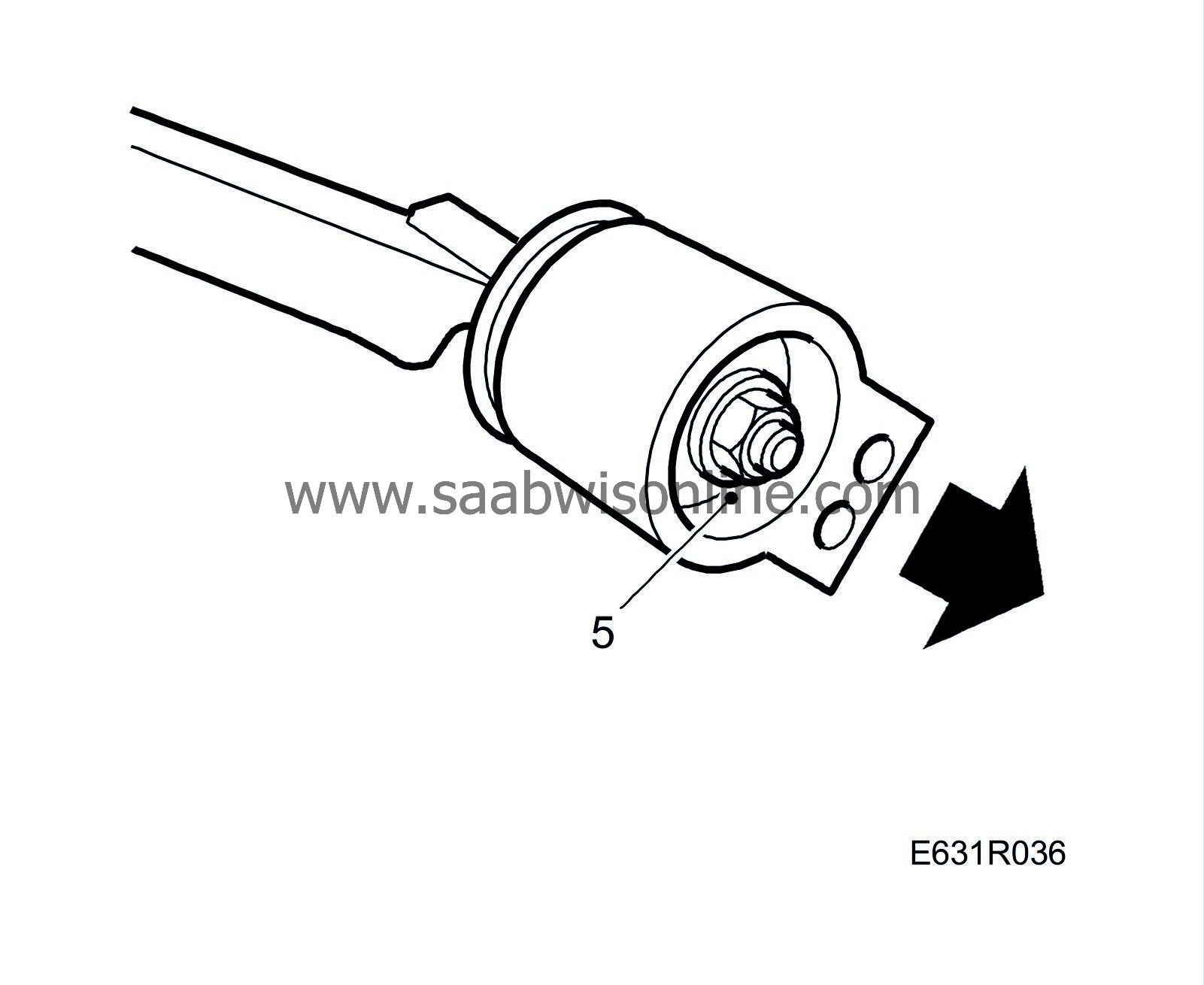

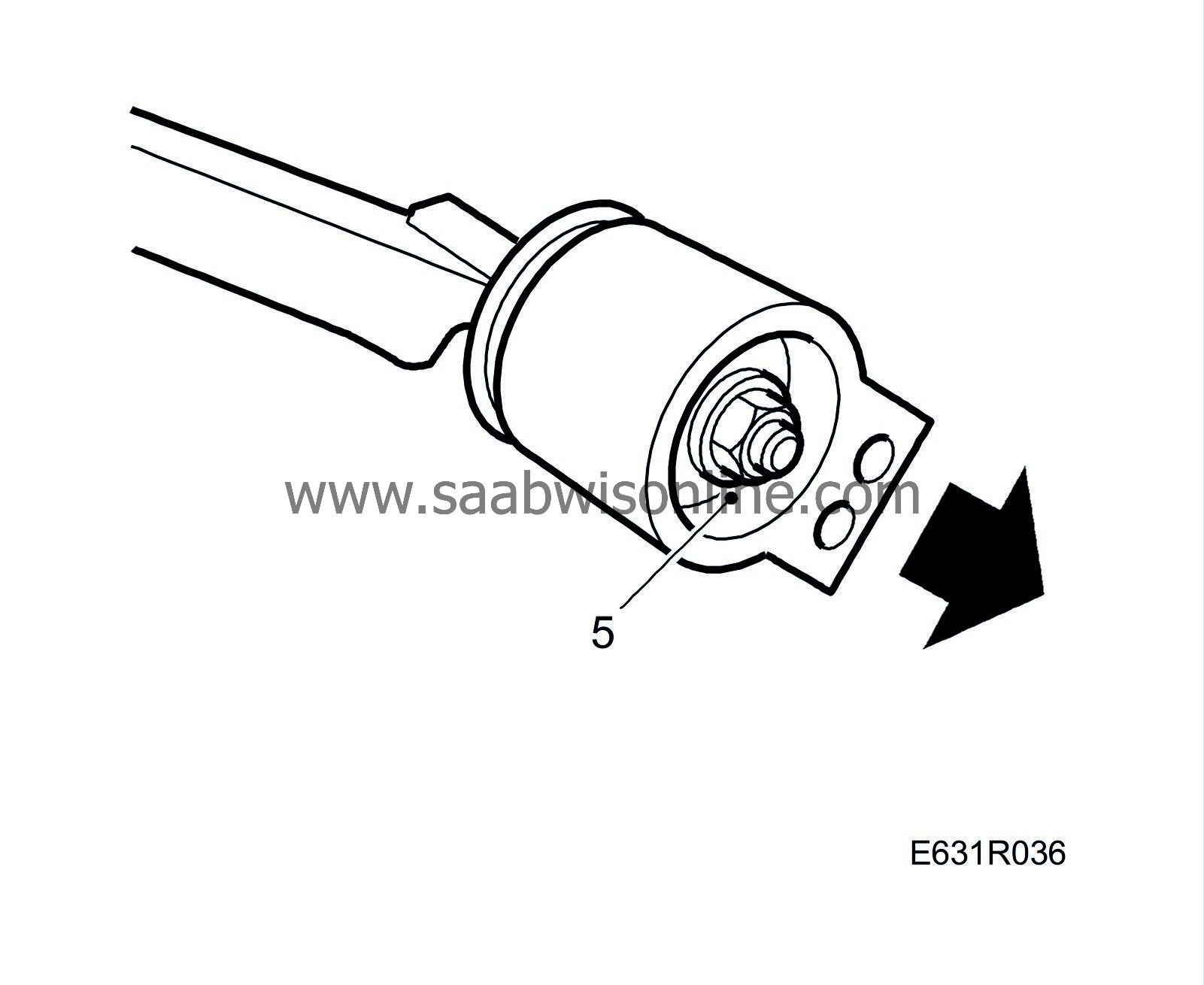

5.

|

Undo the nut and pull off the bush.

|

|

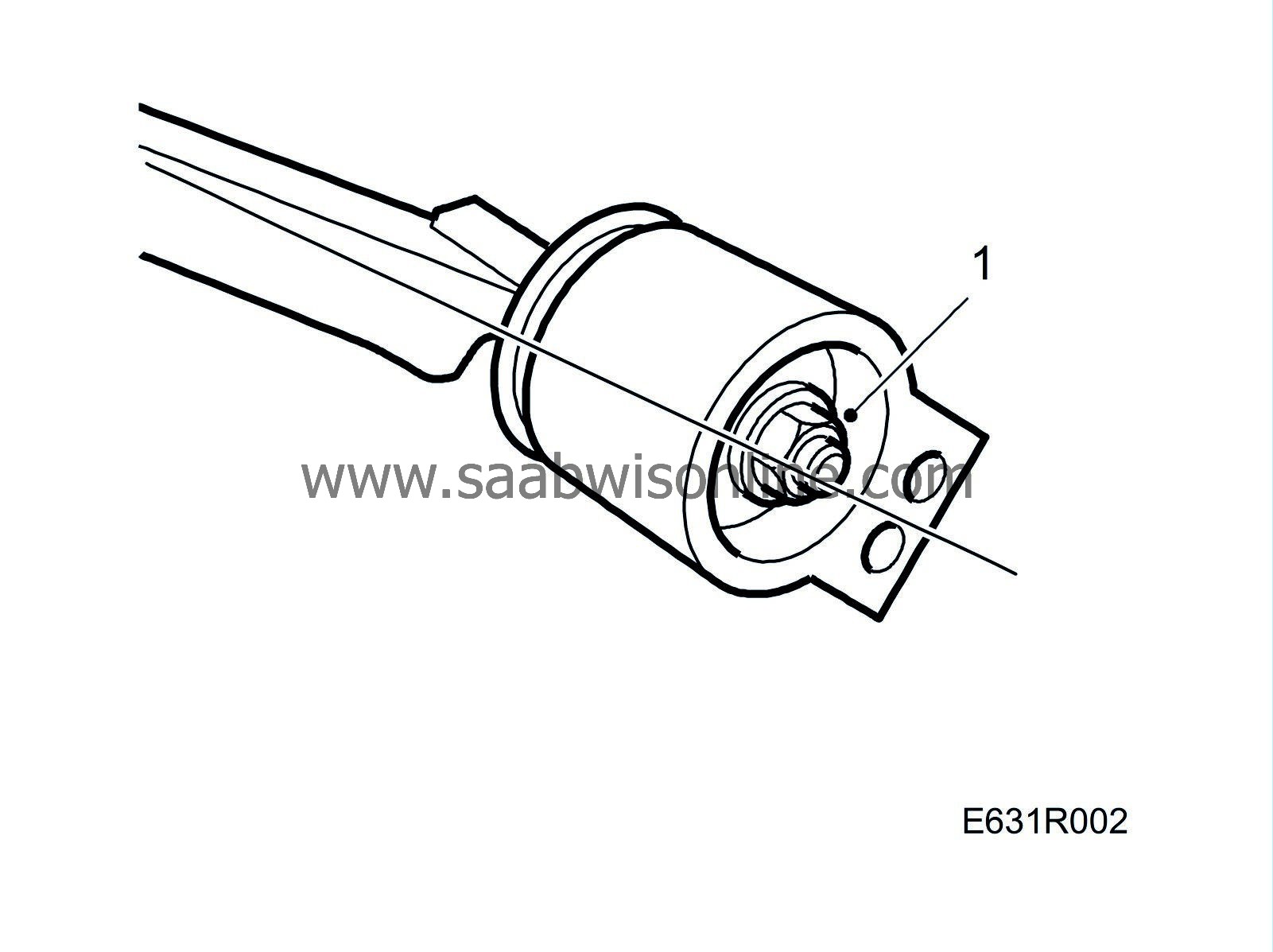

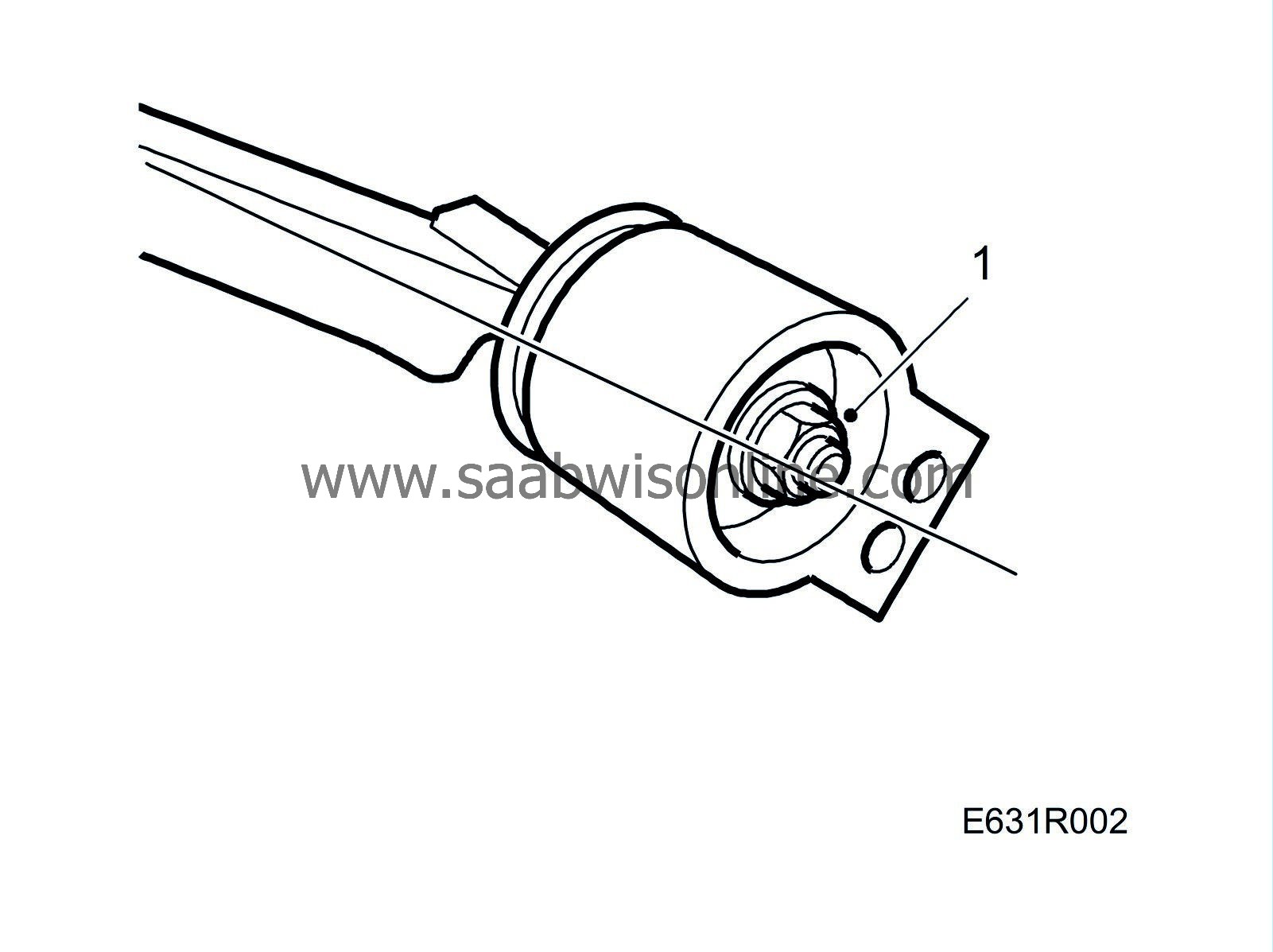

1.

|

Fit the suspension arm bush. It must be in line with the suspension arm.

|

Important

|

|

Use the correct bush for each suspension arm.

|

|

|

Tightening torque, M12 75 Nm (55 lbf ft)

Tightening torque, M14 105 Nm (77 lbf ft)

|

|

2.

|

Position the suspension arm against the subframe and insert the bolts in the front and rear attachment points.

|

|

3.

|

The bolts securing the suspension arm to the subframe must be tightened when all four wheels of the car are on the floor but, depending on the type of car lift, one of the following methods may be used instead:

|

|

|

•

|

Position a high-lift jack under the ball joint of the steering swivel member and jack it up until the suspension arm is 1° below the horizontal.

|

|

|

•

|

Place a stand or the like under the ball joint of the steering swivel member. Lower the car until the suspension arm is 1° below the horizontal.

Tighten the bolts securing the suspension arms to the subframe.

Tightening torque 95 Nm (70 lbf ft).

|

|

4.

|

Remove the jack and fit the wheel. Refer to

Wheels

.

Tightening torques

aluminium wheel 110 Nm (81 lbf ft)

steel wheel 50 Nm + 2x90°, max. 110 Nm (37 lbf ft + 2x90°, max. 81 lbf ft)

Lower the car to the floor.

|

|

5.

|

Tighten the bolts securing the suspension arms to the subframe if this has not already been done.

Tightening torque 95 Nm (70 lbf ft).

|