Balancer shafts

| Balancer shafts |

| Engine vibration |

Through combustion, where chemical energy is converted into mechanical energy, gas forces are generated which act on the piston crown. The reciprocating movement of the pistons and connecting rods, combined with the rotation of the crankshaft, generate inertial forces that act on the engine block and cause it to vibrate in various ways. At low engine speeds these gas forces are greater than the inertial forces but at high engine speeds the converse is true. The most significant forces arise periodically once or twice per crankshaft revolution. They are known as first-order and second-order forces. The first-order inertial forces are completely cancelled out since the crankshaft is balanced and the two piston pairs, 1-4 and 2-3, reverse direction simultaneously when they reach top dead centre and bottom dead centre.

| Second-order forces acting vertically |

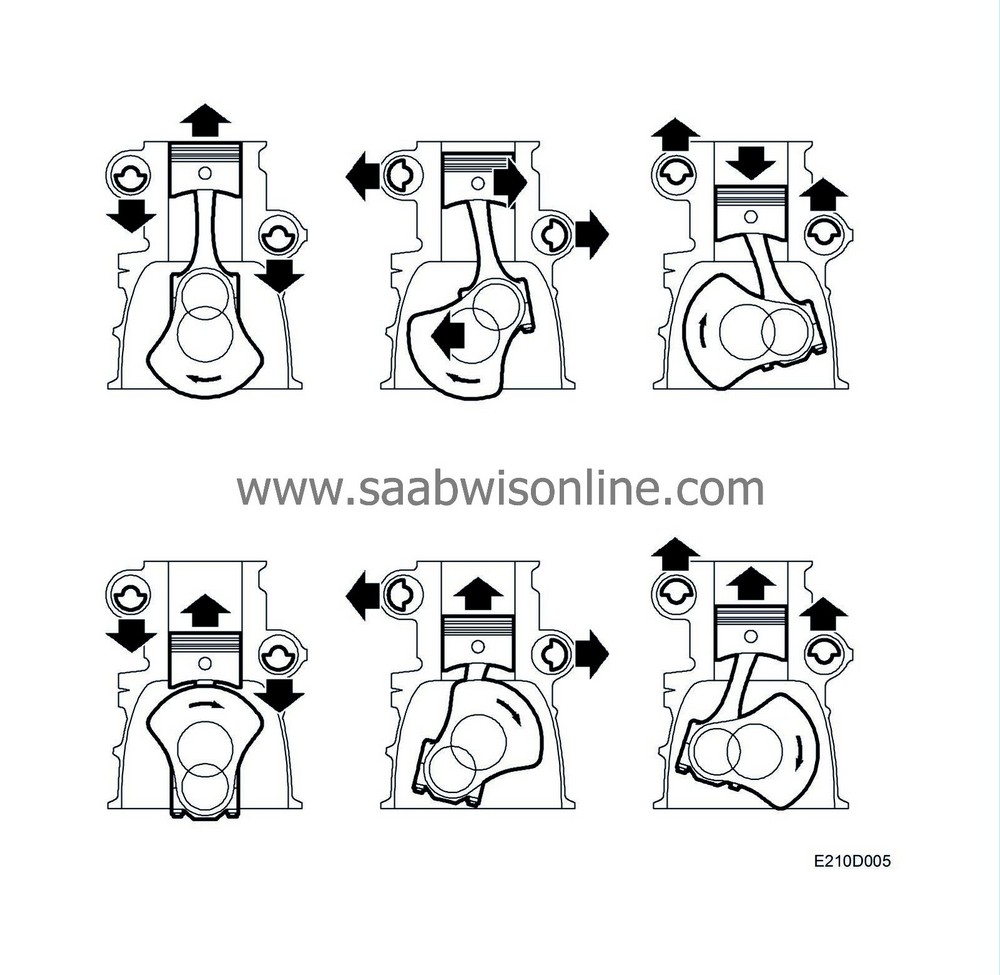

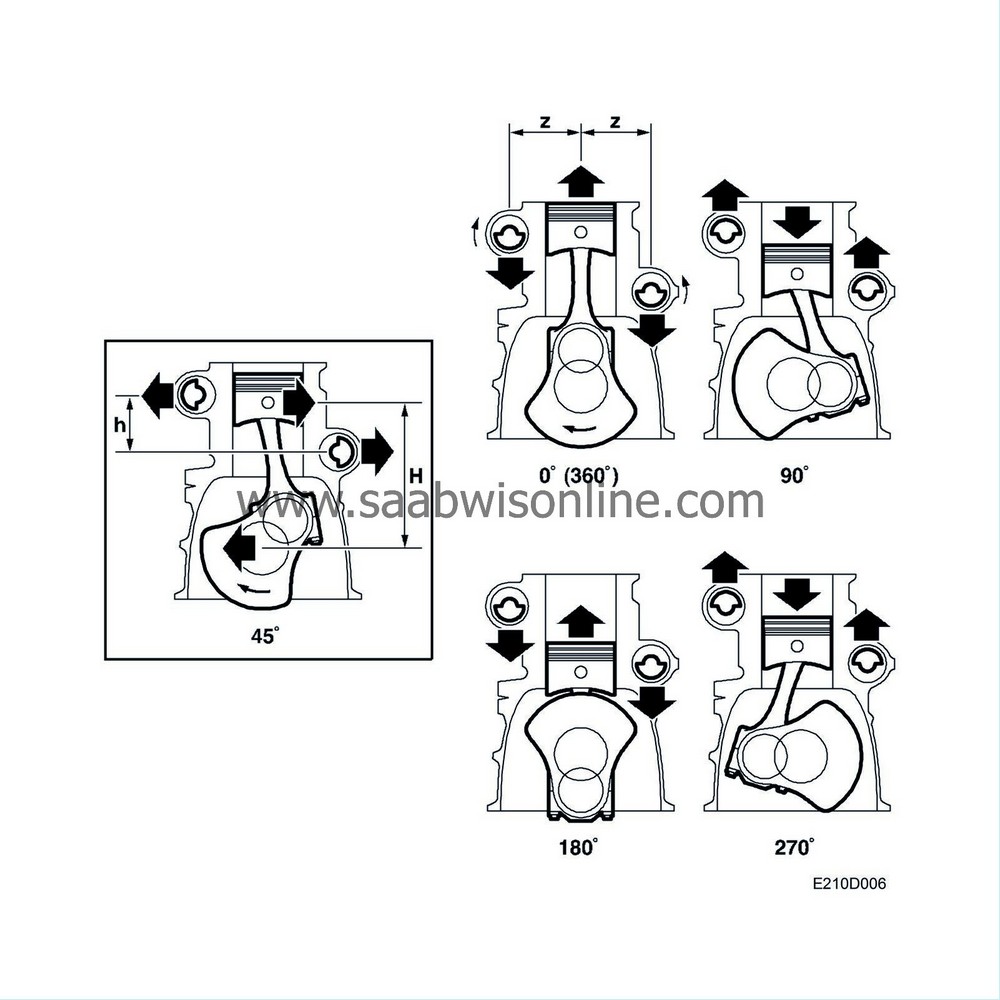

Inertial forces are generated because the pistons are not at half their stroke at 90° and 270° but considerably lower down. This is due to the relationship between stroke and connecting rod length. The common centre of gravity of the ascending and descending masses is therefore much lower down at 90° and 270°, than at 0° and 180°. This gives rise to forces moving upwards and downwards which vary periodically twice per crankshaft revolution and cause the engine to vibrate in a vertical direction.

| Second-order forces acting laterally |

During the power stroke the piston is pressed against the cylinder wall due to the angle of the connecting rod relative to the cylinder. At higher engine speeds, however, the inertial force is much greater. It can then be said that the crankshaft pulls the piston down and due to the angle of the connecting rod relative to the cylinder the piston is pressed against the cylinder wall, but this time on the opposite side. The combined gas and inertial forces acting in a sideways direction vary periodically twice per crankshaft revolution and cause the engine to vibrate in a lateral direction.

| The Saab balancer shaft system |

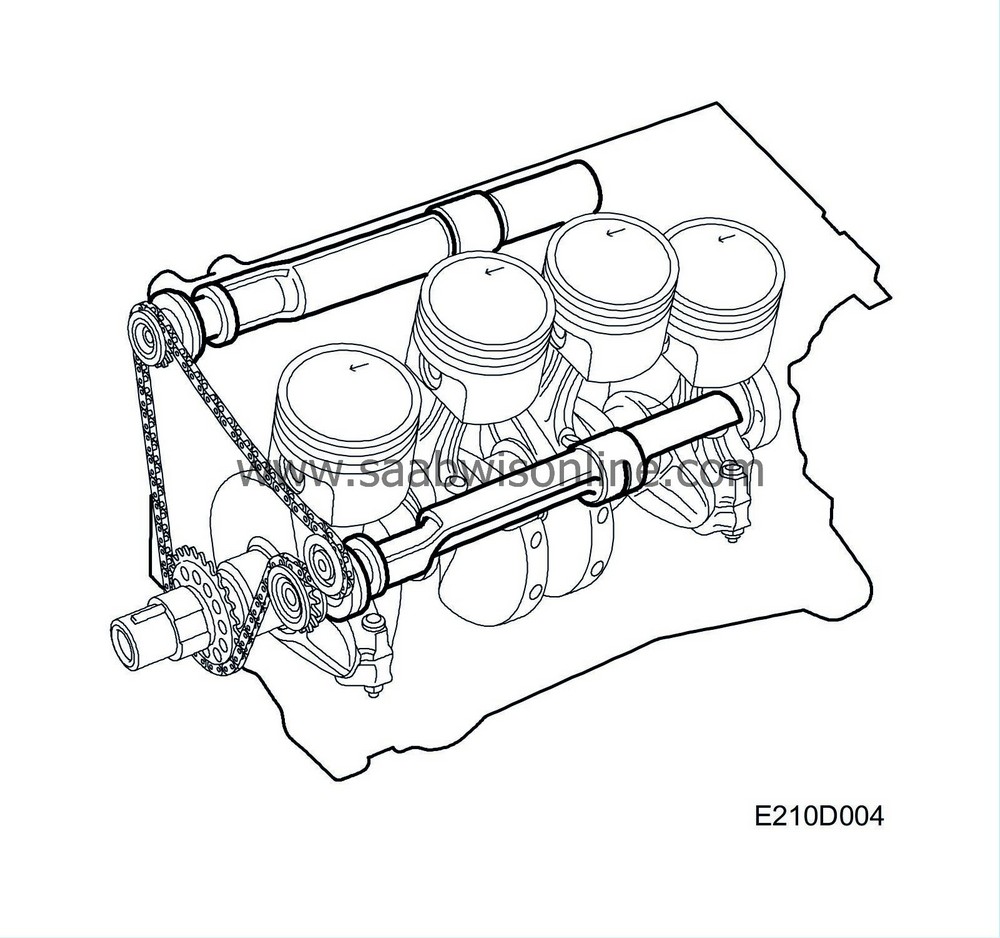

Saab has used the balancer-shaft principle to cancel out second-order inertial forces. Two balancer shafts positioned symmetrically on the sides of the engine block but at different heights above the crankshaft centreline are fitted with eccentrically mounted balance weights. The shafts are driven by a chain and rotate in opposite directions to each other at twice the crankshaft speed.

At 90° and 270° the common centre of gravity of the ascending and descending masses is situated lower down in the engine block than at 0° and 180°. The balancer shaft weights must therefore be directed upwards. At 0° and 180° the centre of gravity has moved upwards and the balancer shaft weights must therefore be directed downwards.

Since the balancer shafts are situated at different heights above the crankshaft centreline, they also cancel out lateral forces. The torque generated by the balancer shafts is designed to counteract the gas and inertial forces acting in a sideways direction.

The balancer shafts are of identical design and are supported by aluminium bushes in the middle (between cylinders 2 and 3). The bushes are a press fit in the block and are lubricated via separate oilways.

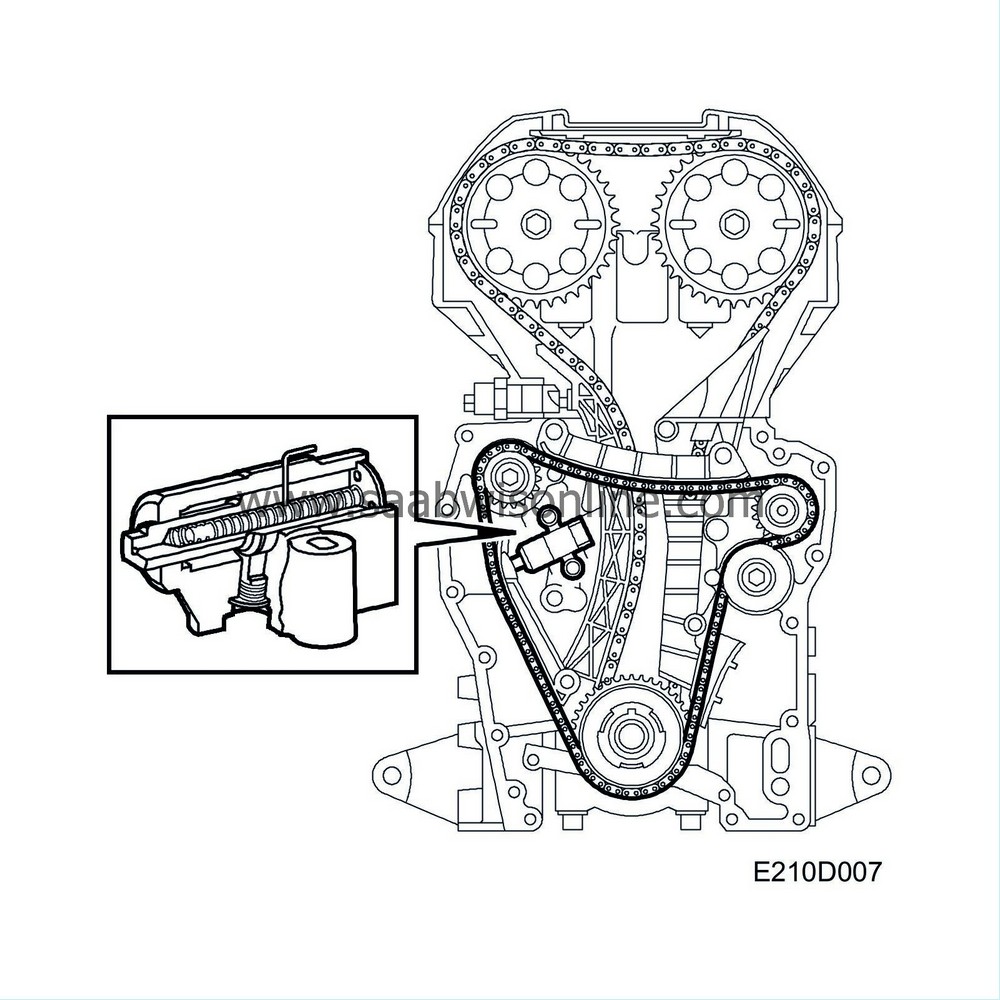

For the balancer shafts to perform as intended, it is absolutely essential for them to be precisely aligned on assembly. Sprocket assemblies of different design for the exhaust and inlet sides are therefore used on the shafts and marked with identifying text.

The balancer shaft, chain sprocket and bearing housing are assembled as a single unit before being mounted in the cylinder block. This unit is then fitted on the correct side of the engine as indicated by the marking on the bearing housing.

| Balancer shaft drive |

The balancer shafts are driven by the crankshaft via a chain, where the gear ratio on the shafts drive gears is such that the balancer shafts speed is double that of the crankshaft. The shaft on the exhaust side rotates in opposite direction since an idler sprocket has been mounted in the chain circuit. The chain is partly guided by two fixed guides and also by a moveable chain guide acted on by a chain tensioner. The chain tensioner tensions the chain with a spring when the engine is not running. When the engine is running, the oil pressure reduces the chain tensioner's spring force to reduce wear and noise in the balancer shaft circuit. The chain noise is reduced by the thrust rings located on the shaft gear and idler sprocket. The thrust rings catch the chain at the ring gear and the chain is thus applied smoother and quieter operation is achieved. Due to the smaller dwell angle, the thrust rings are larger on the exhaust side than on the intake side.