Piston rings

| Piston rings |

| Matching to a new or rebored cylinder |

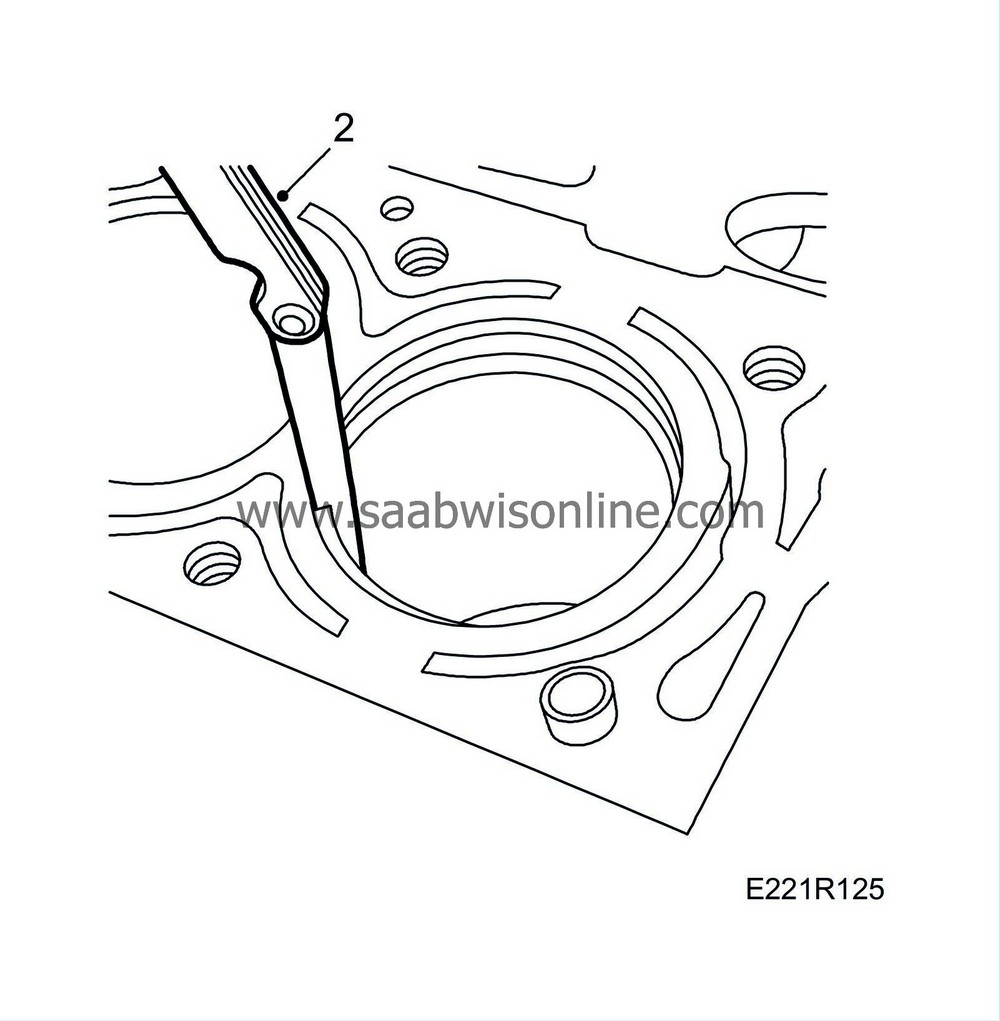

| 1. |

Push the piston rings down into the cylinder one by one, using a piston to position them correctly.

|

|

| 2. |

Measure the ring gap with a feeler gauge. If necessary, the gap can be enlarged by means of a special file. For ring gap clearance, see

.

.

|

|

| Matching in worn cylinder bore |

Matching is carried out in the same way as with a new or rebored cylinder, but when matching in a worn cylinder bore the rings must be tested in the bottom dead centre position because the cylinder bores there have the smallest diameter.

| Fitting piston rings on piston |

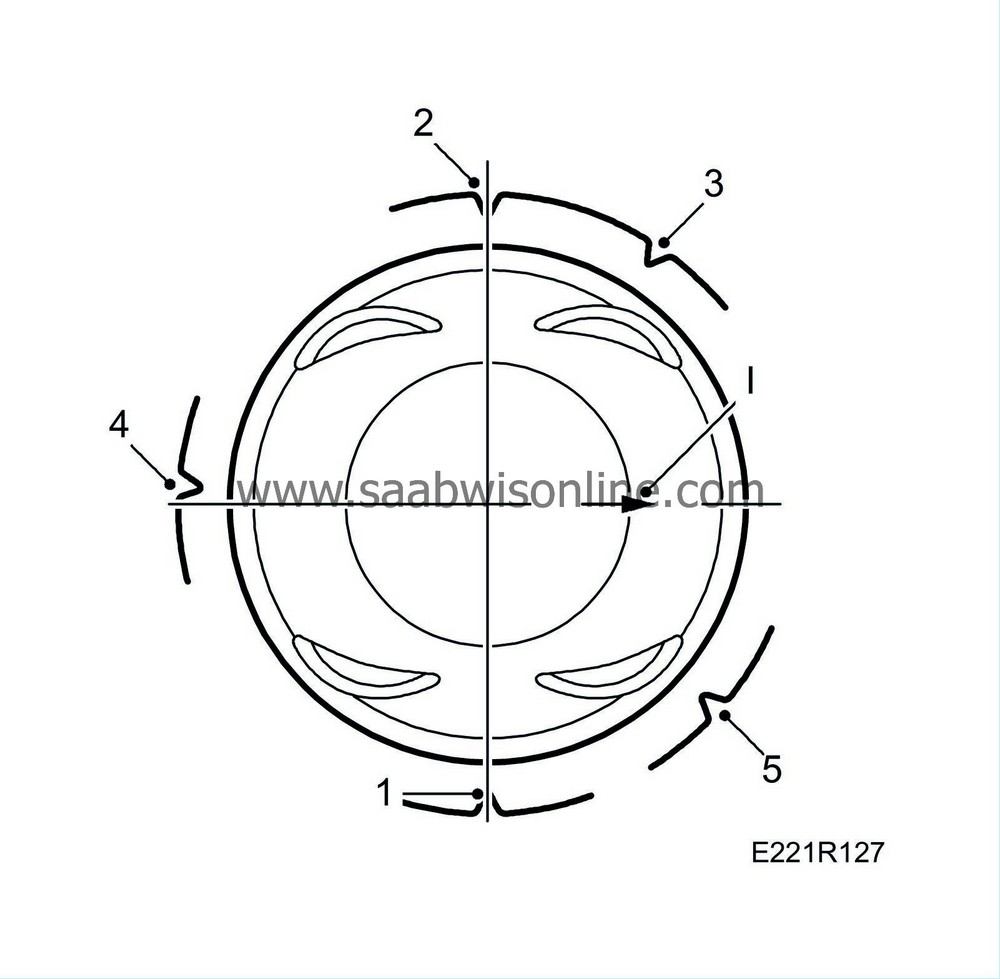

I = Front marking on piston crown, arrow points to timing end.

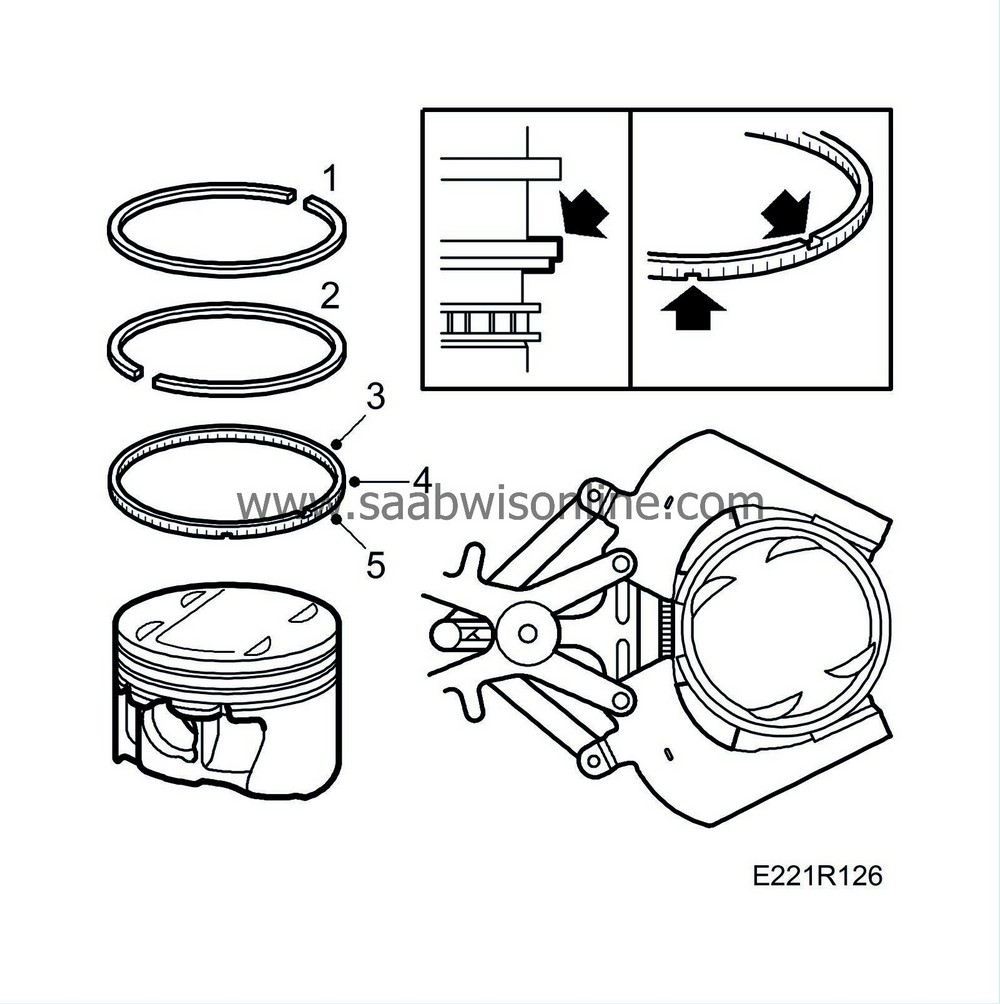

1 = Upper compression ring

2 = Lower compression ring

3 = Steel strip ring (upper oil scraper ring)

4 = Middle ring (oil scraper ring)

5 = Steel strip ring (lower scraper ring)

Oil the piston and rings before fitting. Turn the compression rings so that their gaps are staggered 180°, placing them in line with the ends of the gudgeon pins. Ensure also that the spring gaps in the top and bottom rings of the three-piece oil scraper ring are placed opposite each other.