(260-2316) Abrasion risk on coolant hoses, V6 diesel

Symptom: Abrasion damage on coolant hoses

|

MODIFICATION INSTRUCTION

|

|

Bulletin Nbr:

|

260-2316

|

|

Date:

...........

|

november 2001

|

|

Market:

|

se separat lista

|

|

|

Abrasion risk on coolant hoses, V6 diesel

|

|

Customer Satisfaction Campaign 154 06

|

Cars in stock must be rectified before delivery.

A personal communication must be sent to the owners of cars already delivered requesting them to get in touch with the nearest Saab garage as soon as possible to have the fault rectified.

Saab 9-5 with V6 diesel engine and with chassis numbers in the range 23000132 - 23011471

The mounting of certain coolant hoses is inadequate and may lead to abrasion and coolant leakage. To avoid this the relevant hoses must be constrained with cable ties. The affected locations are:

- hose against the gear-change linkage

- hose against protrusion on hose-clip

- hose against heat shield

Symptoms

Abrasion damage on coolant hoses

79 71 880 Cable tie (3x)

Before proceeding, check box B4 of the modification identity plate. If the box is not marked, continue as follows.

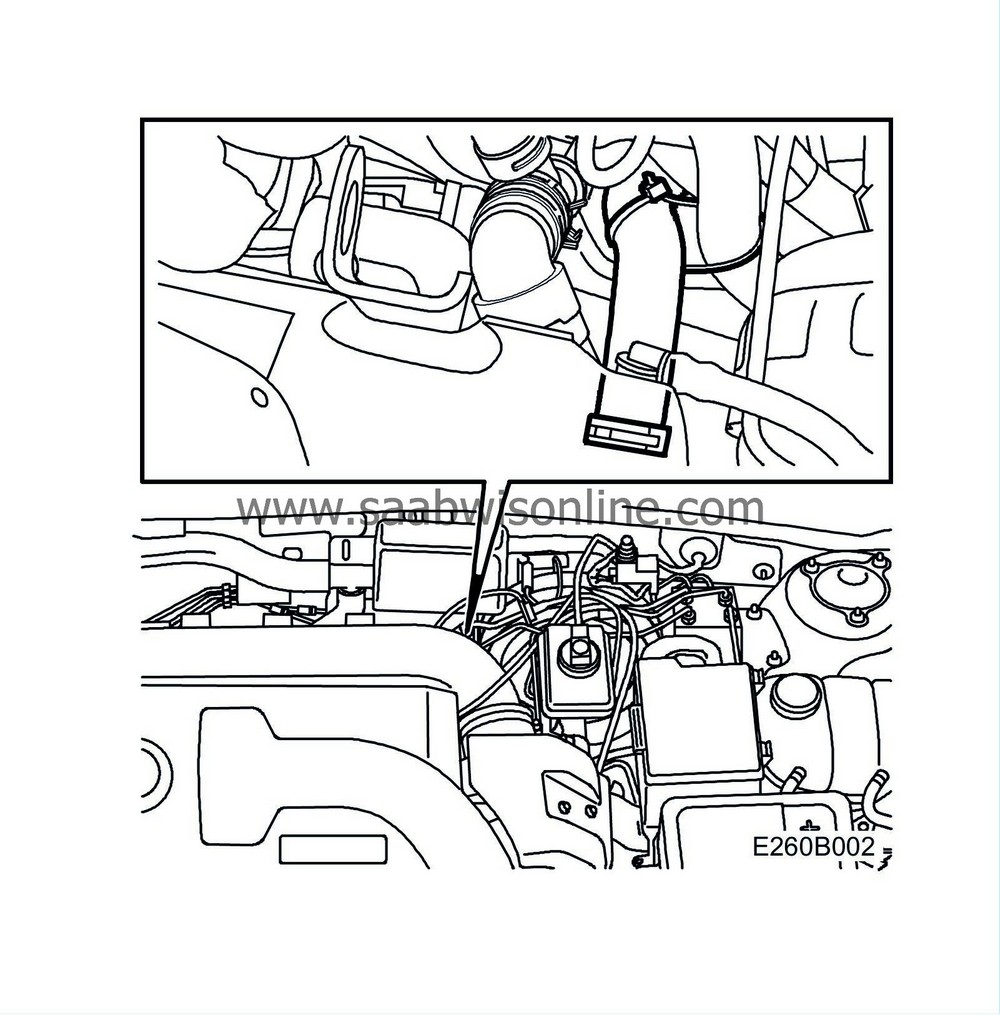

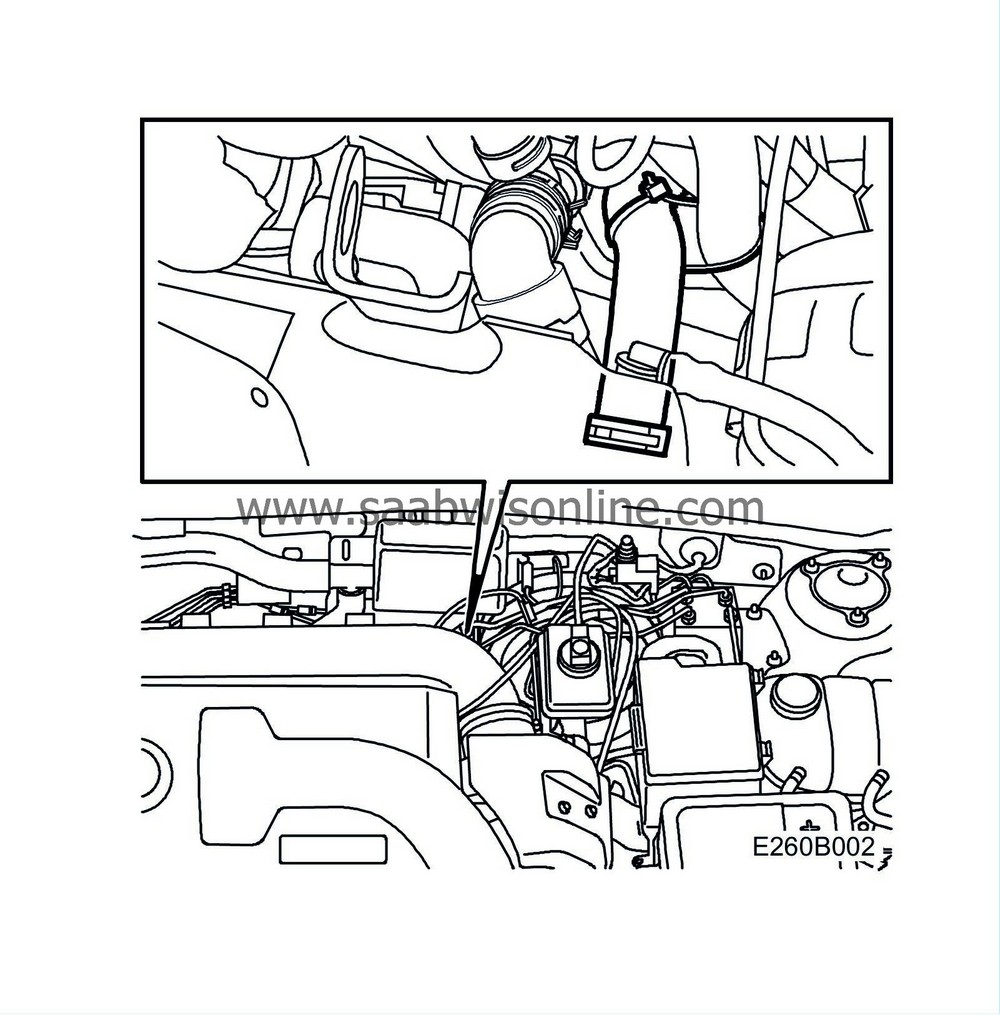

Check for possible abrasion damage on the hose from the electrical pump of the diesel heater. This can be caused by the gear-change linkage, especially when 1st and 2nd gears are selected.

Check also if the hose to the turbo cooling is rubbing against the heat shield of the rearward exhaust manifold. If any of these problems are observed proceed as follows:

|

1.

|

LHD:

Remove the battery cover and the turbo unit heat shield.

|

|

2.

|

Disconnect the cable from the negative battery terminal.

|

|

3.

|

LHD:

Undo and push aside the fuse box.

|

|

4.

|

Connect together two cable ties. Thread the assembled cable ties up through the existing cable tie which fixes the wiring harness to the fuse box. Then thread and connect the ties around the hose leading from the pump to the heater. Check that the tie assembly does not slide out of position.

|

|

5.

|

Tighten the cable ties so that the affected hoses are routed freely without risk of damage.

|

|

6.

|

LHD:

Position the fuse box and check that the hoses are still free. Adjust as necessary.

|

|

7.

|

LHD:

Lift up the fuse box and trim off excess parts from the cable ties.

|

|

8.

|

LHD:

Reassemble the fuse box and the heat shield.

|

|

9.

|

Reconnect the cable to the negative battery terminal and refit the battery cover.

|

|

10.

|

RHD:

Trim off excess parts from the cable ties.

|

|

11.

|

Reset the vehicle clock.

|

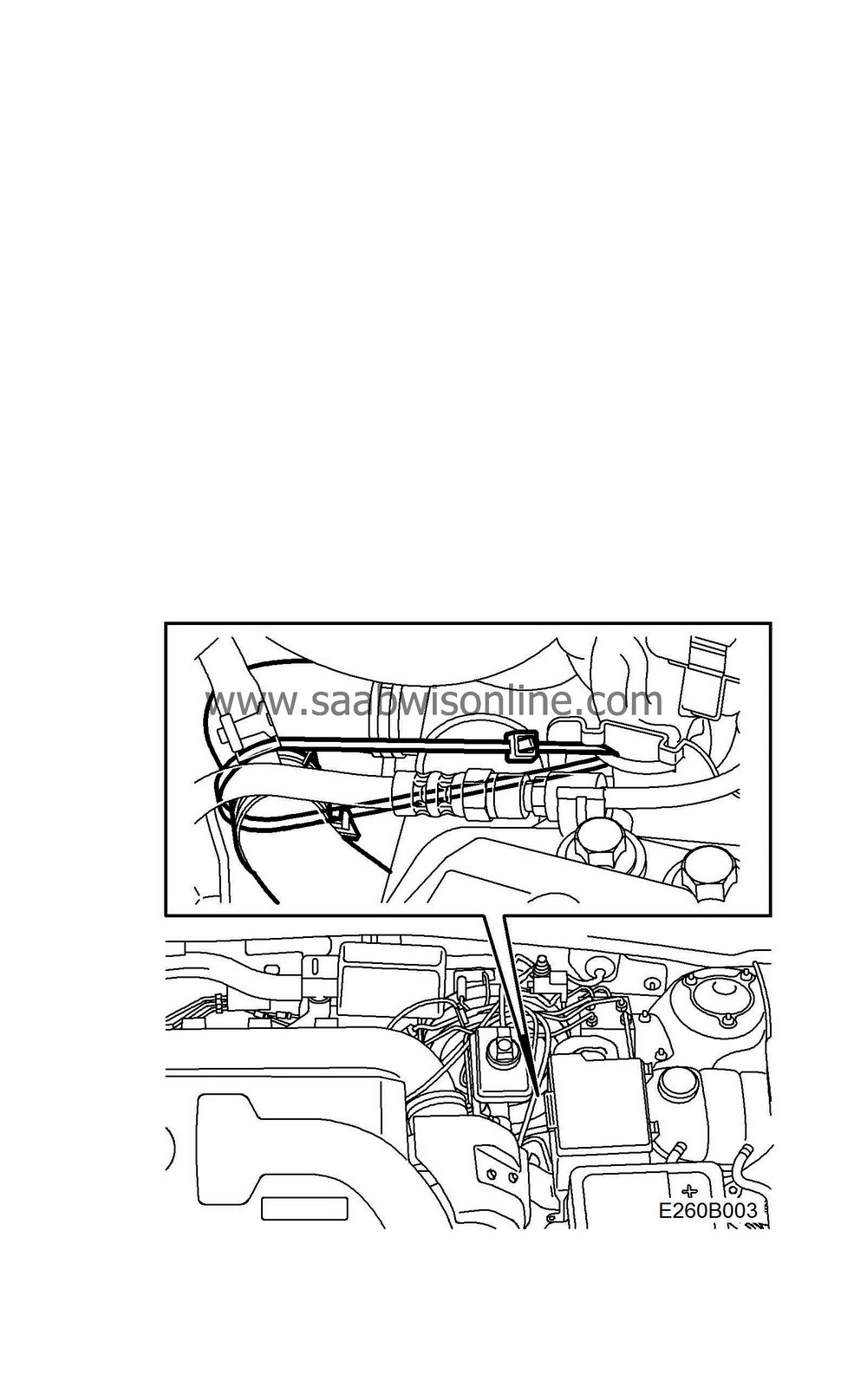

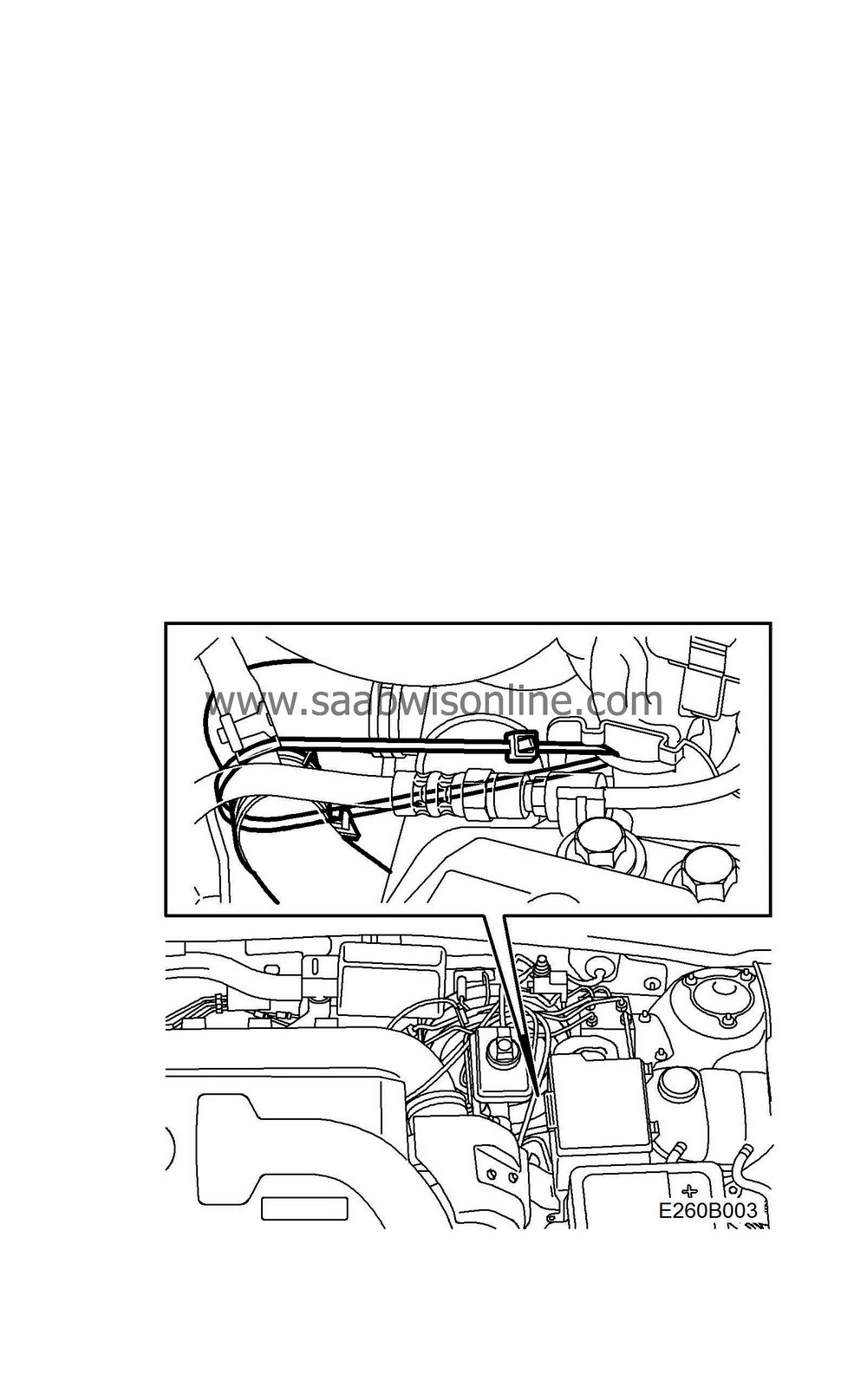

Check the cooling hose from the engine to the electric pump to see if it risks damage from abrasion by adjacent hose clips. Where this risk exists proceed as follows:

|

1.

|

Remove the battery cover and disconnect the cable from the negative battery terminal.

|

|

2.

|

LHD:

Remove the cover from over the engine control module and free the module.

|

|

3.

|

LHD:

Disconnect the engine control module connector and carefully bend up the console.

|

|

4.

|

Thread a cable tie around the coolant hose which goes from the heater to the shut-off valve. Then lead the tie around the coolant hose which goes from the engine to the heater pump.

|

|

5.

|

Assemble and tighten the cable tie sufficiently so that the affected hoses are routed freely without risk of damage.

|

|

6.

|

Trim off the cable tie excess.

|

|

7.

|

LHD:

Refit the engine control module and reconnect the connector.

|

|

8.

|

LHD:

Refit the cover over the module.

|

|

9.

|

Reconnect the cable to the negative battery terminal and refit the battery cover. Set the SID and calibrate the ACC.

|

|

Marking the modification identity plate

|

After completion of the procedure on affected vehicles according to MI 260-2316, MI 248-2318, MI 644-2319 (LHD) and MI 644-2320 the modification identity plate must be marked in square B4. If the procedure has been carried out by an importer mark the square with the number "7" and if by a dealer with the number "8".

|

Standard times-/Warranty information

|

See separate information.