Control module

| Control module |

| • |

Shift points

|

|

| • |

System pressure

|

|

| • |

Lock-up engagement (fixed or slipping)

|

|

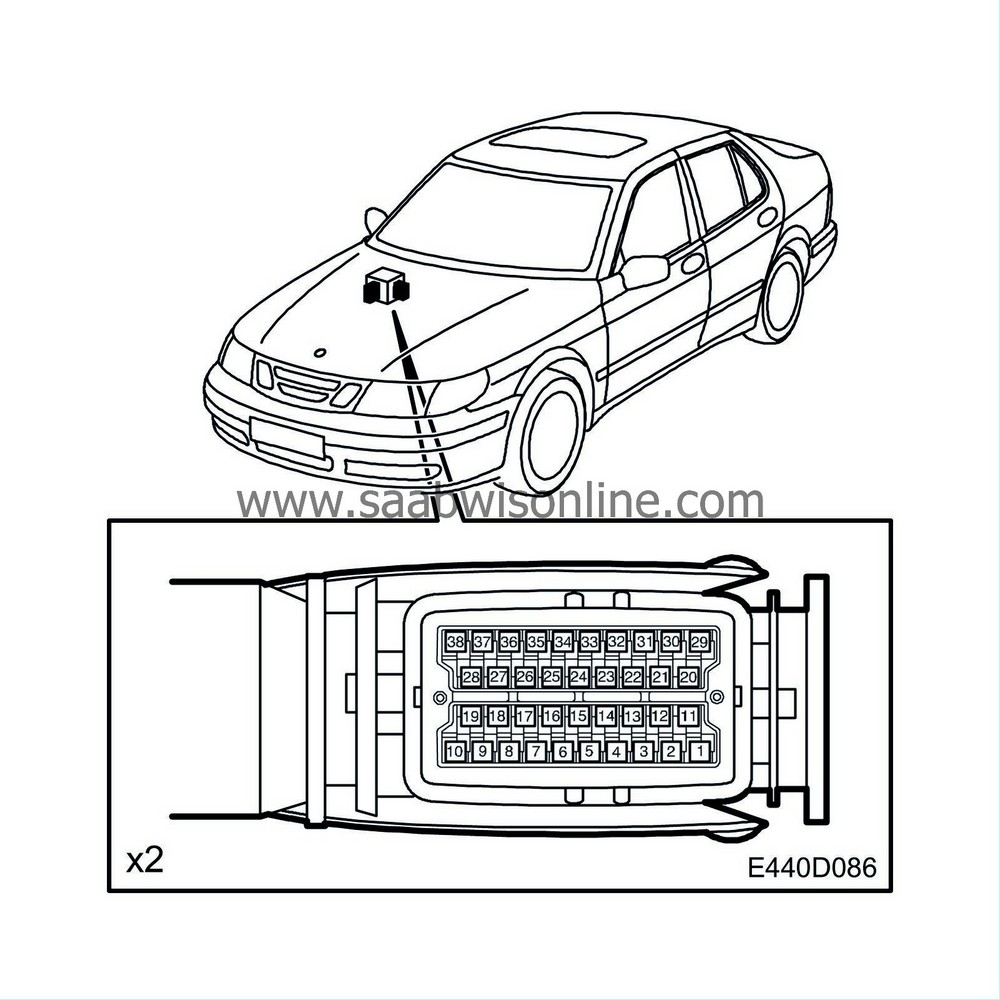

The control module has two 38-pin connectors and is located behind the glove box in the passenger compartment. The control module is programmed for a specific engine variant (B205E, B235E/R or B308E) and must only be used in a Saab 9-5 with that engine variant. When supplied as a spare part the control module is not programmed and must therefore be programmed using Tech 2 and SPS programming to match the engine.

The control module receives information from a number of its own sensors as well as other electrical systems. The information is processed and the control module controls gearchanging and shifting points based on the selected driving program (NORMAL, SPORT or WINTER).

Gear changing takes place when the control module acts on solenoid valves S1, S2, S3, S4 and S5, which are mounted in the transmission valve body. The control module also determines if and when the torque converter lock-up is to be engaged based on a certain combination of solenoid valve settings. Three linear solenoids are mounted in the valve body and control the lock-up (SLU), system pressure (SLT) and the clutch disc pressure (SLS).

The control module is continuously supplied with +30 and is adapted for a voltage of between 9 and 16 V when the car is driven. Stored fault codes are not erased from the memory should the power supply is broken. The TCM and other systems communicate over a bus.

When the ignition switch is turned to the ON position, the control module is activated and turns on the CHECK GEARBOX lamp as a function check. If no faults are found, TCM will turn off the lamp after three seconds.

In the event of a fault in any of the inputs/outputs, the transmission goes into Limp-Home mode. All control module functions will then be disengaged or an emergency operation program will be activated. The car can then be driven but with limited shifting capability.

The TCM also allows for transmission wear. Even if the transmission is warn, gearshifts will be smooth. The TCM compares the actual quality of the gearchanges with a shift matrix in the software and "learns" what pressure and duration is required in different situations to ensure comfortable gearchanges. An EEPROM memory is used for this function as well as to store diagnostic trouble codes. This means that the information is stored even if the power supply is cut. Accordingly, the TCM must be zeroed using Tech 2 if the transmission is changed or repaired.

The control module can be SPS programmed using the diagnostic instrument.

When handling control modules, it is important to ground yourself first by touching the car's engine, for instance. Avoid touching the control module's connecting pins.