Subframe, petrol engines, change

|

|

Subframe, petrol engines, change

|

|

1.

|

Bolt the brackets for the A/C pipes in place.

|

|

2.

|

Mount the brackets for the radiator assembly.

|

|

3.

|

Lift up the subframe carefully. Make sure the rubber boots on the inner drivers do not knock against the middle brackets on the subframe before the subframe is firmly against the body.

|

|

4.

|

Fasten the power steering pipe in the clips.

|

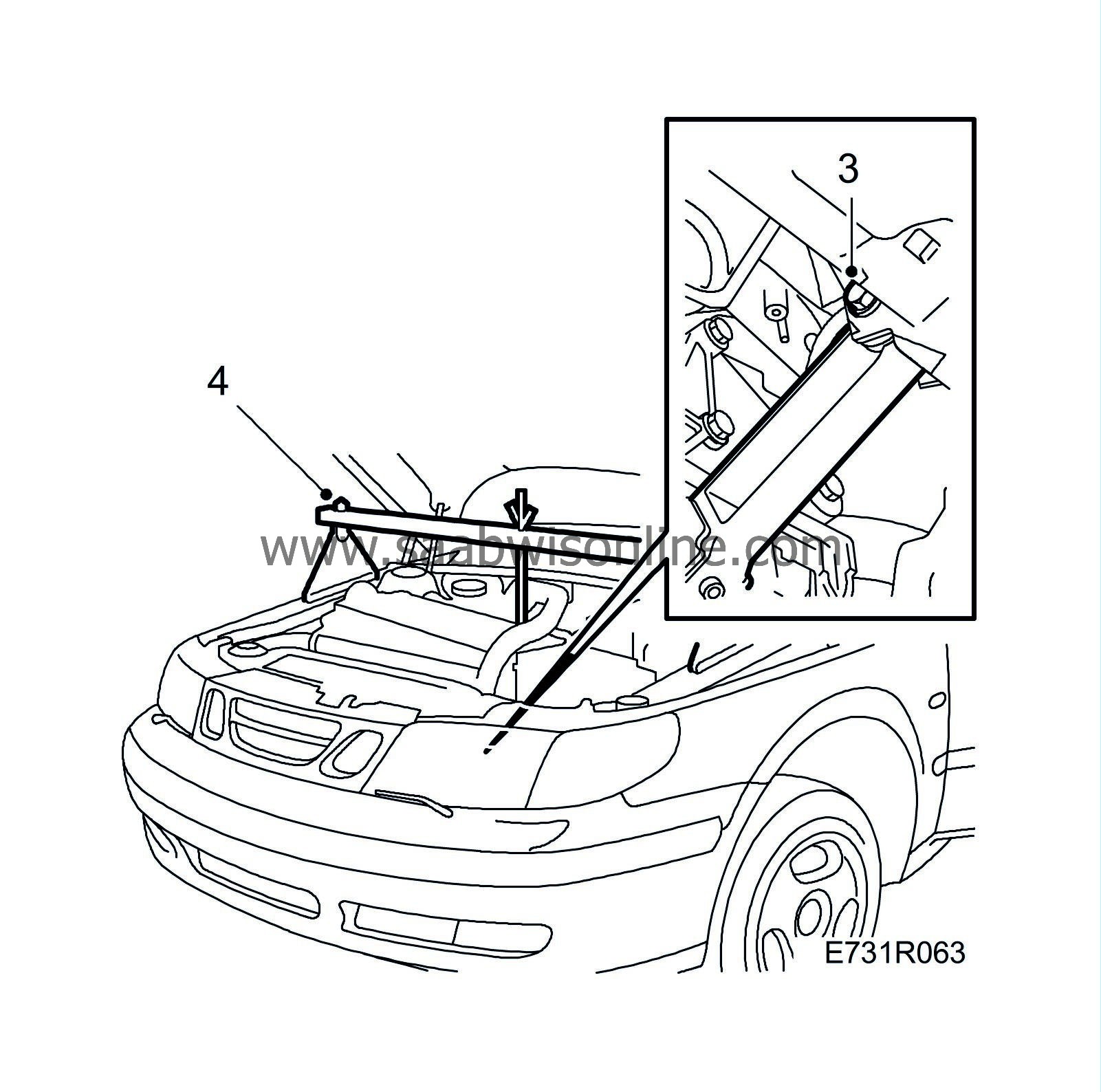

|

5.

|

Guide the radiator guide pins into the subframe. Lubricate with petroleum jelly to make fitting easier.

|

|

6.

|

Guide the A/C pipes into their holders on the subframe.

|

|

7.

|

Fit the power steering cooling pipe.

|

|

8.

|

Adjust the subframe so that the bolt holes are aligned with the body. There are two guide pins front left and rear right on the lifting trolley that will guide the subframe to its correct position.

|

|

9.

|

Fit the bolts to secure the subframe and the rear support plates. Tighten the bolts enough to ensure the subframe does not move when the lifting trolley and fixture are removed.

|

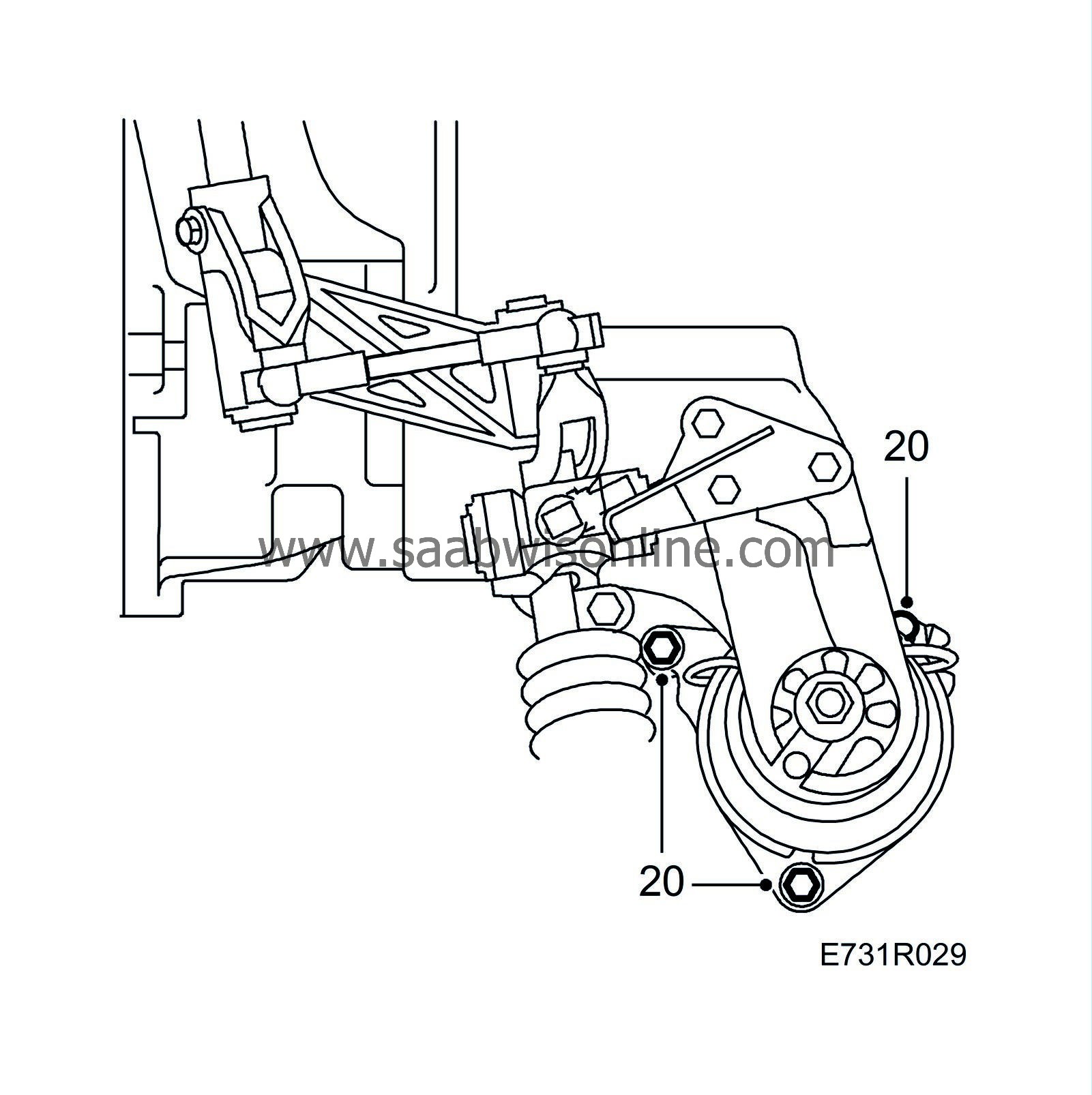

Note

|

|

The middle bolts on the subframe must not get mixed up with the others. The middle bolts have a smaller washer and 20 mm head.

|

|

|

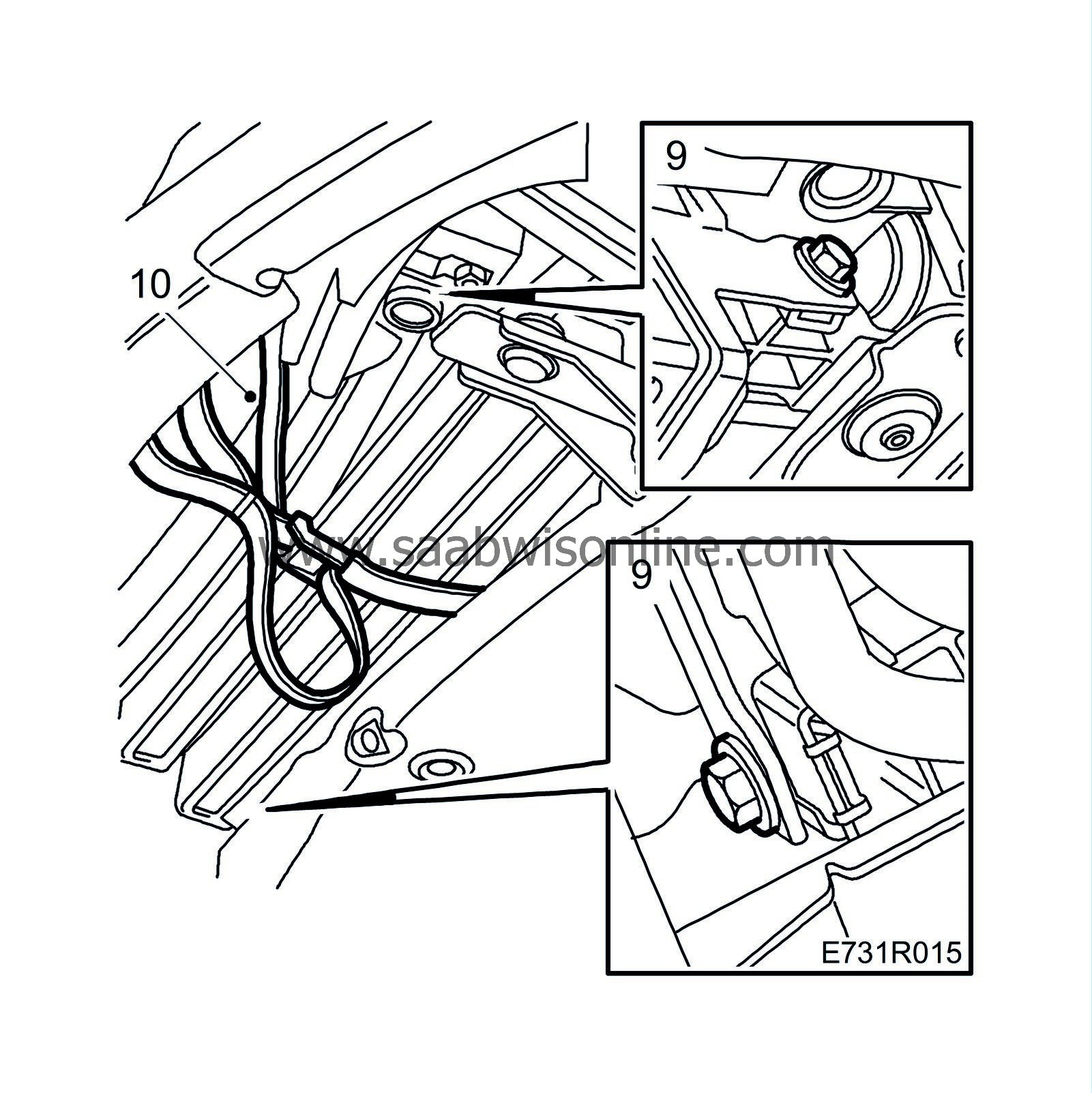

10.

|

Lower the lifting trolley and move it away.

|

|

11.

|

Tighten the bolts on the subframe.

Tightening torque 100 Nm +45° (74 lbf ft +45°)

|

|

12.

|

Tighten the reinforcement at the subframe's rear attachment point.

Tightening torque 65 Nm (50 lbf ft)

|

|

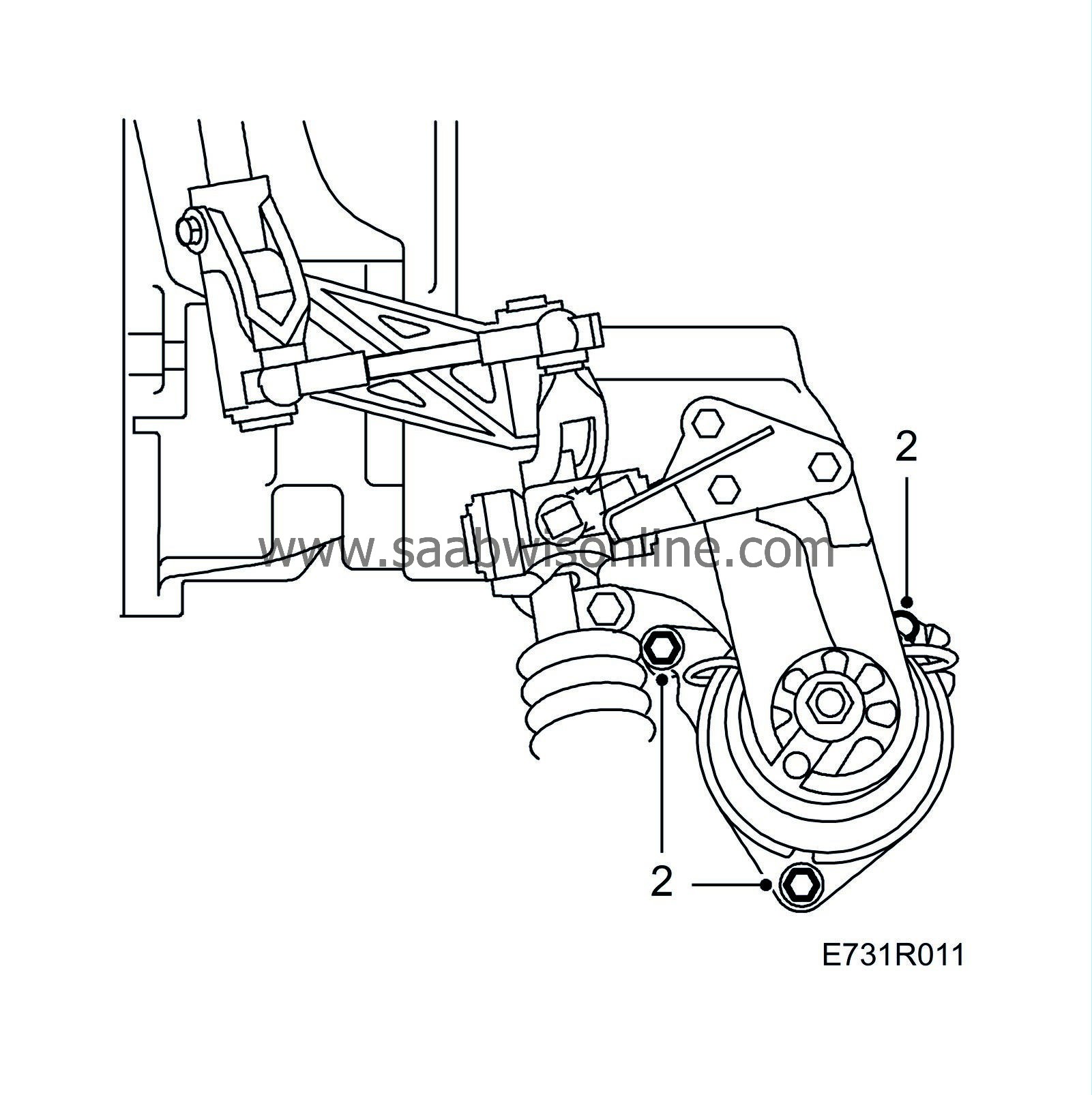

14.

|

Tighten the steering gear's retaining bolts.

Tightening torque 95 Nm (70 lbf ft)

|

|

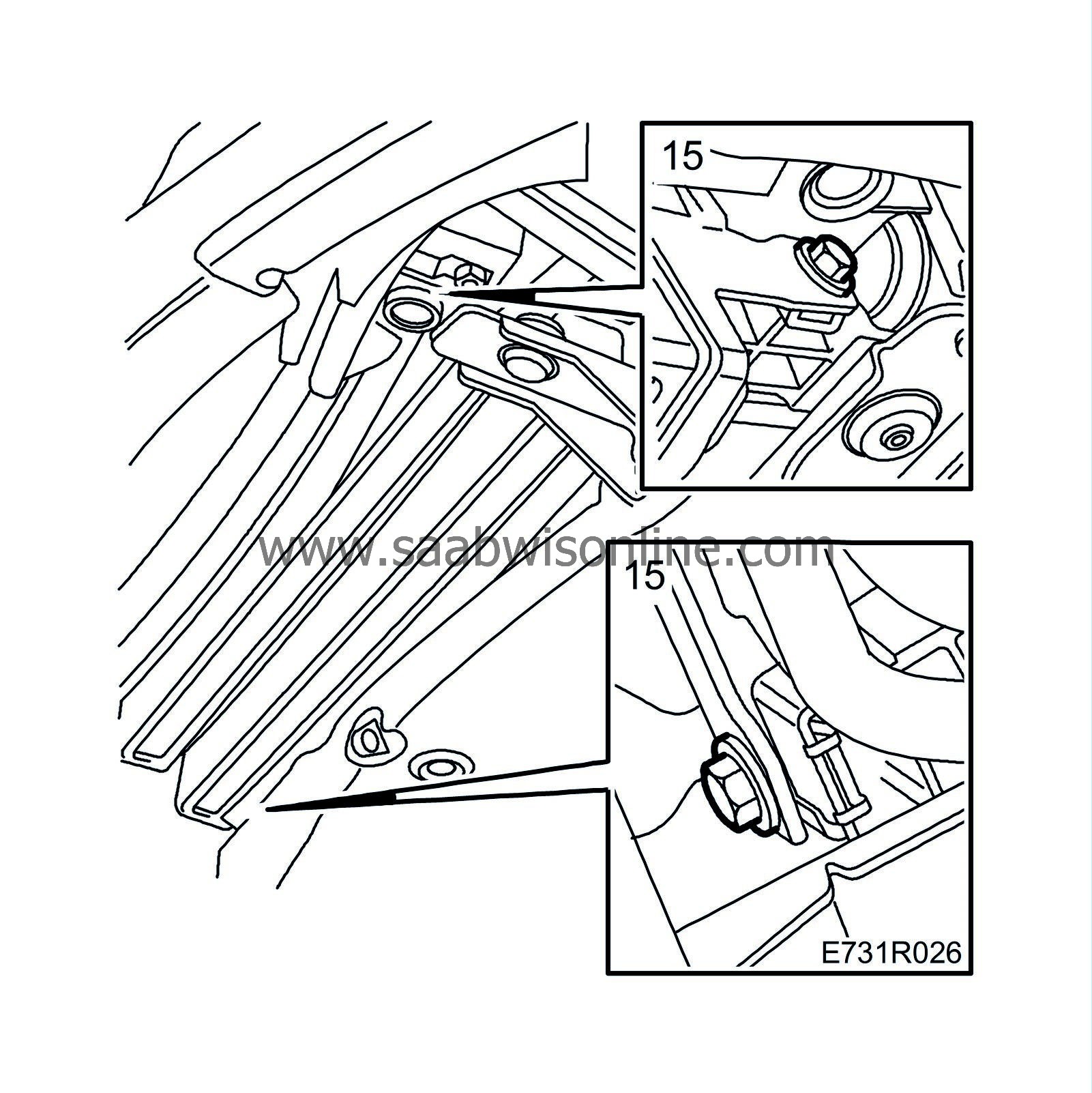

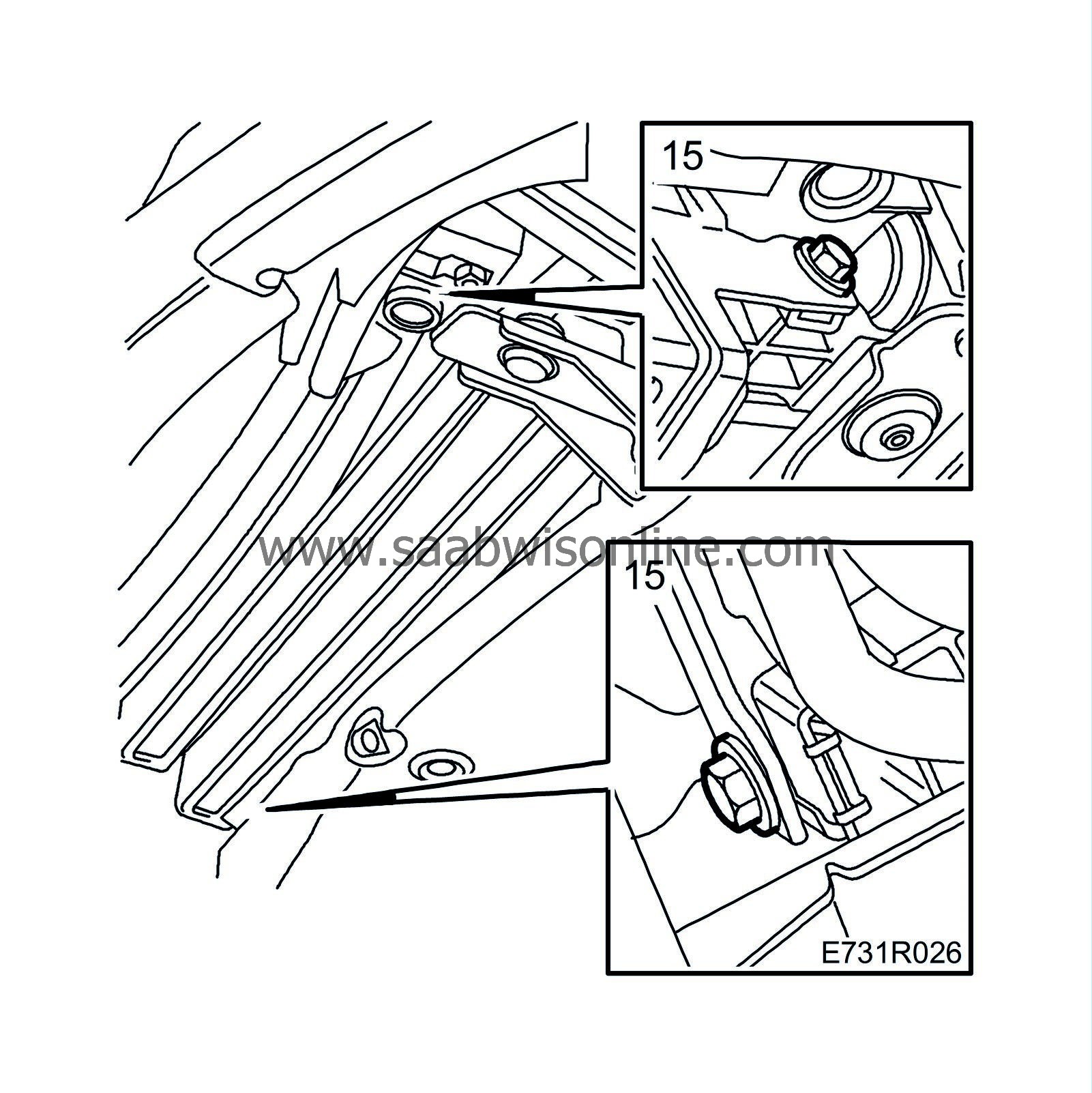

15.

|

Bolt the power steering fluid pipe's rear clamp and front bracket to the subframe and tighten the bolts. The rear clamp must be fitted in such a way that the pipe is located as far away from the drive shaft as possible.

|

|

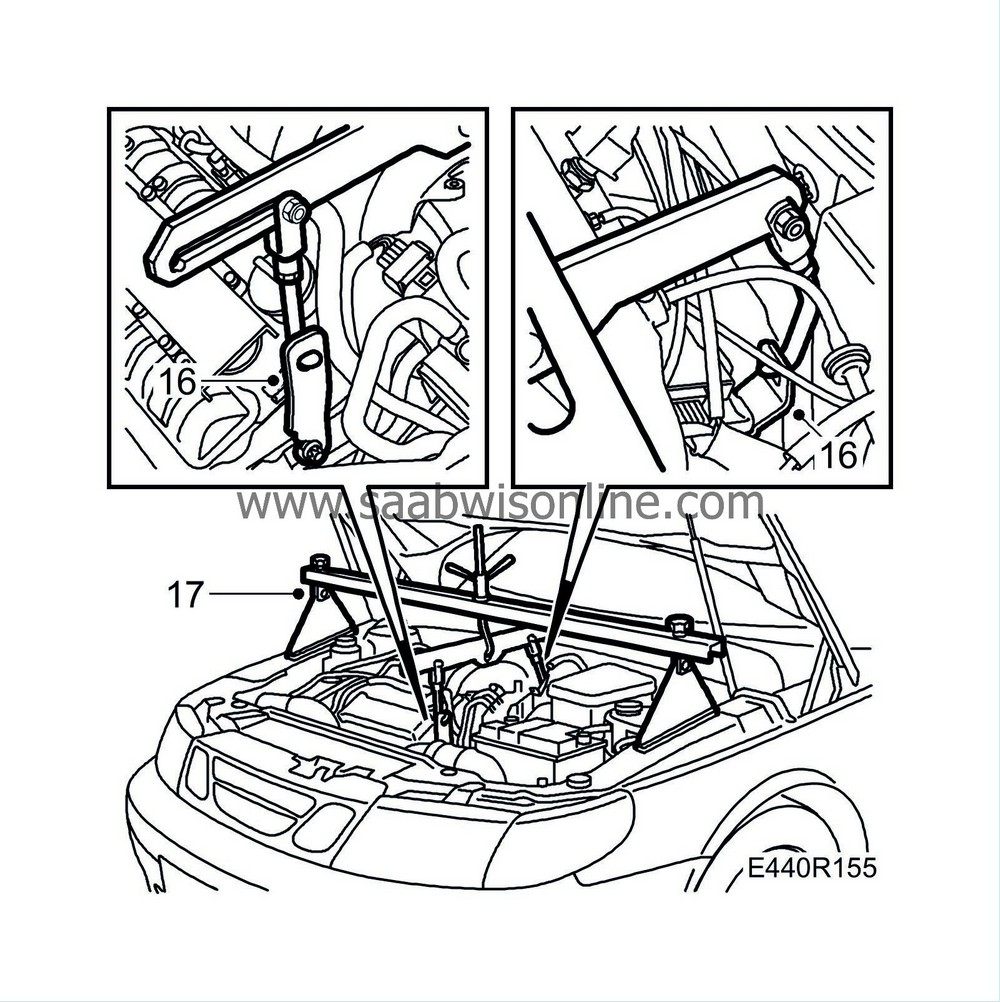

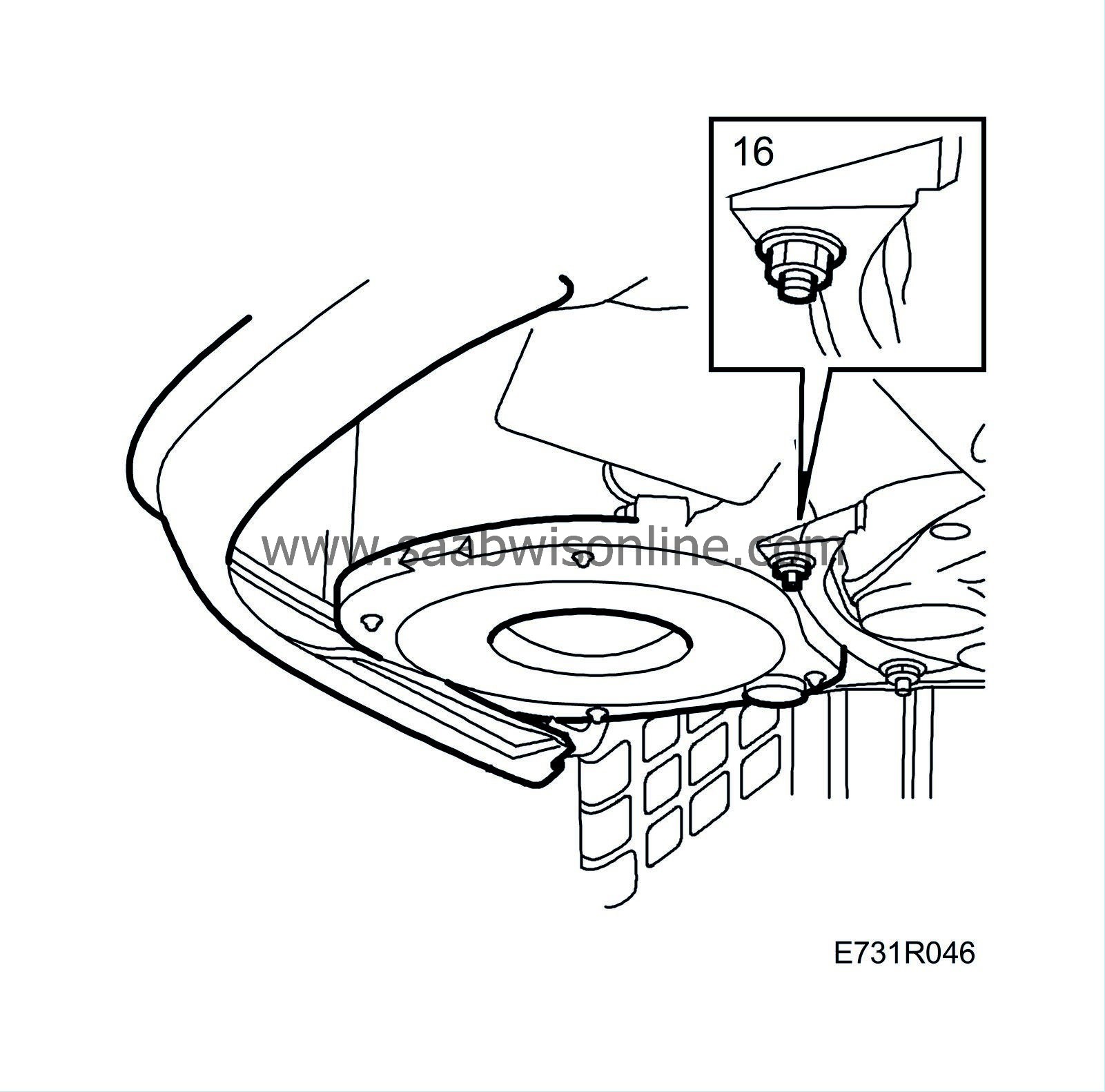

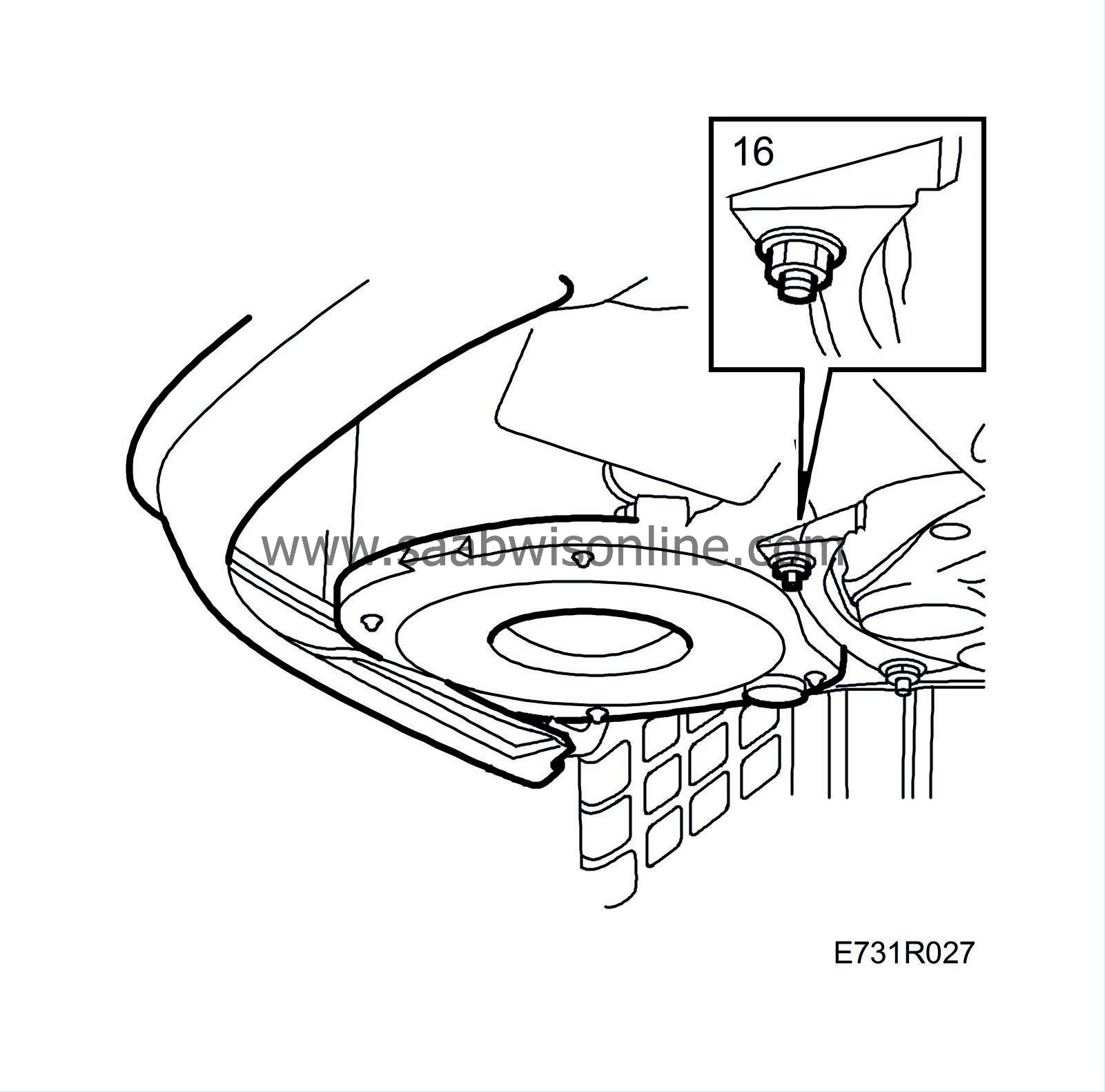

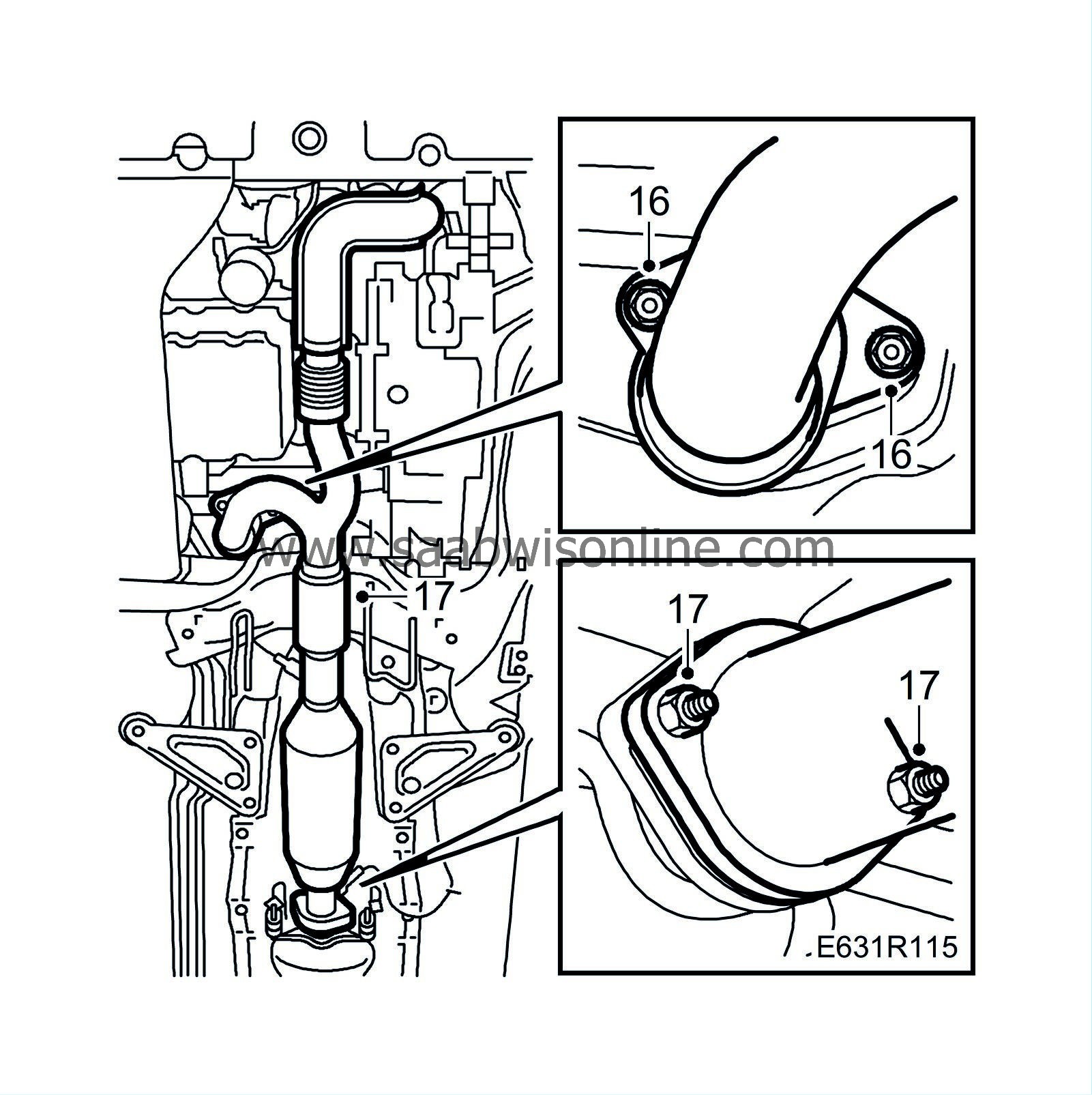

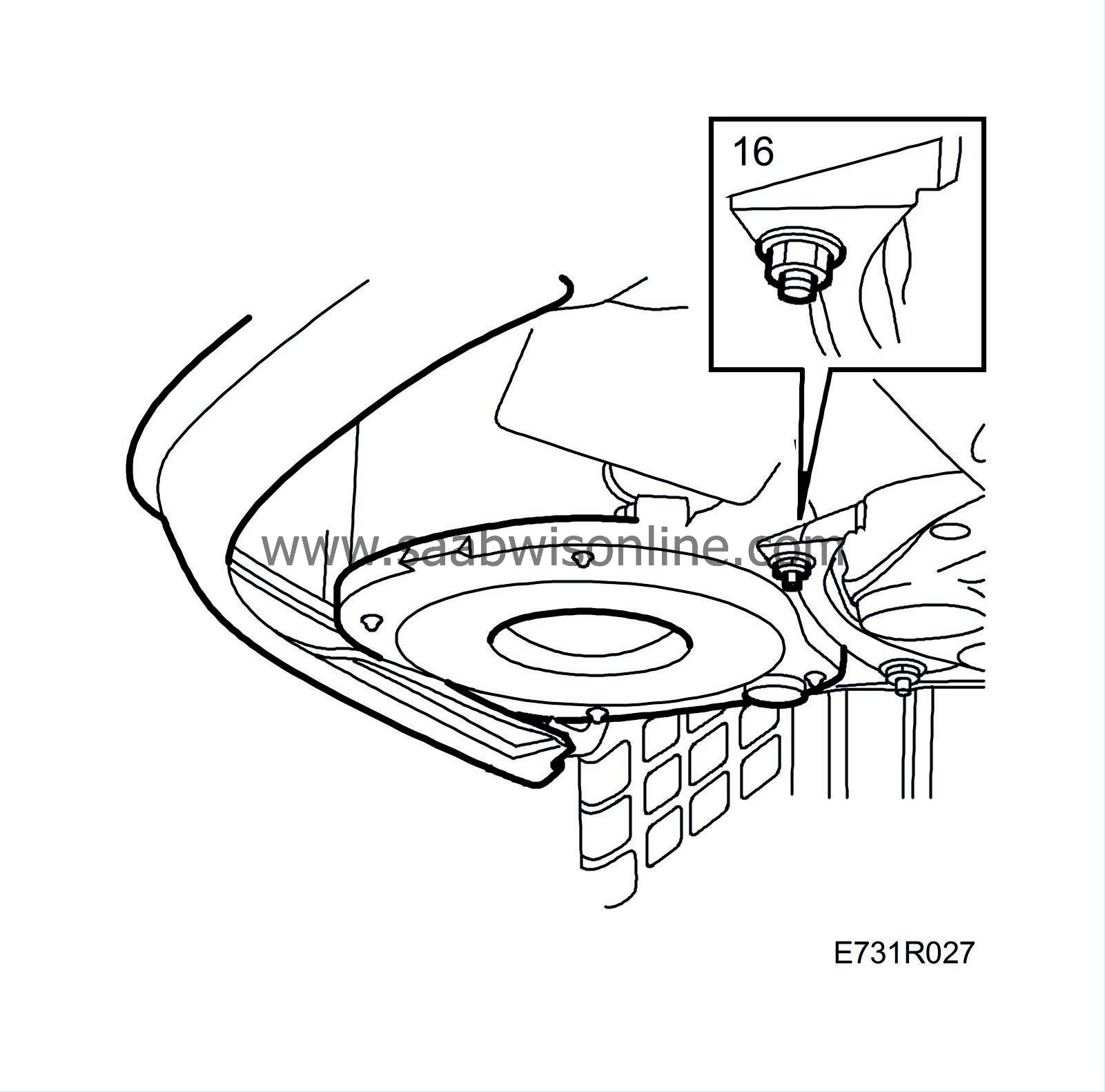

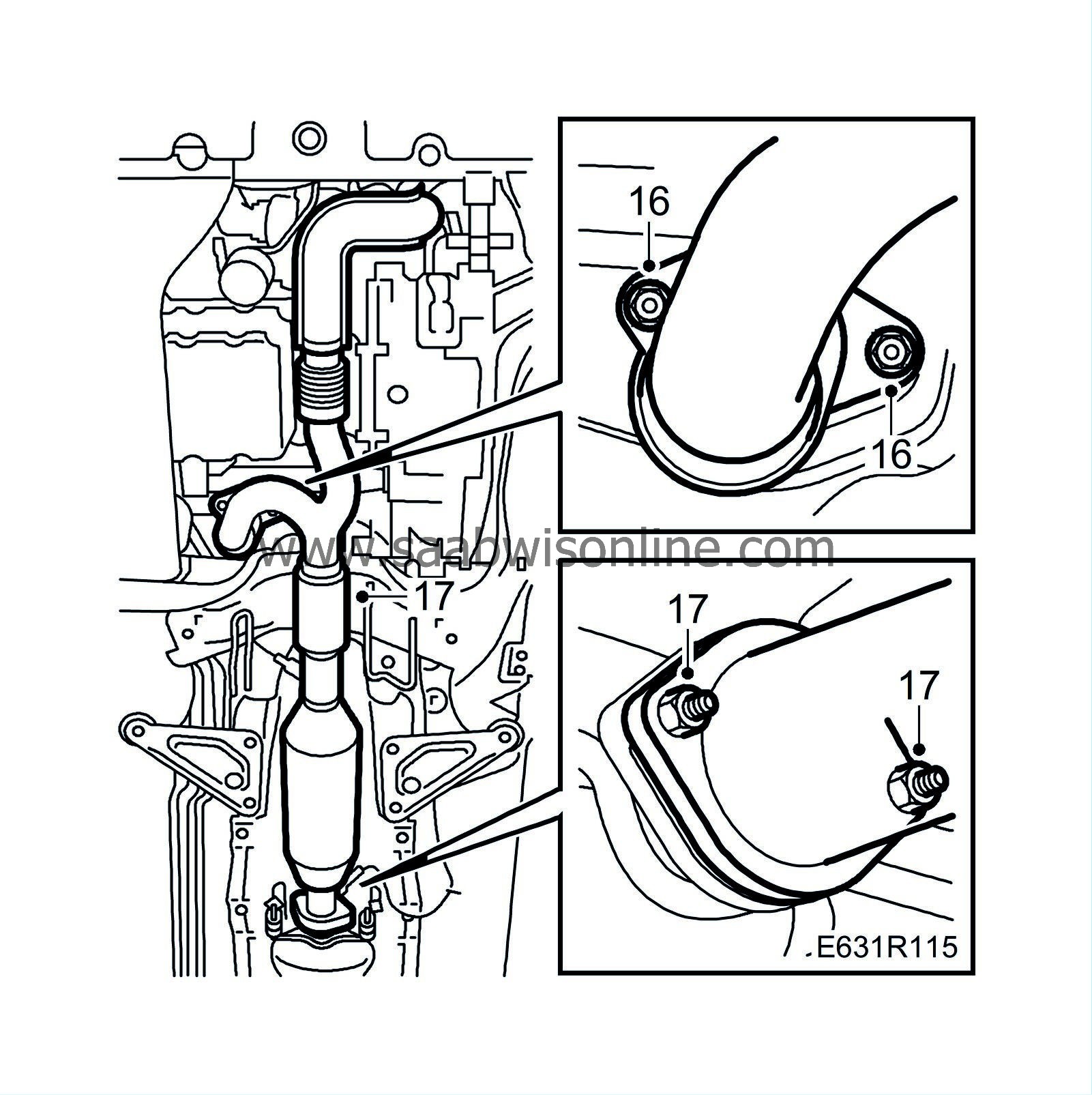

16.

|

Tighten the anti-roll bar's retaining bolts.

Tightening torque 25 Nm (20 lbf ft)

|

|

17.

|

Position the suspension arms on the subframe and fit the bolts for the front and rear attachment points.

|

|

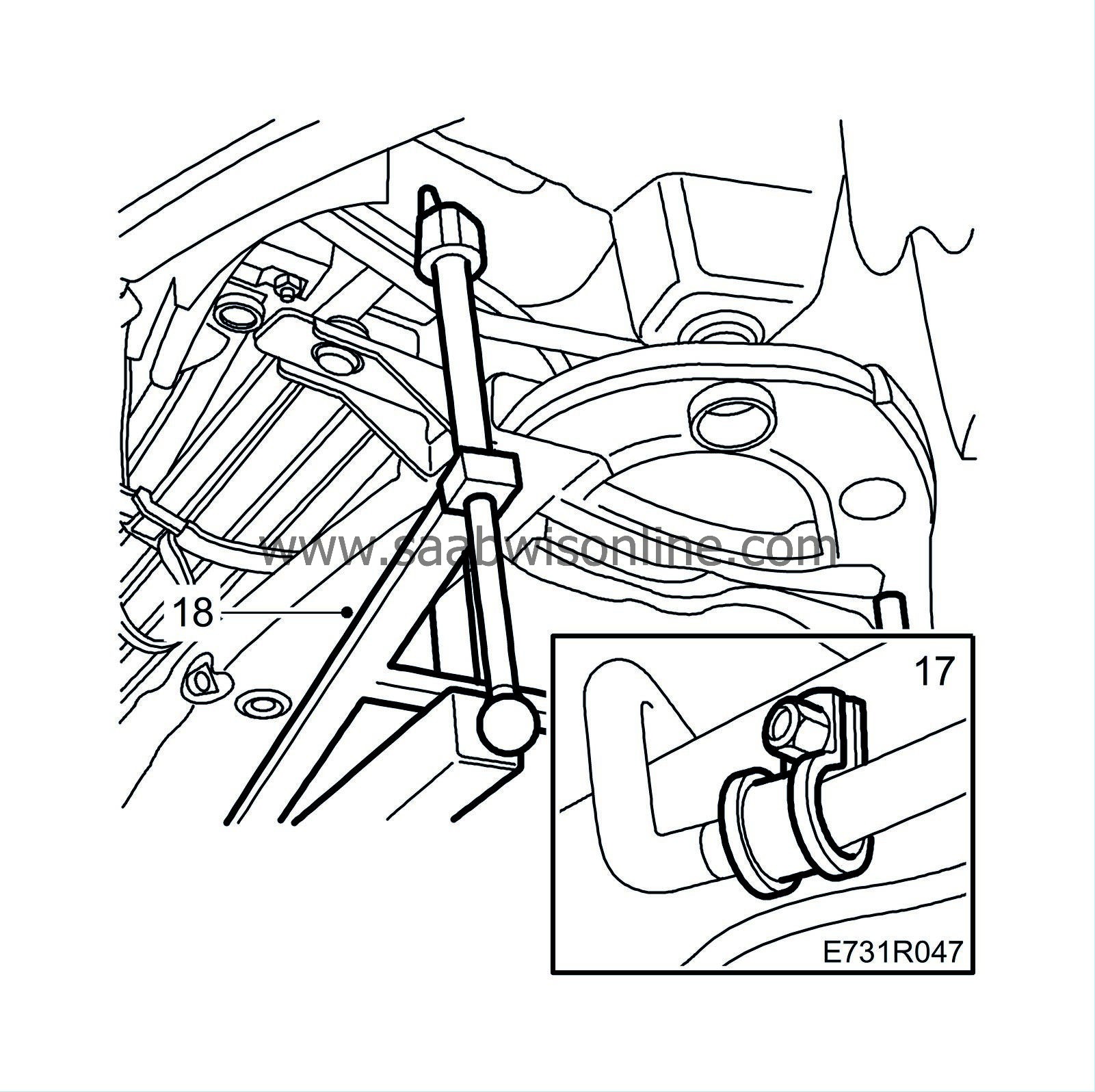

18.

|

Place a jack under the steering swivel member's ball joint and raise sit until the suspension arm is 1° below the horizontal line.

Alternatively, axle stands or similar can be placed under the steering swivel member's ball joint and the car lowered until the suspension arm is 1° below the horizontal line.

|

|

19.

|

Tighten the bolts securing the suspension arms to the subframe.

Tightening torque, front 110 Nm +90°(81 lbf ft +90°)

Tightening torque, rear 120 Nm +90°(88 lbf ft +90°)

|

|

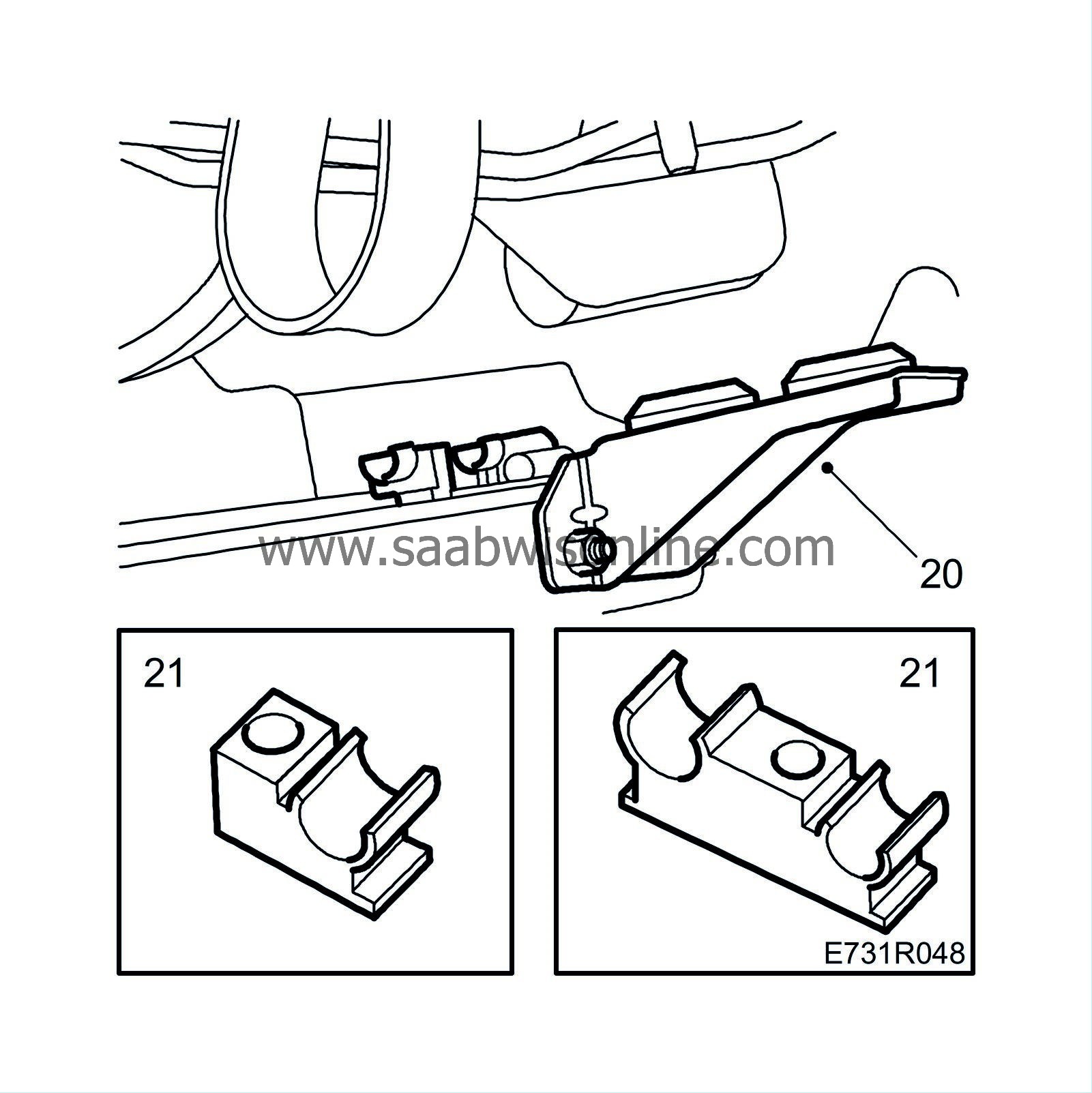

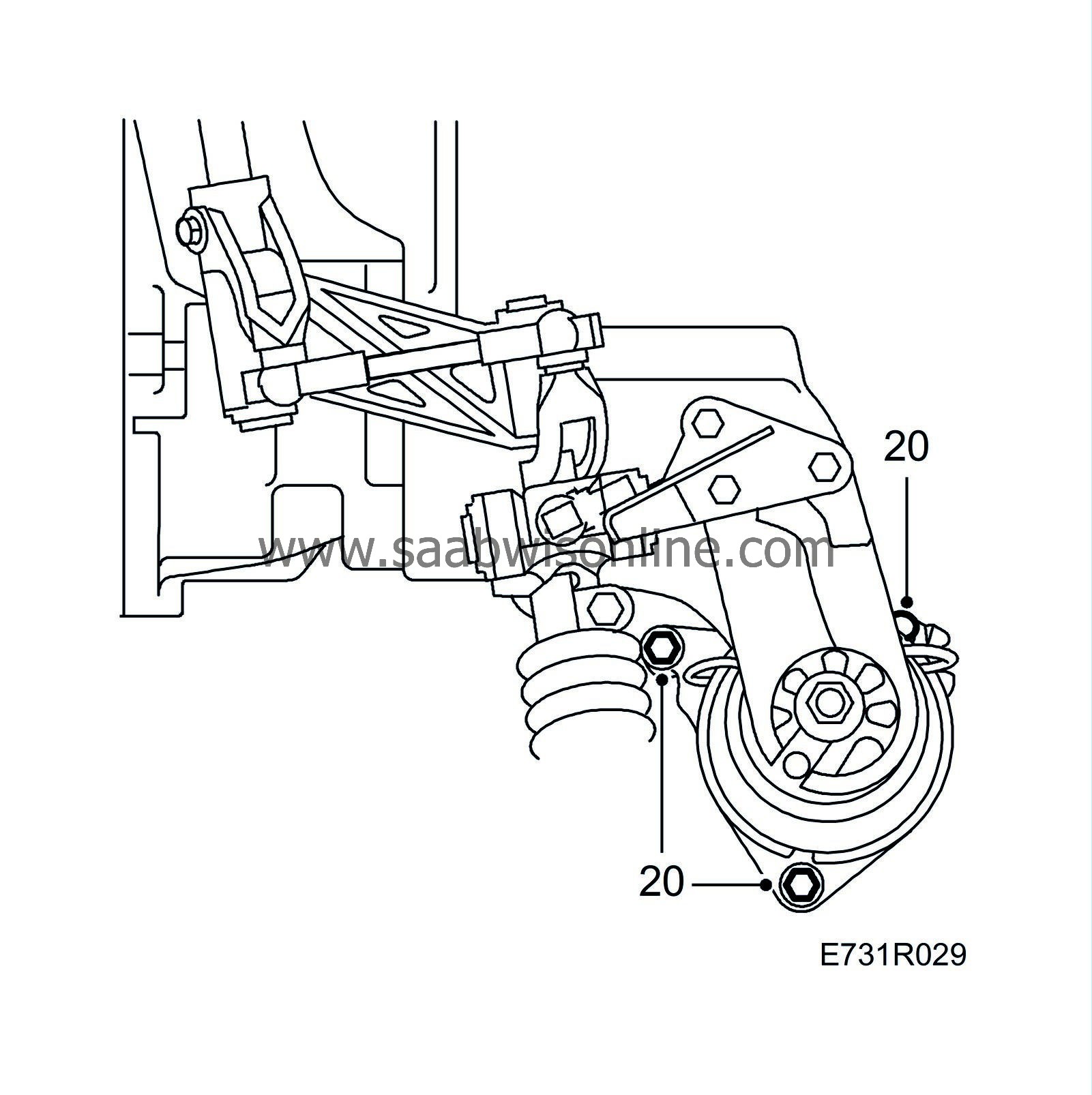

20.

|

Hang the oil cooler back in place and tighten its retaining bolts.

|

|

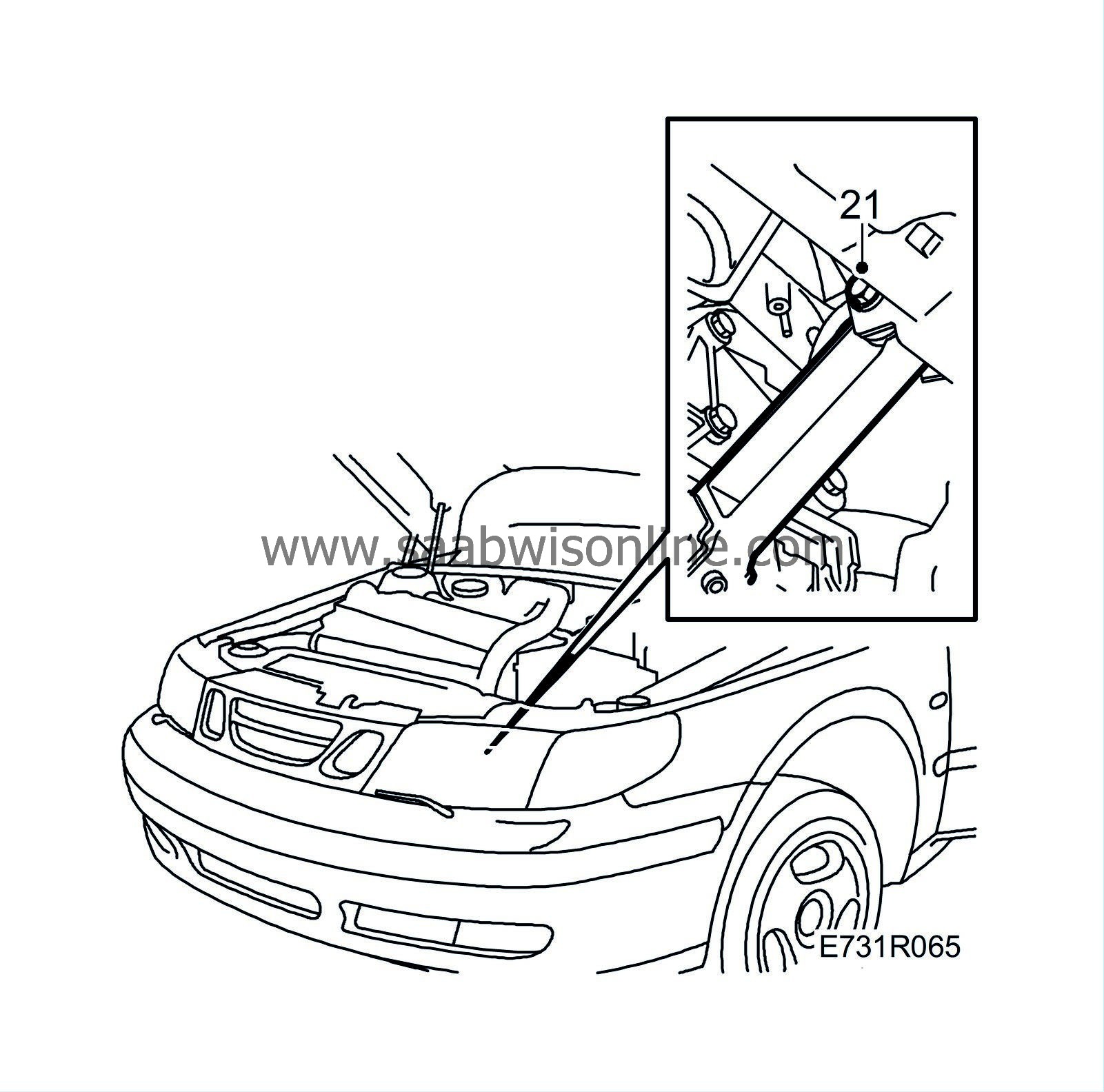

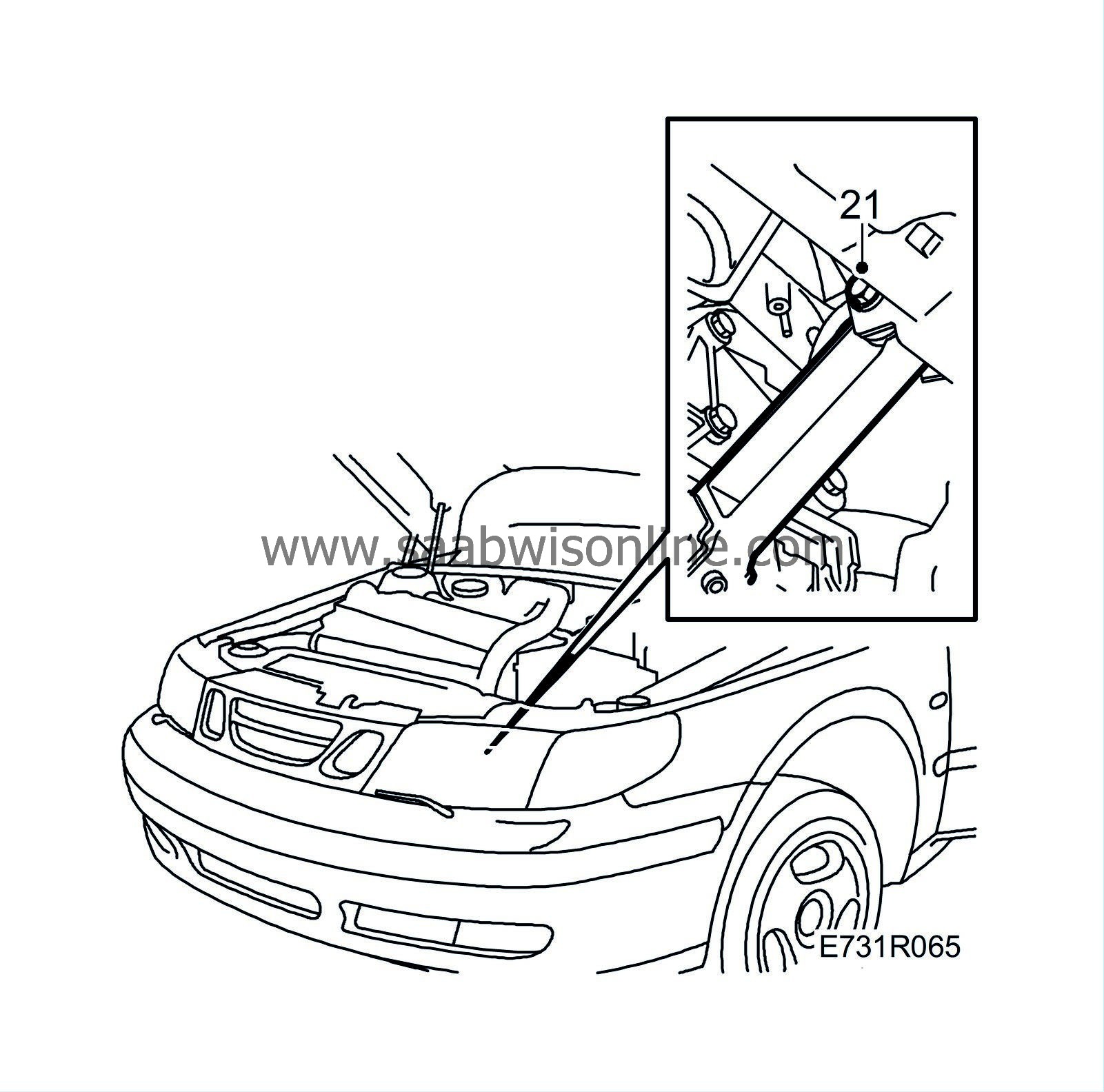

21.

|

Tighten the air cleaner retaining nuts.

|

|

22.

|

4-cyl:

Raise the front exhaust pipe section and tighten the joint between the catalytic converter and the silencer as well as the connection to the turbocharger. Refit the temperature sensor where appropriate.

Tightening torque 25 Nm (20 lbf ft)

V6:

Fit the exhaust pipe to the rear exhaust manifold.

Fit the exhaust pipe to the catalytic converter and the silencer.

Tightening torque 40 Nm (30 lbf ft)

|

|

24.

|

Fit the wheels, see

Wheels

.

Tightening torques

aluminium rim 110 Nm (81 lbf ft)

pressed steel rim 50 Nm +2x90°, max. 110 Nm (37 lbf ft +2x90°, max. 81 lbf ft)

Lower the car to the floor.

|

|

25.

|

Remove the lifting beam and tighten the bolts securing the rear engine cushion to the subframe.

Tightening torque 25 Nm (20 lbf ft)

|

|

26.

|

Tighten the bolts securing the gearbox torque arm to the subframe.

Tightening torque 90 Nm +90° (66 lbf ft +90°) .

|

|

27.

|

Fit the exhaust pipe to the turbocharger.

Tightening torque 25 Nm (18 lbf ft)

|

|

28.

|

Plug in the front heated oxygen sensor's connector and that of the rear heated oxygen sensor, if fitted, and secure the cable at suitable places.

|

|

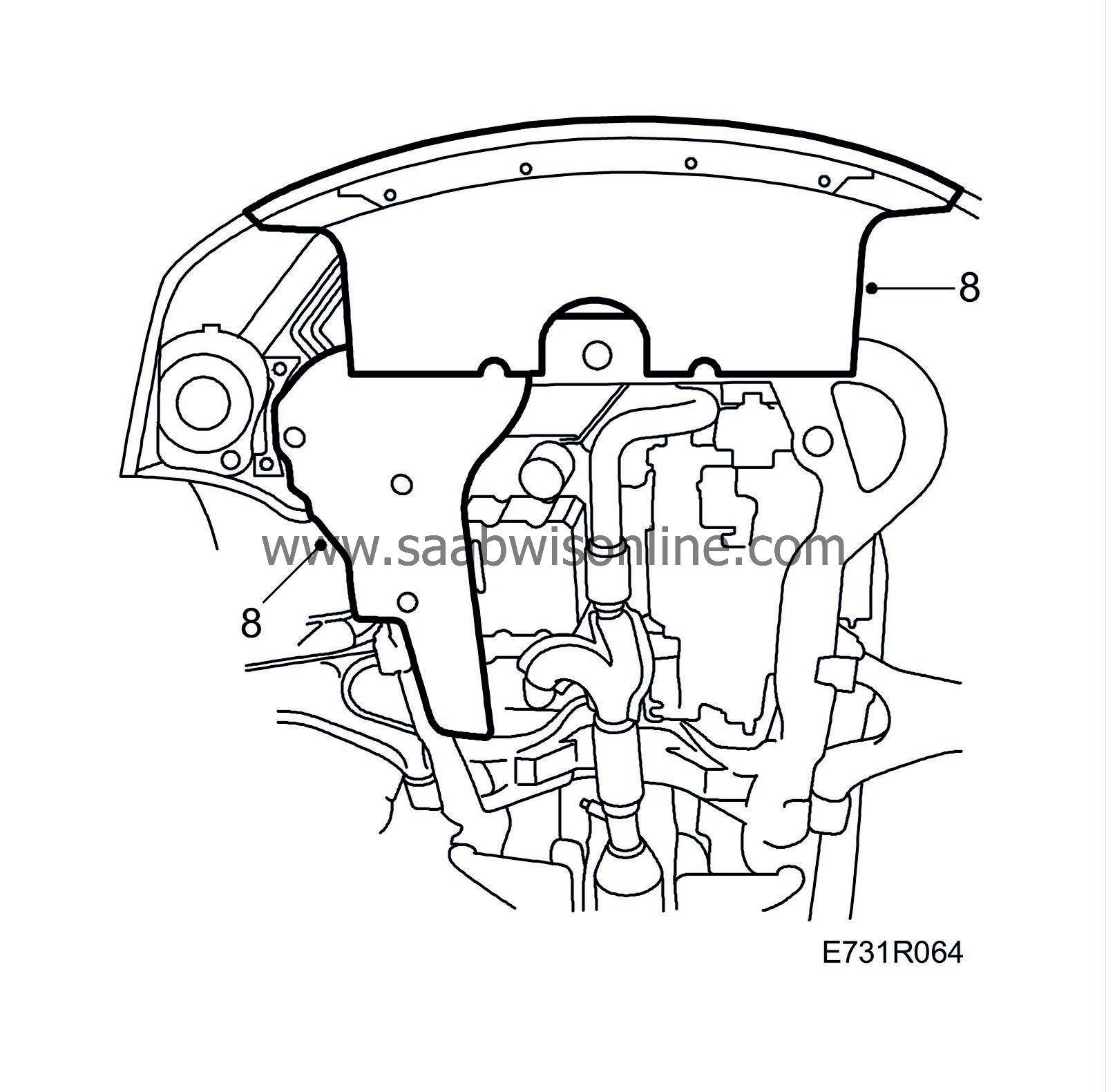

29.

|

Refit the cover over the intake manifold.

|

|

30.

|

Check the toe-in and adjust as necessary, see “Wheel alignment” in the “Steering linkage” section.

|