Oil sump assy

| Oil sump assy |

| To remove |

| 1. |

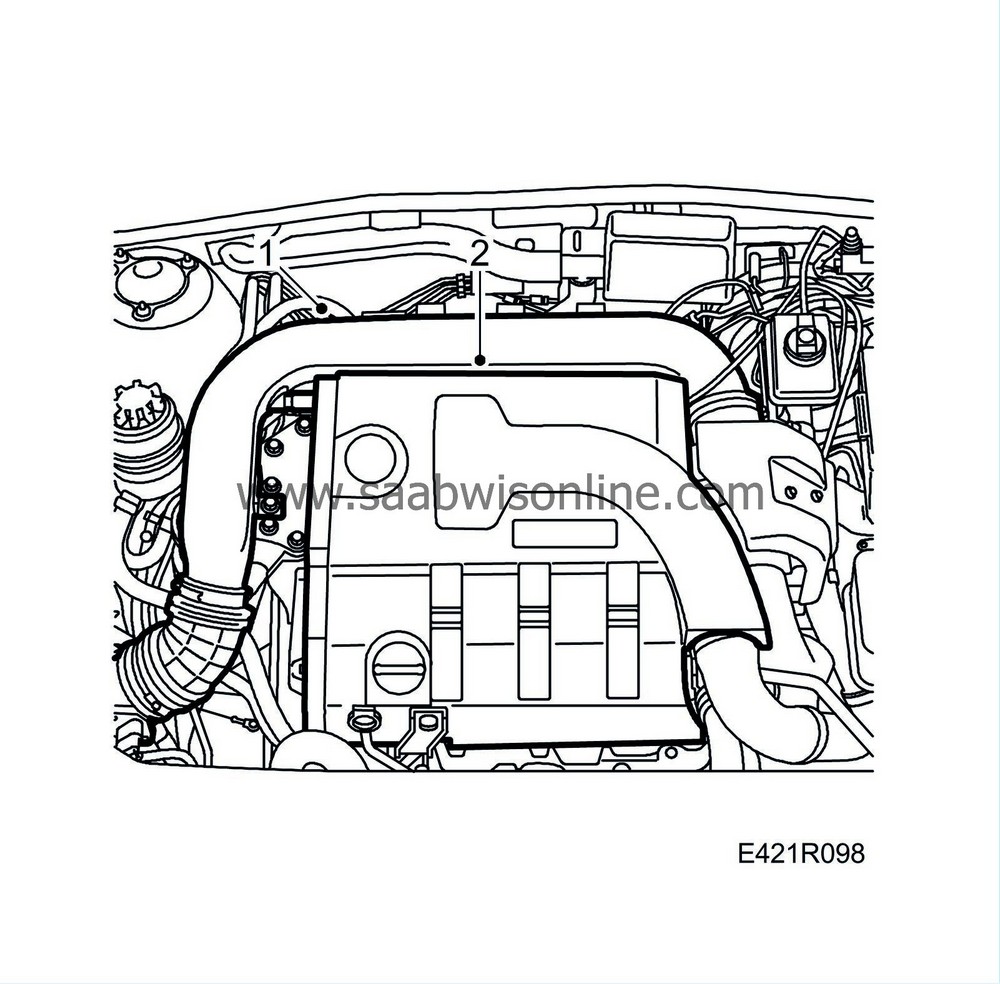

Remove the intake manifold with mass air flow sensor from the turbocharger.

|

|

| 2. |

Remove the upper engine cover.

|

|

| 3. |

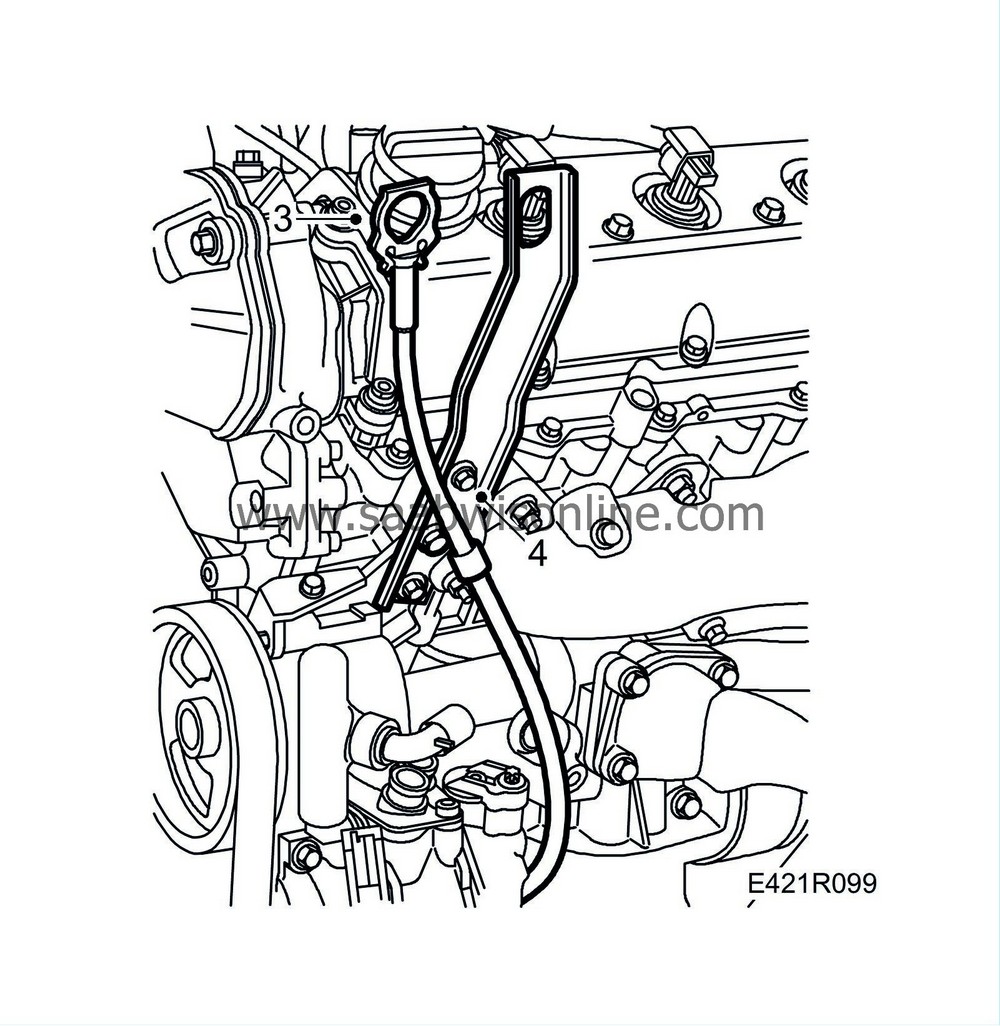

Remove the dipstick.

|

|

| 4. |

Remove the cable tie from the dipstick tube and the bolt of the dipstick tube from the lifting eye.

|

|

| 5. |

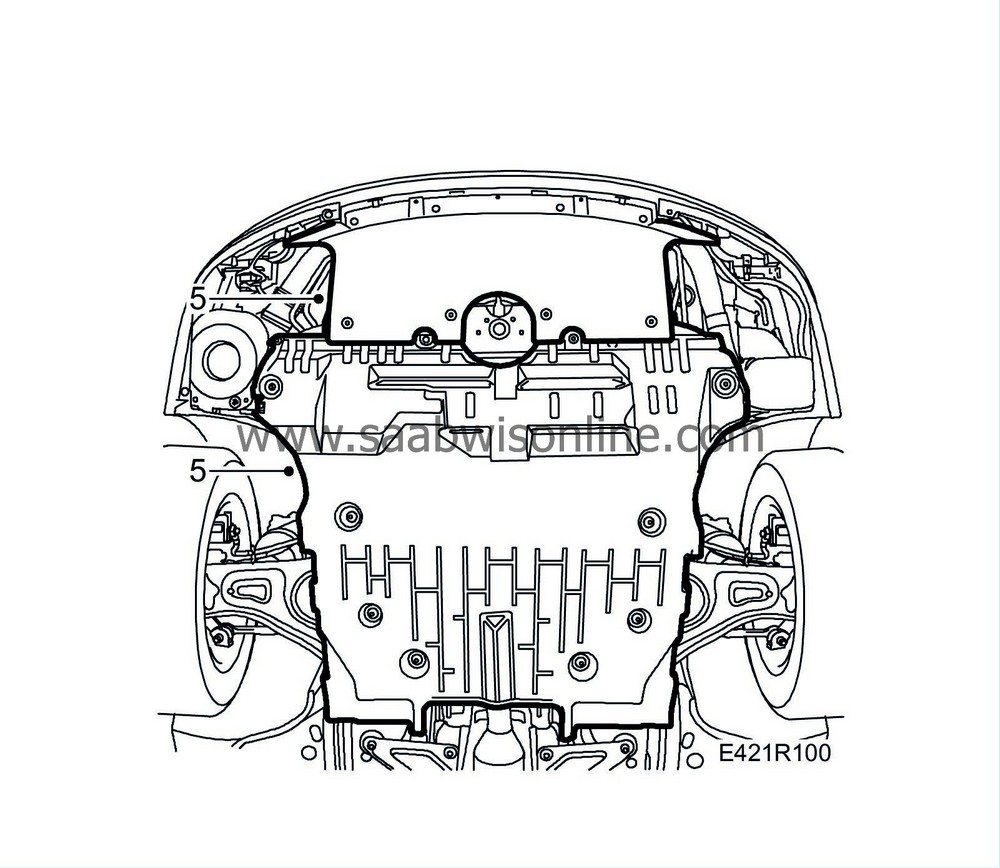

Raise the car and remove the lower engine cover.

|

|

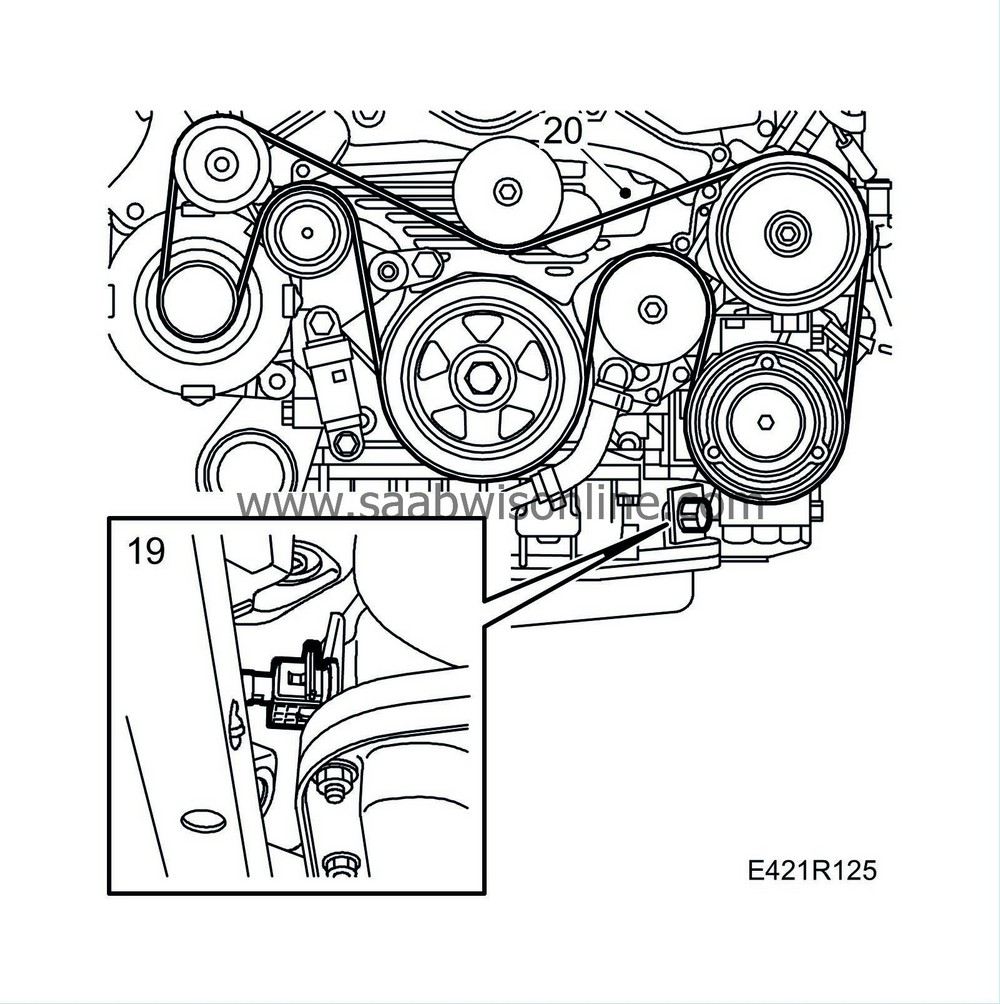

| 6. |

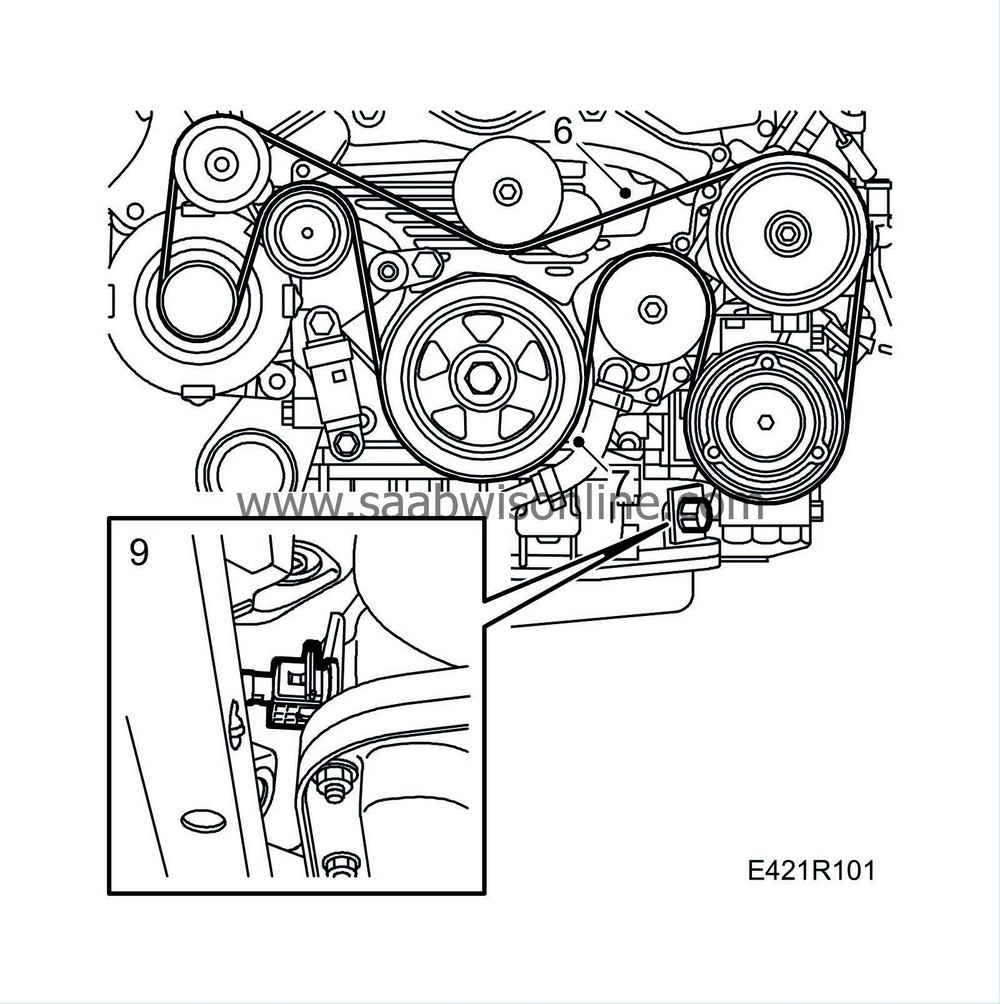

Unload and remove the multigroove V-belt.

|

|

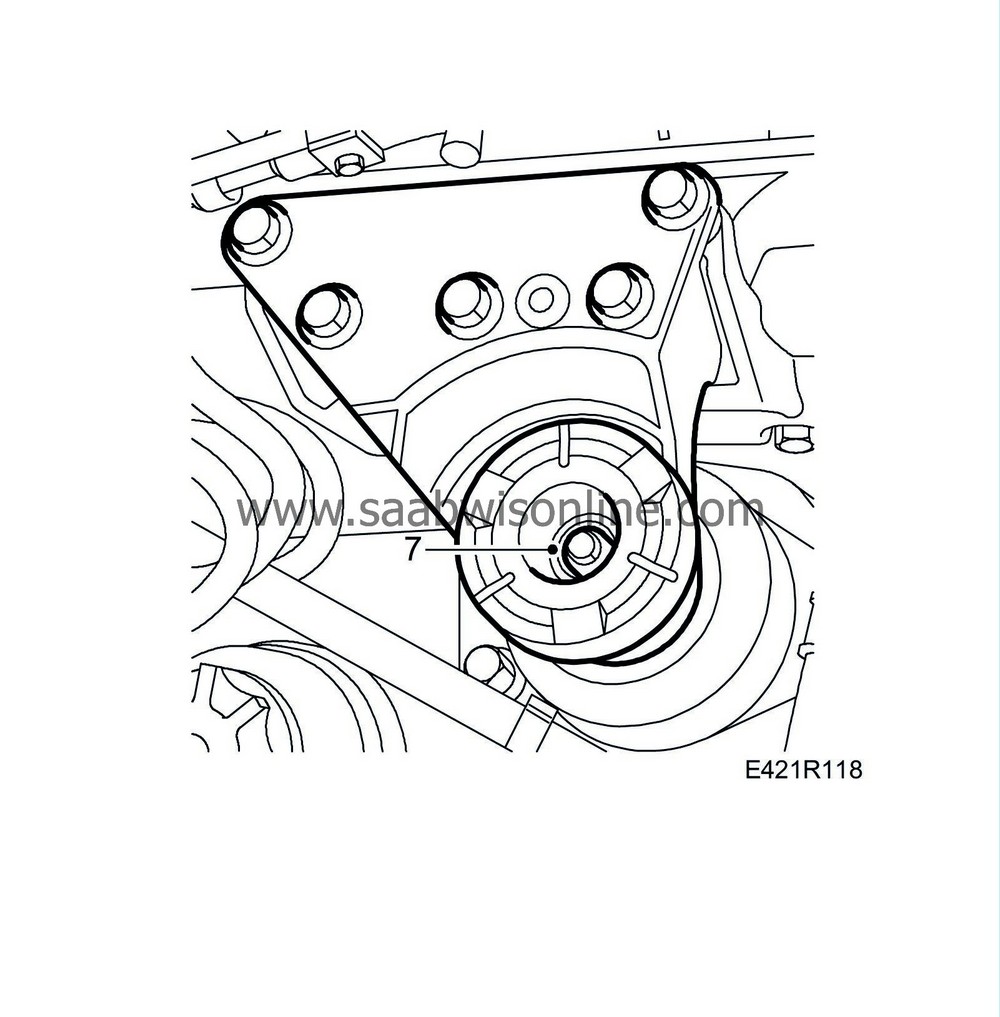

| 7. |

Detach the connector for the crankshaft position sensor.

|

|

| 8. |

Loosen the oil plug and drain the oil from the engine.

|

|

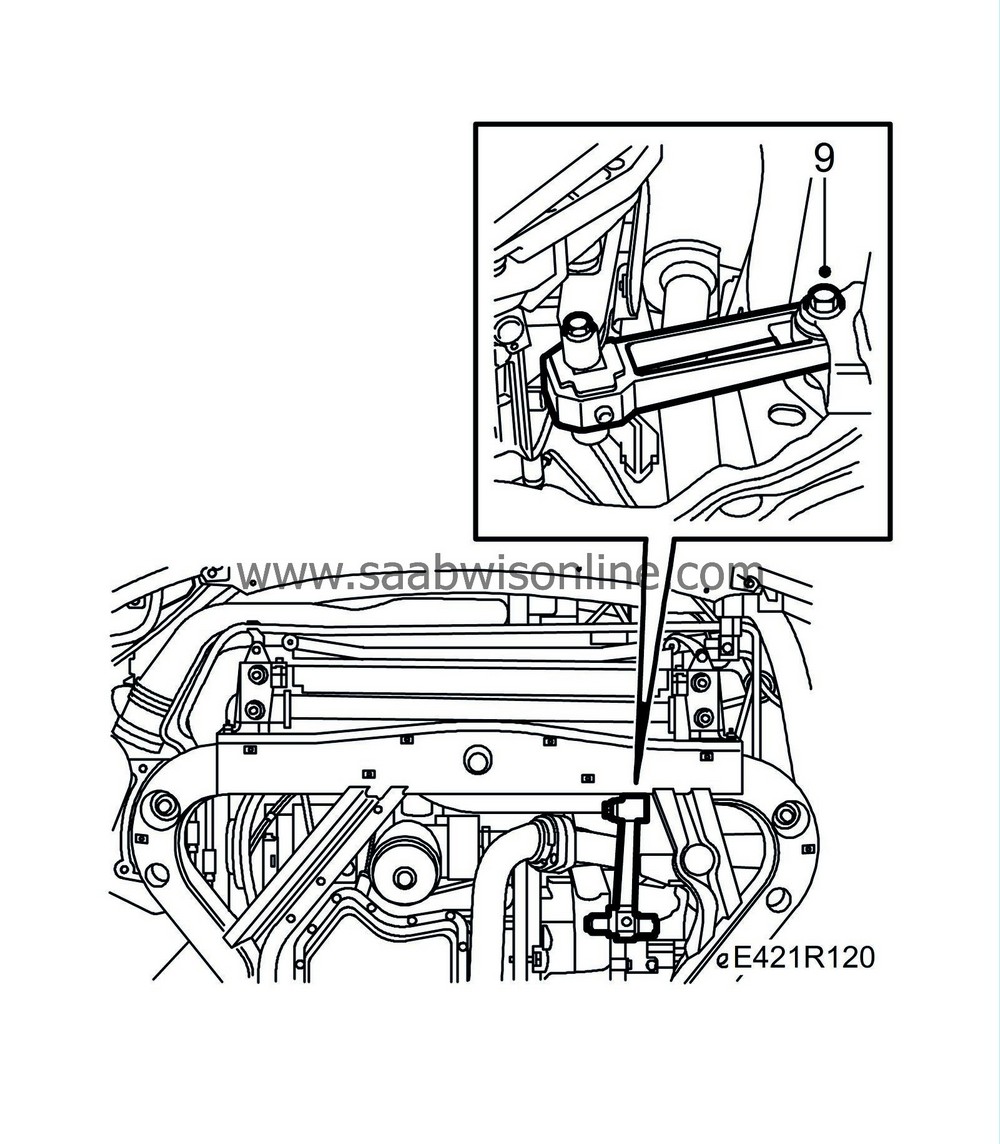

| 9. |

Detach the connector to the oil level sensor.

|

|

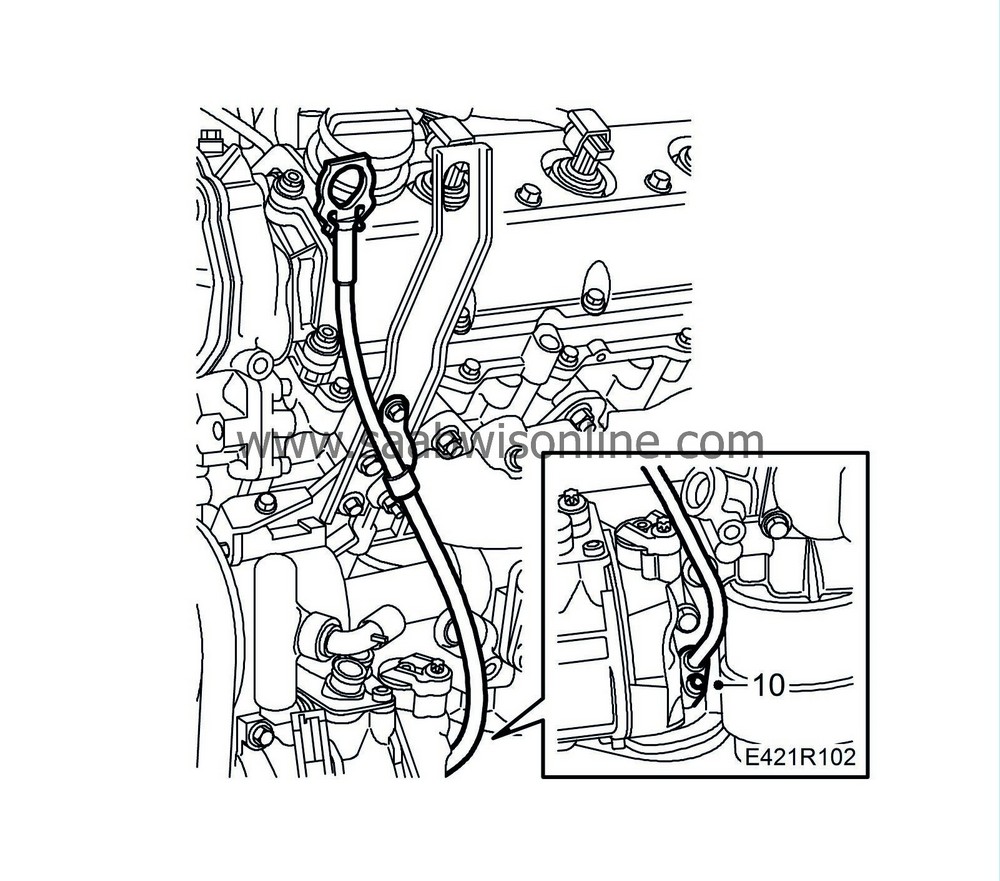

| 10. |

Remove the dipstick tube.

|

|

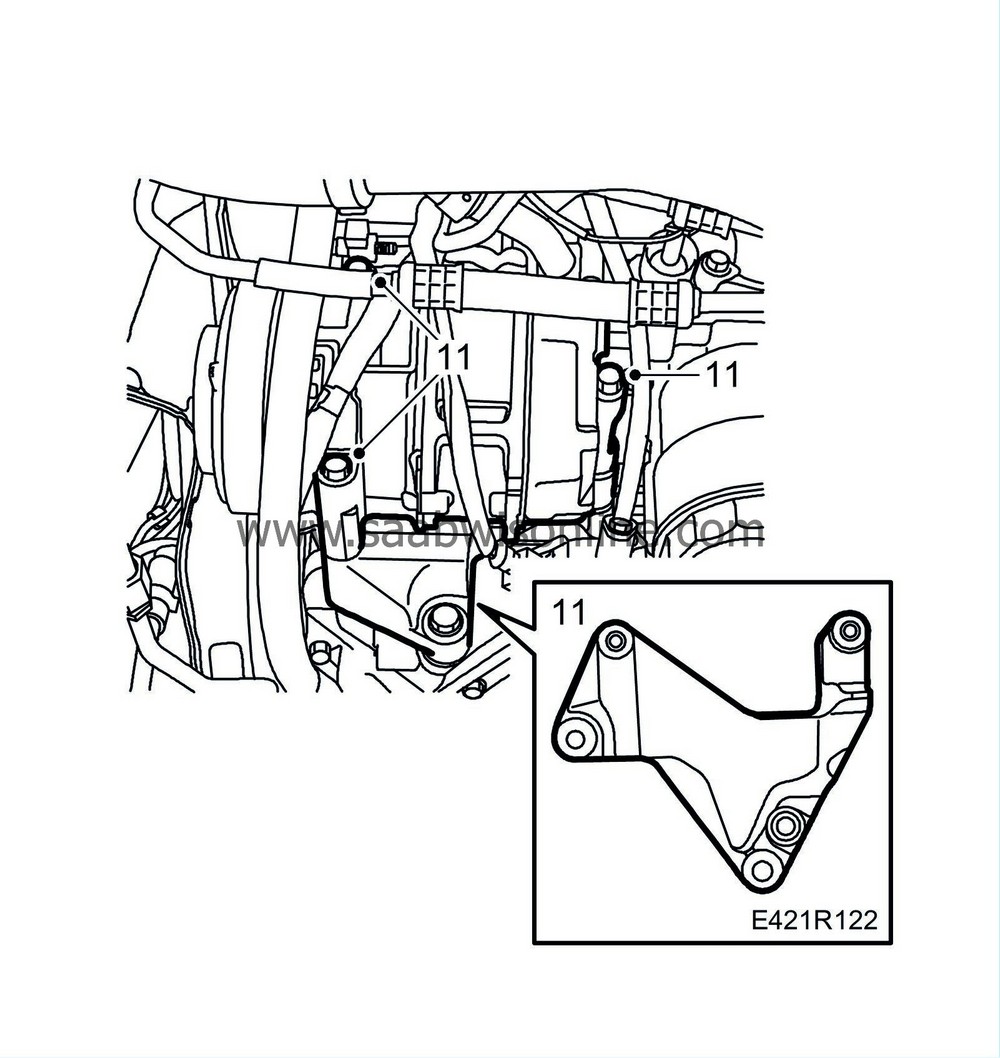

| 11. |

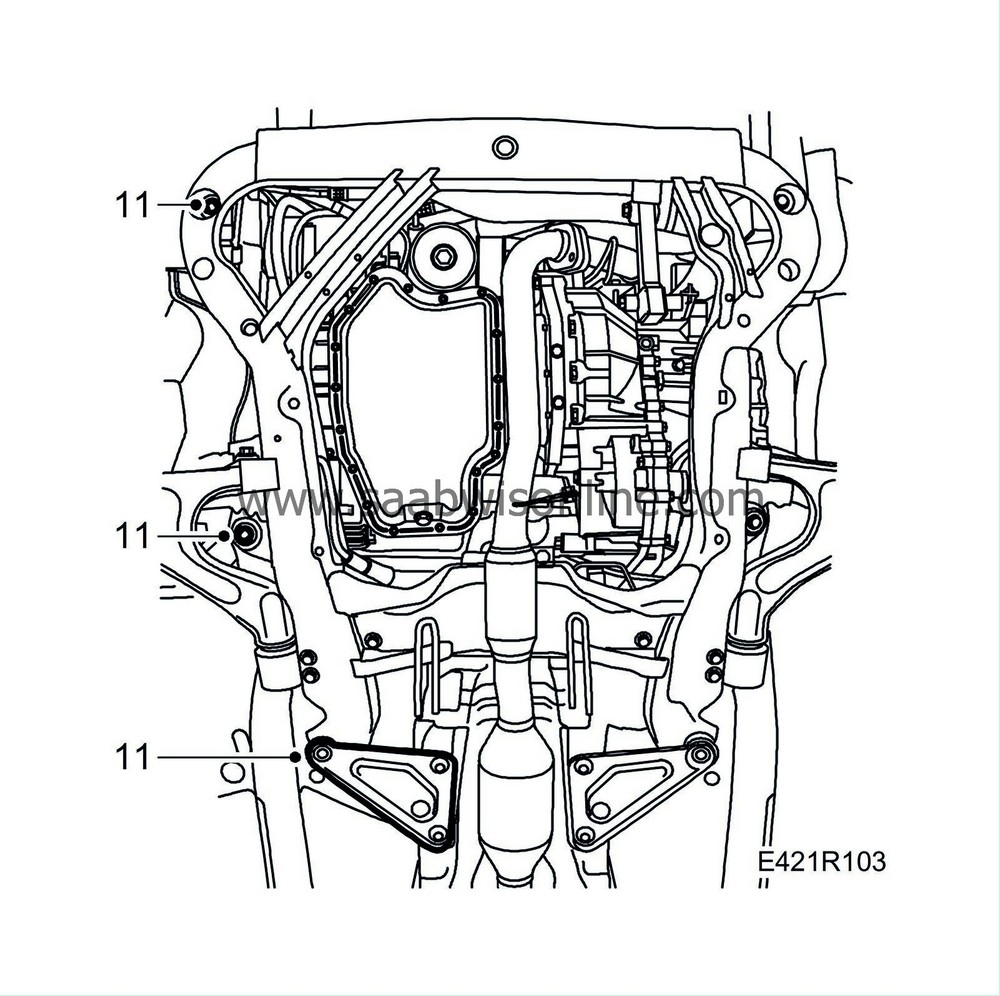

Loosen the subframe bolts on the RH side and the RH triangle plate.

|

|

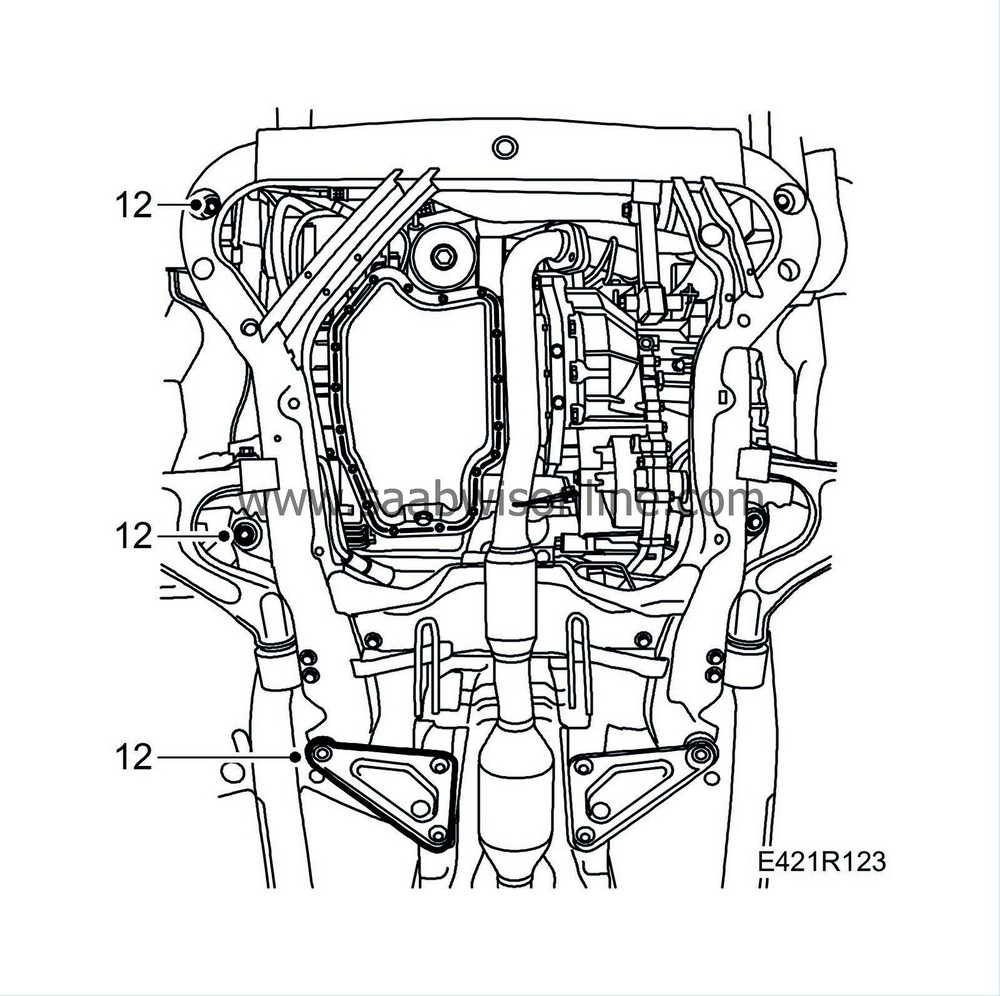

| 12. |

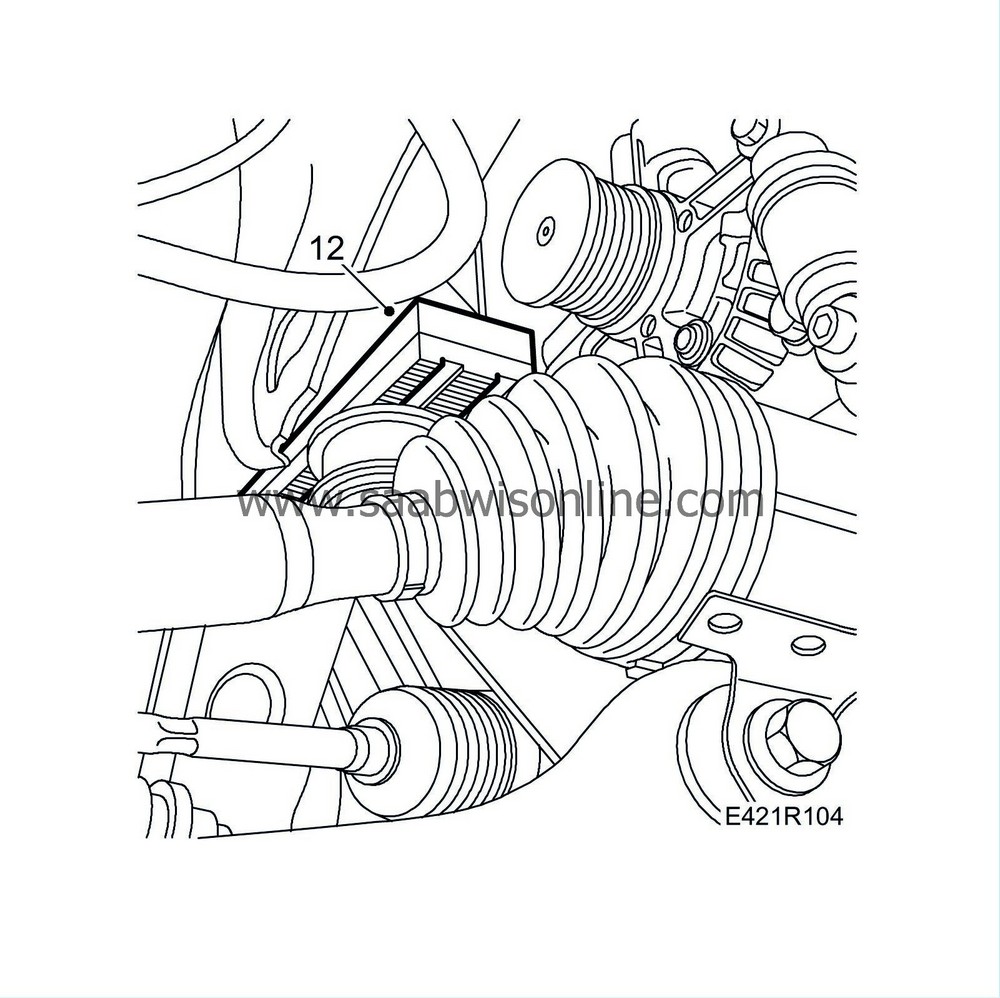

Insert

83 95 238 Wedge

between the subframe's centre mounting and the body.

|

|

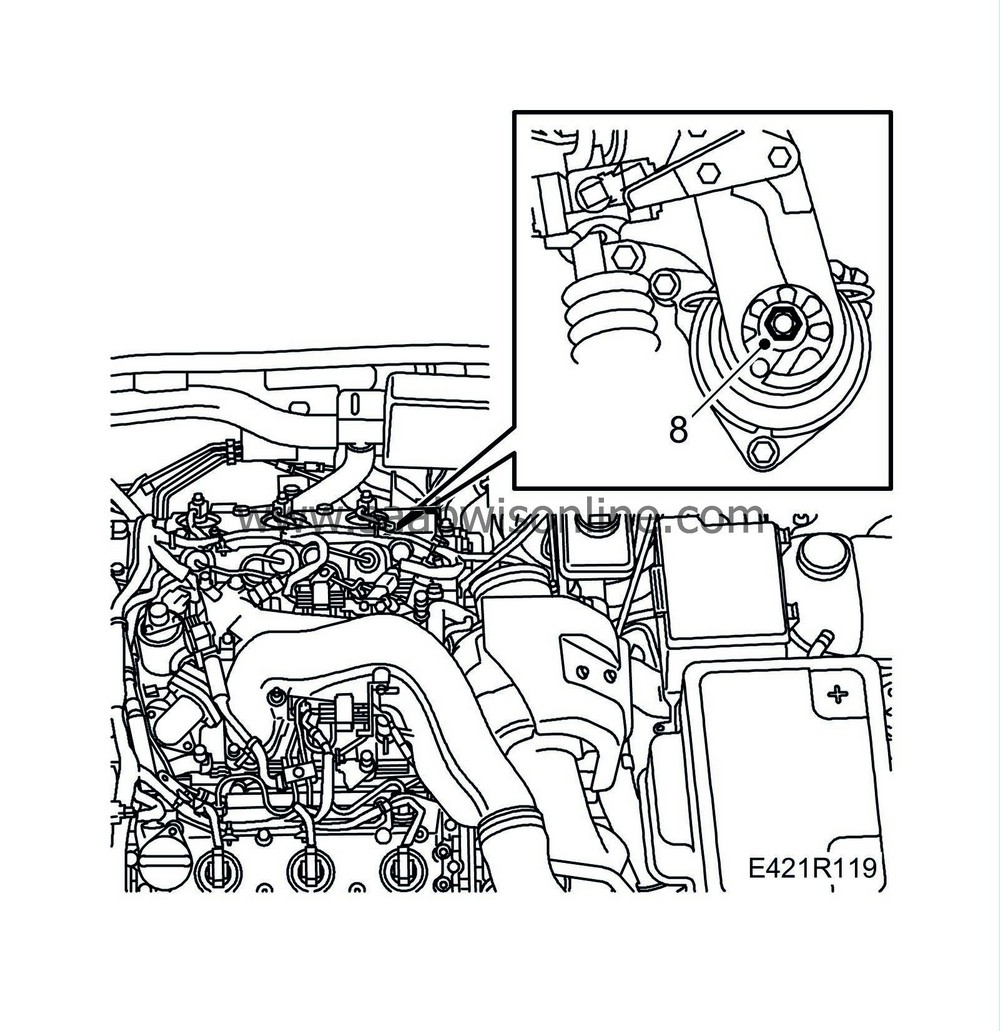

| 13. |

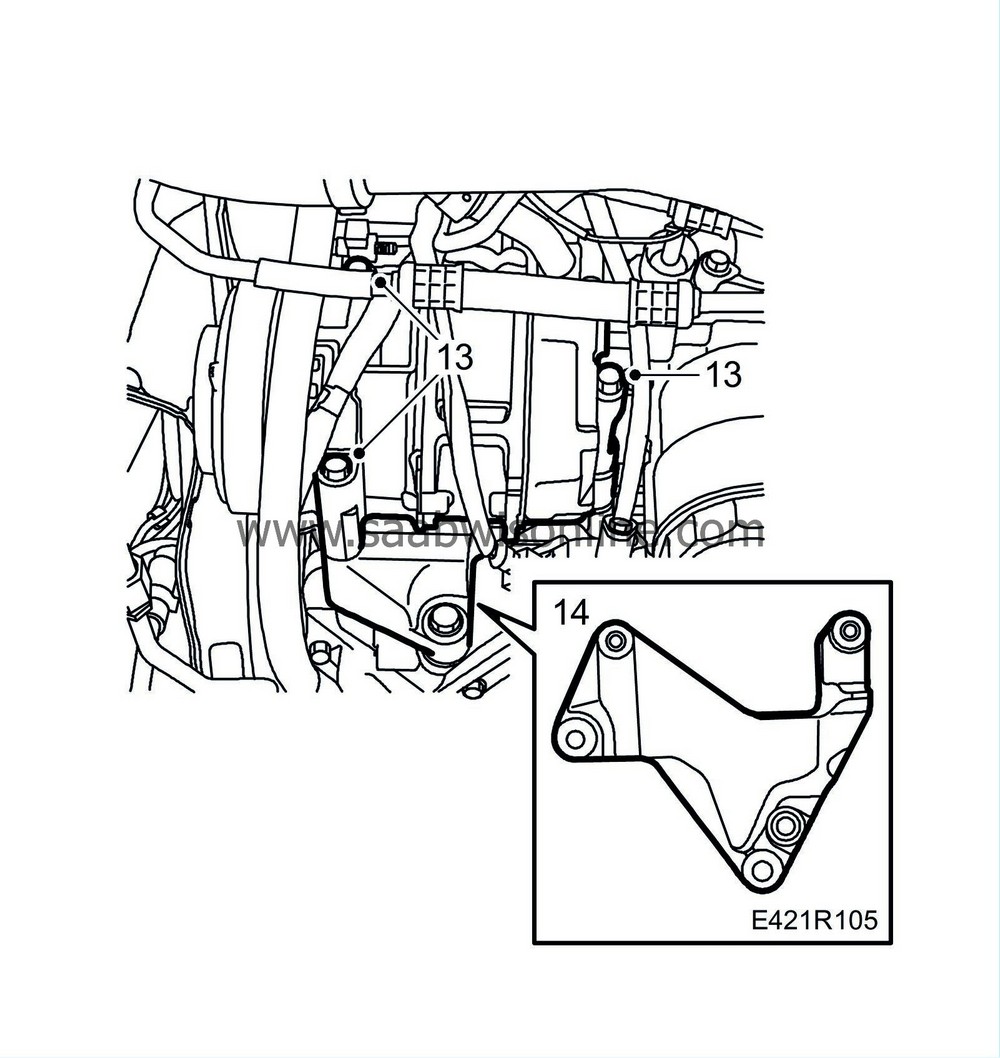

Loosen and hang aside the A/C compressor.

|

|

| 14. |

Remove the A/C compressor bracket.

|

|

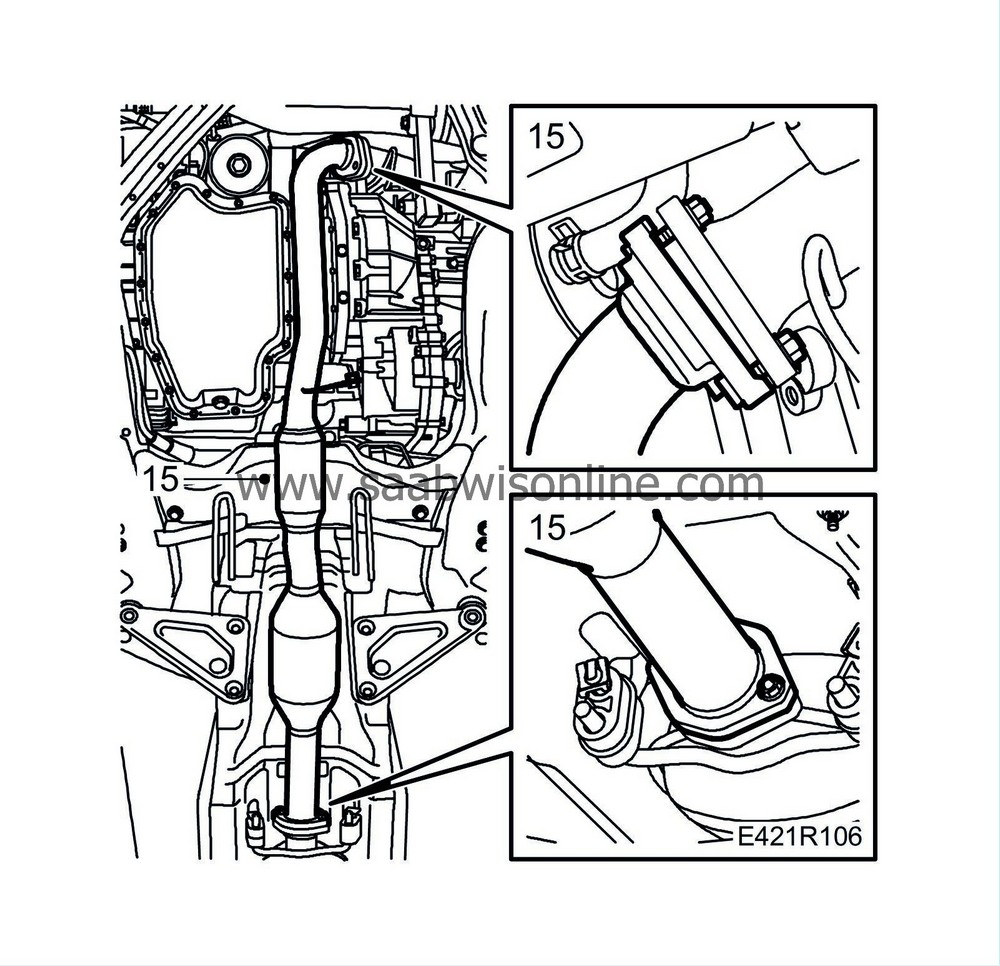

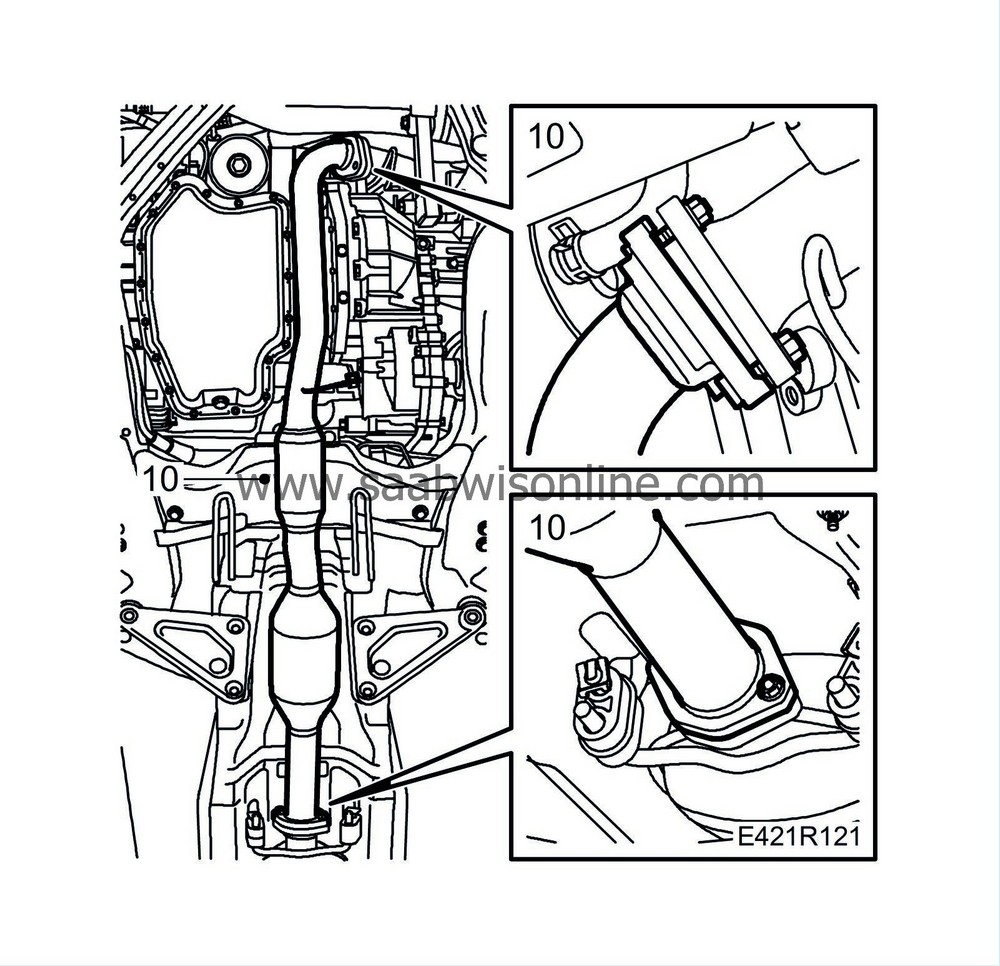

| 15. |

Remove the front exhaust pipe.

|

|

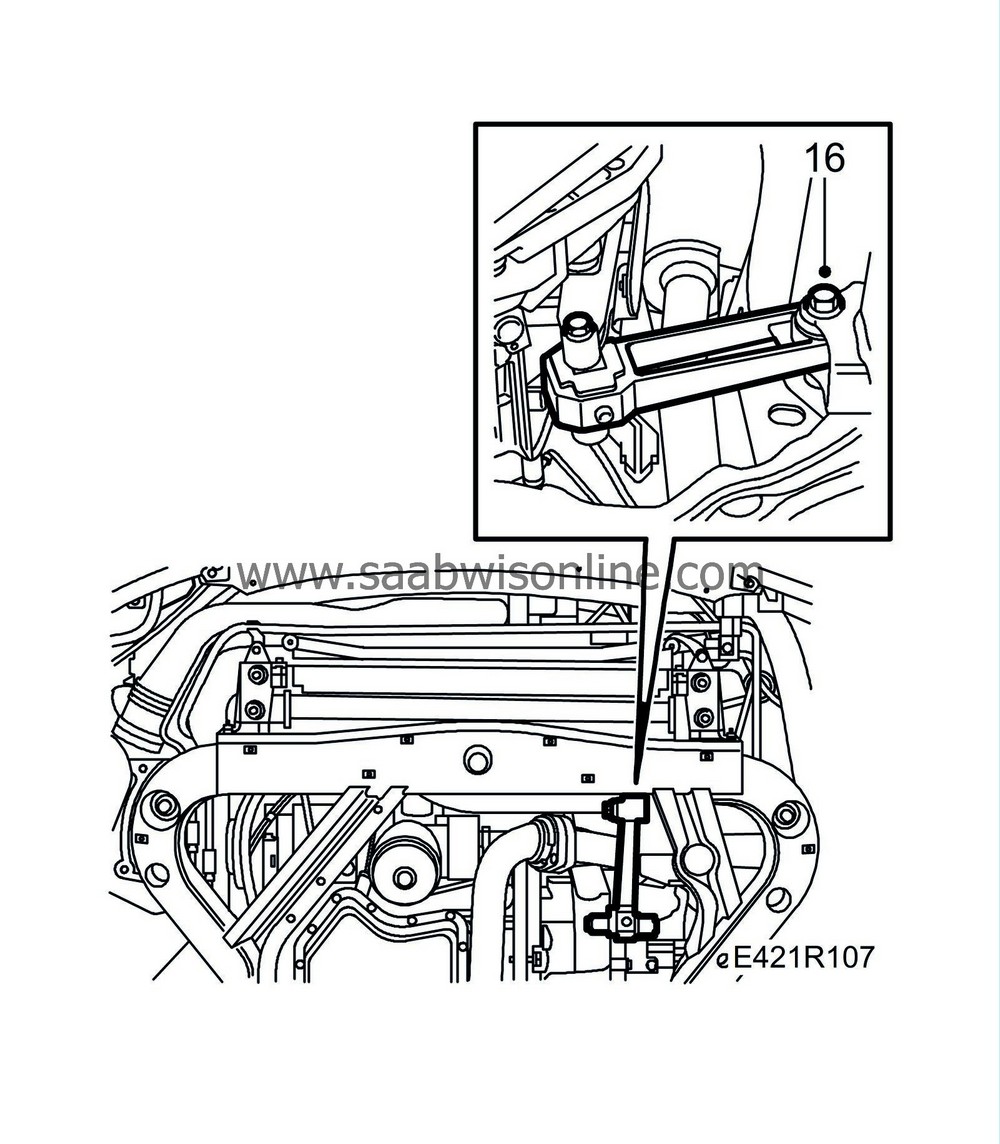

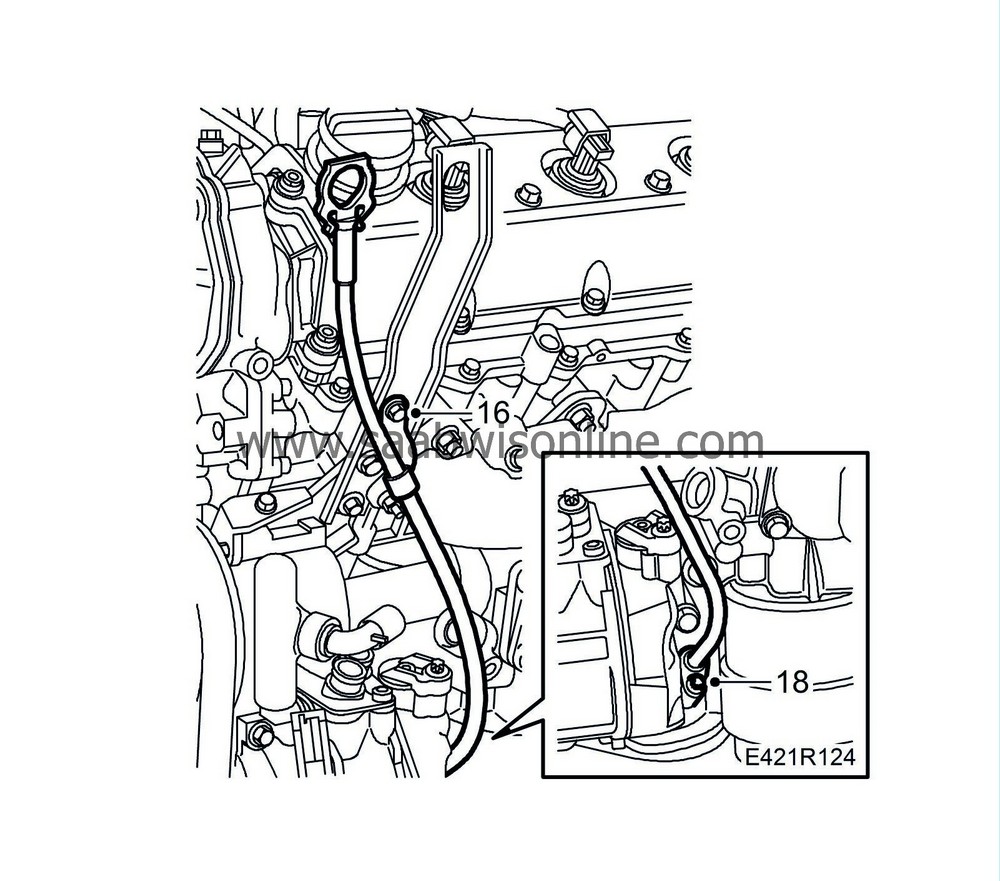

| 16. |

Remove the front bolt on the front torque arm.

|

|

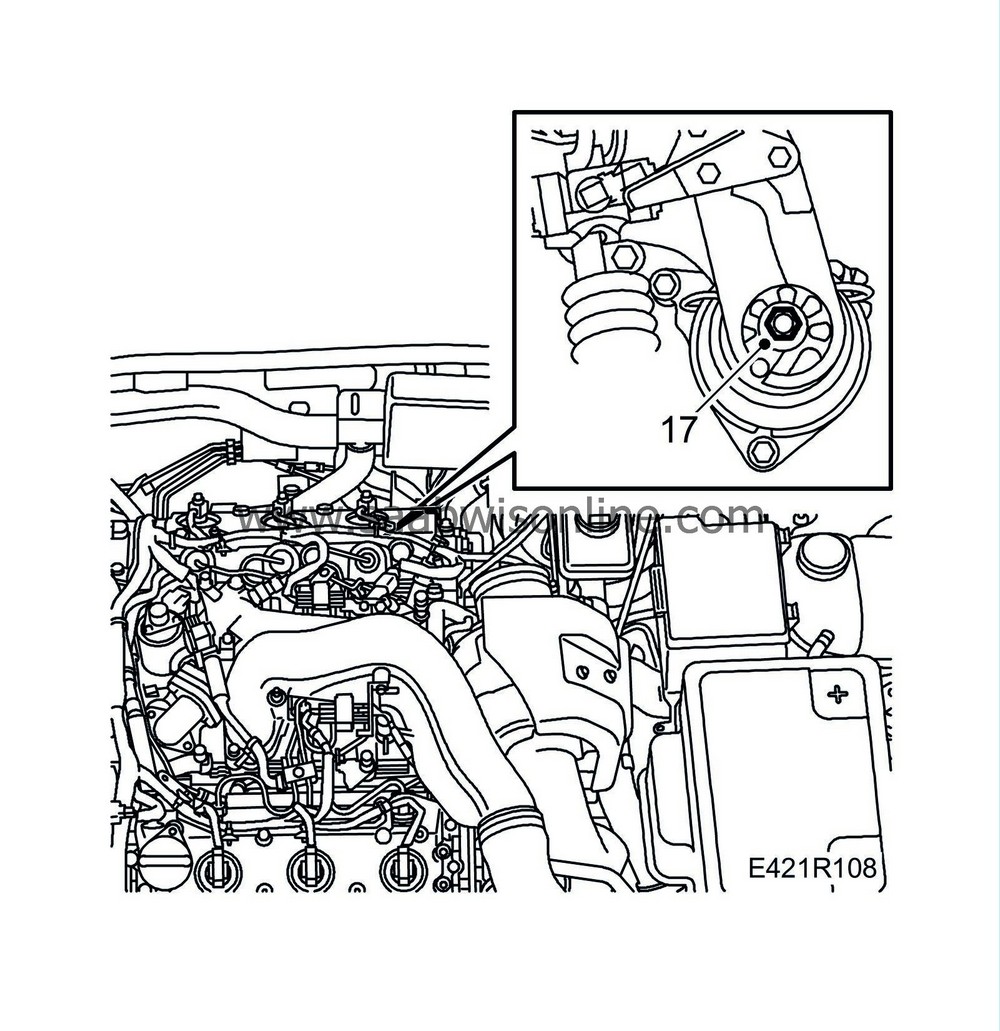

| 17. |

Lower the car and remove the nut of the rear engine pad.

|

|

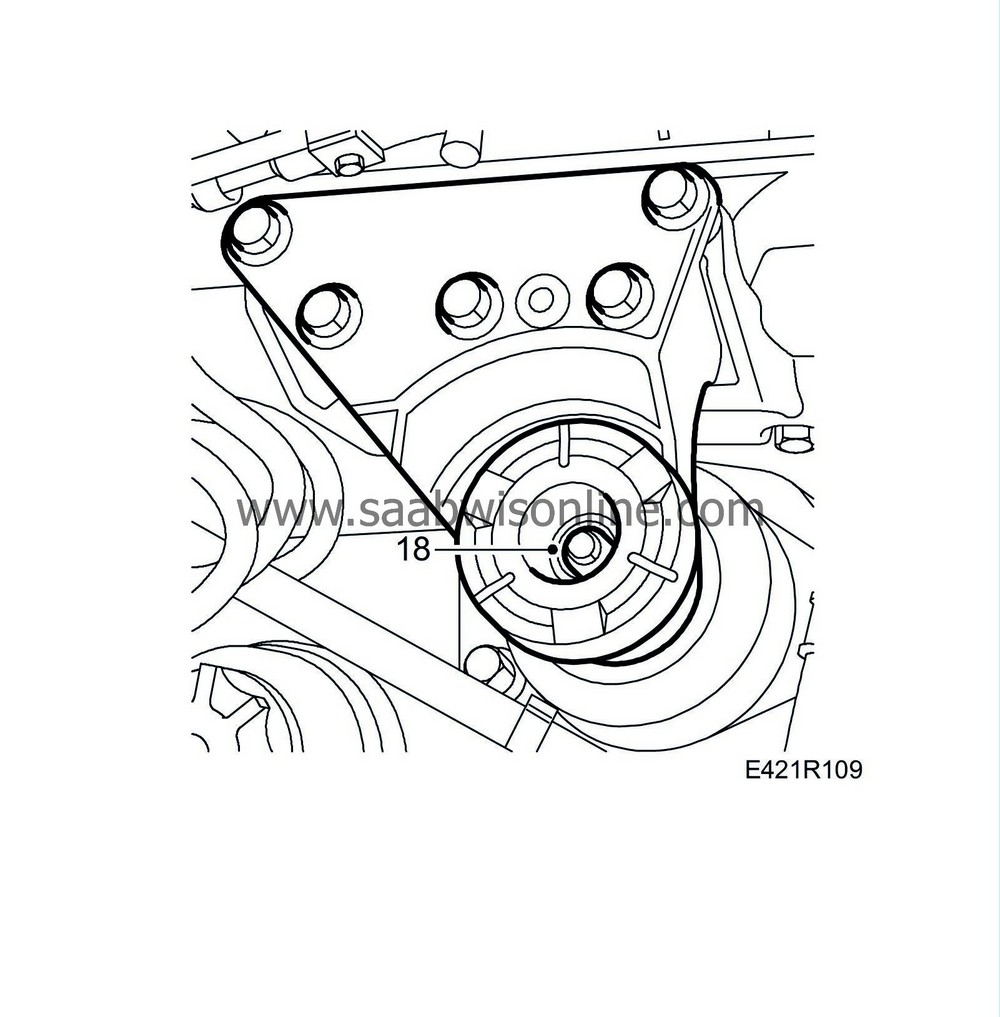

| 18. |

Remove the RH engine pad nut.

|

|

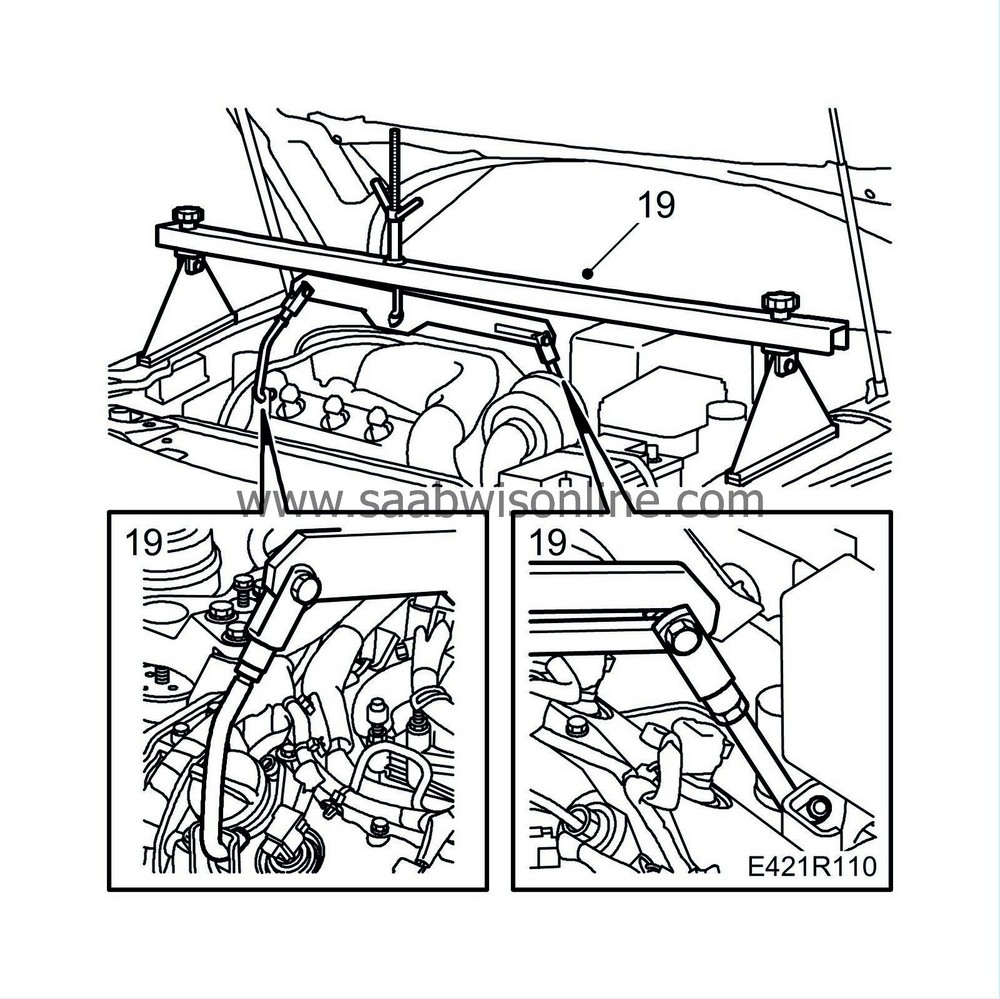

| 19. |

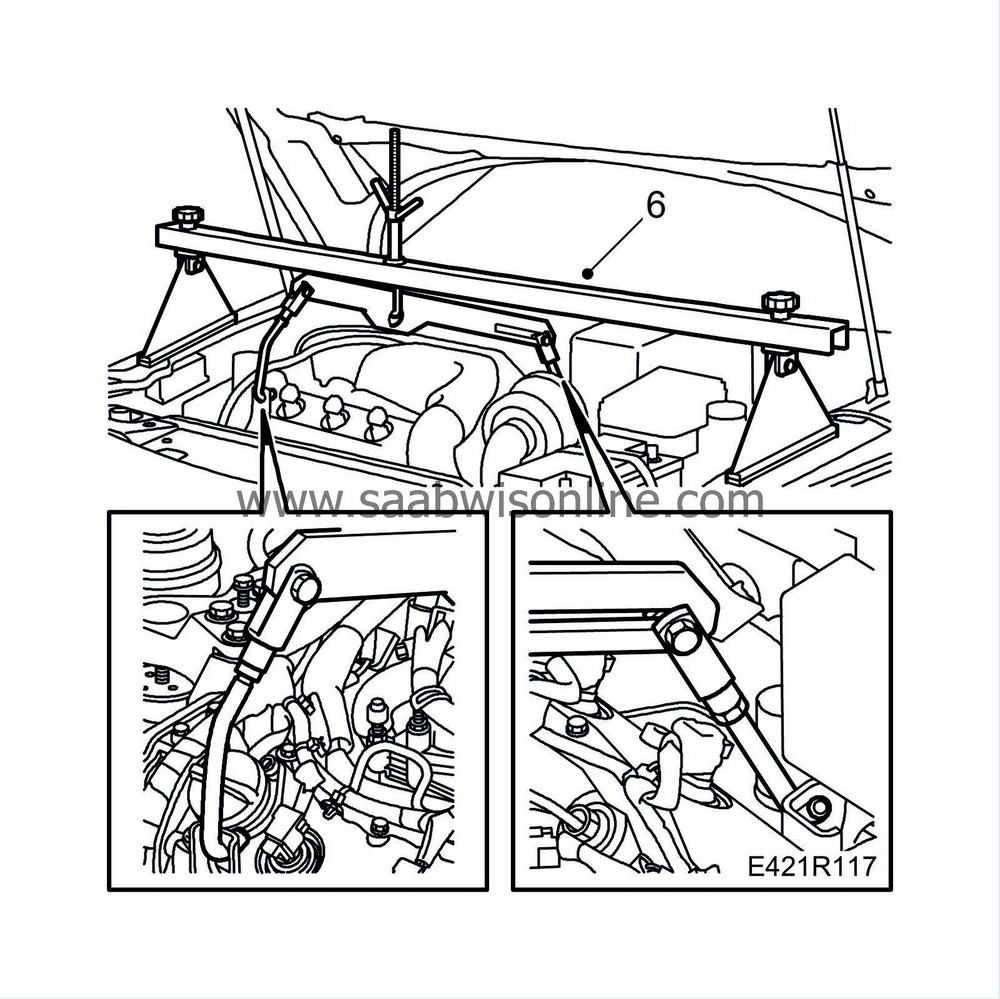

Fit

83 94 850 Lifting beam

and

Holder

83 95 287.

|

|

| 20. |

Raise the engine with the lifting beam.

|

|

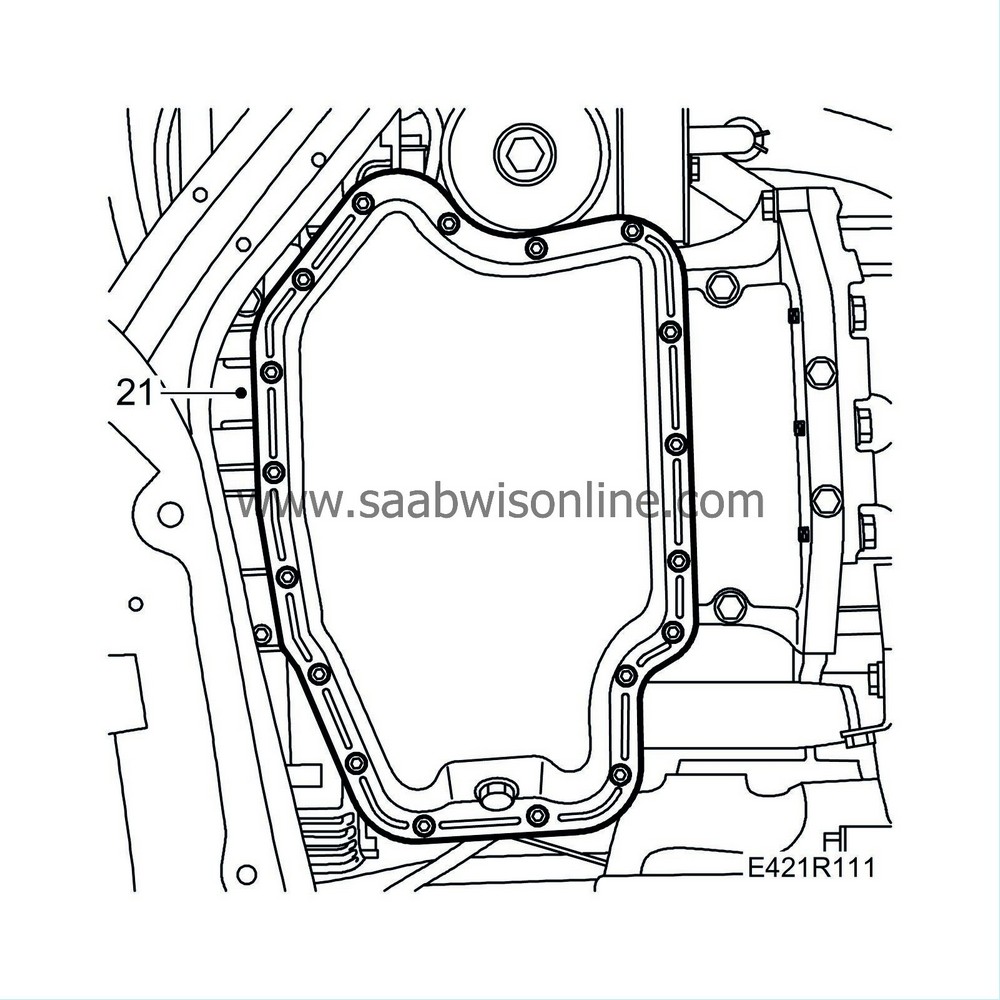

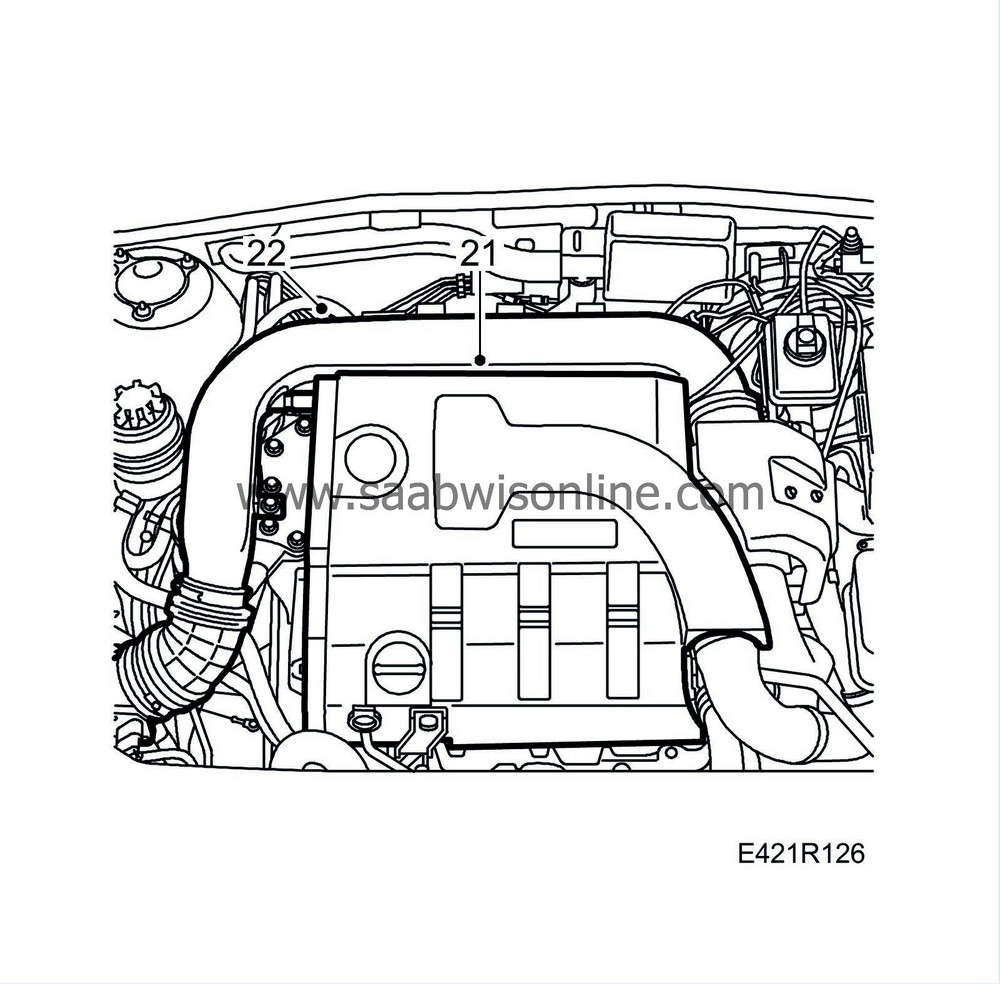

| 21. |

Raise the car and remove the sheet metal oil sump.

|

|

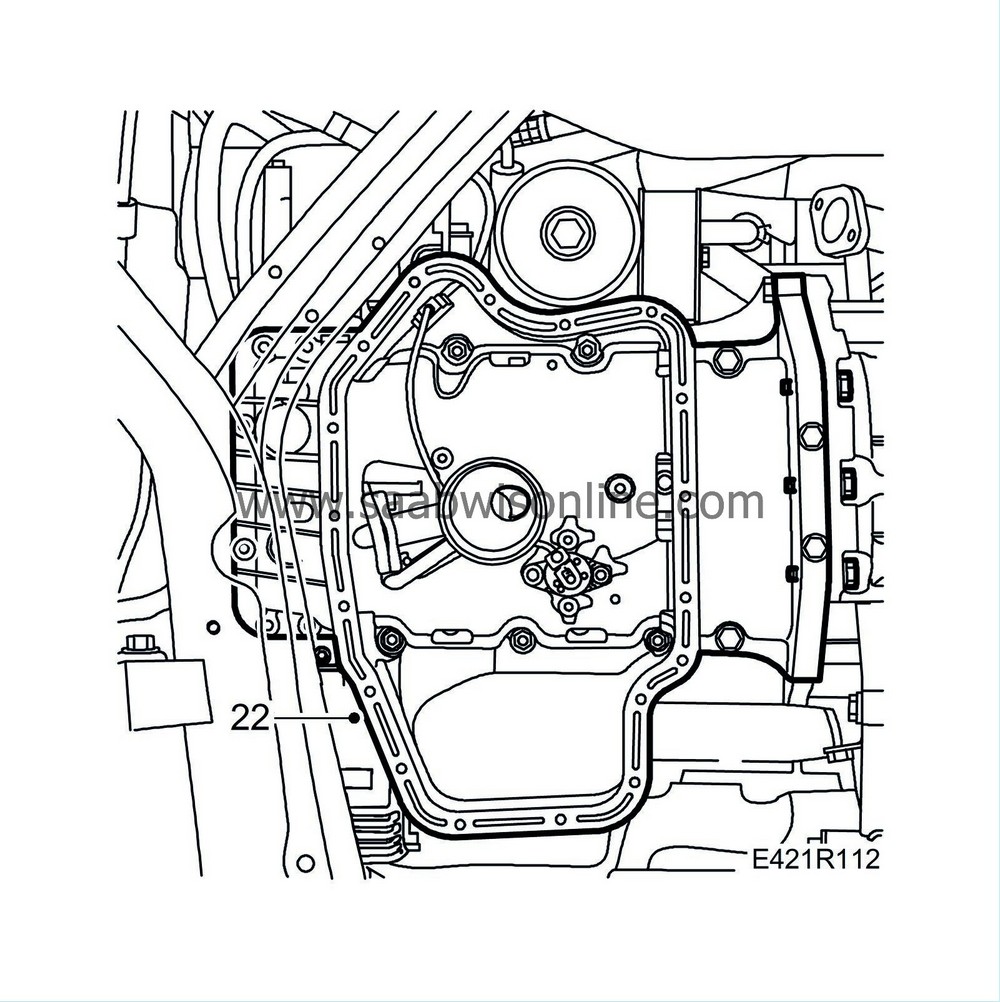

| 22. |

Remove the aluminium sump.

|

|

| 23. |

Clean the seal faces of the cylinder block and oil sump.

|

|

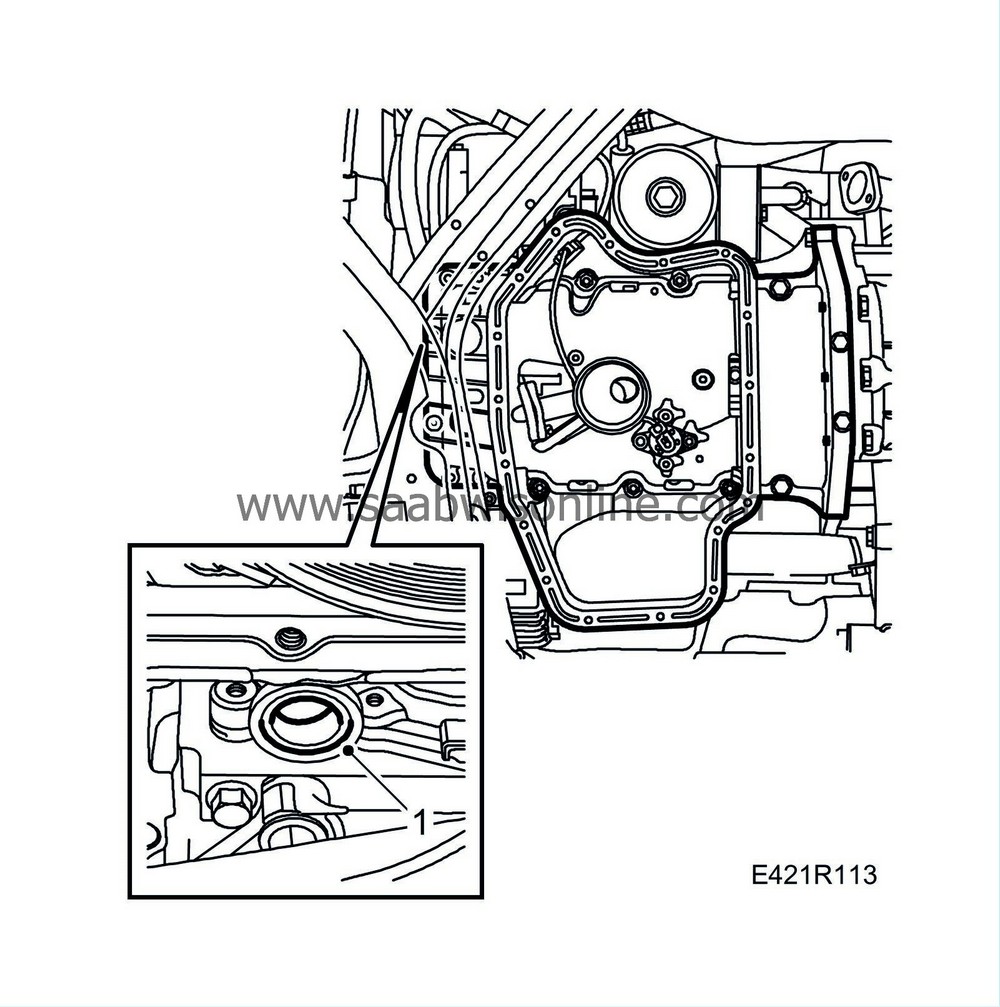

| To fit |

| 1. |

Fit new O-ring on the oil suction pipe.

|

|

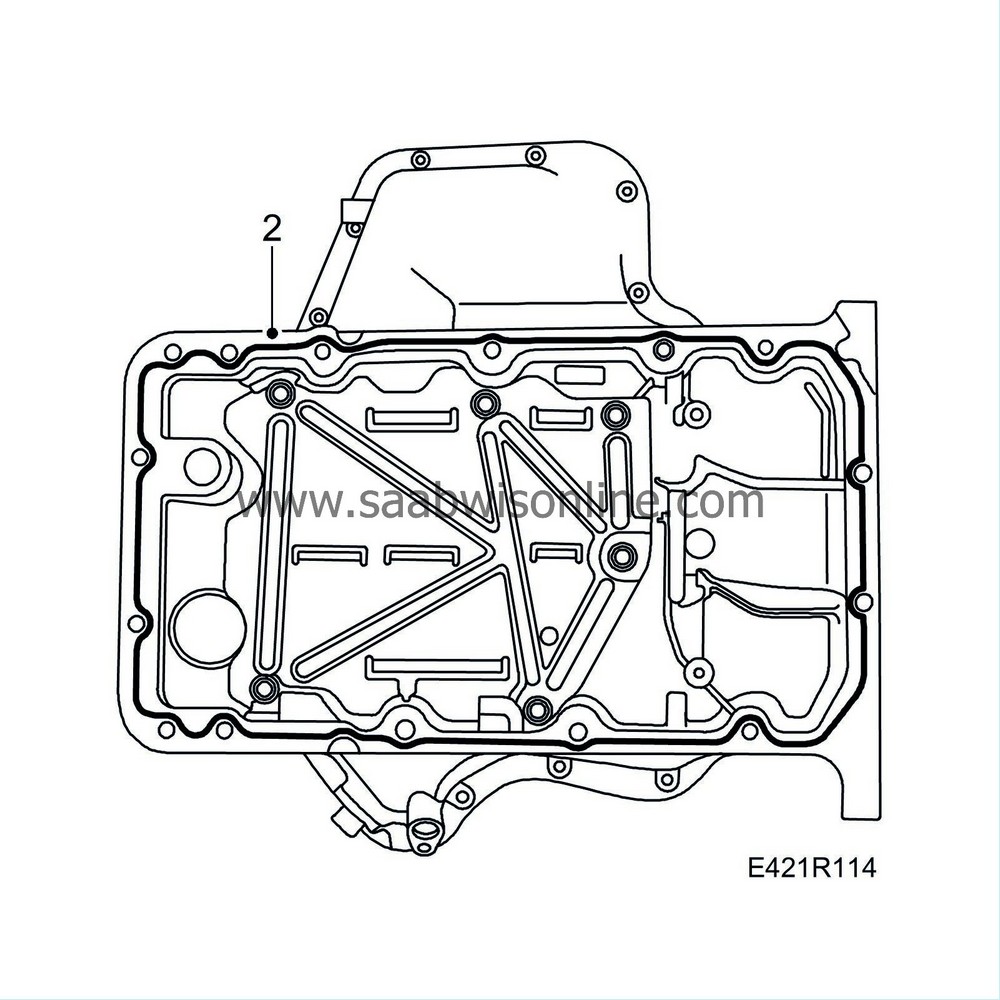

| 2. |

Fit the aluminium oil sump. Apply a 2 mm bead of flange sealant 87 81 841 on the seal face.

|

|

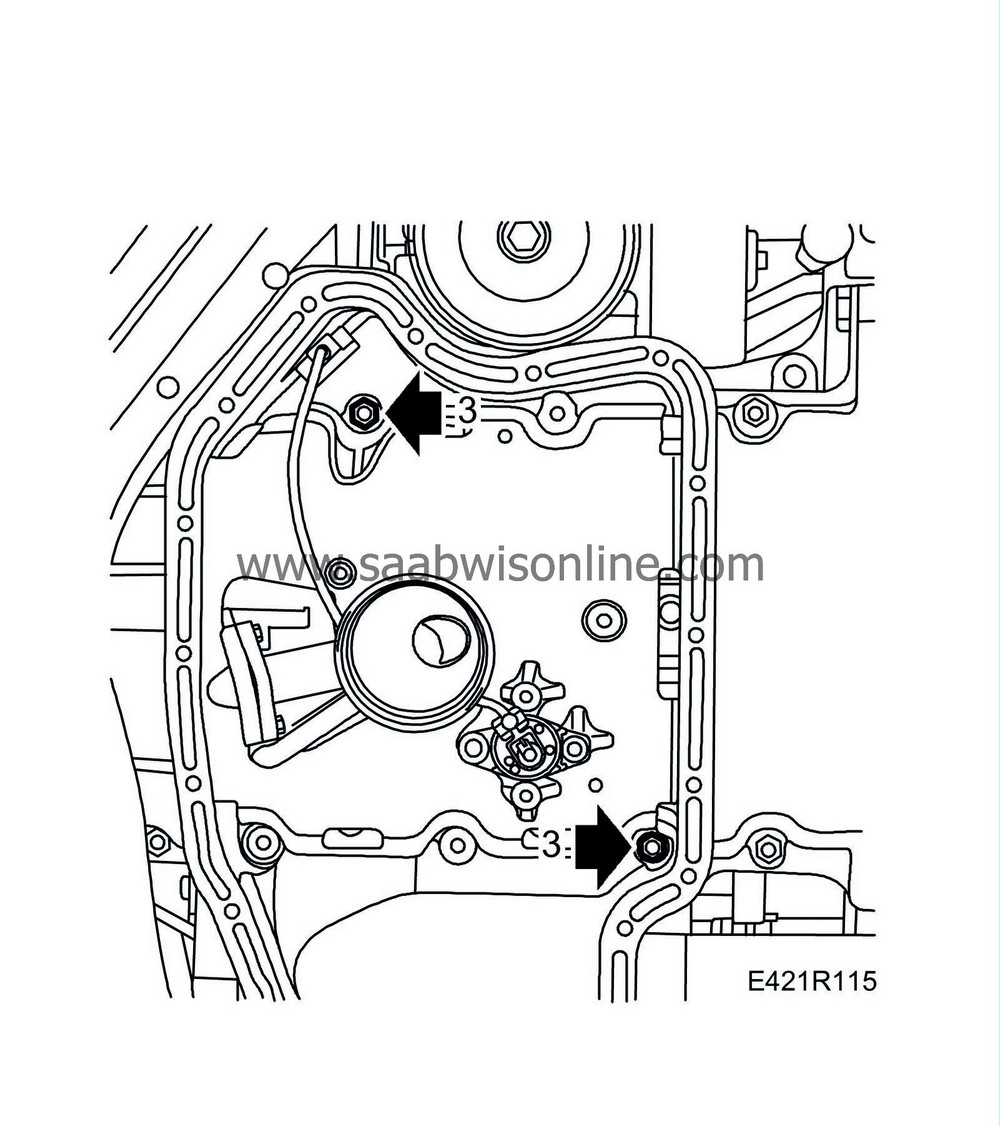

| 3. |

Fit all bolts and nuts. Tighten the two nuts first. See illustration. Tighten the remaining bolts and nuts.

Tightening torque: 25 Nm (18 lbf ft)

|

|

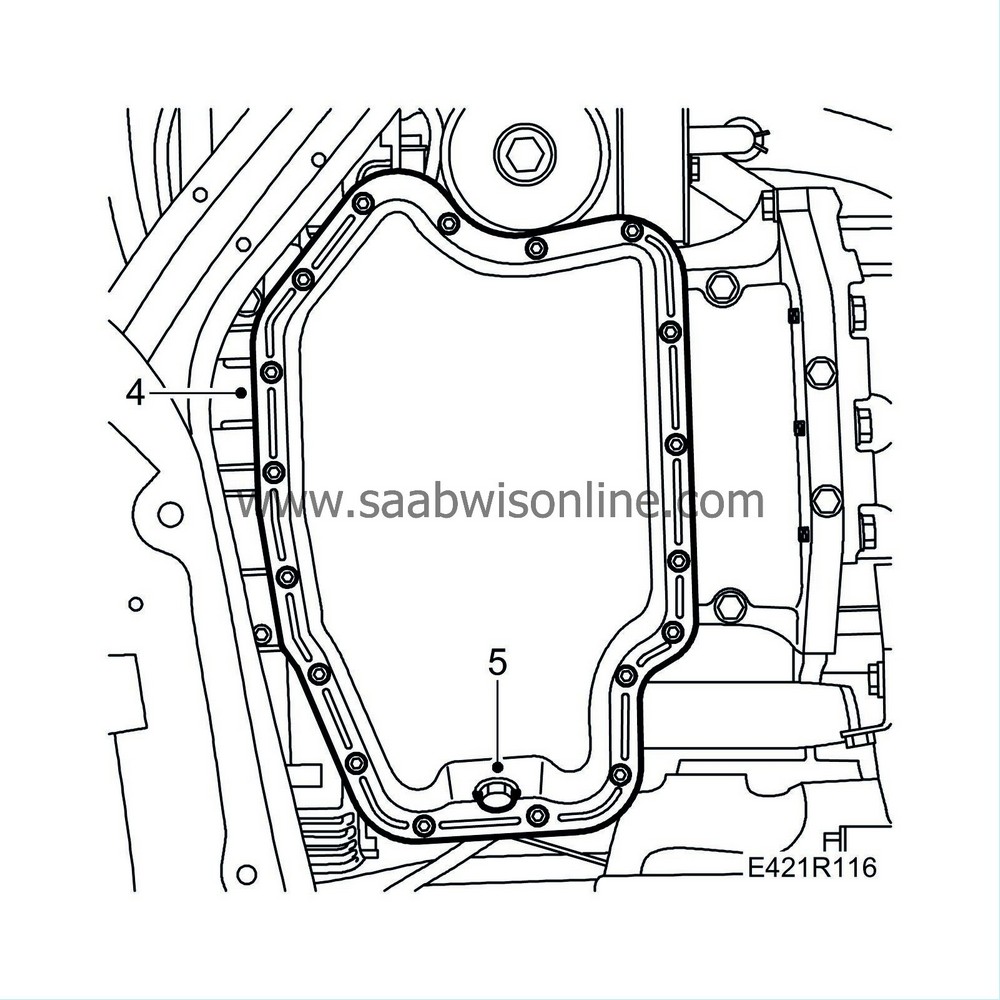

| 4. |

Fit the sheet metal oil sump. Apply a 2 mm thick bead of flange sealant 87 81 841 on the seal face.

Tightening torque: 25 Nm (18 lbf ft)

|

|

| 5. |

Fit the oil plug with a new gasket.

|

|

| 6. |

Lower the car. Lower the engine and remove the lifting beam with shackle.

|

|

| 7. |

Fit and tighten the nut of the RH engine pad.

Tightening torque: 47 Nm (35 lbf ft)

|

|

| 8. |

Fit and tighten the nut of the rear engine pad.

Tightening torque: 47 Nm (35 lbf ft)

|

|

| 9. |

Raise the car. Fit and tighten the bolt of the front torque arm.

|

|

| 10. |

Fit the front exhaust pipe.

Tightening torque, toward turbo 25 Nm (18 lbf ft) Tightening torque, toward rear exhaust pipe 40 Nm (30 lbf ft)

|

|

| 11. |

Fit the A/C compressor with bracket.

|

|

| 12. |

Remove the key and fit the triangle plate and subframe bolts.

Tightening torque, triangle plate 63 Nm (46 lbf ft) Tightening torque, subframe 100 Nm + 45° (74 lbf ft + 45°)

|

|

| 13. |

Fit the dipstick tube at the sump with a new O-ring. Do not tighten.

|

|

| 14. |

Attach the connector to the oil level sensor.

|

|

| 15. |

If needed, replace the oil filter. See

Engine oil and oil filter

.

|

|

| 16. |

Lower the car and fit the dipstick tube on the front lifting eye.

|

|

| 17. |

Fix the wiring at the dipstick tube. Fit the dipstick.

|

|

| 18. |

Raise the car and tighten the lower bolt of the dipstick tube.

|

|

| 19. |

Attach the connector to the crankshaft position sensor.

|

|

| 20. |

Fit the belt to the auxiliary unit and fit the lower engine cover.

|

|

| 21. |

Lower the car and fit the upper engine cover.

|

|

| 22. |

Fit the intake manifold with mass air flow sensor to the turbo.

Tightening torque, mass air flow sensor: 3.5 Nm (2.5 lbf ft) |

|

| 23. |

Top up with engine oil. See

Lubrication diagram, lubricant

|

|