Test readings, control module connections

| Test readings, control module connections |

| Scope |

The following pages contain specified values and directions for measuring signals and levels on the automatic transmission control module.

| Points to remember: |

| • |

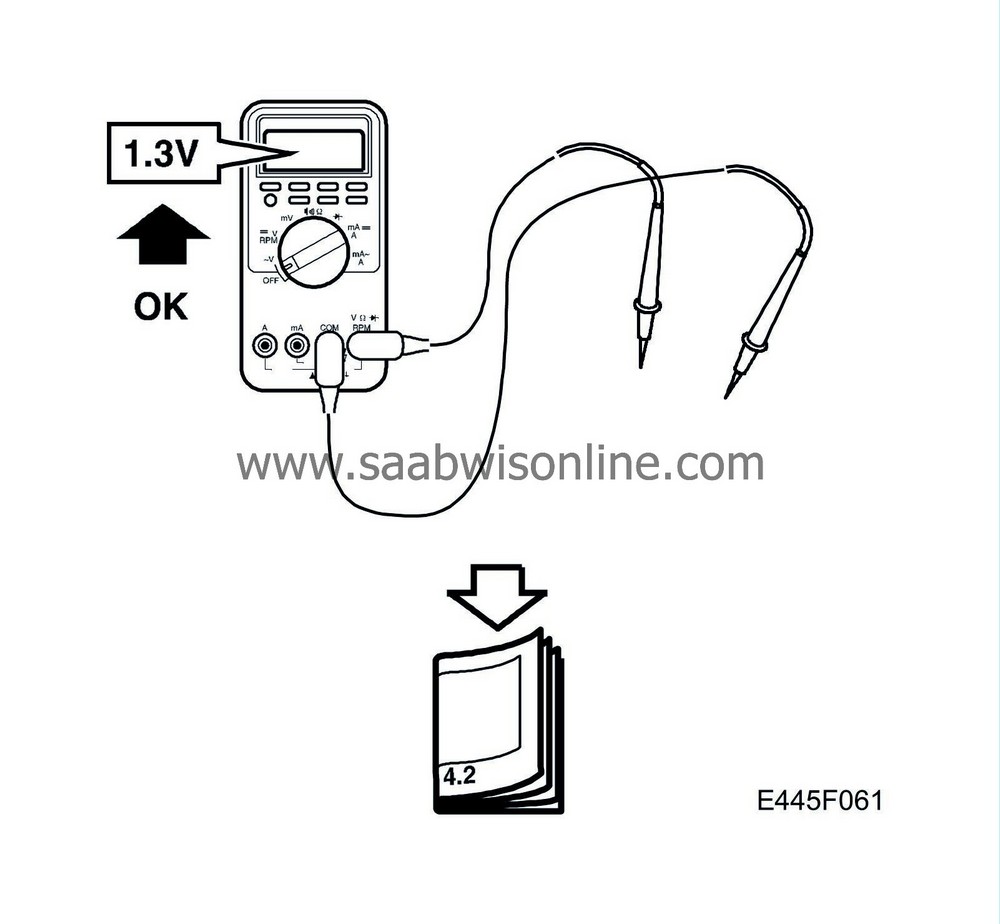

Observe the test conditions, use your common sense when judging the readings obtained.

|

|

| • |

The specified values are with the ignition in position ON unless stated otherwise.

|

|

| • |

First check that the control module is supplied with current and grounded.

|

|

| • |

Then check all sensor inputs and signals from other systems.

|

|

| • |

Finally, check the control module inputs. Remember that the test readings do not indicate whether or not the actuator is in working order.

|

|

| • |

If any reading is not OK, consult the wiring diagram to trace the leads, connectors or components which ought to be checked more thoroughly.

|

|

| • |

The specified test readings refer to those obtained with a calibrated Fluke 88/97.

|

|

| • |

Test readings %(+) and ms(+) indicate the signal's pulse ratio and pulse duration. A test instrument capable of measuring pulse ratio and pulse width must be used. The sign denotes a positive trigger pulse, TRIG+.

|

|

| Table, connector A |

|

Pin, connector

A

|

Cable colour

|

Component/ Function

|

In/Out

|

Test conditions

|

Test between

|

Test reading

|

See

|

|

1

|

no connection

|

||||||

|

2

|

no connection

|

||||||

|

3

|

no connection

|

||||||

|

4

|

no connection

|

||||||

|

5

|

no connection

|

||||||

|

6

|

no connection

|

||||||

|

7

|

OG/WH

|

WINTER mode switch

|

In

|

7-23

|

ON=B+

OFF=0 V |

||

|

8

|

No connection

|

||||||

|

9

|

No connection

|

||||||

|

10

|

No connection

|

||||||

|

11

|

No connection

|

||||||

|

12

|

No connection

|

||||||

|

13

|

No connection

|

||||||

|

14

|

No connection

|

||||||

|

15

|

No connection

|

||||||

|

16

|

No connection

|

||||||

|

17

|

BU

|

SPORT mode switch

|

In

|

||||

|

18

|

No connection

|

||||||

|

19

|

No connection

|

||||||

|

20

|

No connection

|

||||||

|

21

|

No connection

|

||||||

|

22

|

RD/BU

|

Battery voltage (+15 circuit)

|

In

|

Ignition ON

|

|||

|

23

|

BK

|

Ground

|

|

|

|||

|

24

|

No connection

|

||||||

|

25

|

GN

|

Bus +

lead 1 |

in/out

|

|

|||

|

26

|

WH

|

Bus -

lead 1 |

in/out

|

|

|||

|

27

|

No connection

|

||||||

|

28

|

No connection

|

||||||

|

29

|

No connection

|

||||||

|

30

|

No connection

|

||||||

|

31

|

RD/BU

|

Battery voltage (+15 circuit)

|

In

|

Ignition ON

|

|||

|

32

|

BK

|

Ground

|

|||||

|

33

|

RD

|

Battery voltage (+30 circuit)

|

In

|

||||

|

34

|

No connection

|

||||||

|

35

|

No connection

|

|

|

||||

|

36

|

No connection

|

|

|||||

|

37

|

No connection

|

||||||

|

38

|

No connection

|

*A vehicle speed reading can be obtained with the diagnostics instrument, command menu "Read functions" and "Output speed”.

Table, connector B

|

Pin, connector

B

|

Cable colour

|

Component/ Function

|

In/Out

|

Test conditions

|

Test between

|

Test reading

|

See

|

|

1

|

no connection

|

||||||

|

2

|

no connection

|

||||||

|

3

|

no connection

|

||||||

|

4

|

no connection

|

||||||

|

5

|

no connection

|

||||||

|

6

|

BN/WM

|

Selector lever, position A

|

In

|

Ignition ON

Signal grounded in positions P, R, 4 and 3 |

6 - 23

|

Selector lever position P, R, 4, 3: 0-0.5 V

Other positions: 0-2 V |

|

|

7

|

OG/WH

|

Selector lever, position C

|

In

|

Ignition ON

Signal grounded in positions D, 4, 3 and L |

7-23

|

Selector lever position: D, 4, 3, L: 0-0.5 V

|

|

|

8

|

BU/WH

|

Solenoid S3

|

Out

|

Solenoid supplied with voltage when activated by the TCM for 1st, 2nd and 3rd gears

|

Signal activated: 0-2 V

Not activated: Low |

||

|

9

|

No connection

|

||||||

|

10

|

No connection

|

||||||

|

11

|

No connection

|

||||||

|

12

|

BK/WH

|

Lock-up solenoid, SLU ground

|

In

|

Signal = Low

|

|||

|

13

|

GN/WH

|

Solenoid S5

|

Out

|

Ignition ON

Solenoid supplied with voltage when activated by the TCM for reverse and for changing between 2nd and 3rd gears |

Activated: 0-2 V

Not activated: Low |

||

|

14

|

GN/WH

|

Solenoid S4

|

Out

|

Ignition ON

Solenoid supplied with voltage when activated by the TCM for 3rd, 4th and 5th gears |

Activated: 0-2 V

Not activated: Low |

||

|

15

|

BK/WH

|

System pressure solenoid, SLT ground

|

In

|

Signal = Low

|

|||

|

16

|

VT

|

Selector lever, position B

|

In

|

Ignition ON

Signal grounded in positions R, N, D and 3 |

16 - 23

|

Selector lever position R, N, D, 3: 0-0.5 V

Other positions: 0-2 V |

|

|

17

|

GY

|

Selector lever, position PA

|

In

|

Ignition ON

Signal grounded in positions P, N, 4, and L |

17 - 23

|

Selector lever position P, N, 4, L: 0-0.5 V

Other positions: 0-2 V |

|

|

18

|

No connection

|

||||||

|

19

|

No connection

|

||||||

|

20

|

No connection

|

||||||

|

21

|

GN

|

Fluid temperature +

|

Out

|

Voltage decreases as temperature increases

|

Cold transmission (+20°C): 3.4 V ±10%

Warm transmission (100°C): 0.7 V ± 10% |

||

|

22

|

WH/PK

|

Sensor, input shaft speed signal

|

In

|

When the toothed wheel rotates, the sensor generates a square wave signal. The frequency increases with speed.

|

Tooth aligned with sensor: 14 mA

Gap aligned with sensor: 7 mA |

||

|

23

|

PK

|

Sensor, output shaft speed signal

|

In

|

When the toothed wheel rotates, the sensor generates a square wave signal. The frequency increases with speed.

|

Tooth aligned with sensor: 14 mA

Gap aligned with sensor: 7 mA |

||

|

24

|

BU/WH

|

Solenoid S2

|

Out

|

Ignition ON

Solenoid supplied with voltage when activated by the TCM for 1st and 5th gears |

Activated: 0-2 V

Not activated = Low |

||

|

25

|

BU/WH

|

Lock-up solenoid, SLU +

|

Out

|

Solenoid supplied with voltage when activated by the TCM

|

PWM = 300 Hz. The frequency remains constant irrespective of driving conditions. It is the signal's "duty cycle" that changes with changes in system pressure.

|

||

|

26

|

BU/WH

|

Clutch system pressure solenoid, SLS +

|

Out

|

Solenoid supplied with voltage when activated by the TCM

|

PWM = 300 Hz. The frequency remains constant irrespective of driving conditions. It is the signal's "duty cycle" that changes with changes in system pressure.

|

||

|

27

|

No connection

|

||||||

|

28

|

No connection

|

||||||

|

29

|

No connection

|

||||||

|

30

|

No connection

|

||||||

|

31

|

WH/PK

|

Fluid temperature sensor, ground

|

In

|

Signal = Low

|

|||

|

32

|

WH

|

Sensor, input shaft speed, power supply

|

In

|

|

Signal = B+

|

||

|

33

|

RD/GN

|

Sensor, output shaft speed, power supply

|

In

|

|

Signal = B+

|

||

|

34

|

GN/WH

|

Solenoid S1

|

Out

|

Ignition ON

Solenoid supplied with voltage when activated by the TCM for 1st gear |

Activated: 0-2 V

Not activated: Low |

||

|

35

|

BU/WH

|

System pressure solenoid, SLT +

|

Out

|

Solenoid supplied with voltage when activated by the TCM

|

PWM = 300 Hz. The frequency remains constant irrespective of driving conditions. It is the signal's "duty cycle" that changes with changes in system pressure.

|

||

|

36

|

BK/WH

|

Clutch system pressure solenoid, SLS ground

|

In

|

Signal = Low

|

|||

|

37

|

No connection

|

||||||

|

38

|

No connection

|