To assemble, engine block

|

|

To assemble, engine block

|

|

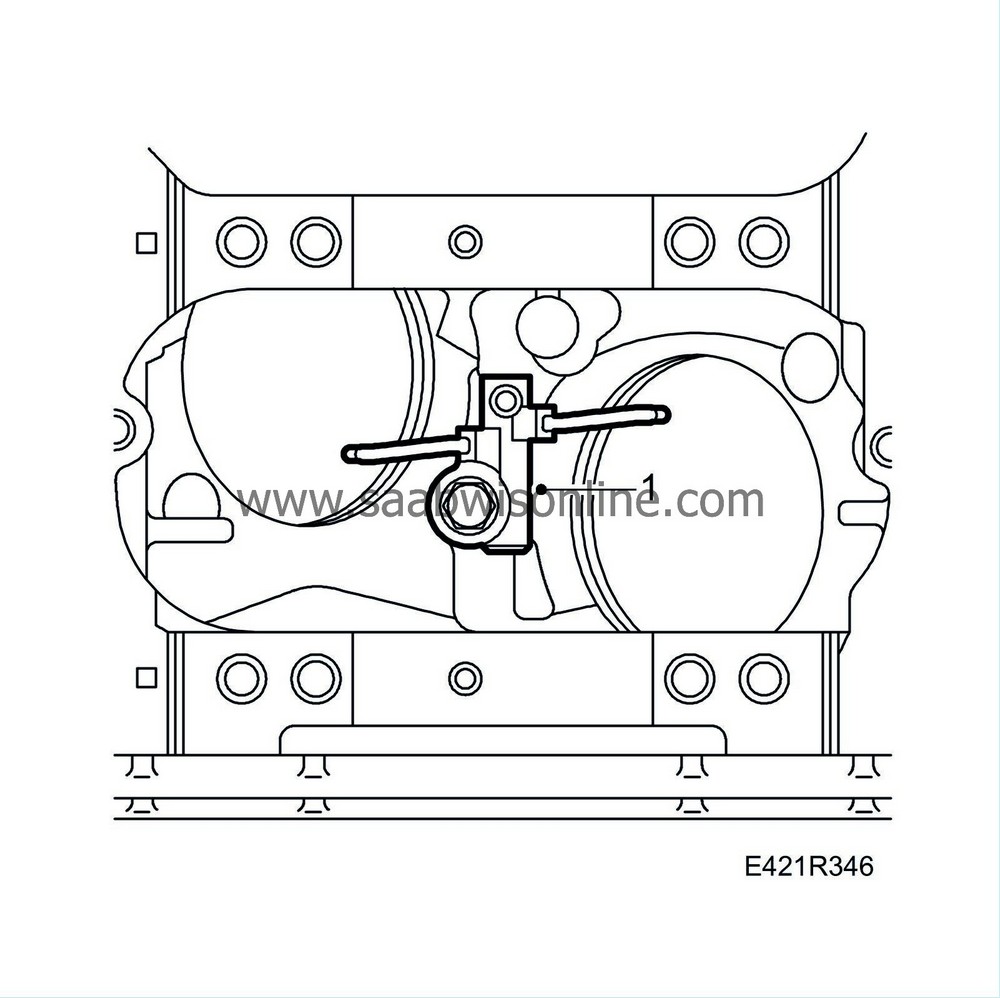

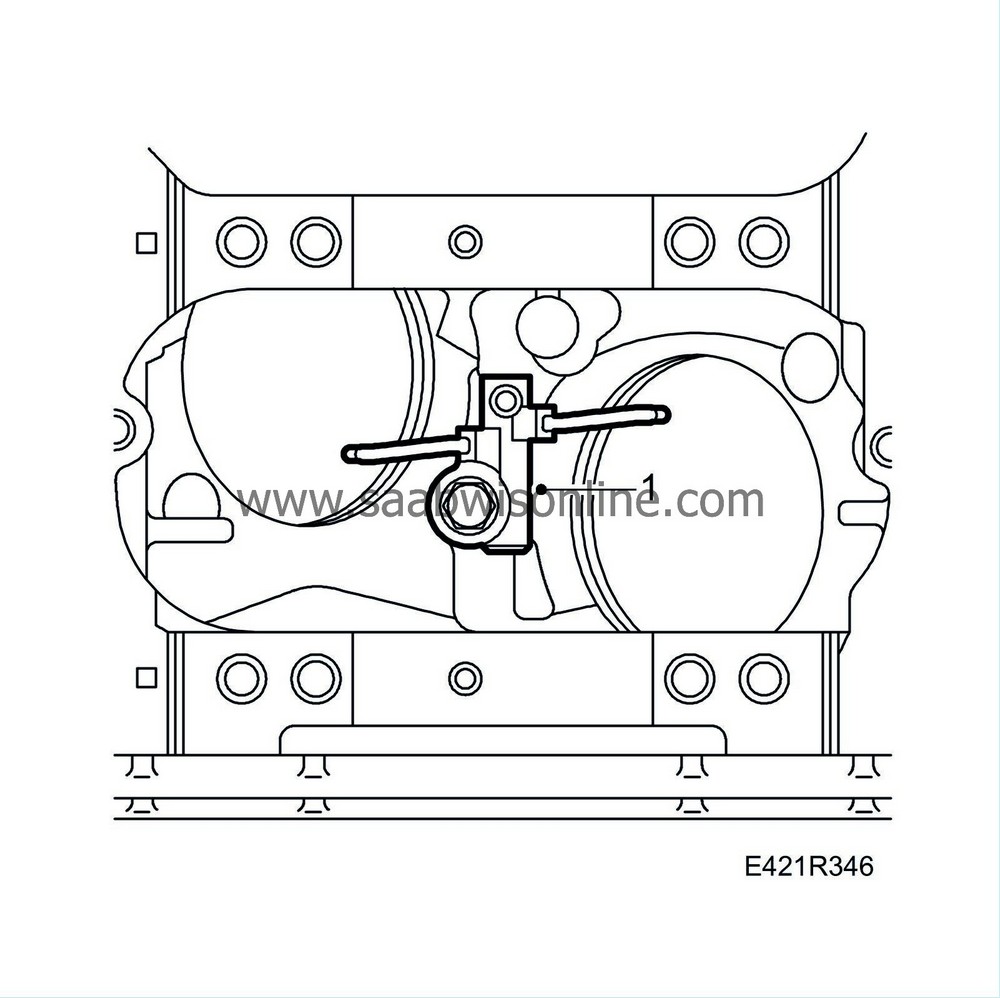

1.

|

Fit the oil cooling nozzles with new seals.

|

|

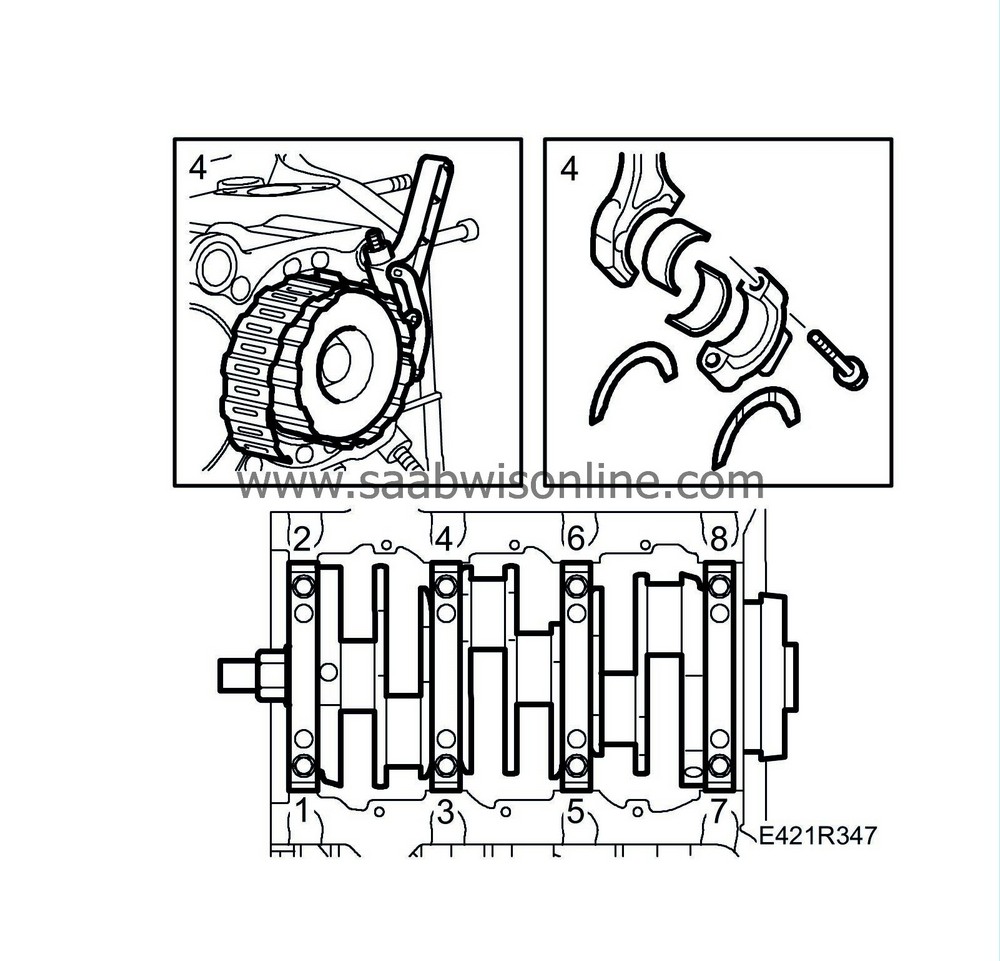

2.

|

Insert the thrust bearing with grooves outward and lubricate all bearing shells with engine oil. Fit the crankshaft.

|

|

3.

|

Fit the main bearing caps. Tighten the bottom bolts.

Tightening torque: 39 Nm (29 lbf ft)

|

|

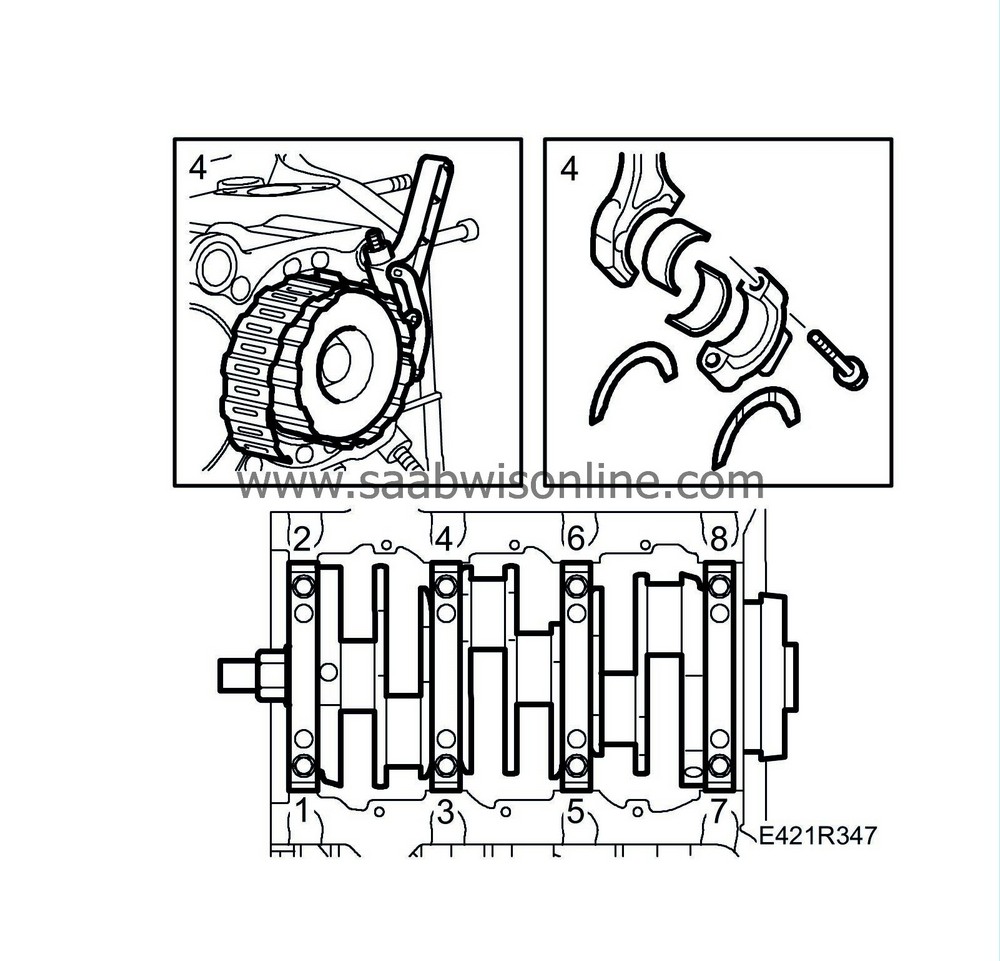

4.

|

Fit the pistons with connecting rods and big-end bearing caps. Note the direction of the arrow and other markings so as to fit the pistons correctly. Set the piston rings at 120 deg. intervals.

Tightening torque, step 1, 22 Nm (16 lbf ft)

Tightening torque step 2, 60°

Tightening torque step 3, 60°

|

|

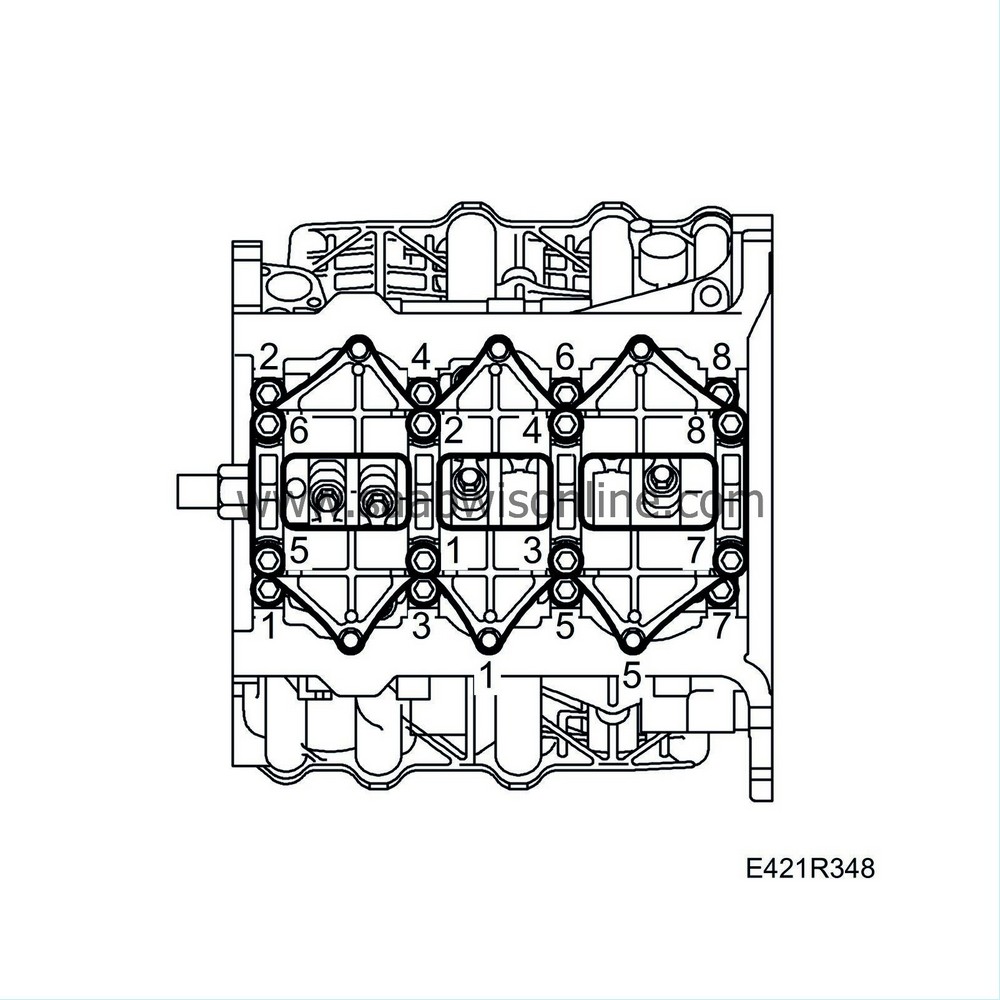

5.

|

Fit the main bearing member. Tighten the inner bolts in the sequence indicated in the illustration.

Tightening torque: 30 Nm + 60° (22 lbf ft + 60°)

|

|

6.

|

Control tighten the bolts of the main bearing caps.

|

|

7.

|

Tighten the side bolts of the main bearing caps. 39 Nm

Tightening torque: 39 Nm (29 lbf ft)

|

|

8.

|

Tighten the outer bolts of the main bearing frame (bedplate) in the order indicated in the illustration.

Tightening torque: 25 Nm (18 lbf ft)

|

|

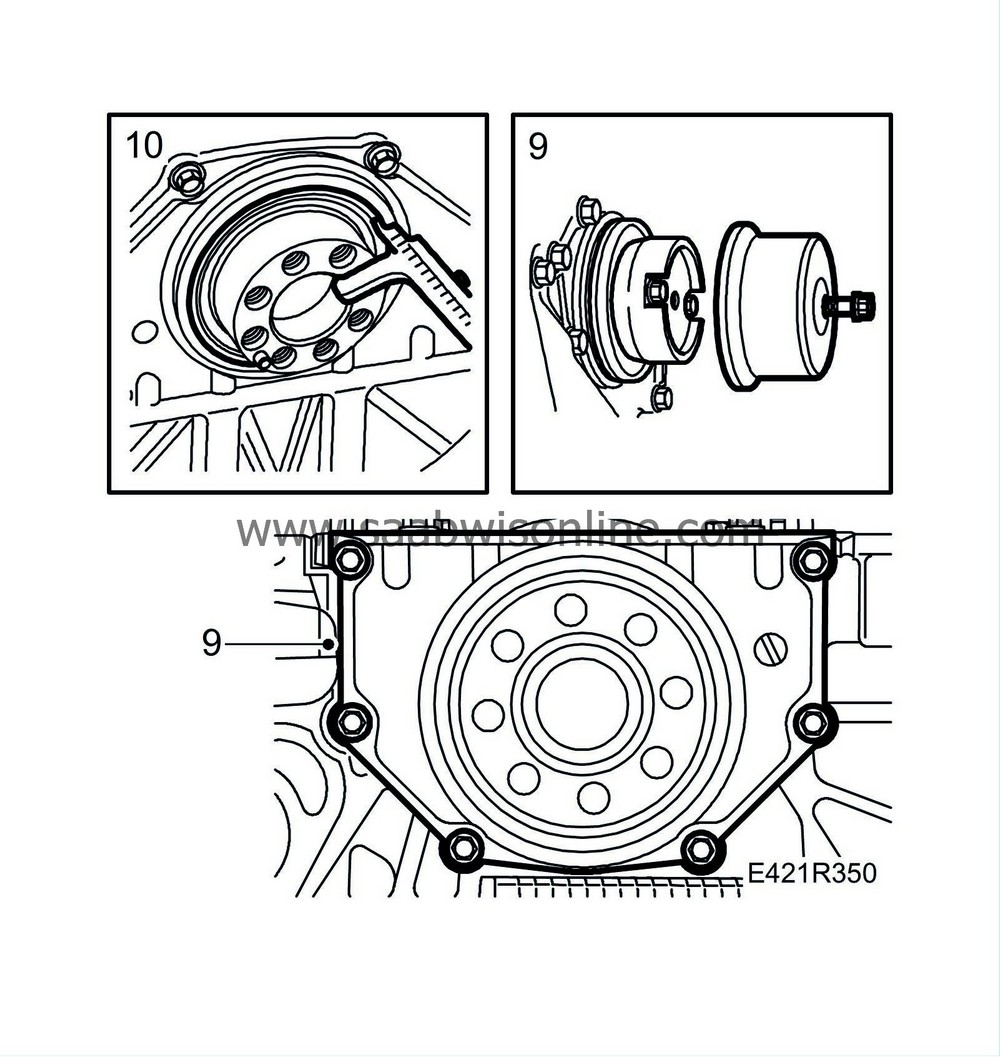

10.

|

Fit the rear crankshaft seal with tool 83 95 790. Check the distance between the rubber seal and the rear end surface of the crankshaft. It should be 3.2 - 3.8 mm.

|

|

11.

|

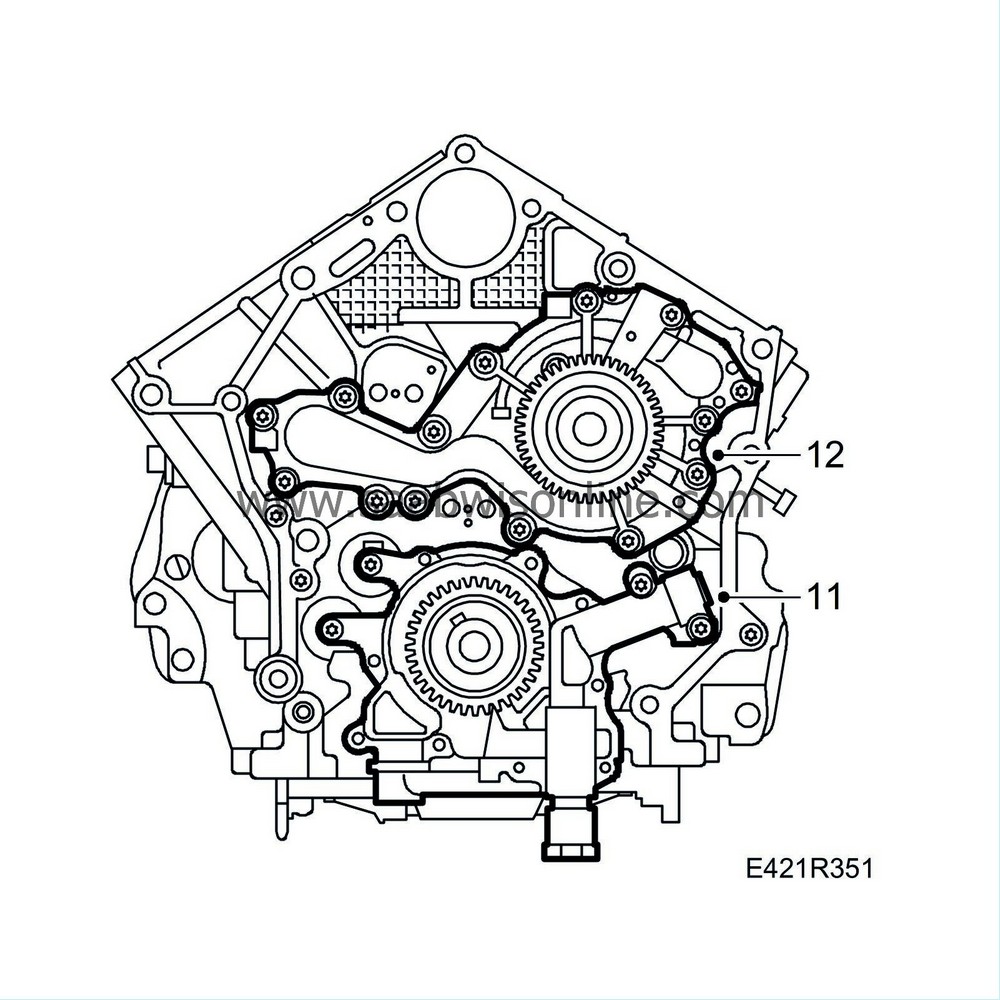

Fit the oil pump with new seals.

Tightening torque: 10 Nm (7 lbf ft)

|

|

12.

|

Fit the coolant pump with a new gasket.

Tightening torque: 11 Nm (8 lbf ft)

|

|

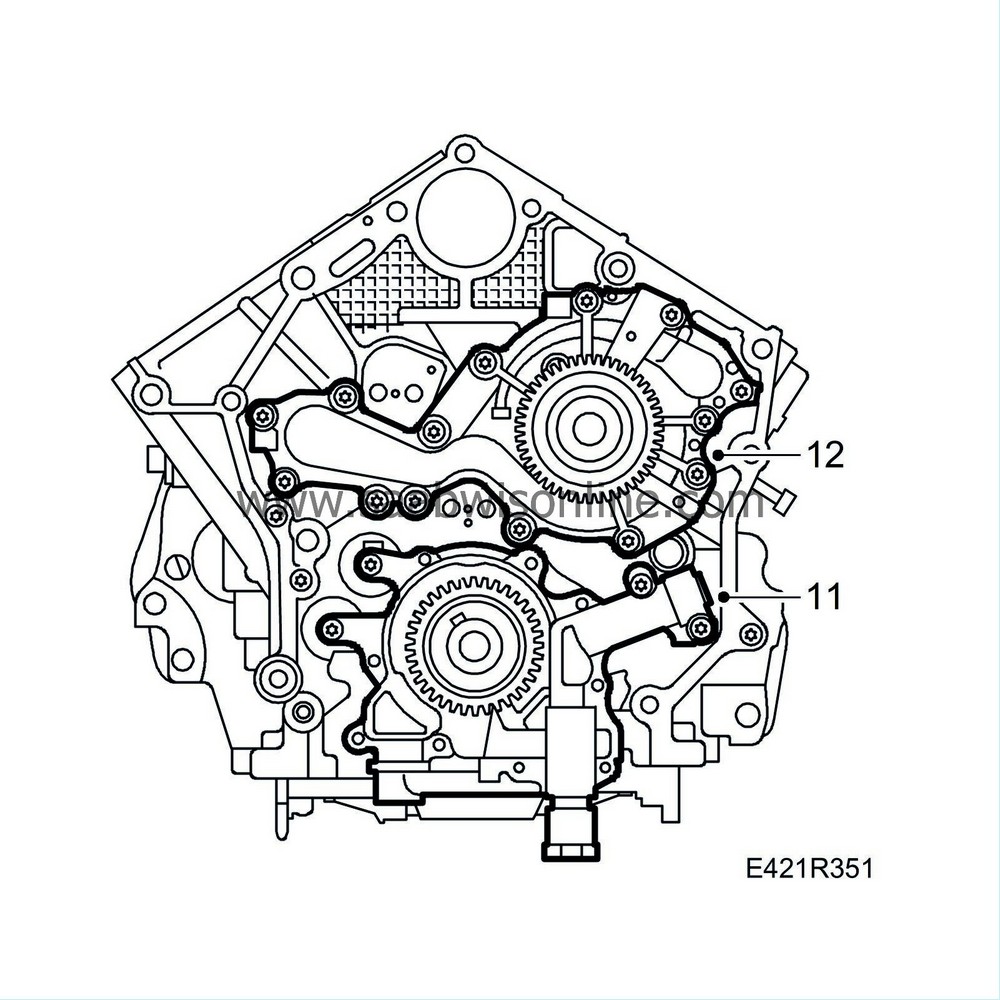

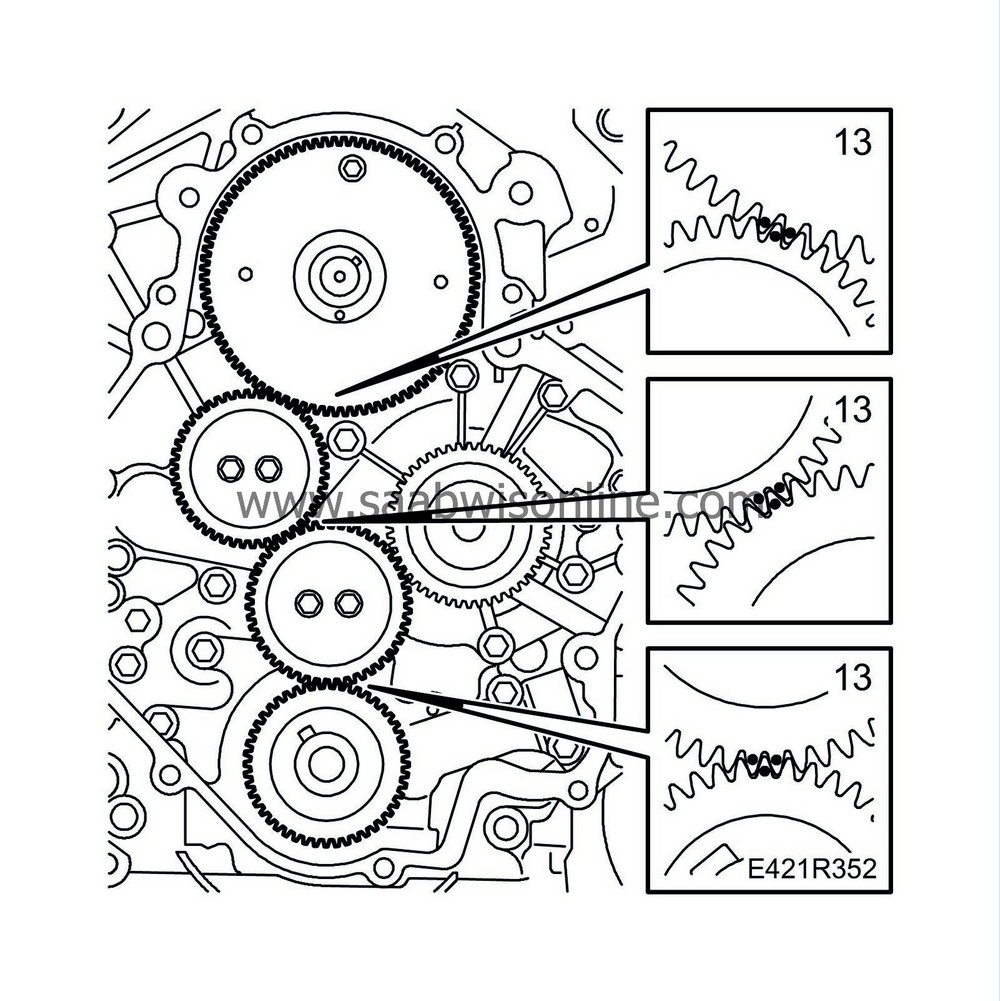

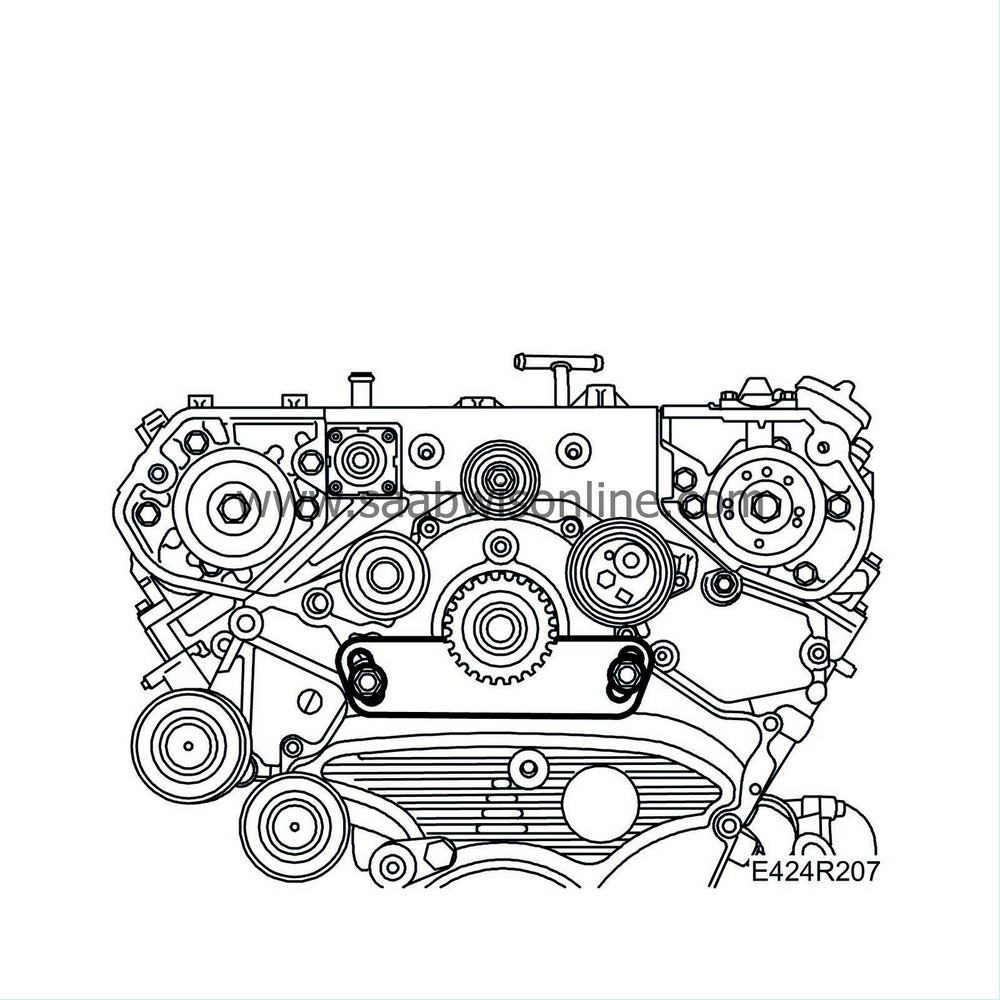

13.

|

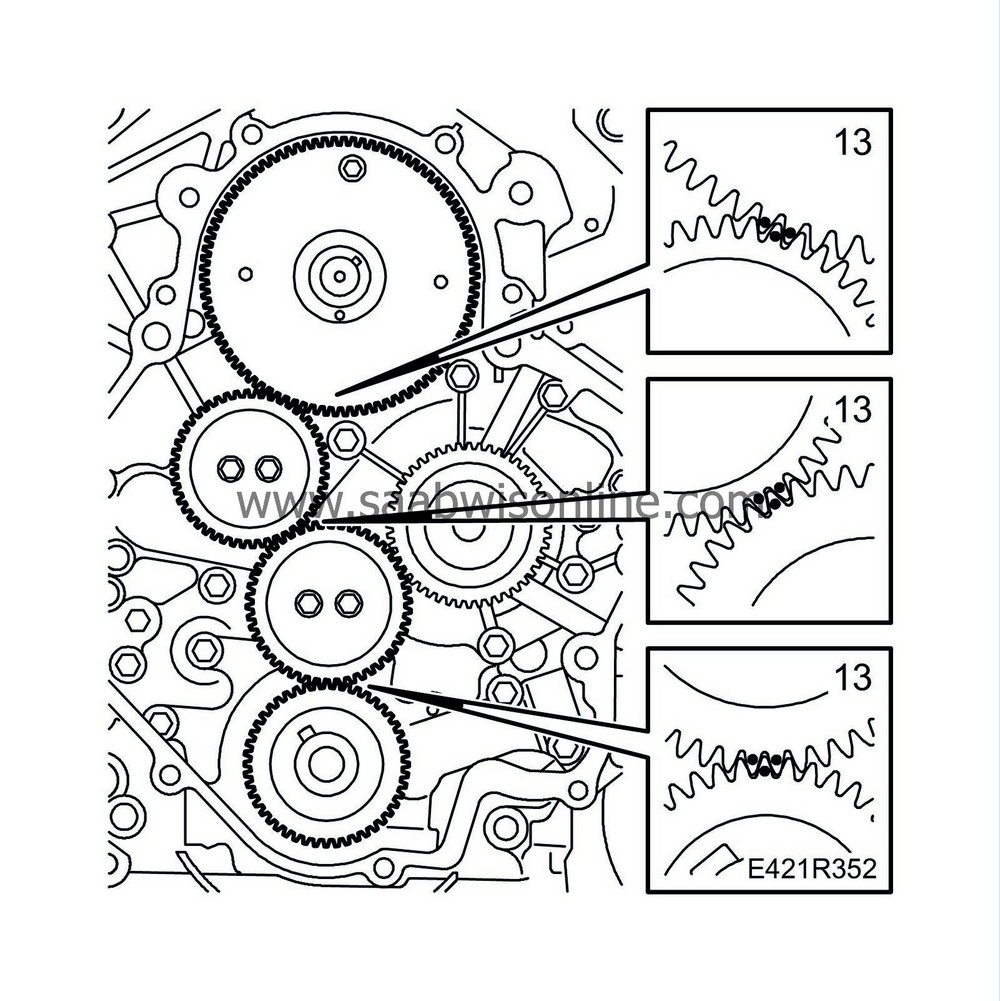

Fit the timing belt following the markings.

Tightening torque: 35 Nm (26 lbf ft)

|

|

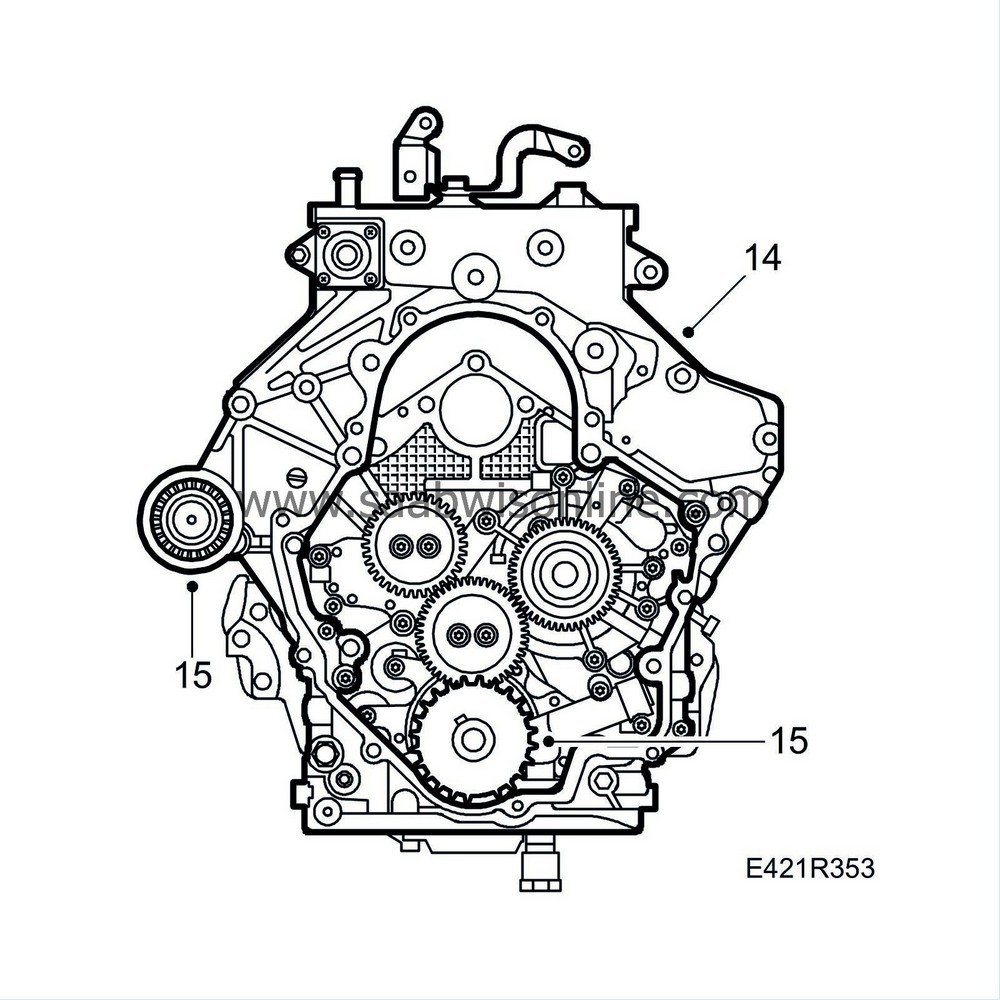

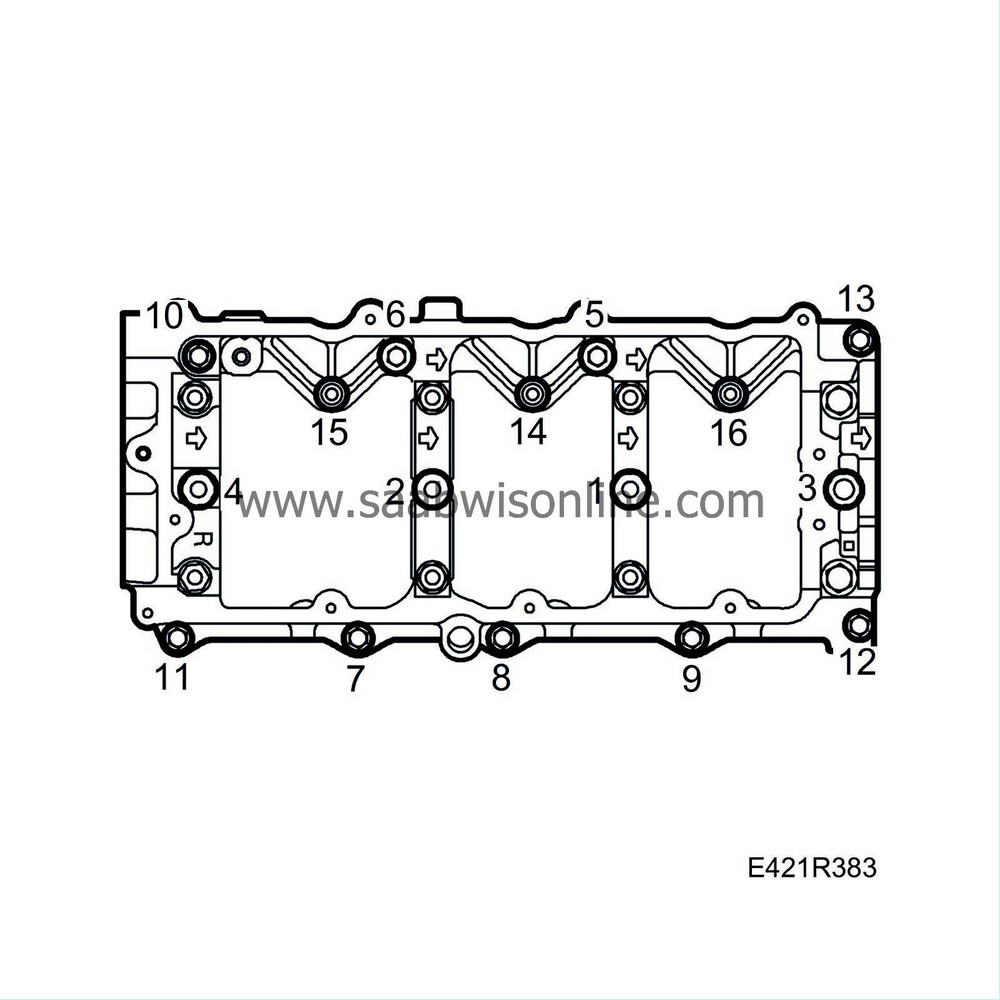

14.

|

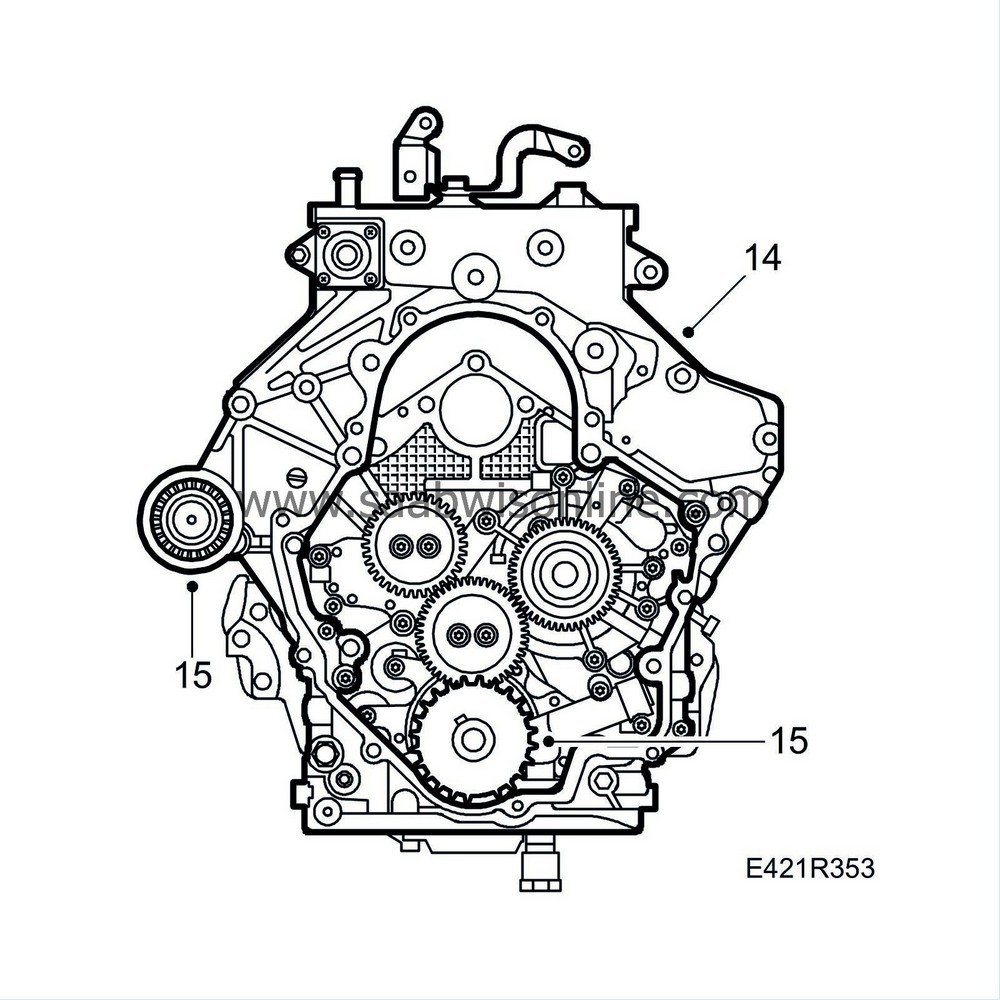

Apply a thin bead of

87 81 841 Silicon flange sealant

on the seal faces and fit the inner timing cover. Tighten in the order indicated by the illustration.

Tightening torque, M8 25 Nm (18 lbf ft)

Tightening torque, M10 50 Nm (37 lbf ft)

Tightening torque, M12 90 Nm (66 lbf ft)

|

|

15.

|

Fit the crankshaft position sensor sprocket with the marking outward.

|

|

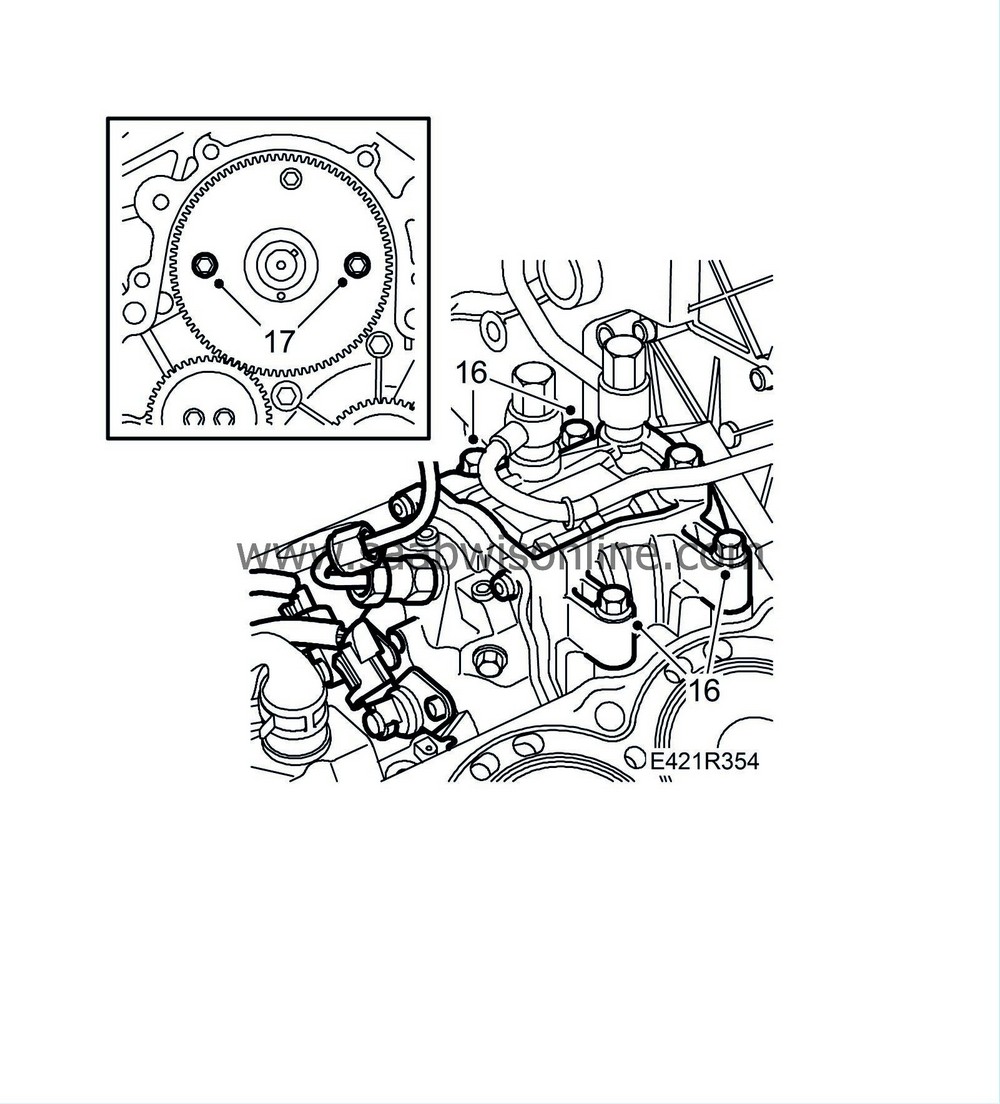

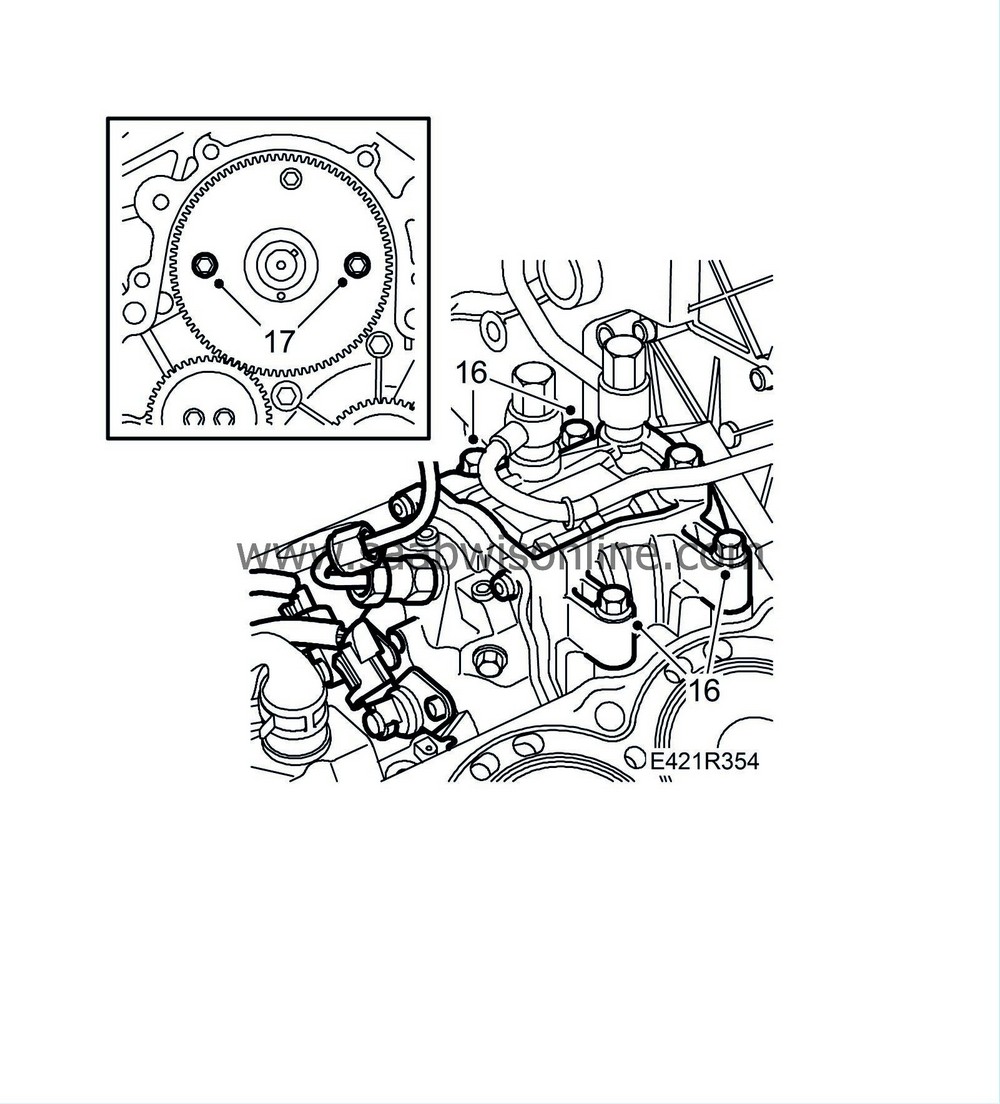

16.

|

Fit the fuel pump with a new seal. Lubricate the seal with vaseline. Pay attention to the location of the guide screws.

Tightening torque: 21 Nm (15 lbf ft)

|

|

17.

|

Set the rear half of the fuel pump gear in a vice. Set two M6 bolts into the front portion. Add the front portion and use a screwdriver and the M6 bolts to turn it clockwise so that the teeth lie correctly against each other. Lock into position with a lock screw.

|

|

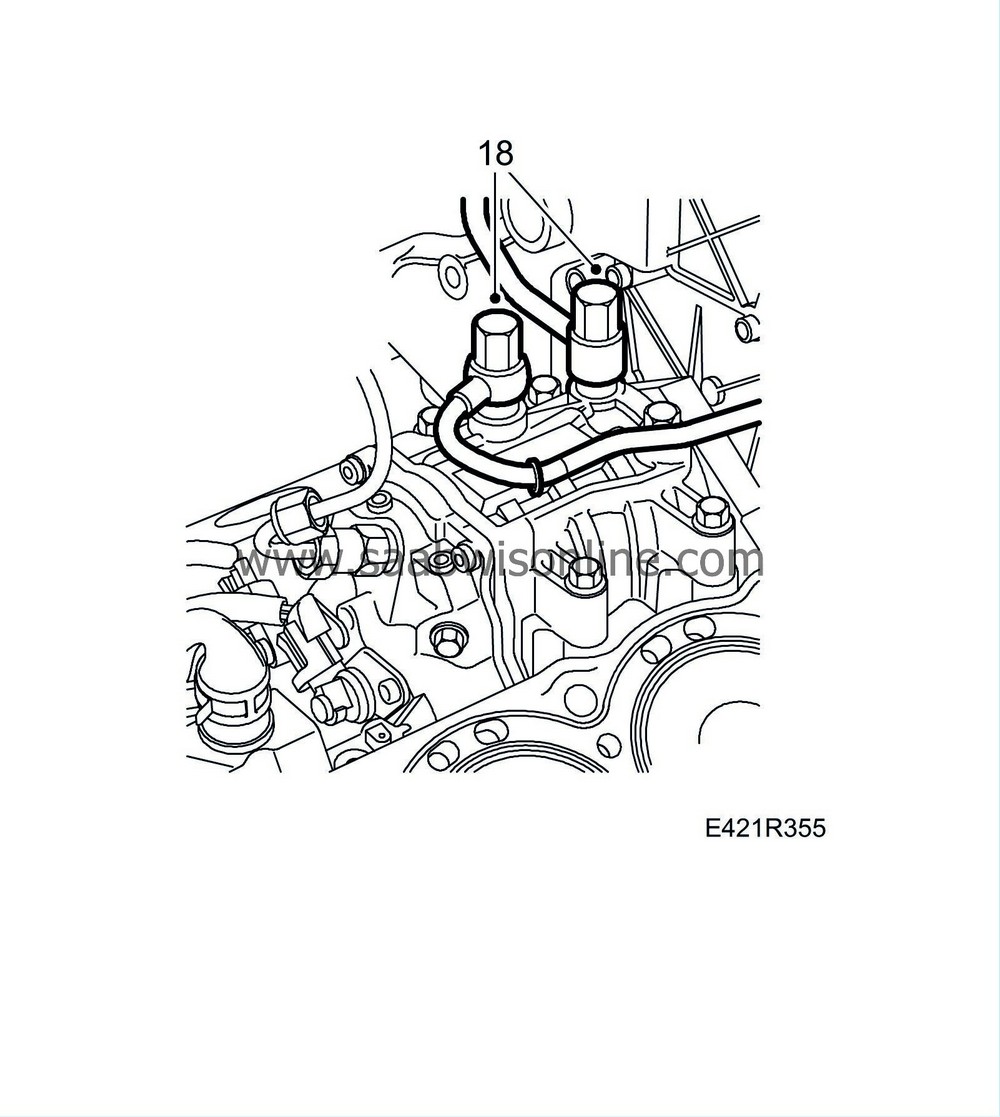

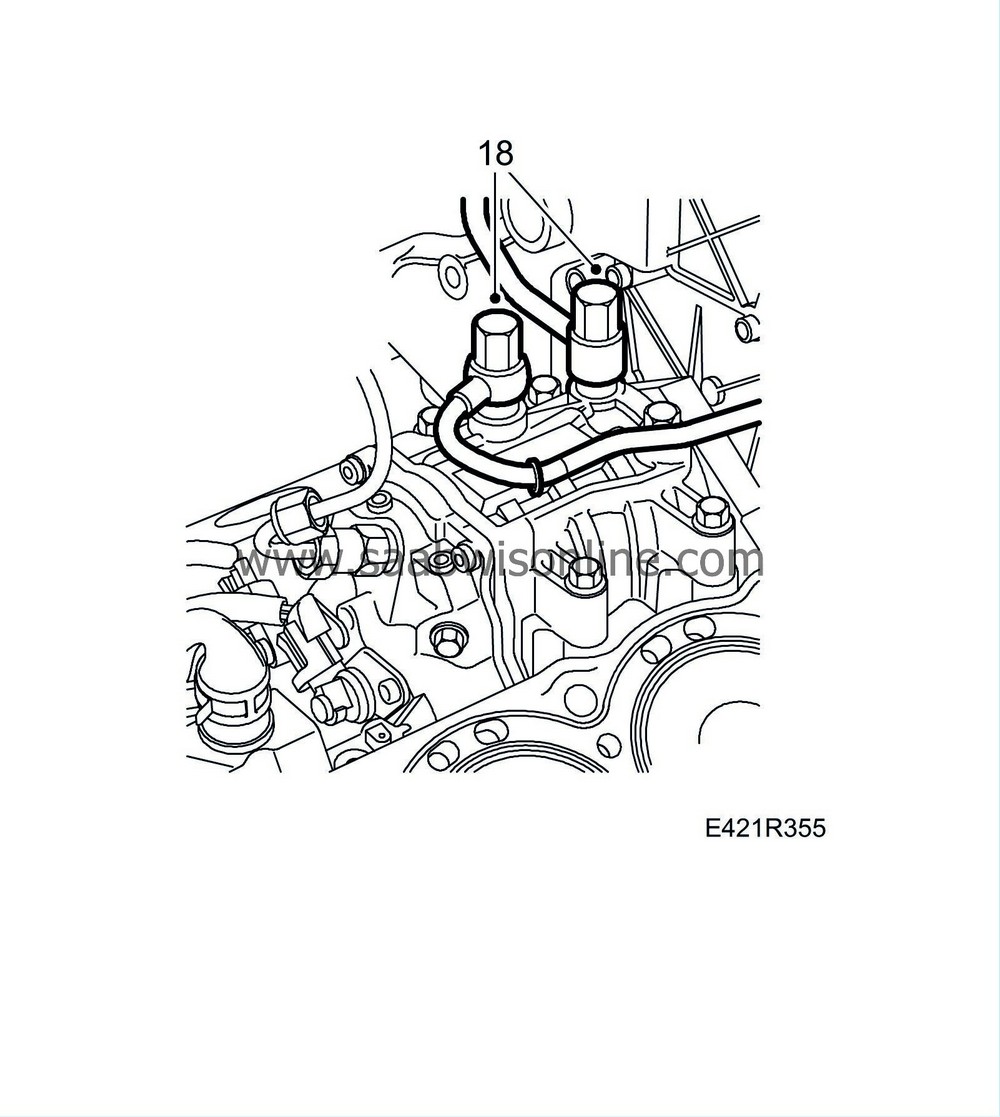

18.

|

Fit the fuel feed pipes on the fuel pump.

|

|

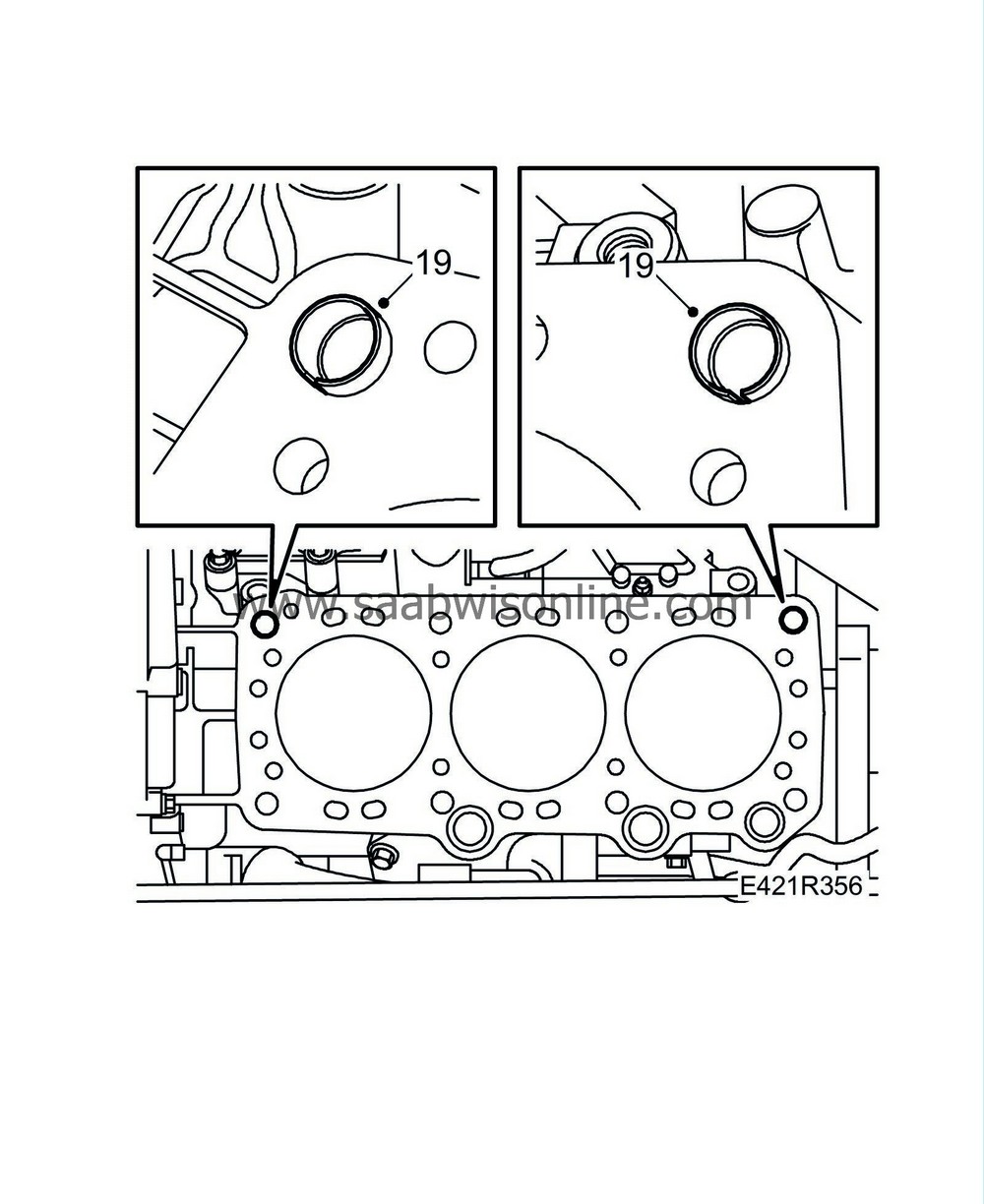

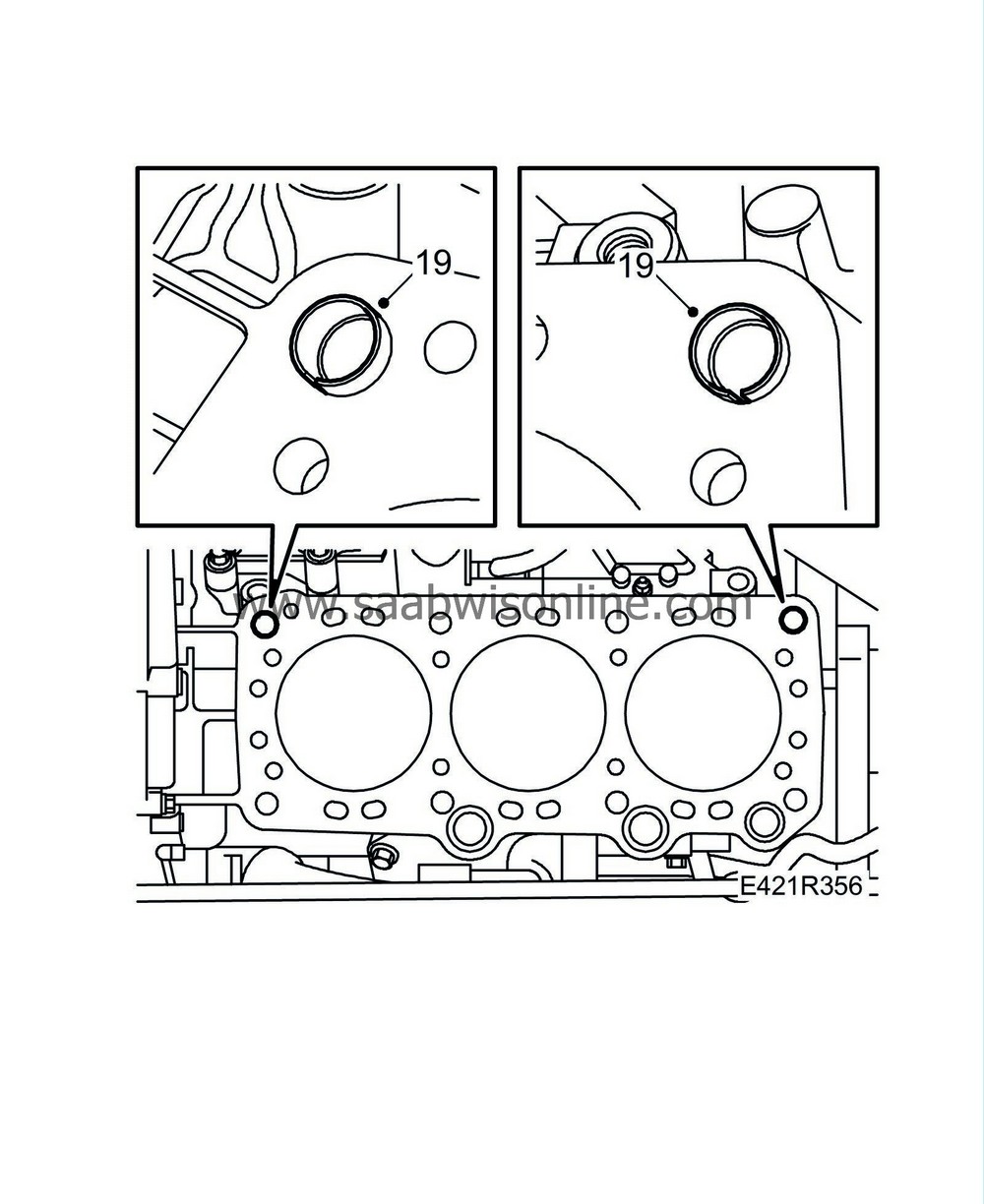

19.

|

Clean the seal faces and the combustion chamber on the cylinder head and cylinder block. Blow clean the bolt holes with compressed air. Make sure that the guide rings are correctly located in the cylinder block.

|

|

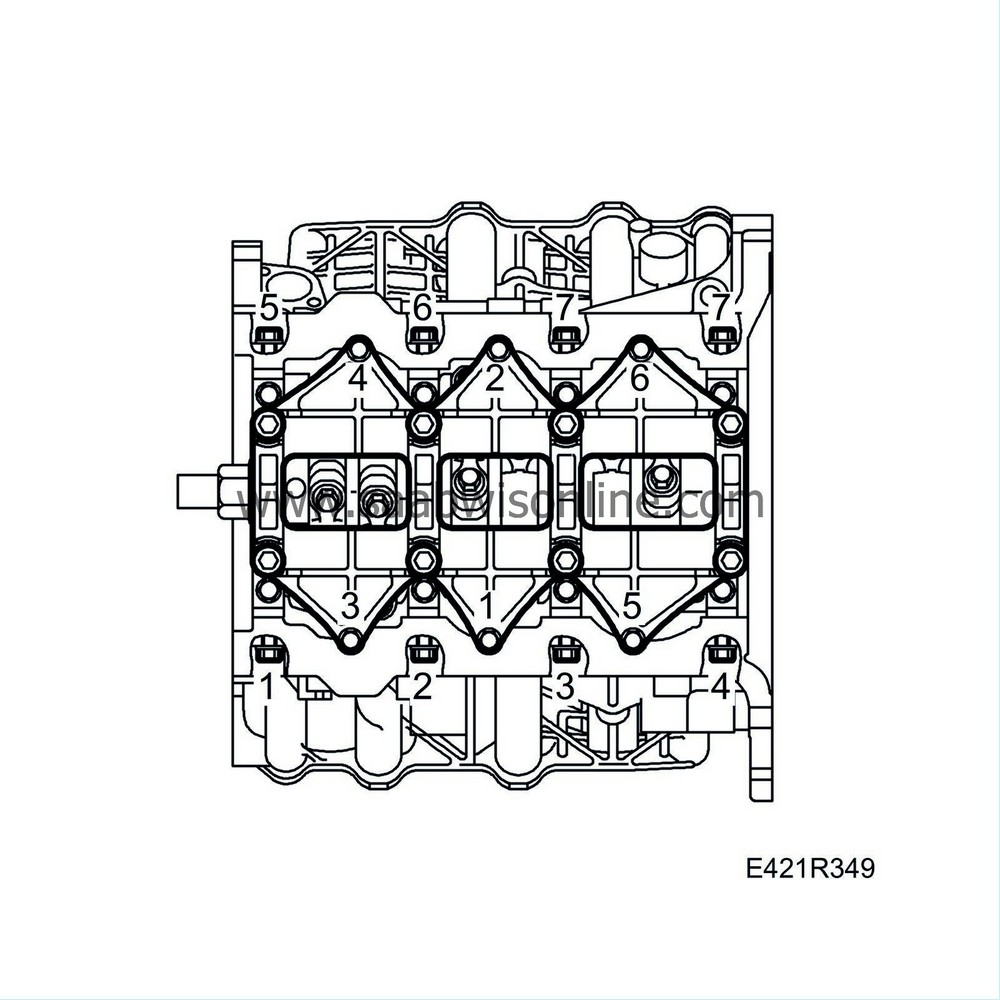

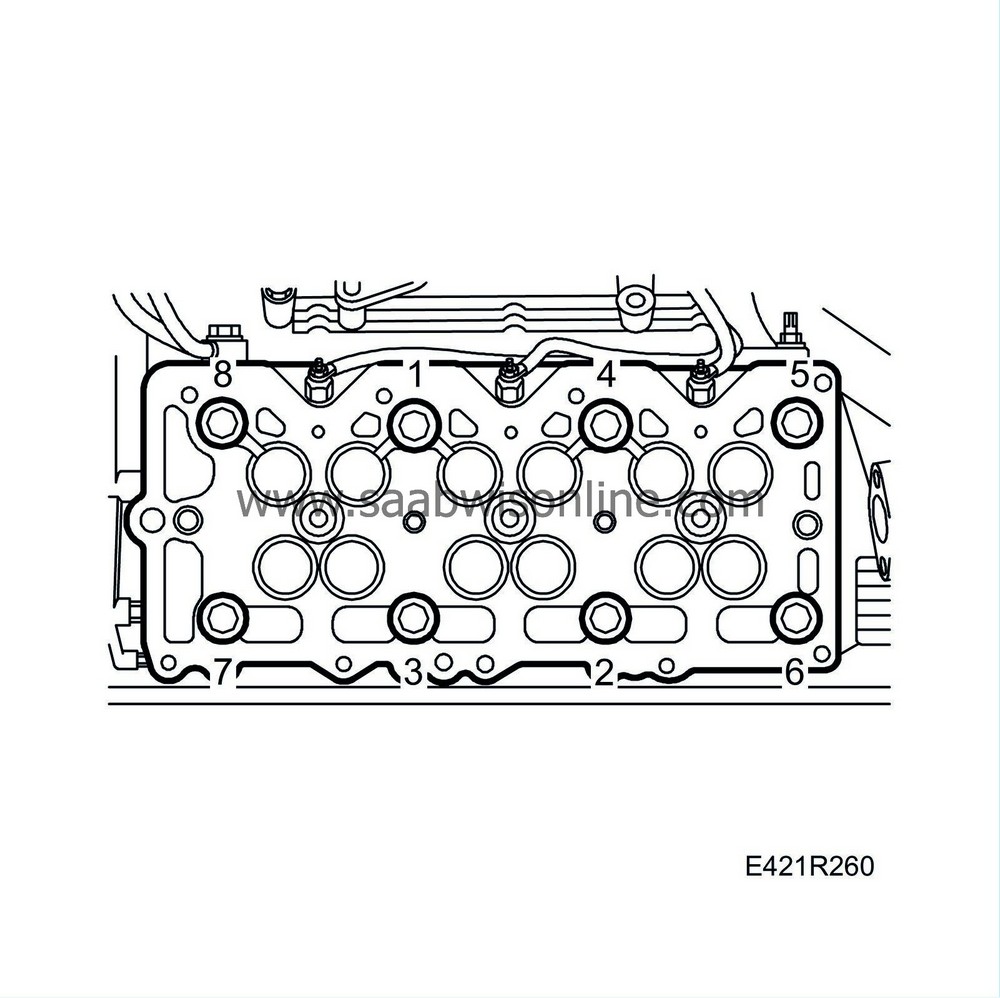

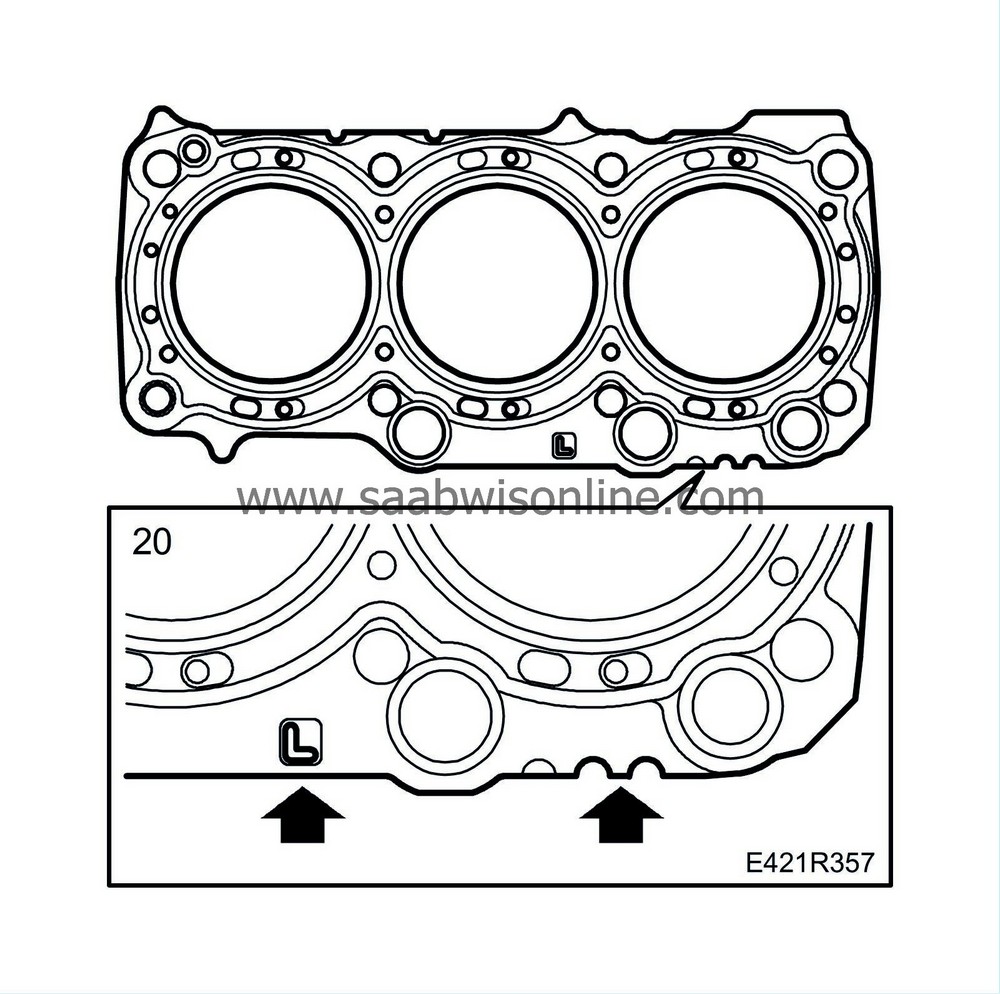

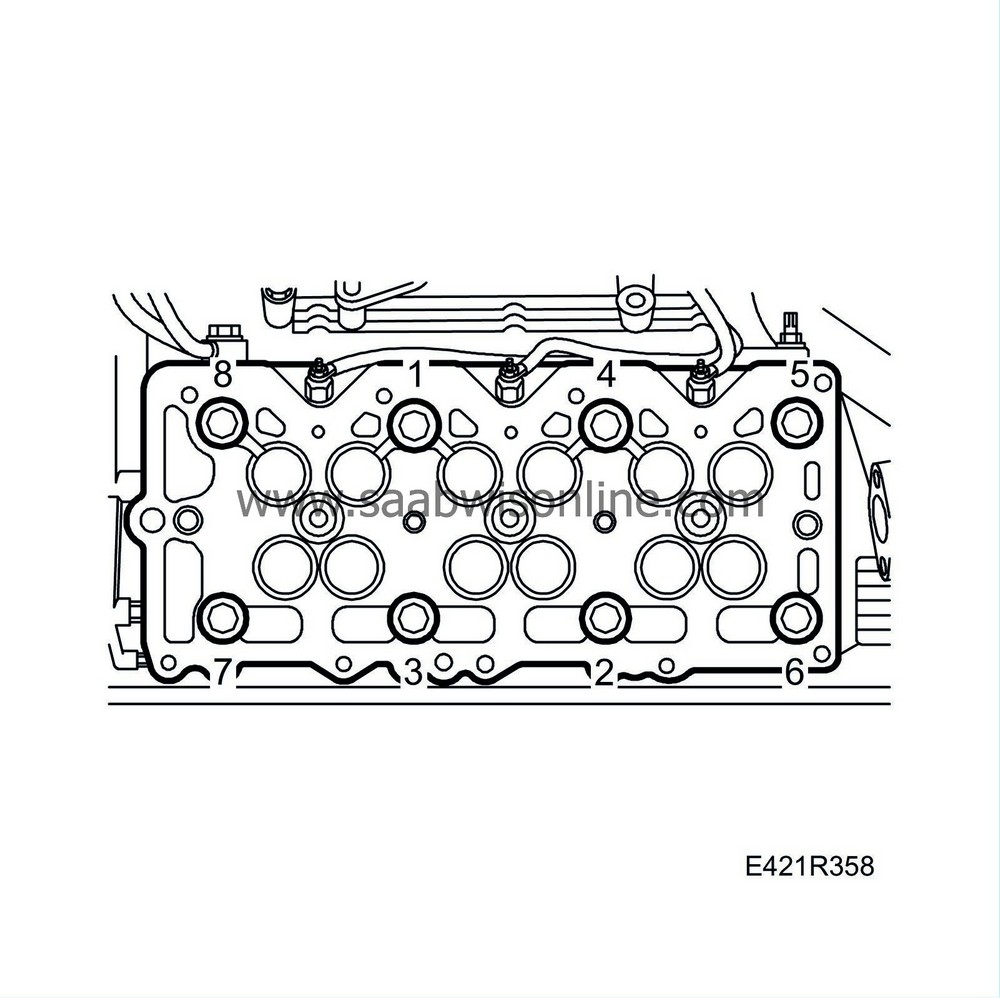

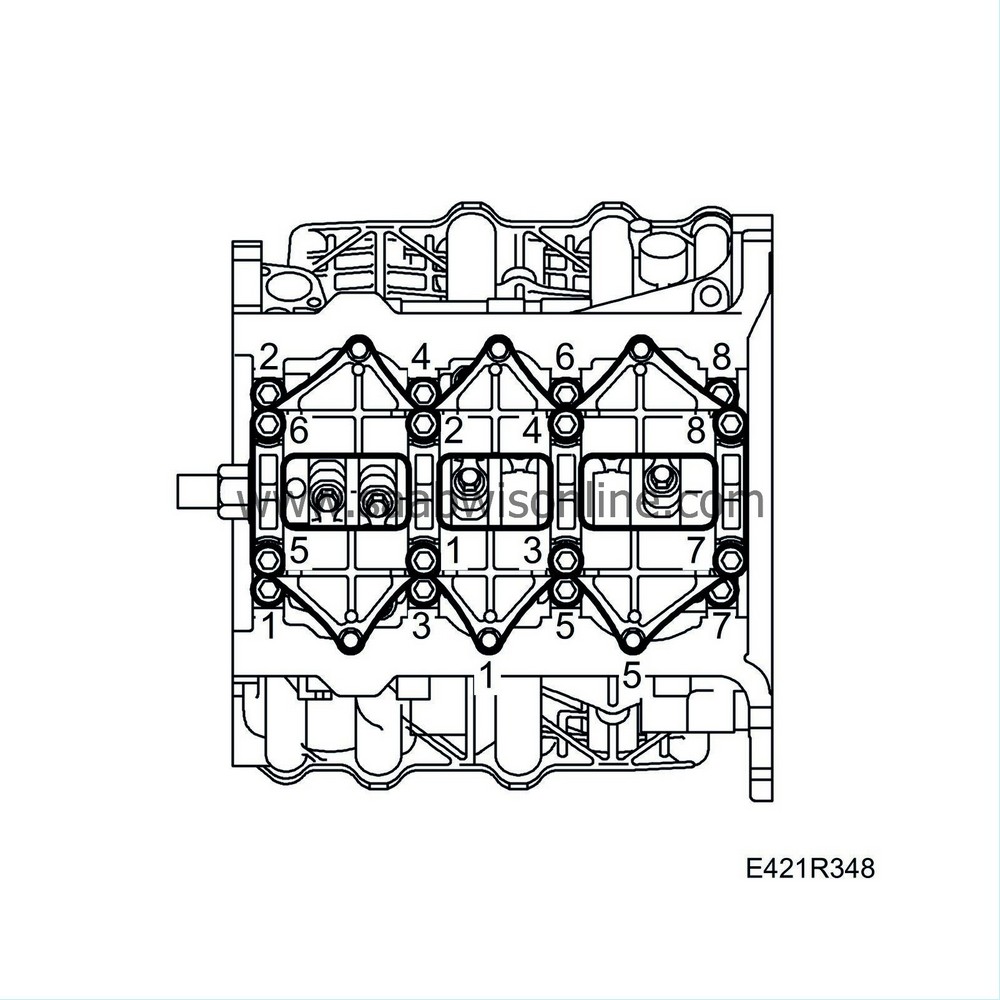

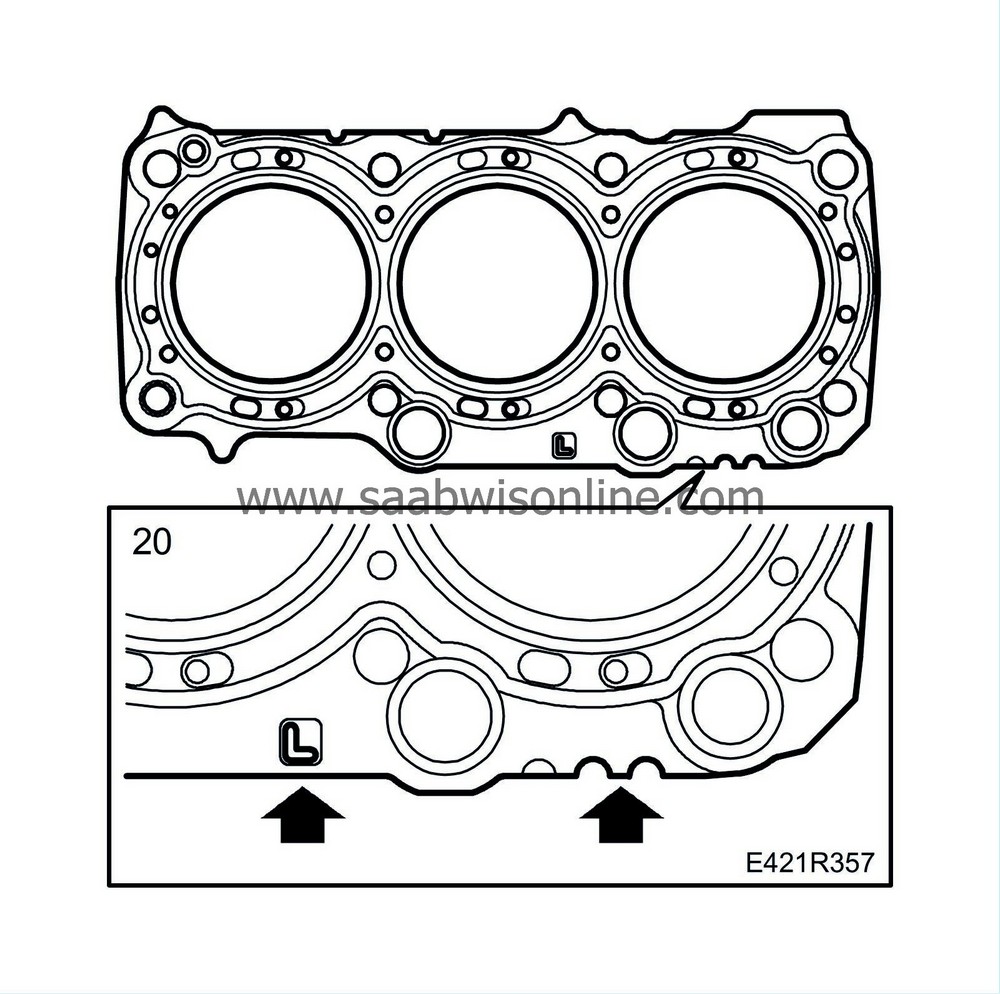

20.

|

Fit the cylinder head with new gasket and bolts. Note different bolt lengths. Check that the gasket has the correct graduation as in the illustration. Tighten the bolts following the illustration (L=front cylinder bank, R=rear cylinder bank). See

Piston height, measuring

Tightening torque, short bolts

Step I 39 Nm (29 lbf ft)

Step II Angle tighten 110°

Step III Angle tighten 110°

Tightening torque, long bolts

Step I 39 Nm (29 lbf ft)

Step II Angle tighten 130°

Step III Angle tighten 130°

|

|

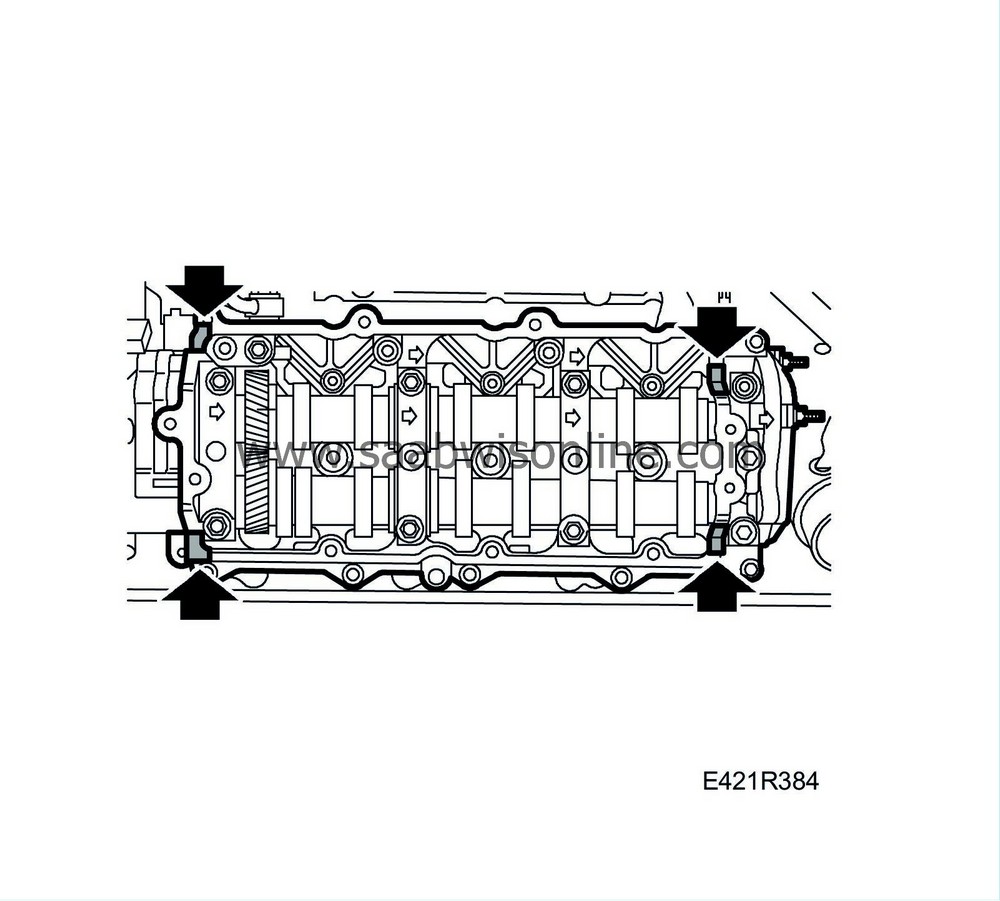

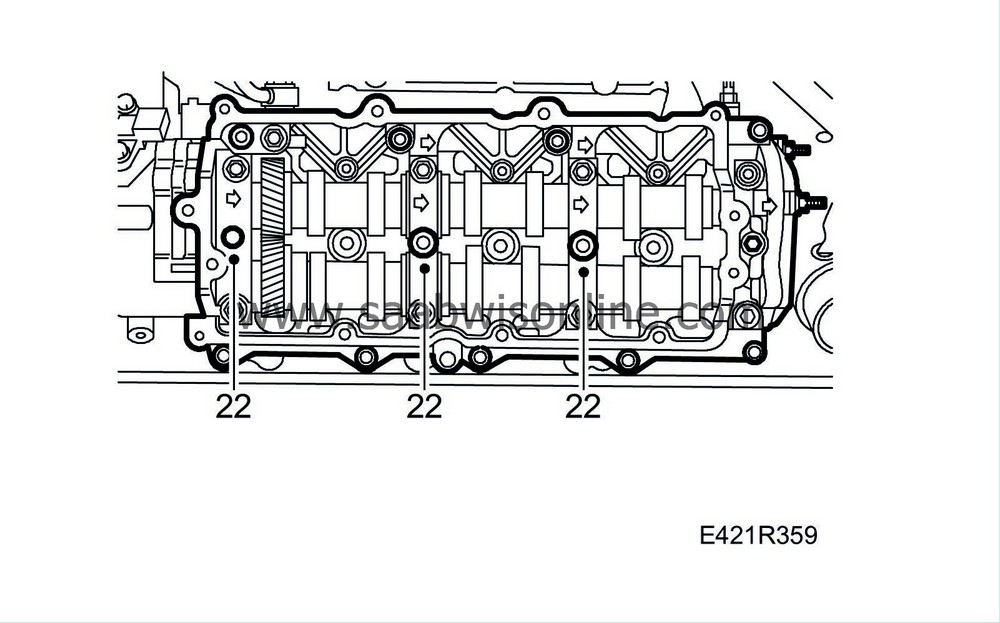

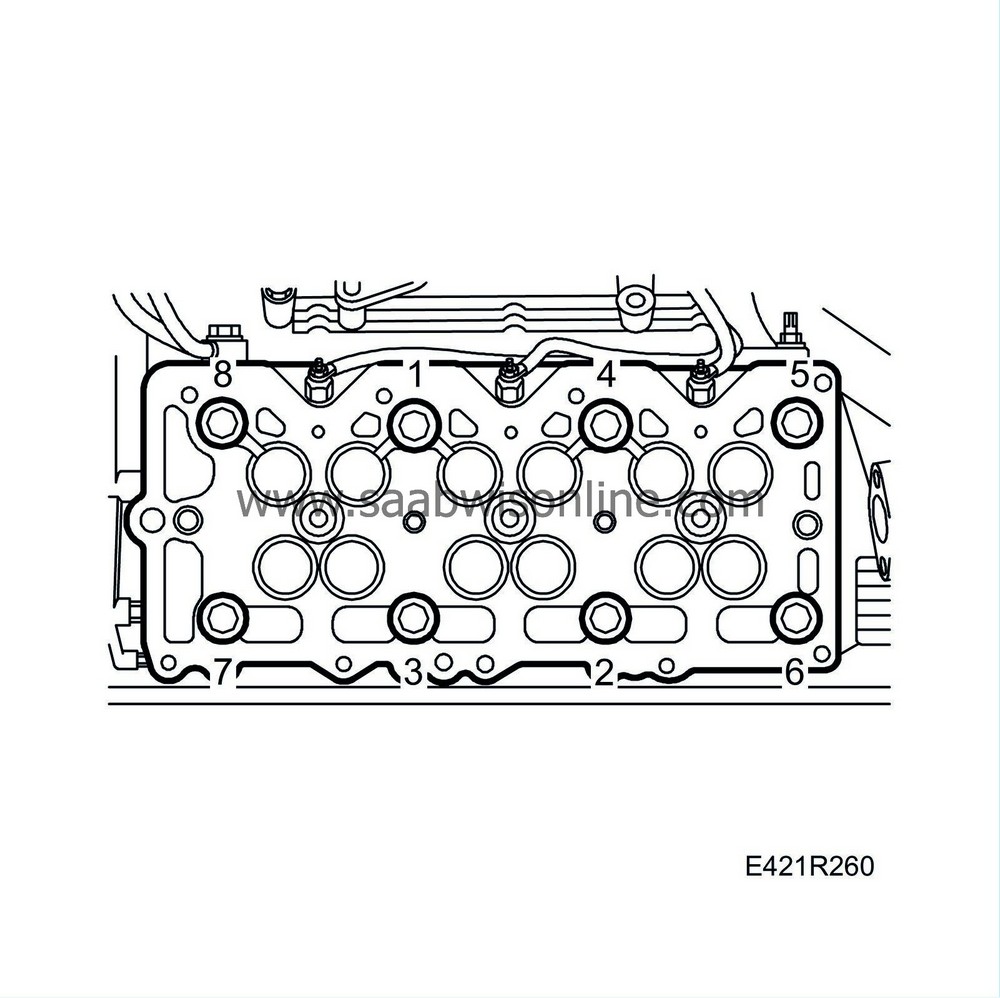

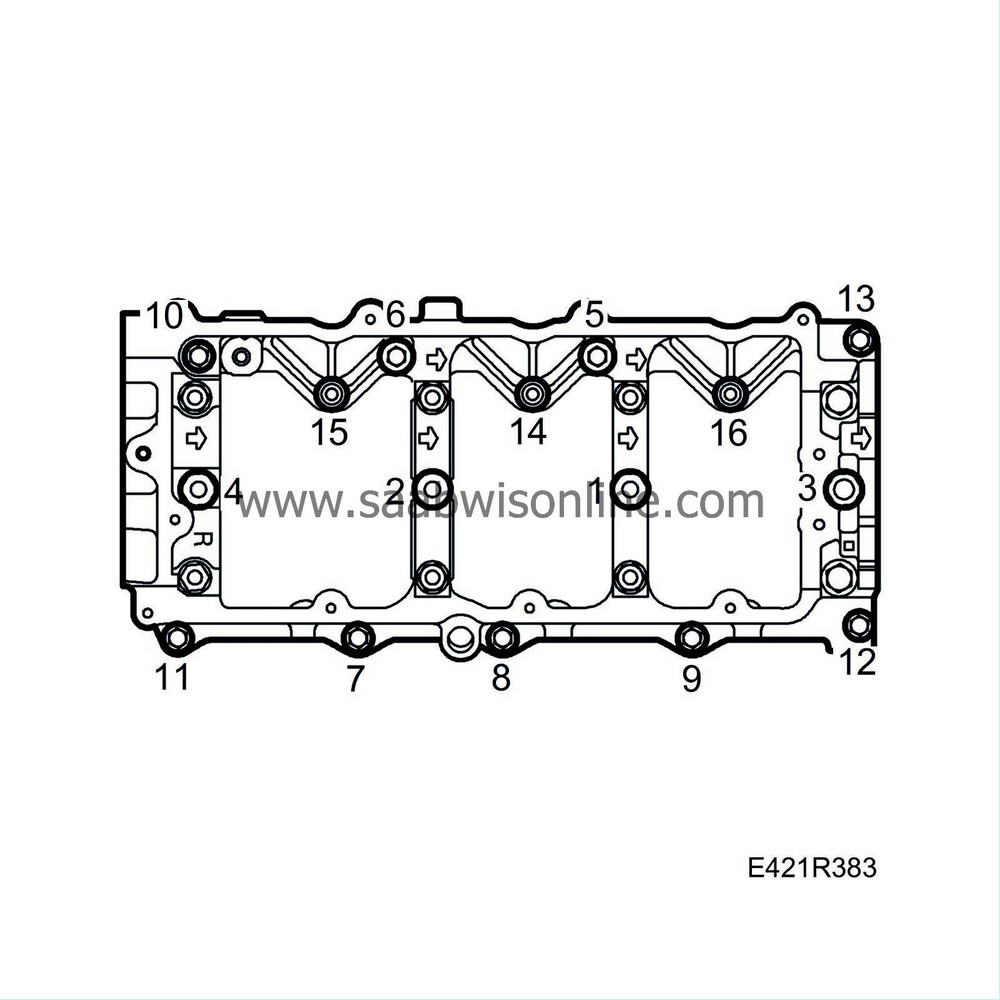

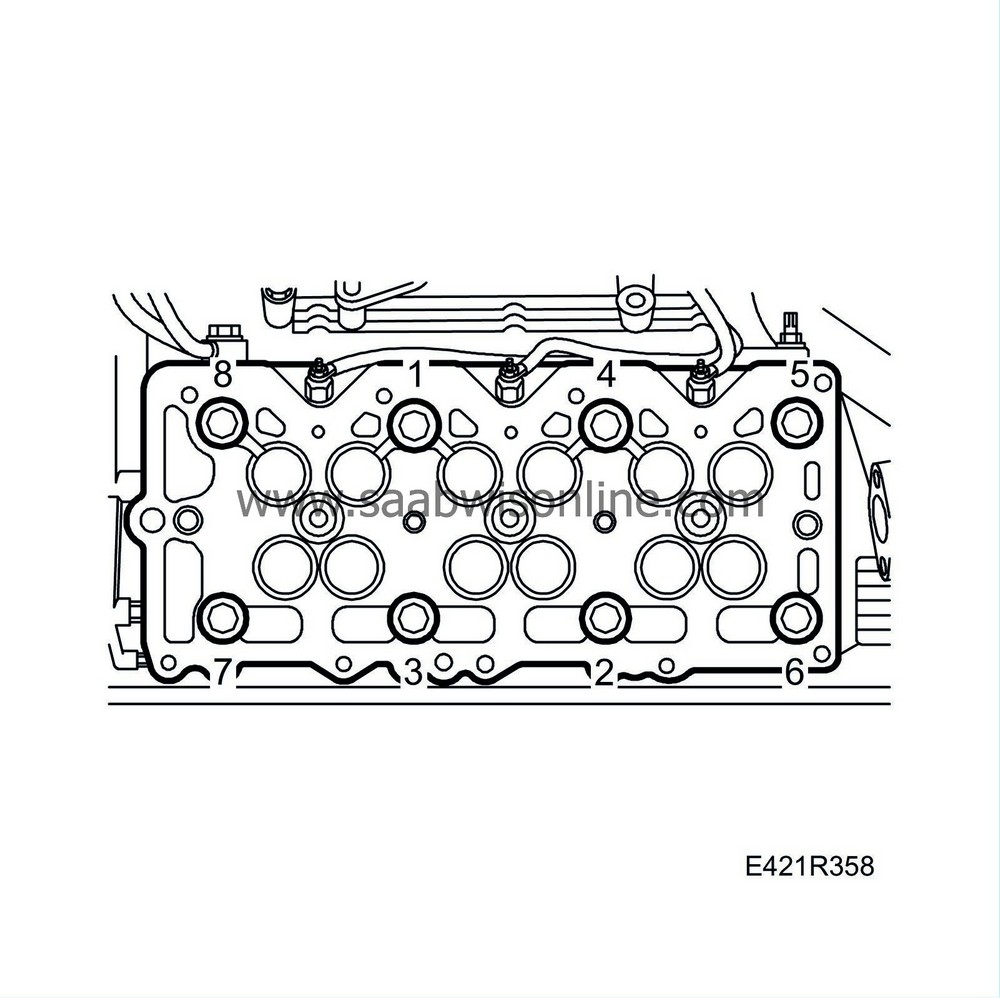

21.

|

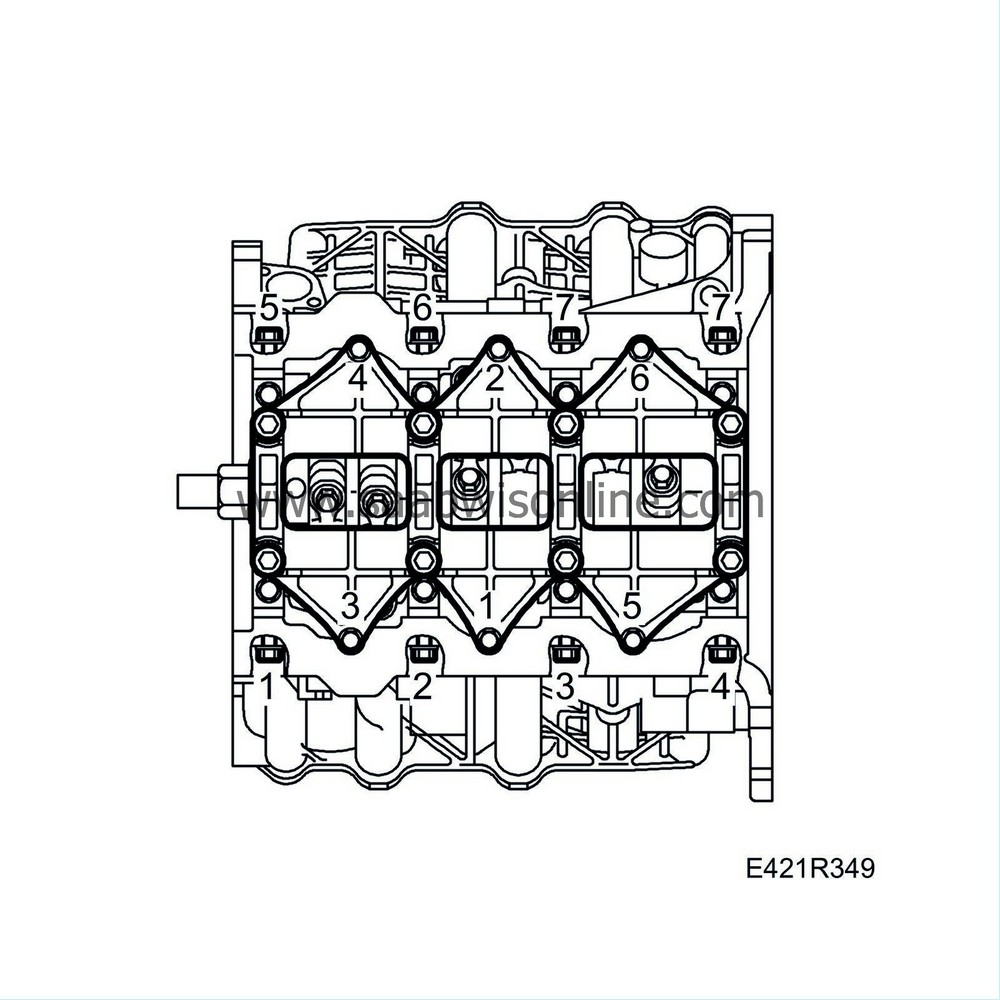

Cleaning the seal faces and make sure that the holes are free from oil. Fit the rear and front camshaft holder frame. Mounting sequence, see illustration.

Tightening torque, M8 22 Nm (16 lbf ft)

Tightening torque, M6 12 Nm (9 lbf ft)

|

|

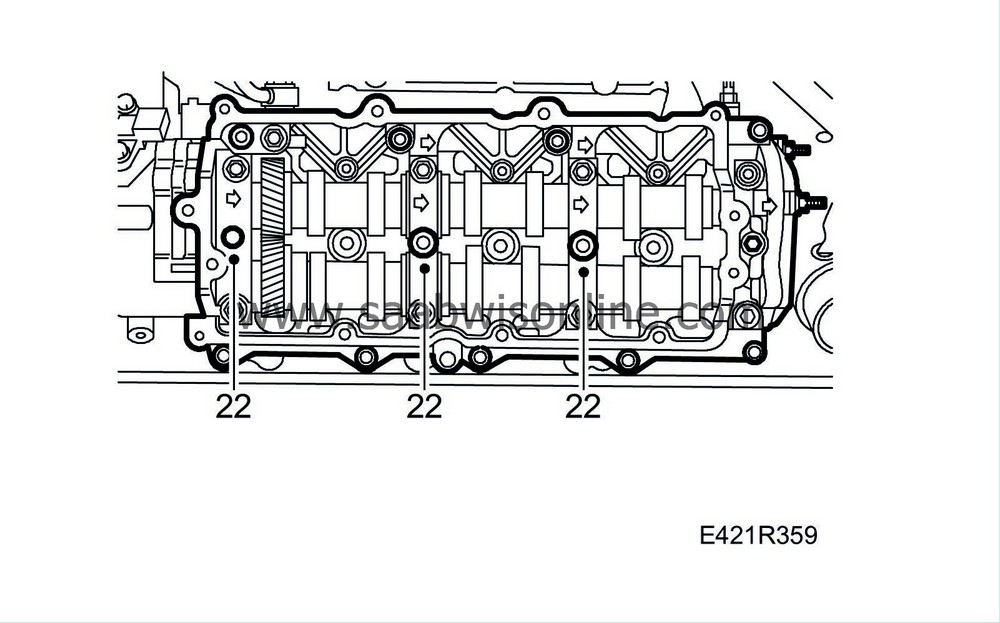

22.

|

Fit the studs to the injector bracket.

Tightening torque, M8 22 Nm (16 lbf ft)

Tightening torque, M10 43 Nm (32 lbf ft)

|

|

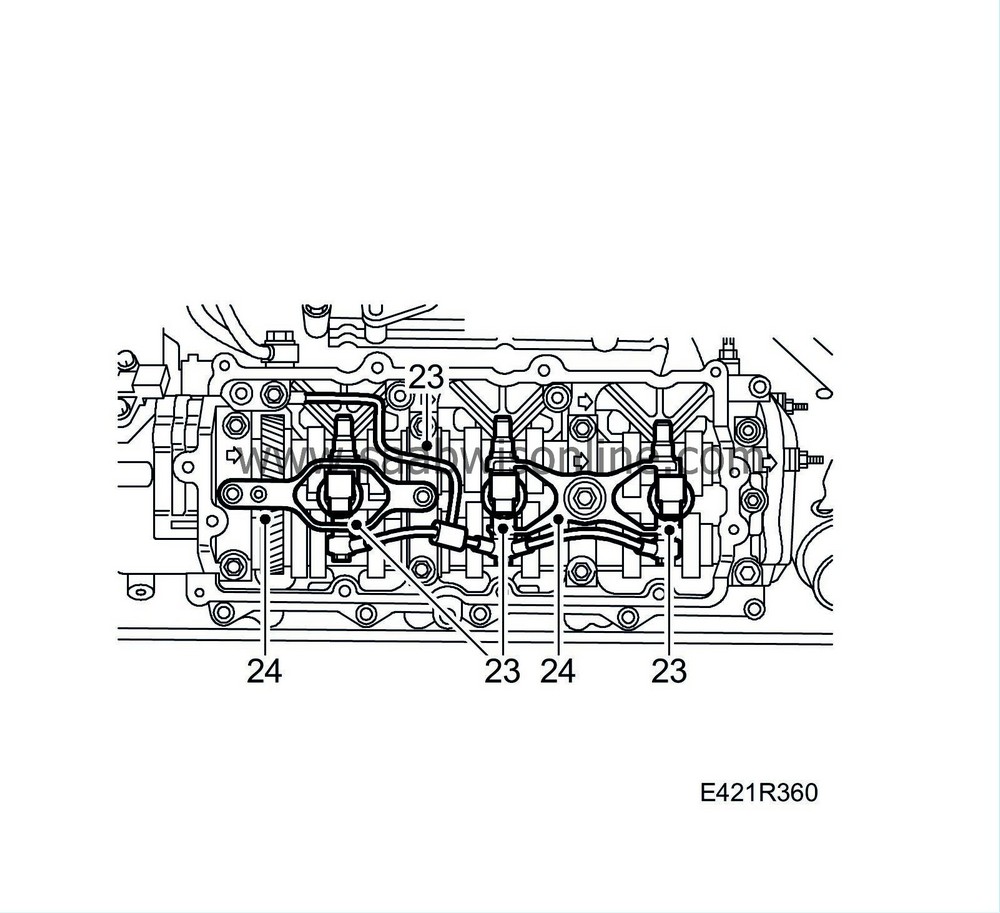

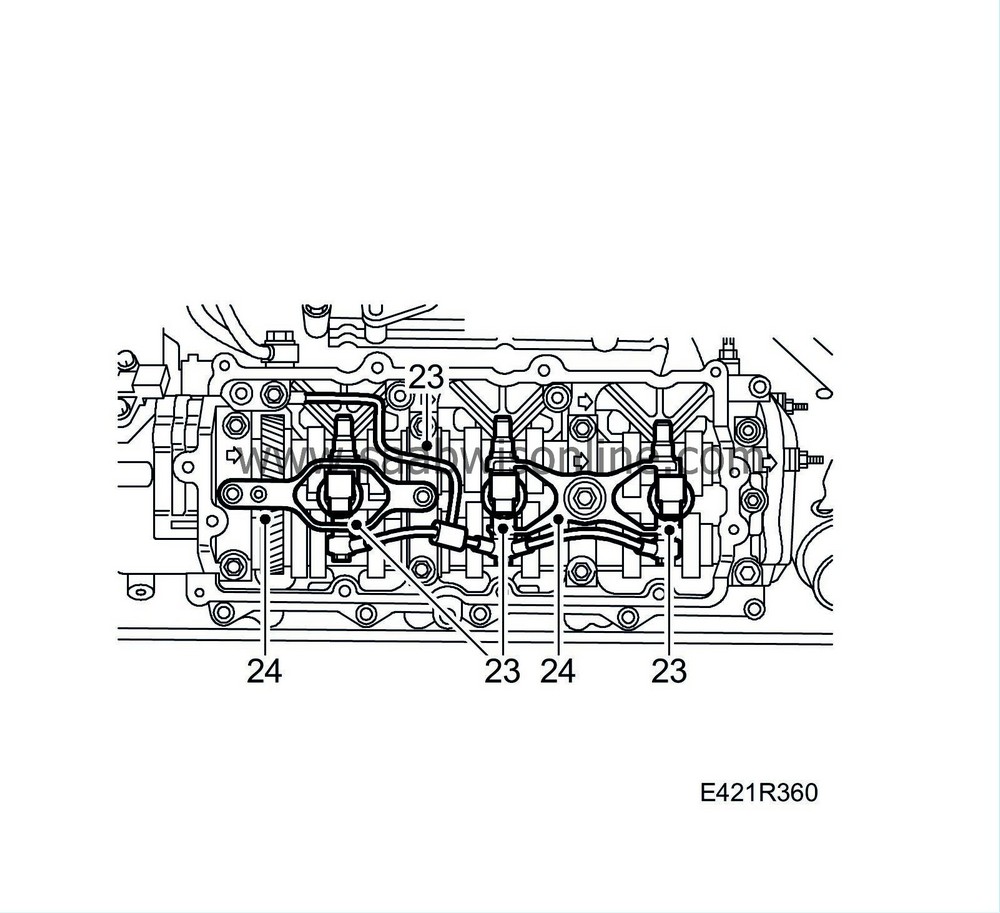

23.

|

Fit the injectors with return lines and new seals.

|

|

24.

|

Fit the injector bracket.

Tightening torque, M6 nut 5 Nm (4 lbf ft)

Tightening torque, M10 nut 29 Nm (21 lbf ft)

|

|

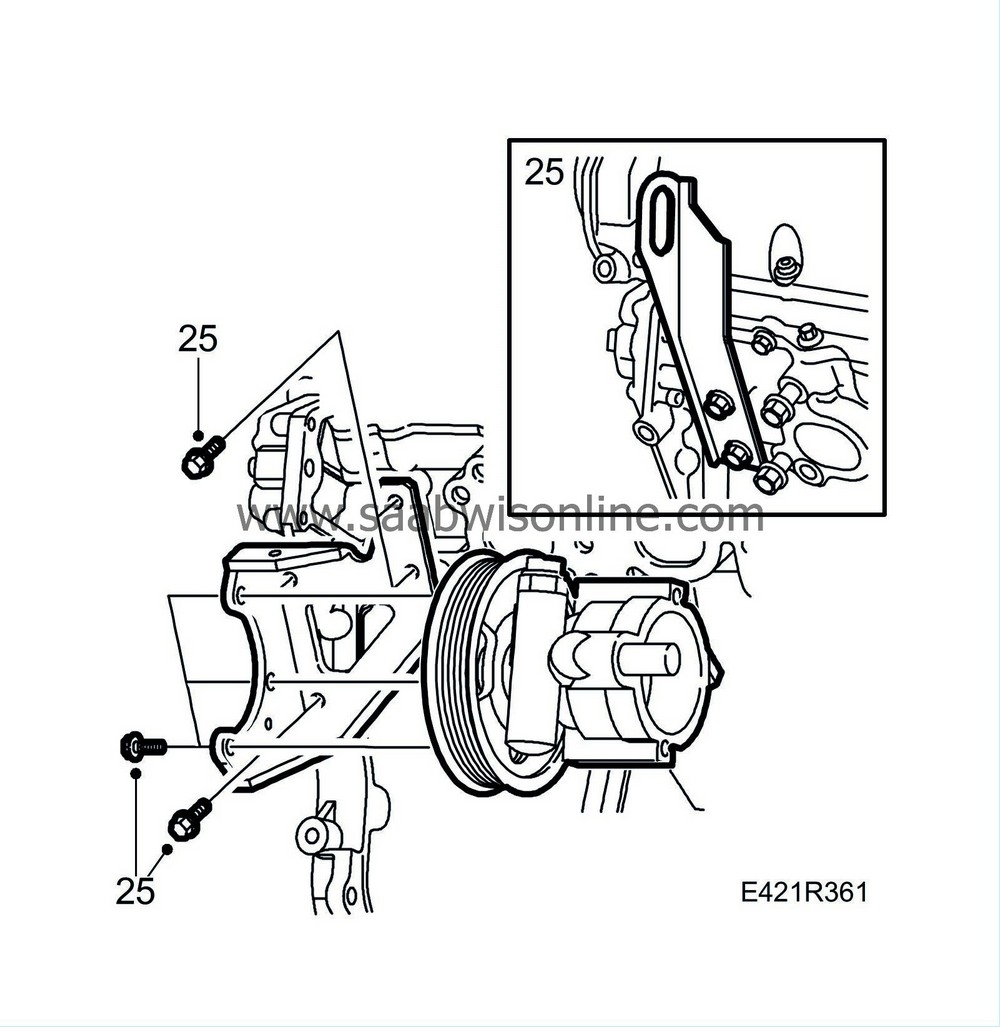

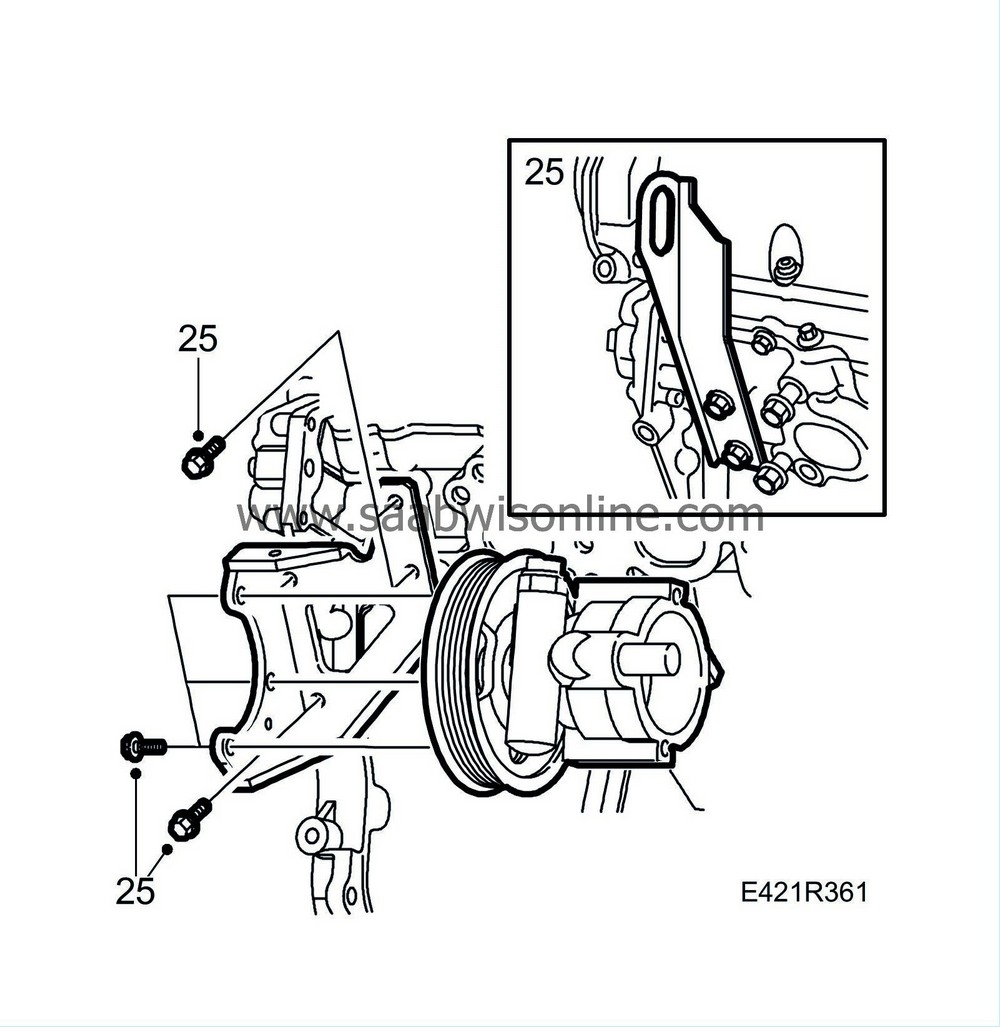

25.

|

Loosely fit the towing eyes and fit the power steering pump with bracket.

Tightening torque: 25 Nm (18 lbf ft)

|

|

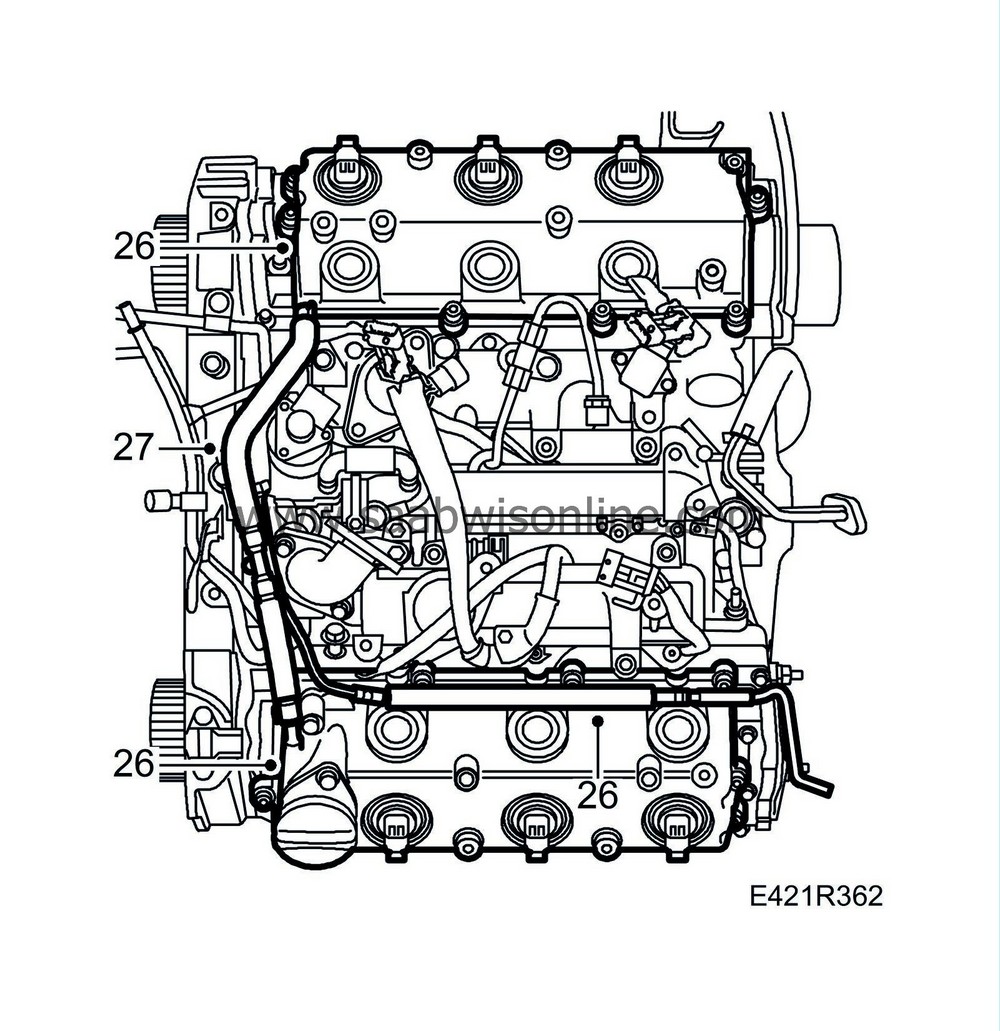

27.

|

Fit the hose and pipe for crankcase ventilation.

|

|

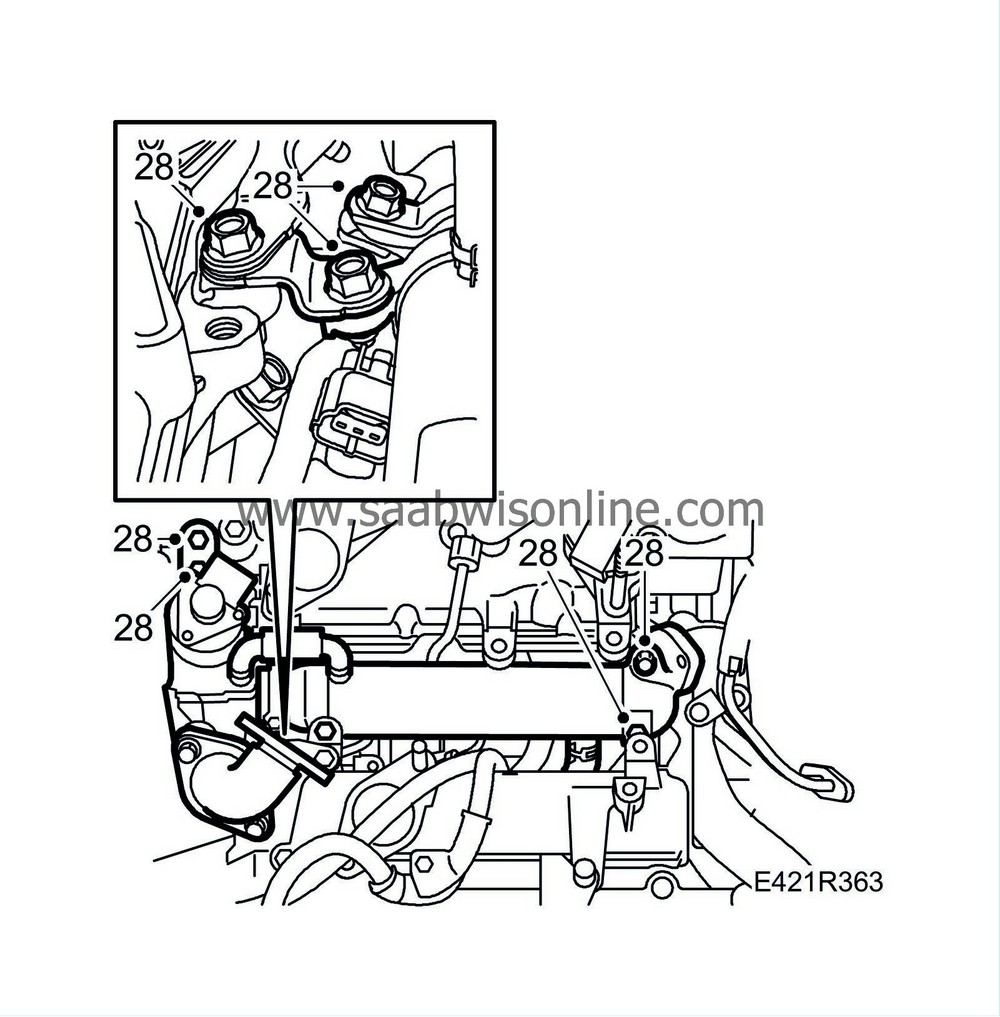

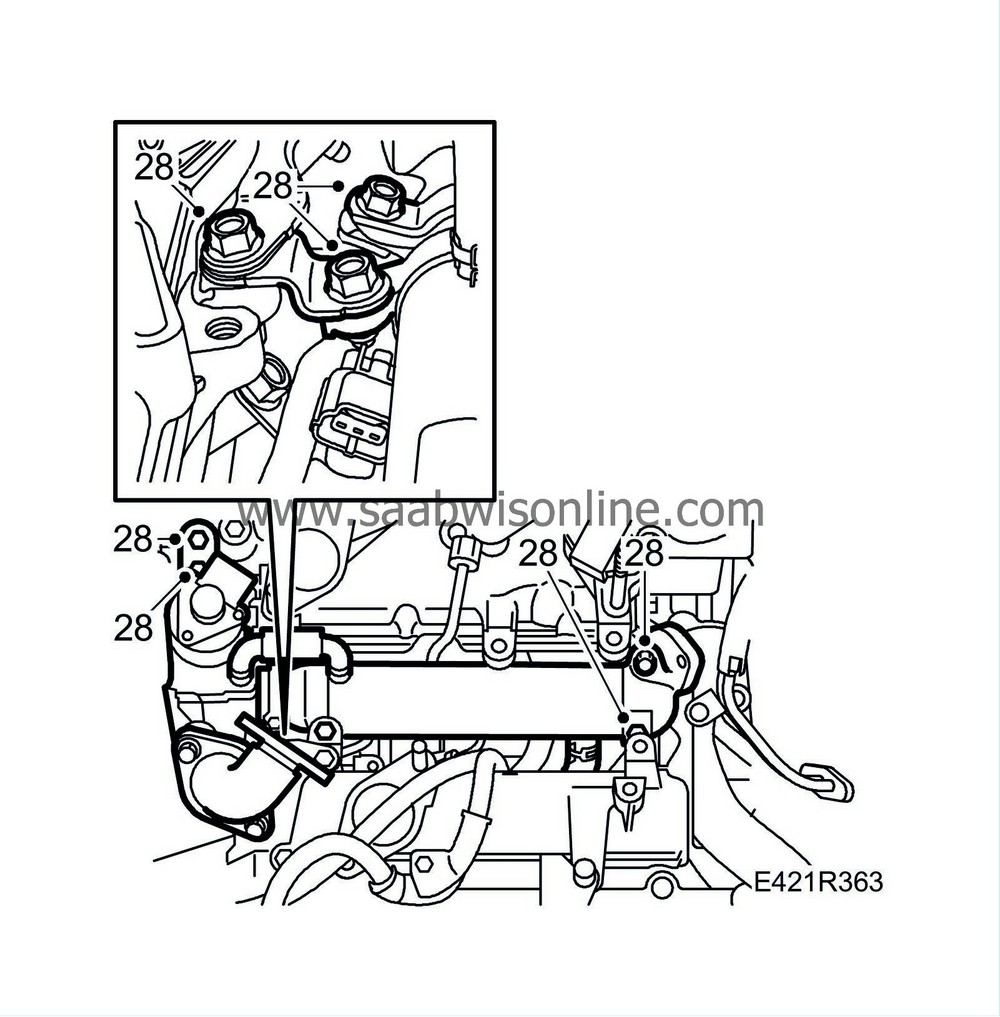

28.

|

Fit the EGR valve with pipe and the coolant pipe as one unit.

|

|

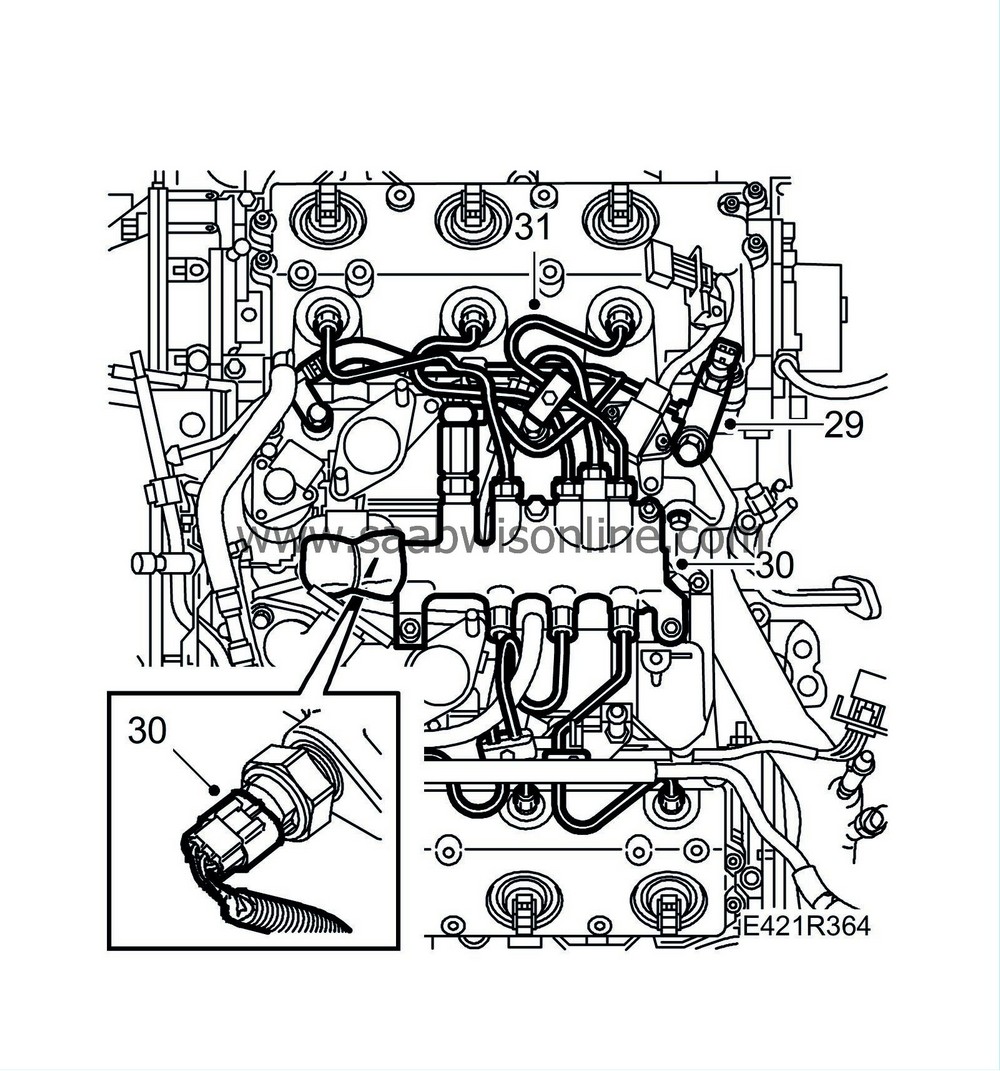

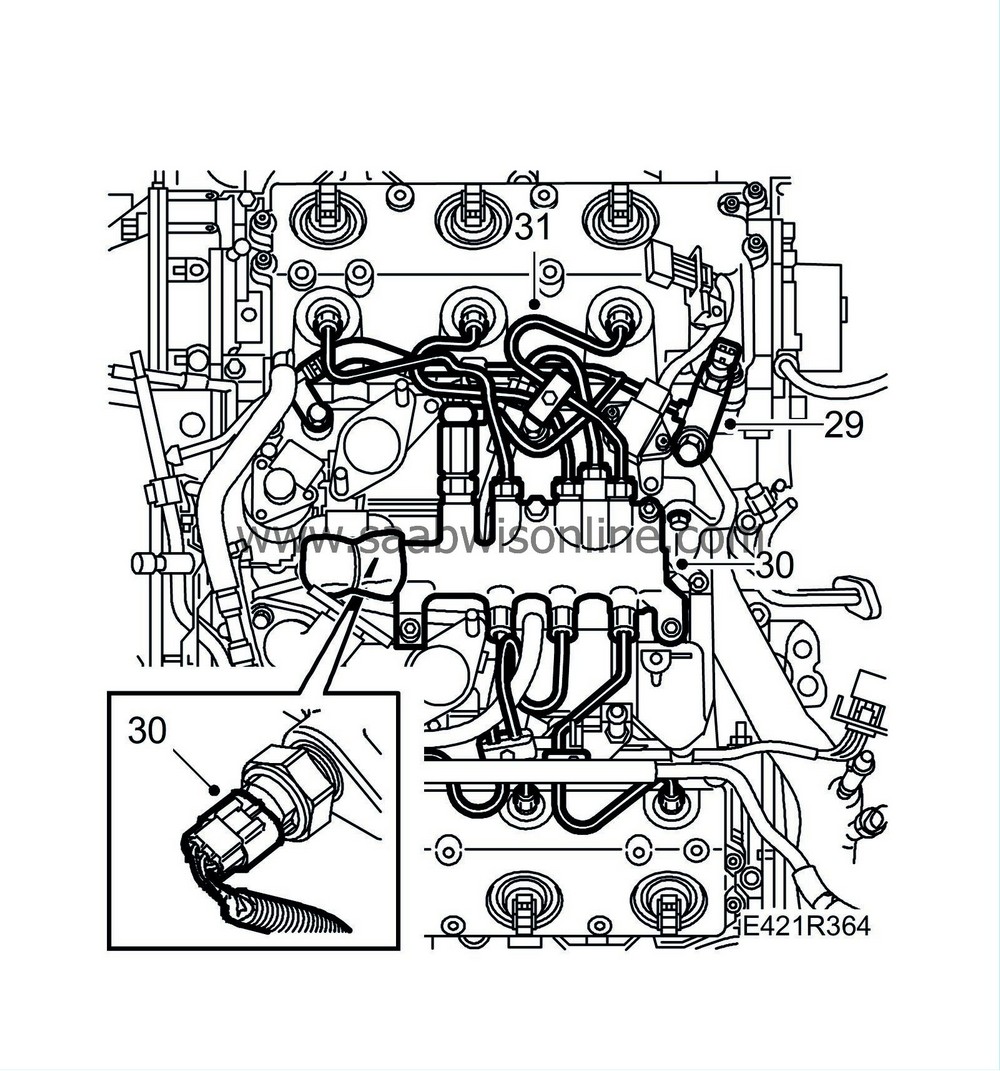

29.

|

Fit a new fuel delivery pipe for the fuel pressure sensor with bracket (banjo connections).

Tightening torque: 20 Nm (15 lbf ft)

|

|

30.

|

Fit the fuel rail and attach the connector.

|

|

31.

|

Fit all fuel feed pipes with holders. Use new pipes.

Tightening torque, banjo bolts 30 Nm (22 lbf ft)

|

|

32.

|

Fit the engine harness's cable ducts and the engine harness. Attach the connector.

|

|

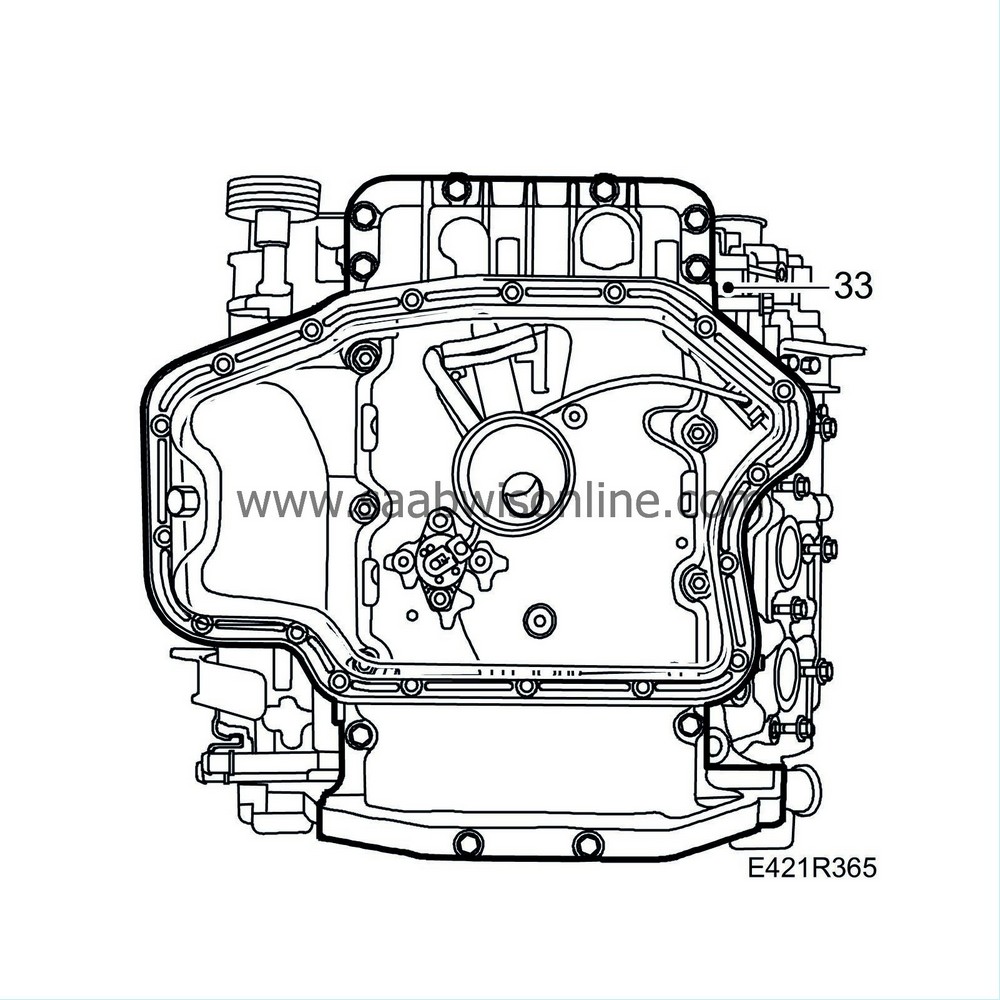

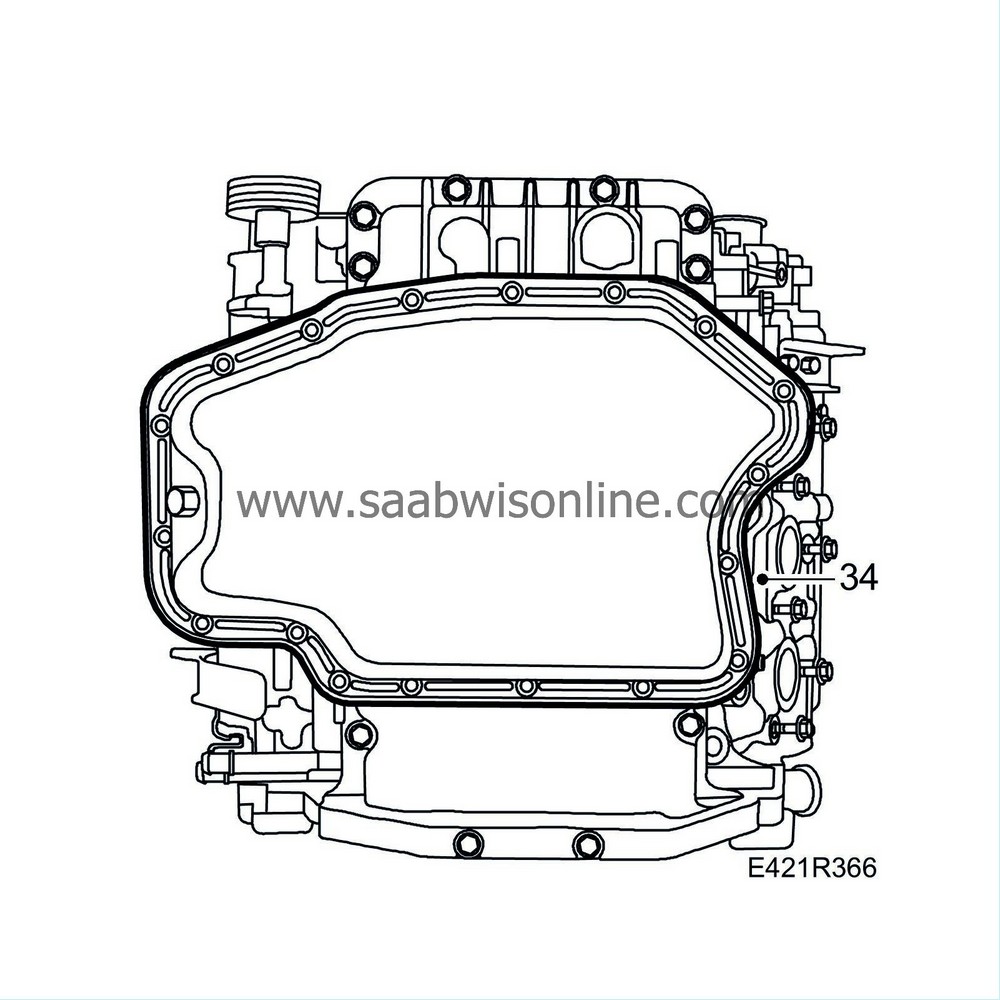

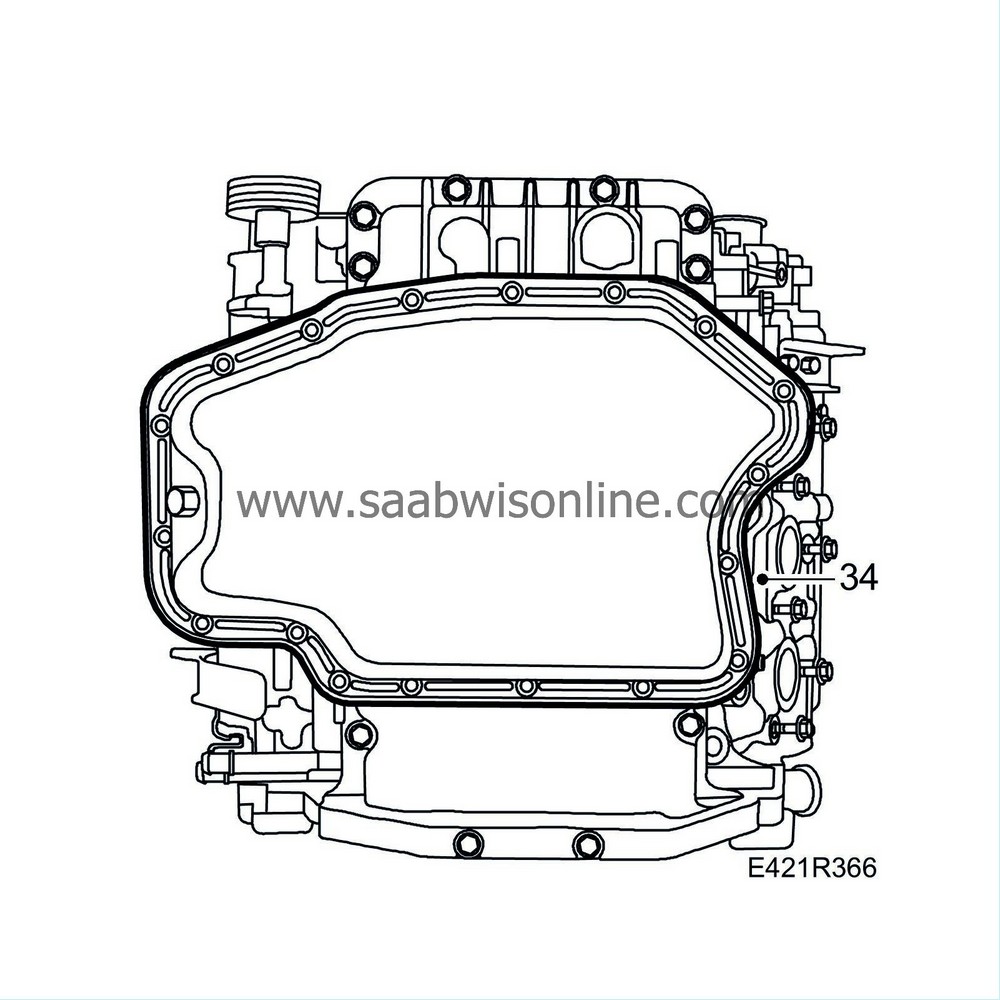

34.

|

Apply a 2 mm bead of

87 81 841 Silicon flange sealant

on the upper oil sump's seal faces and fit the sheet metal oil sump.

Tightening torque: 9 Nm (7 lbf ft)

|

|

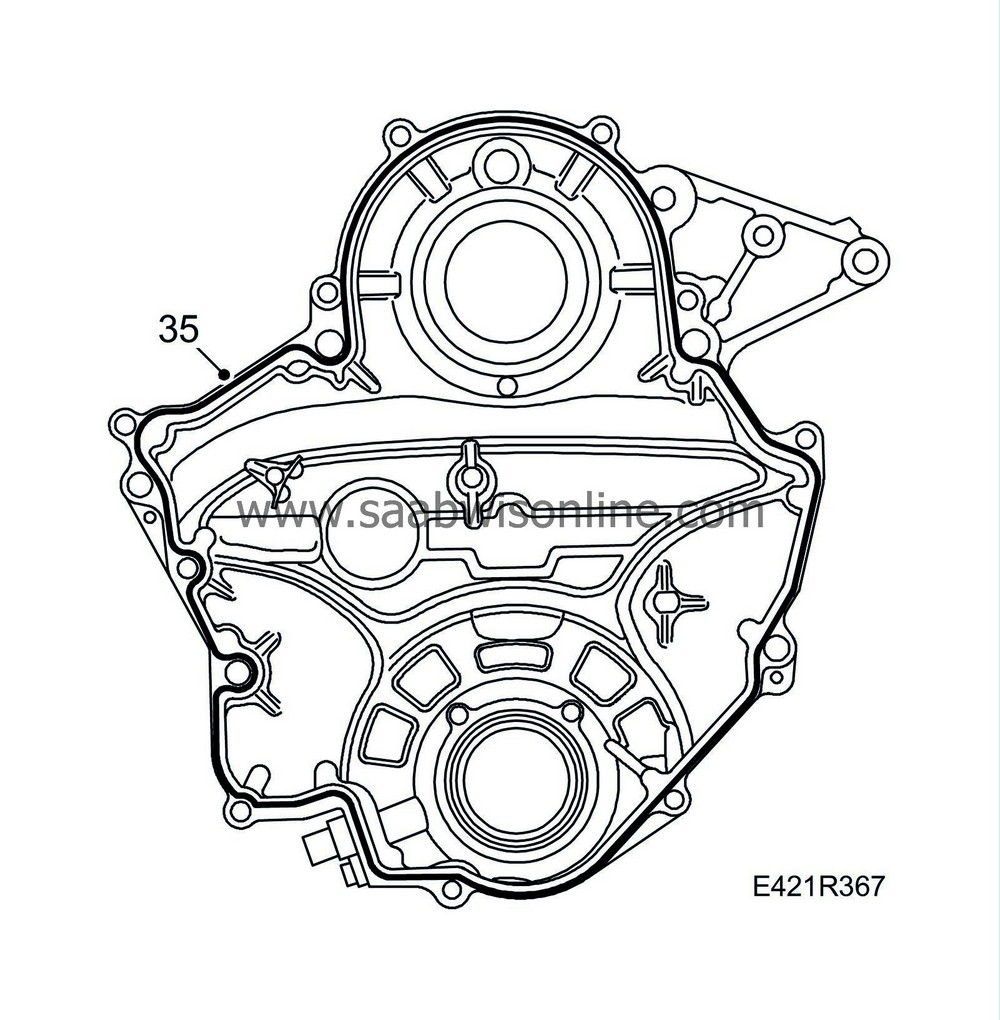

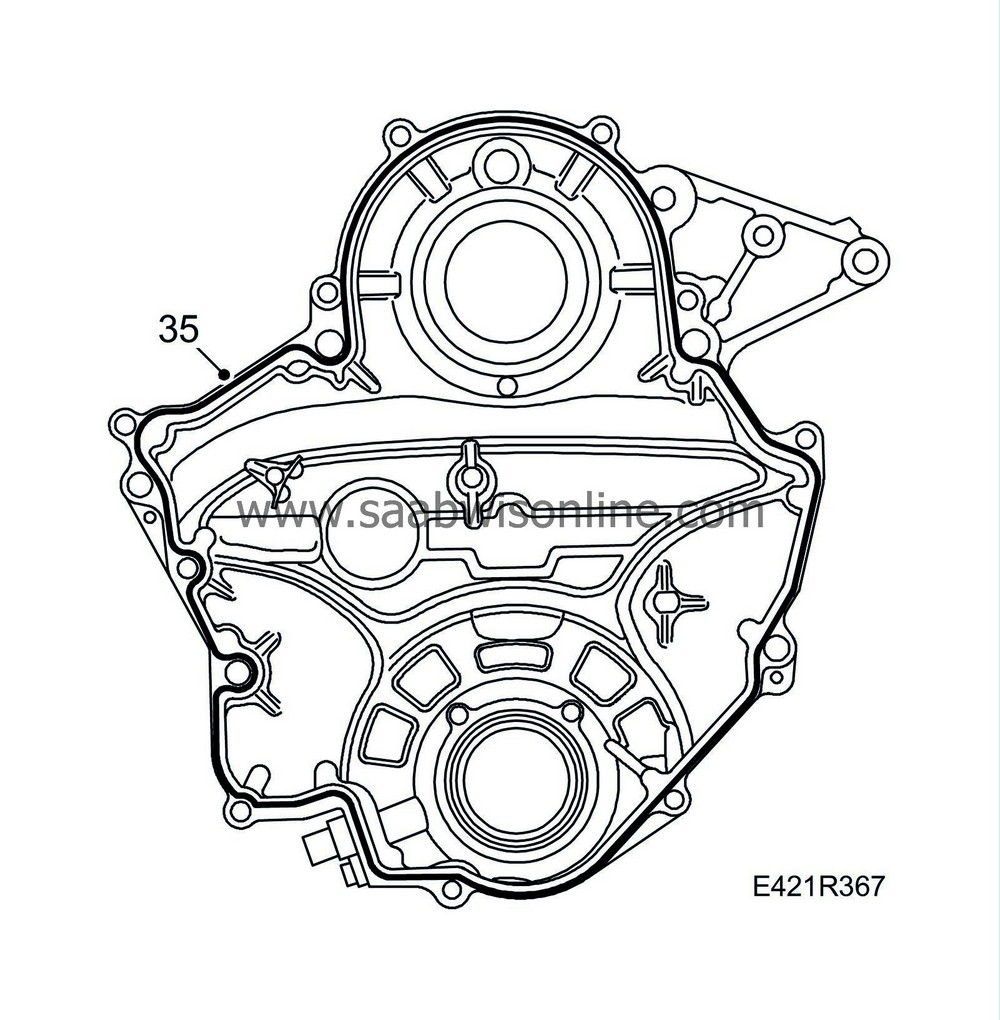

35.

|

Apply a 2 mm bead of

87 81 841 Silicon flange sealant

on the inner timing cover's seal faces and fit the outer timing cover.

Tightening torque: 25 Nm (18 lbf ft)

|

|

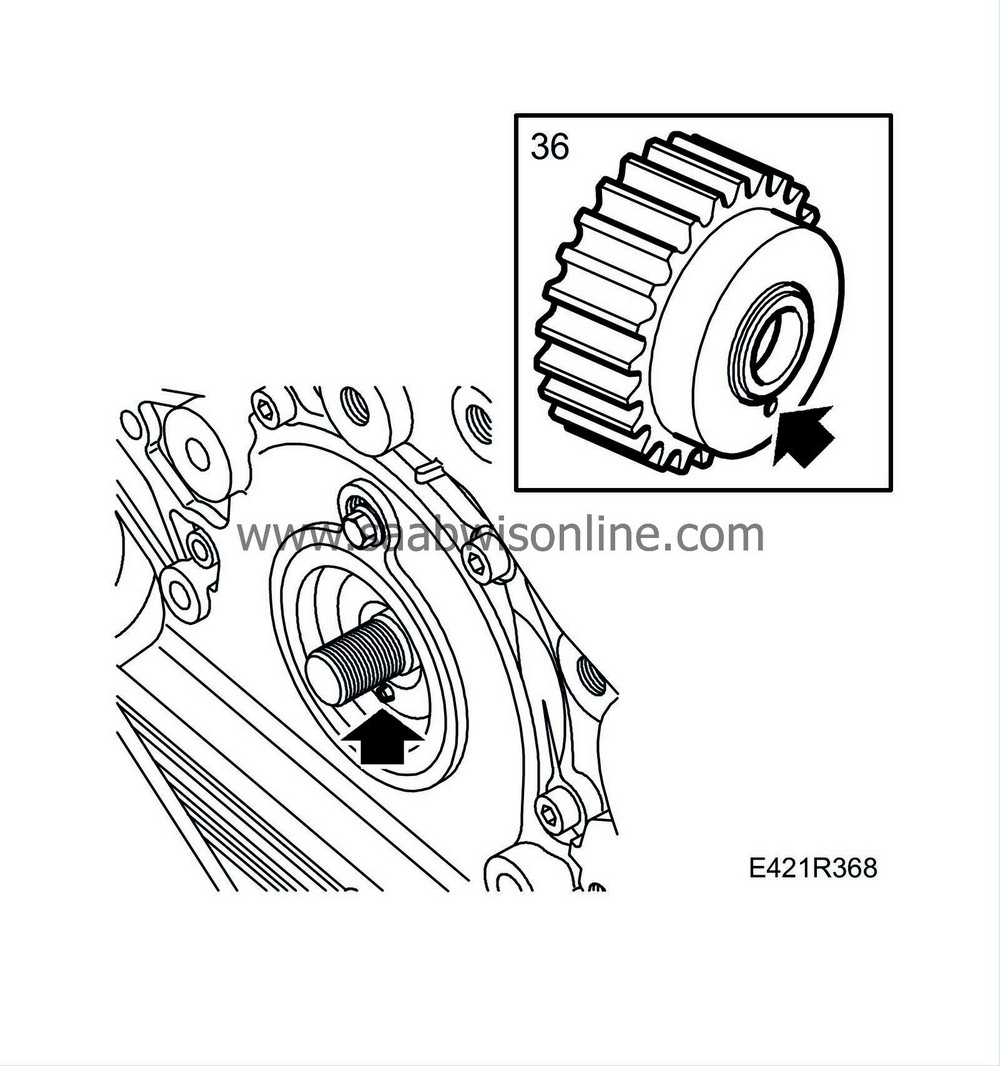

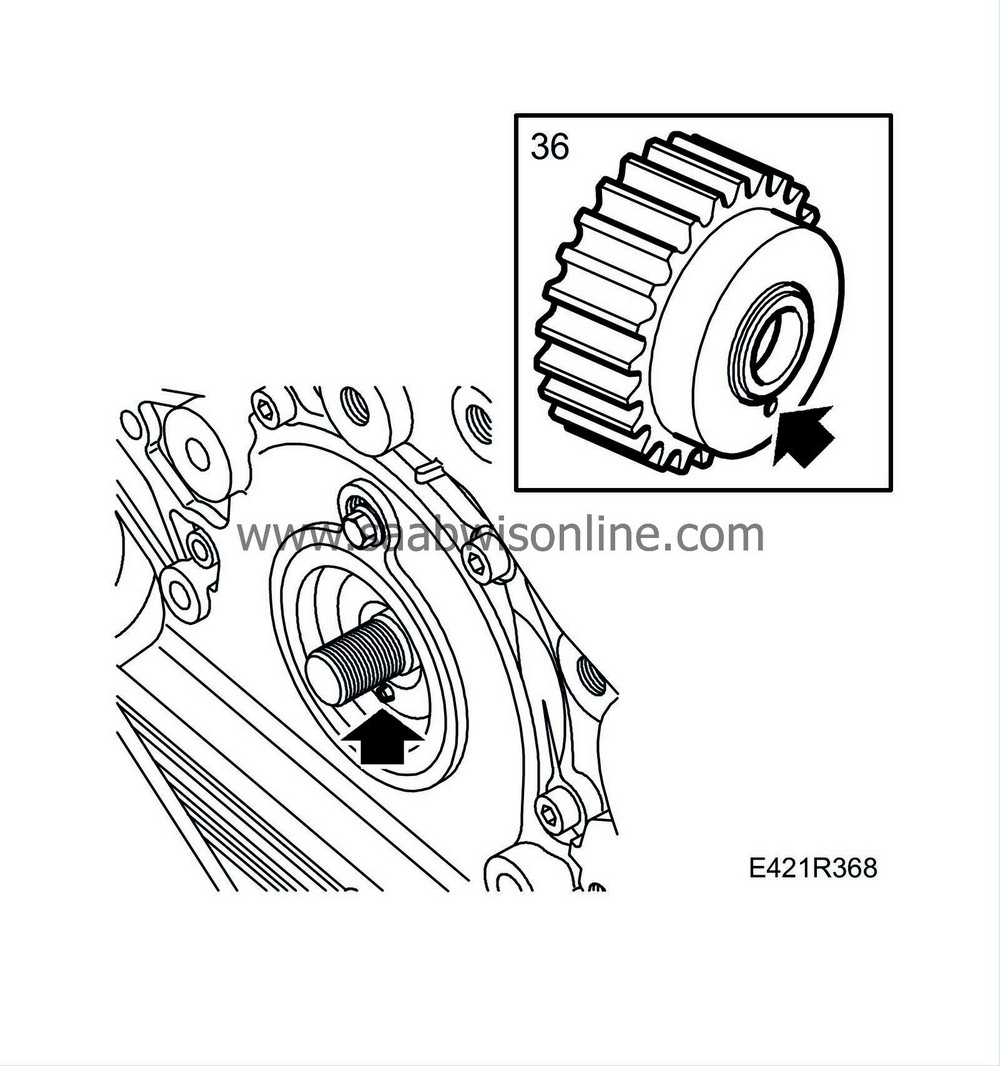

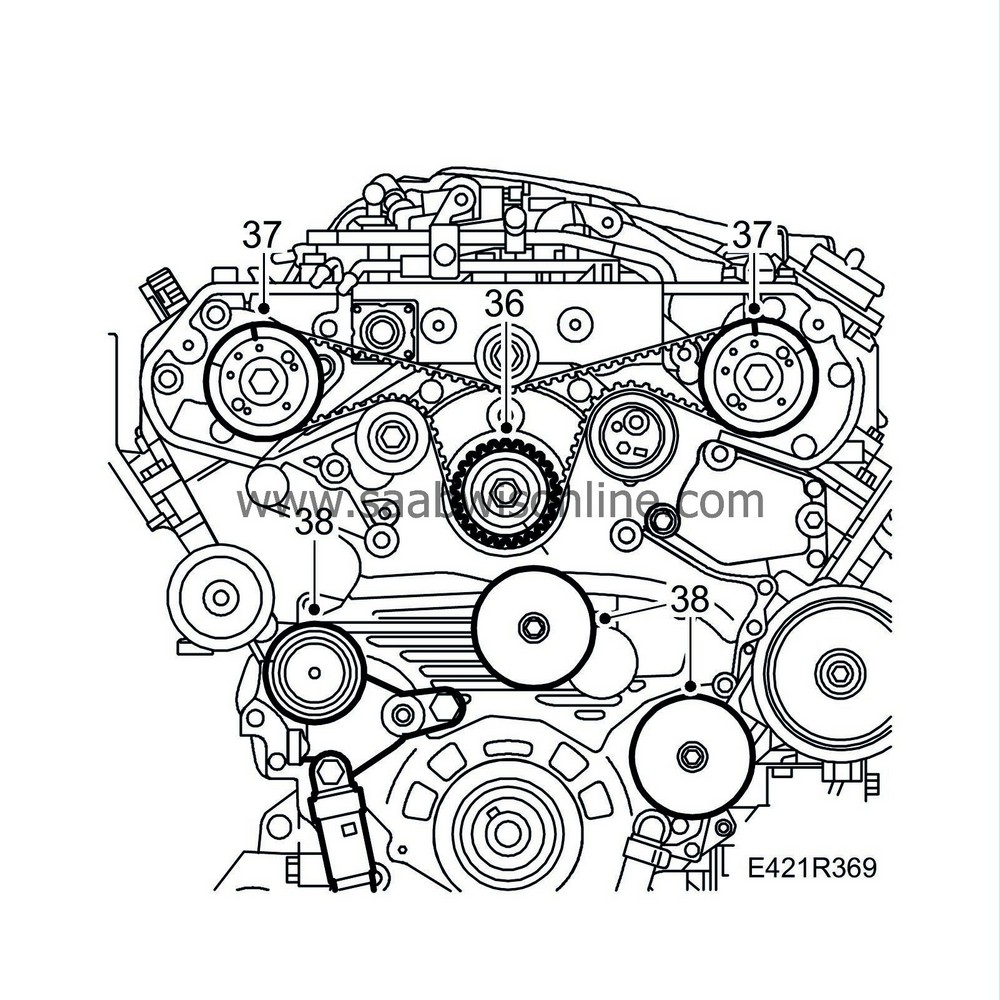

36.

|

Fit the fuel pump's pinion on the shaft. Check that the markings correspond. Use

EN-47646 Holding tool, fuel pump

. Remove the holding tool after tightening.

Tightening torque: 160 Nm (118 lbf ft)

|

|

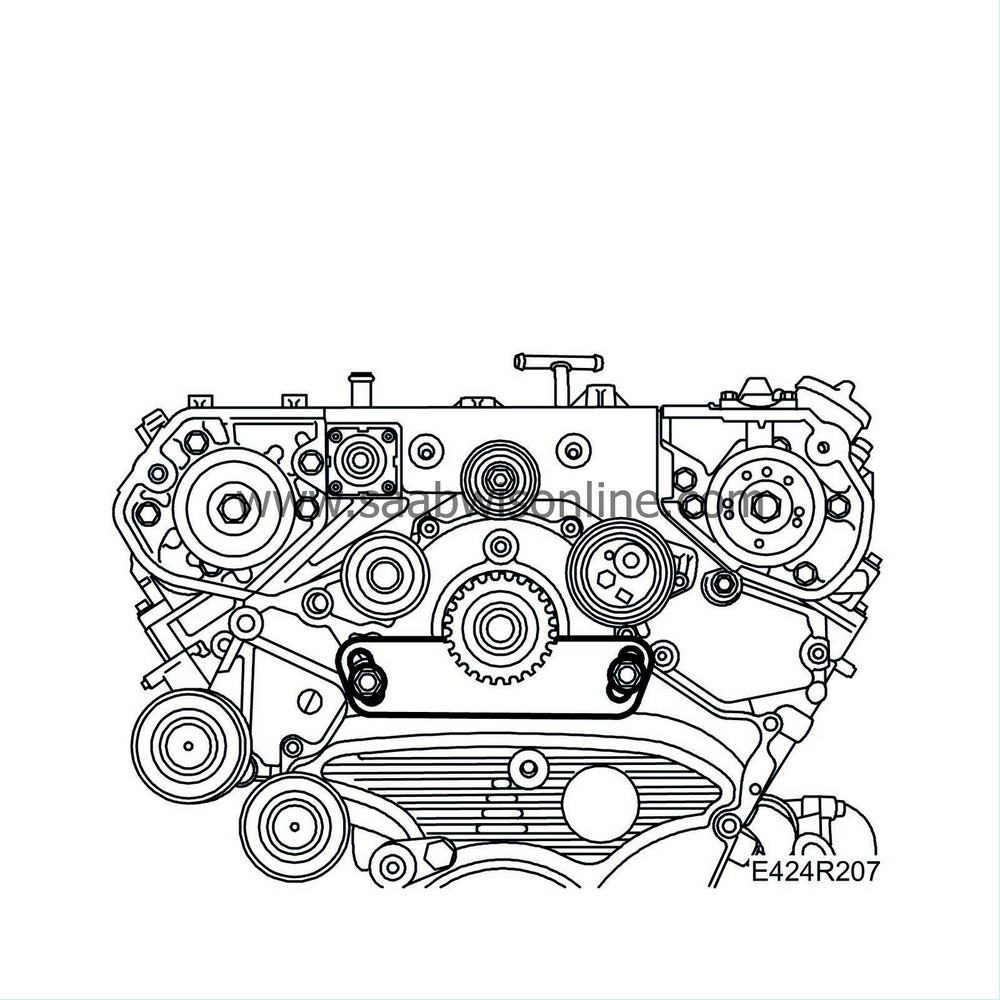

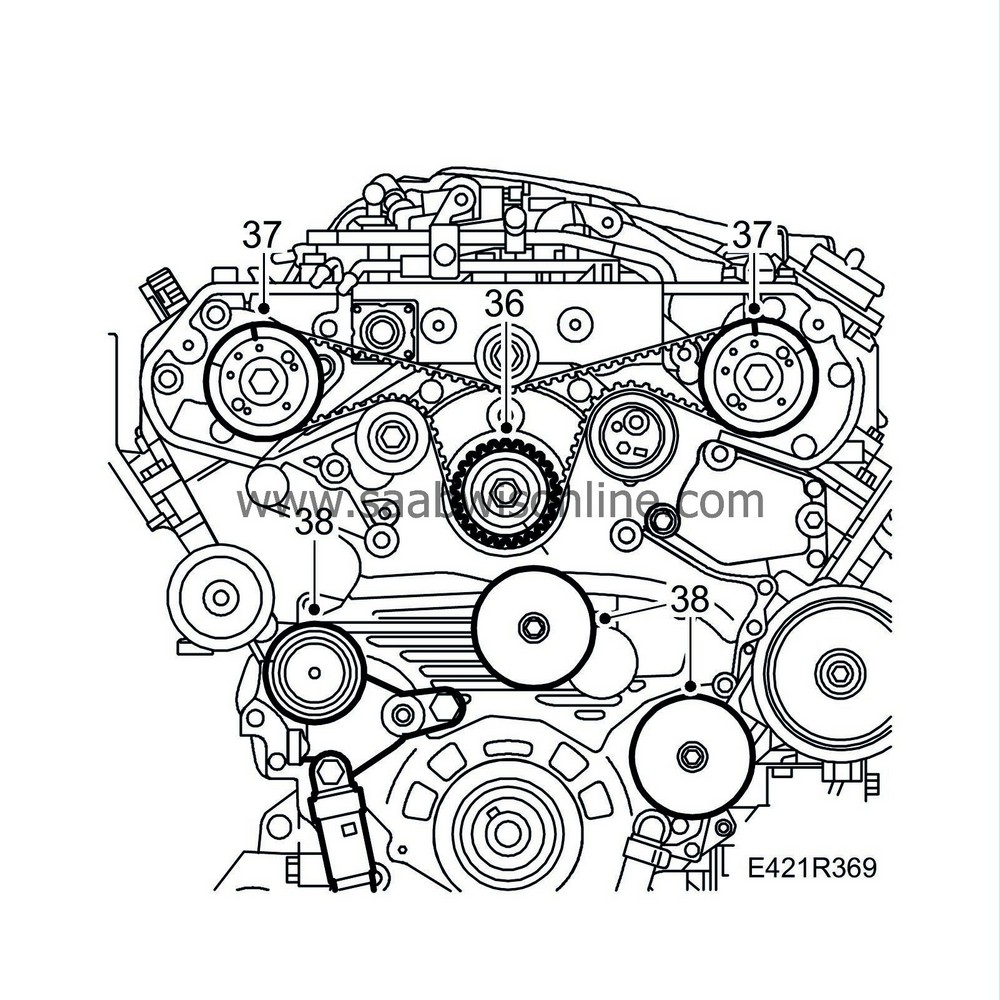

37.

|

Fit the idler pulleys for the timing belt.

Tightening torque: 50 Nm (37 lbf ft)

|

|

38.

|

Fit the idler pulley, belt tensioner and belt pulley for the auxiliary equipment belt circuit.

Tightening torque, idler pulley with smooth surface 58 Nm (48 lbf ft)

Tightening torque, idler pulley with multigroove V 50 Nm (37 lbf ft)

|

|

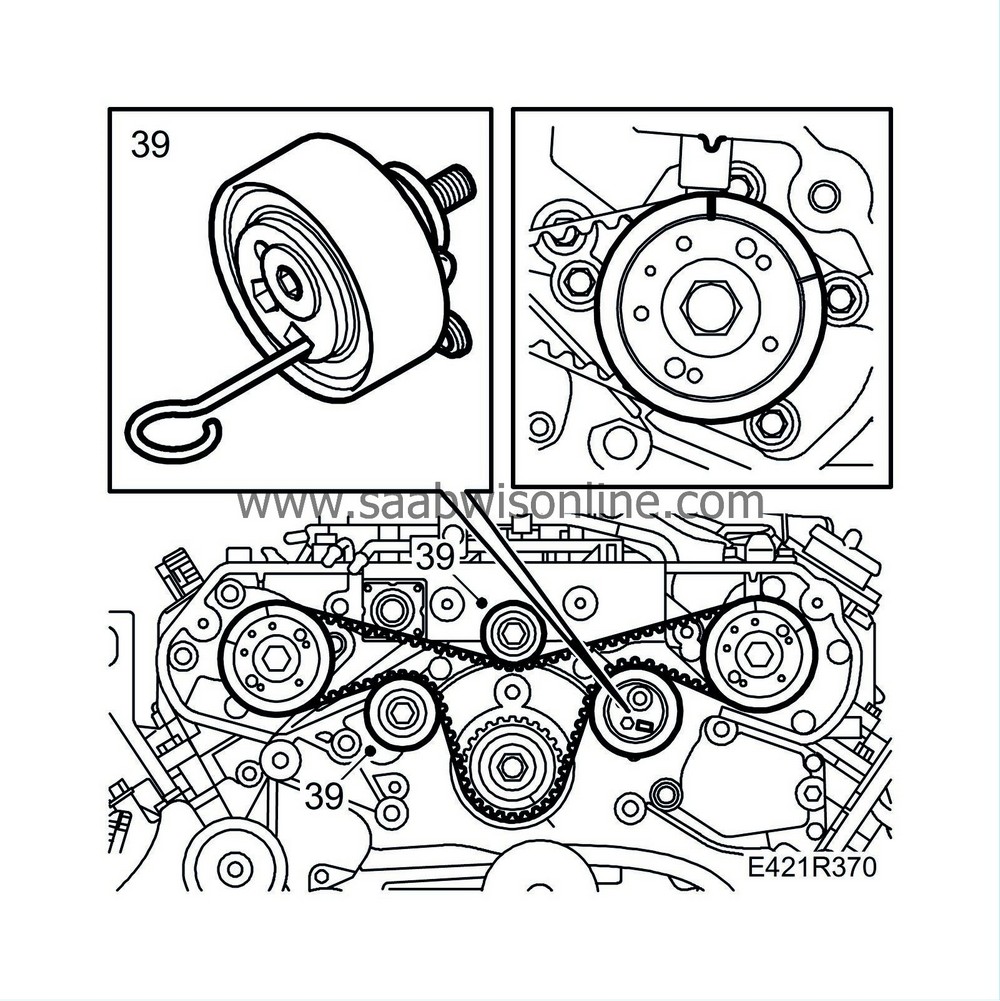

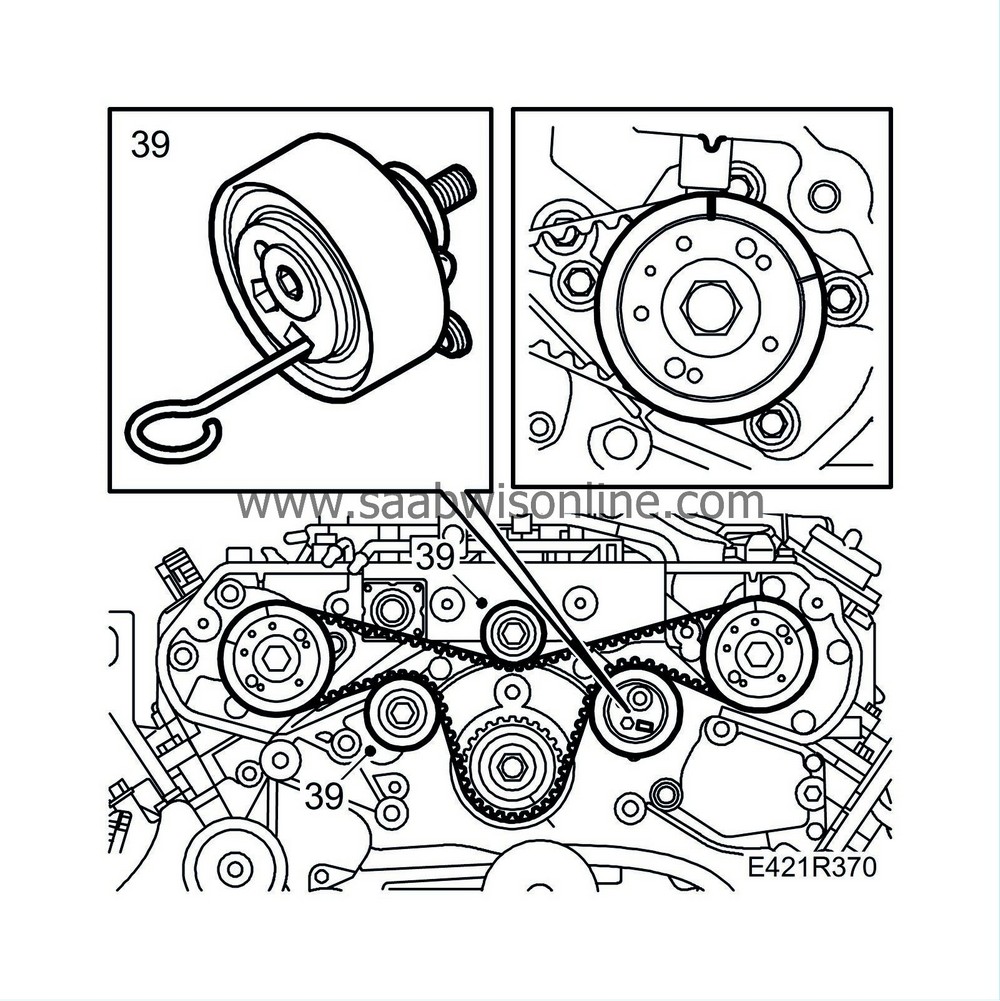

39.

|

Release the tension of the belt tensioner slowly and carefully in a vice and fit the locking pin. Fit the belt tensioner. Fit the belts so the markings coincide with the markings on the belt pulleys. Fit the idler pulleys and remove the locking pin.

Tightening torque, belt tensioner 43 Nm (32 lbf ft)

|

|

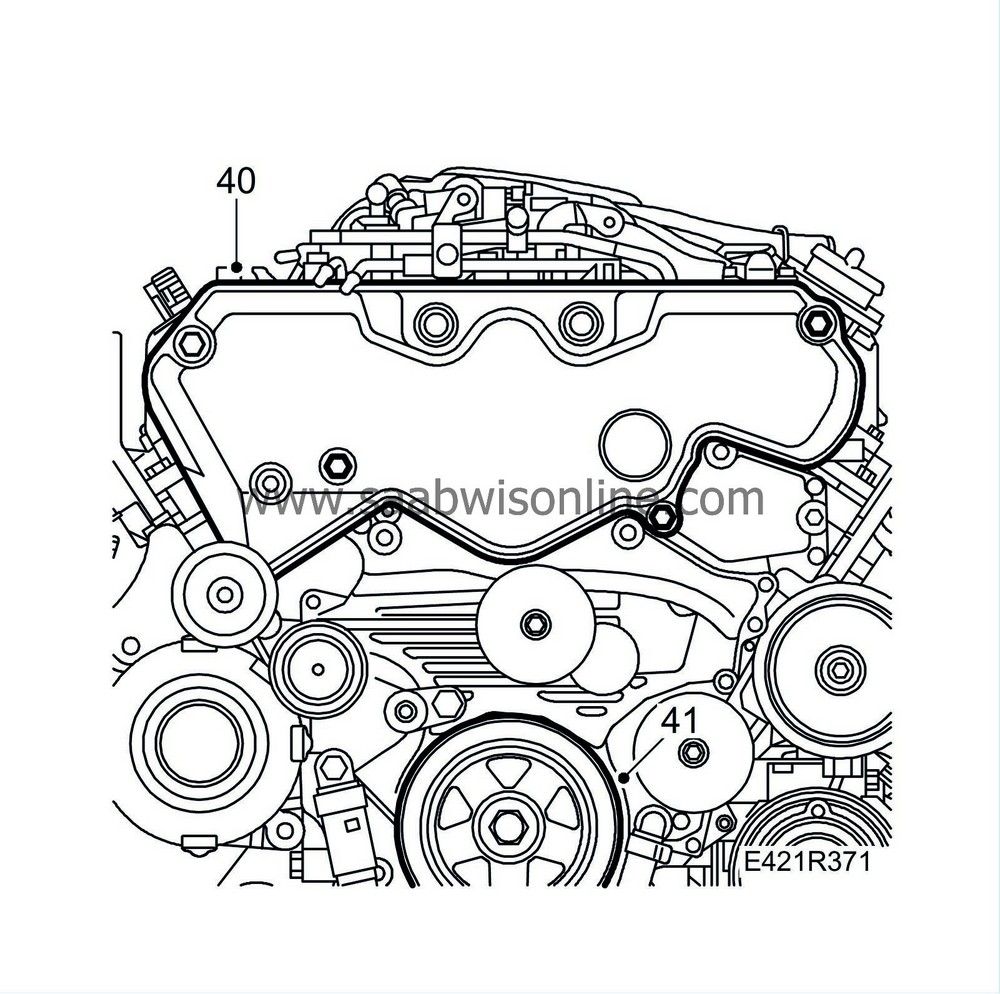

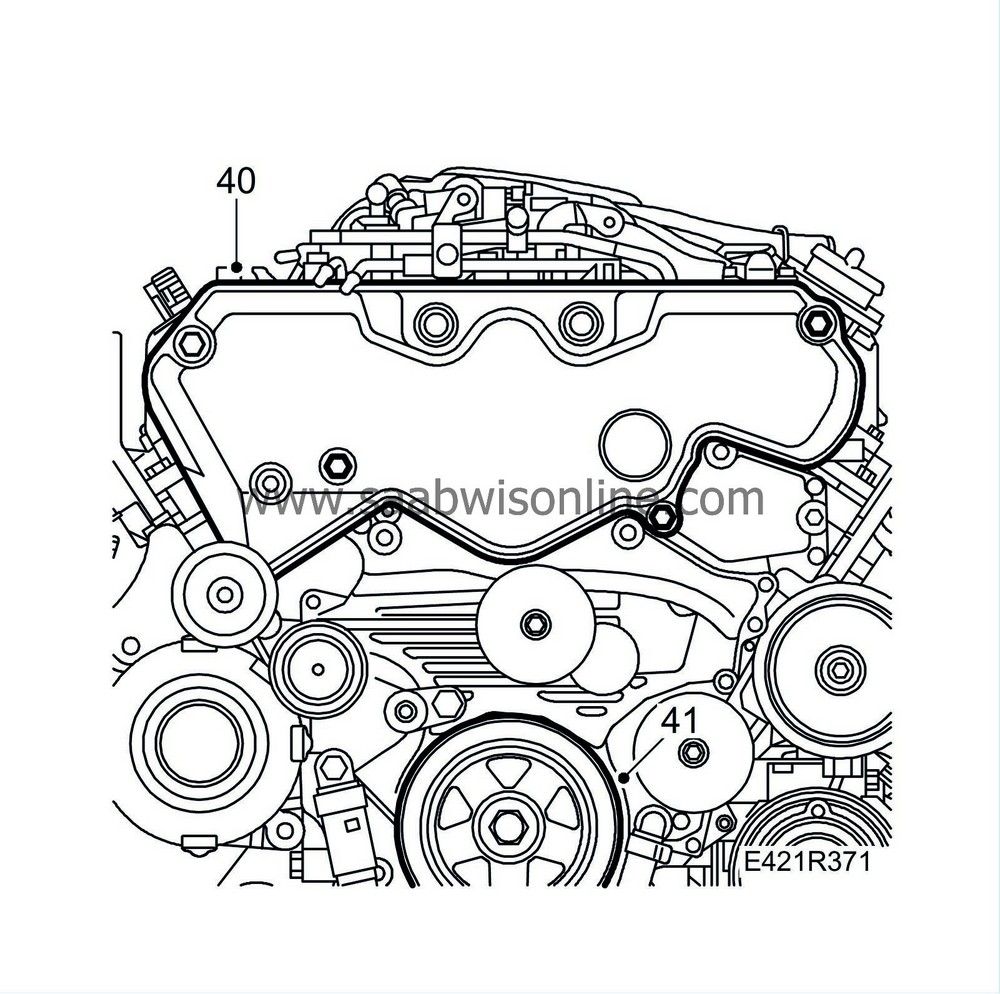

40.

|

Fit the timing belt cover.

Tightening torque: 25 Nm (18 lbf ft)

|

|

41.

|

Fit the belt pulley to the crankshaft.

Tightening torque: 235 Nm (173 lbf ft)

|

|

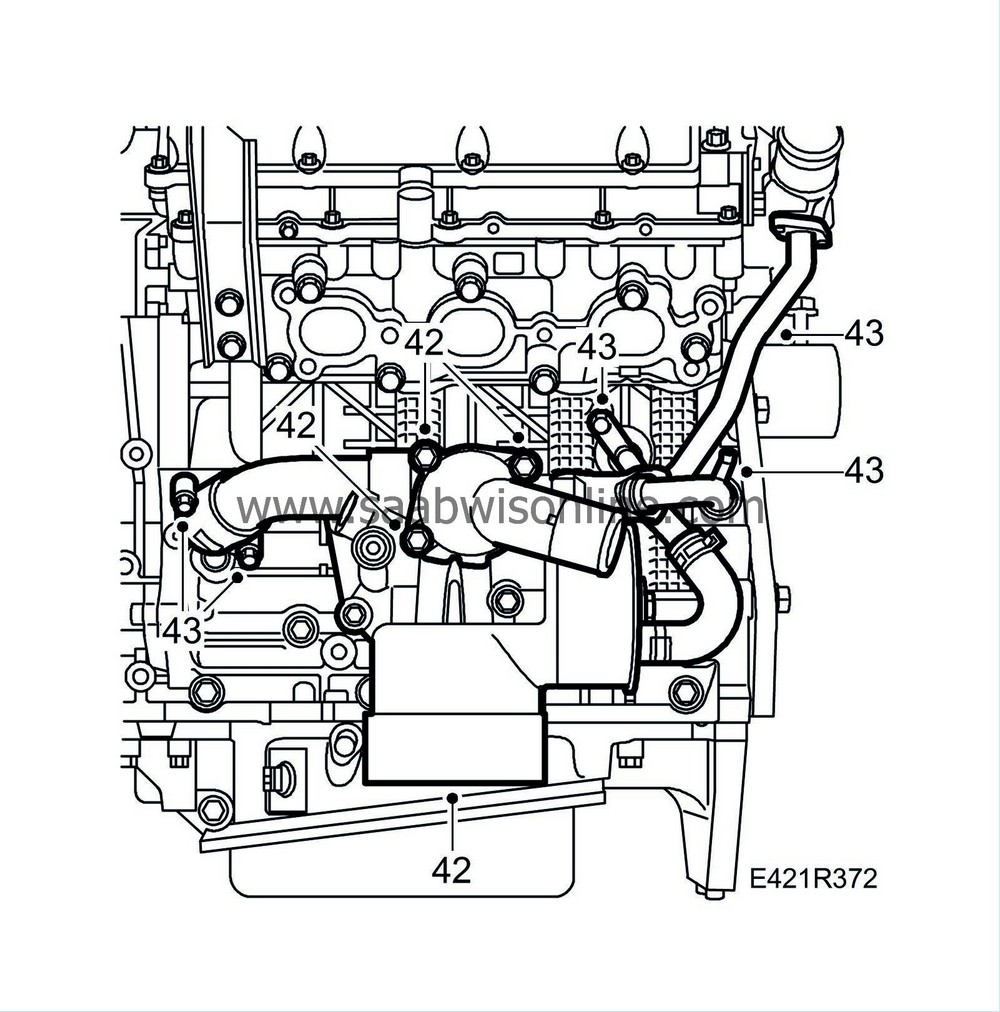

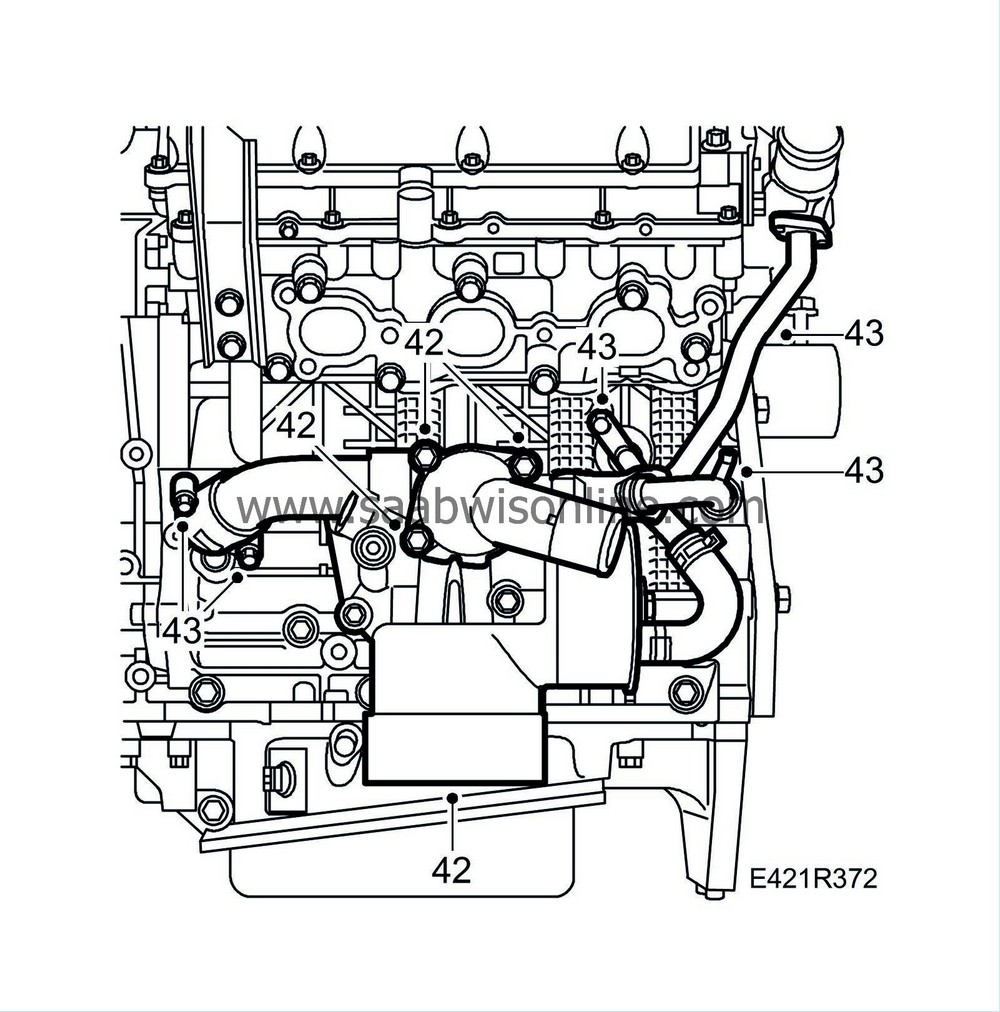

42.

|

Fit the oil filter housing and the thermostat housing.

Tightening torque: 25 Nm (18 lbf ft)

|

|

43.

|

Fit the water and oil pipes to the thermostat and oil filter housings.

|

|

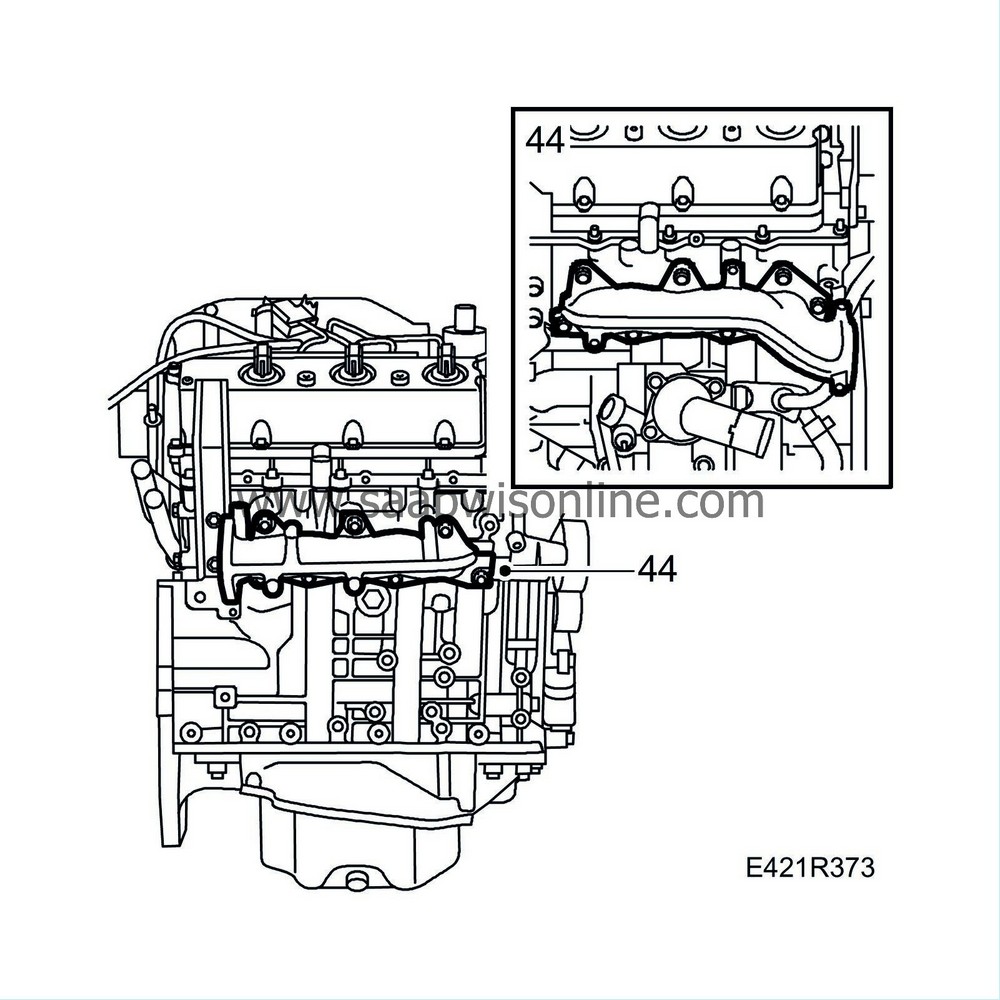

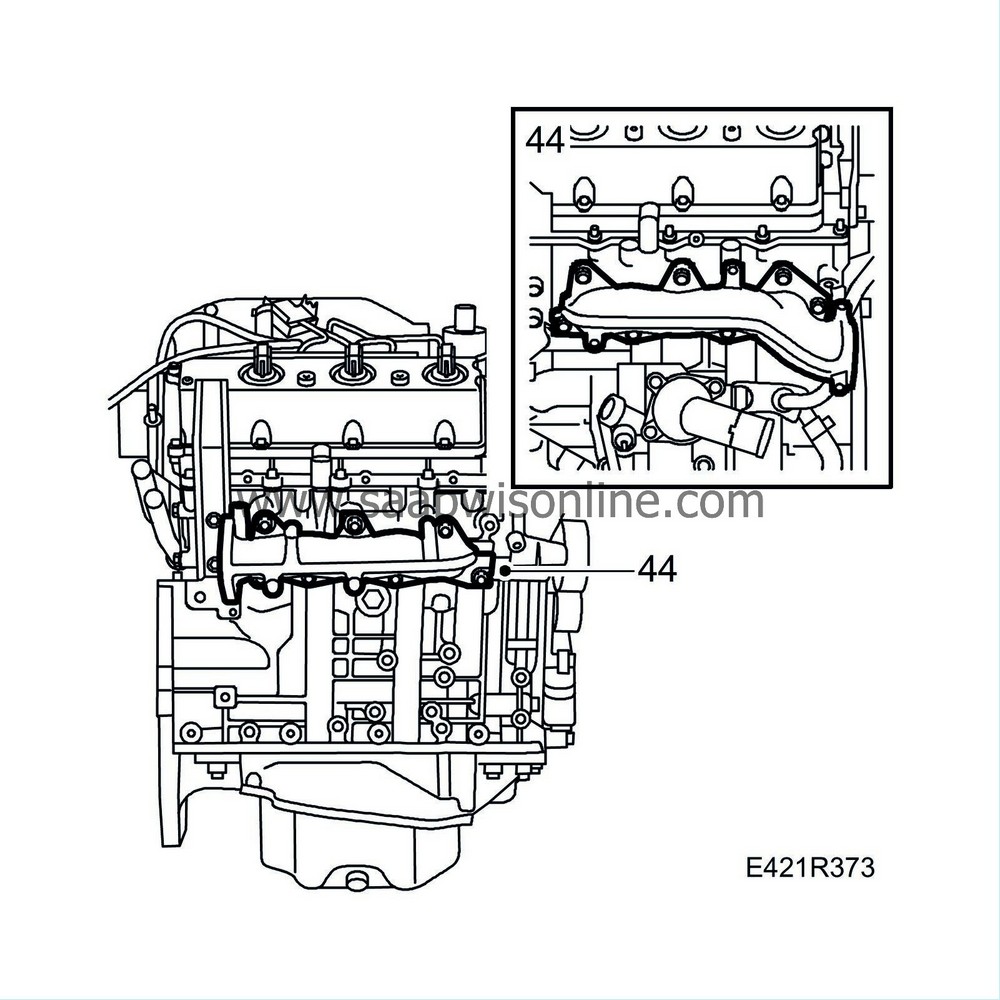

44.

|

Fit the rear and front exhaust manifolds.

Tightening torque: 52 Nm (38 lbf ft)

|

|

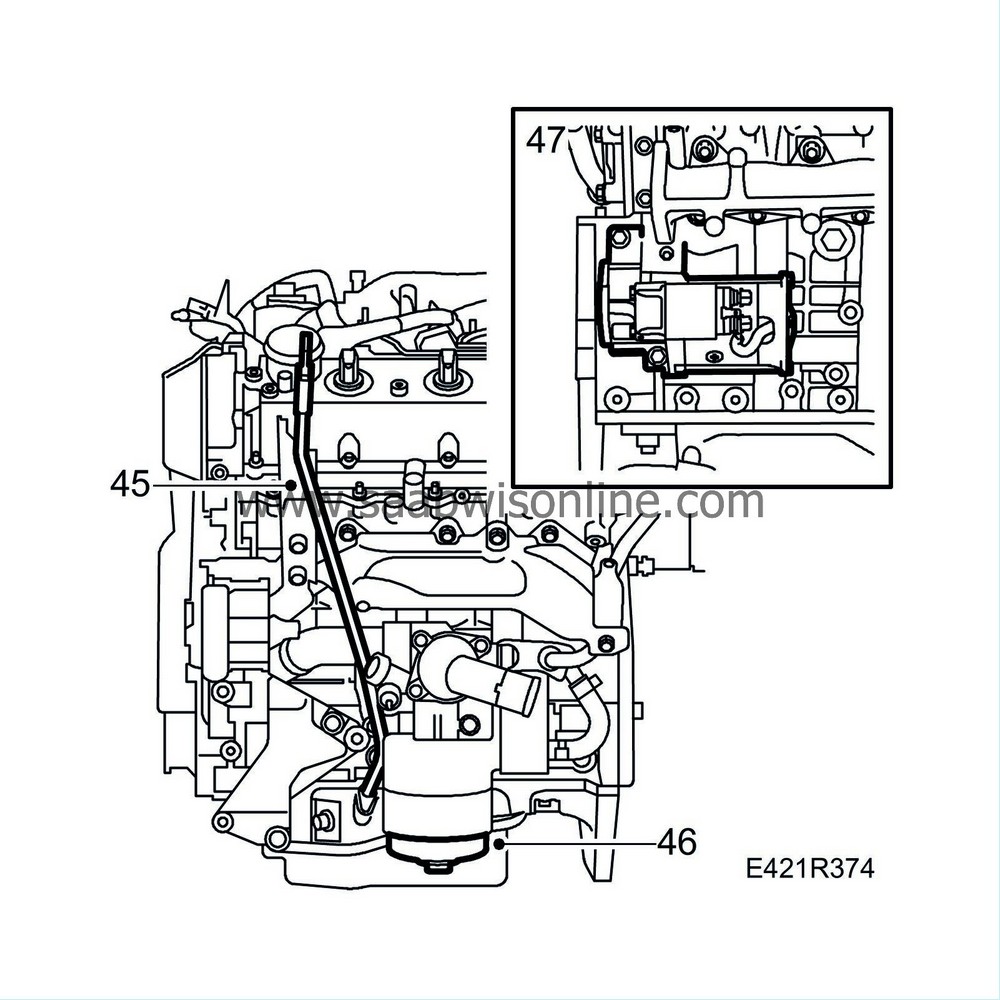

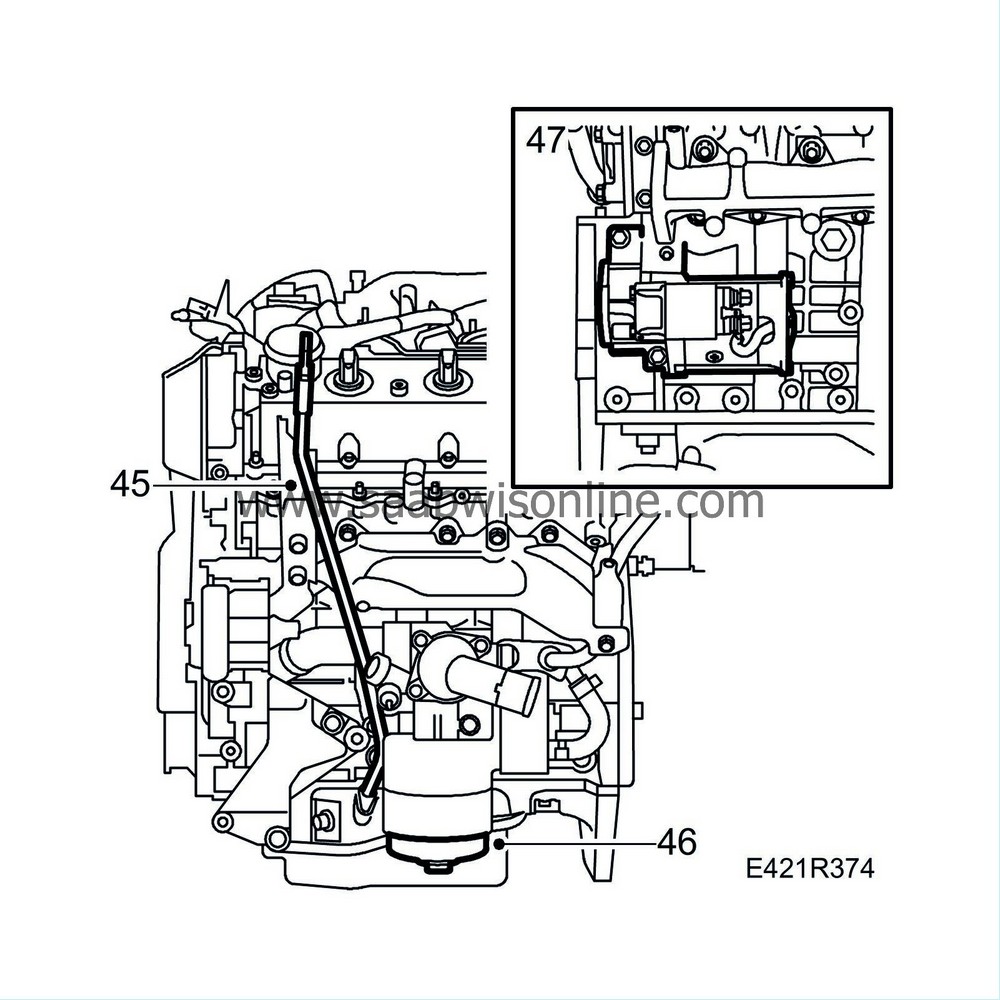

45.

|

Fit the dipstick.

|

|

47.

|

Fit the starter motor.

Tightening torque: 50 Nm (37 lbf ft)

|

|

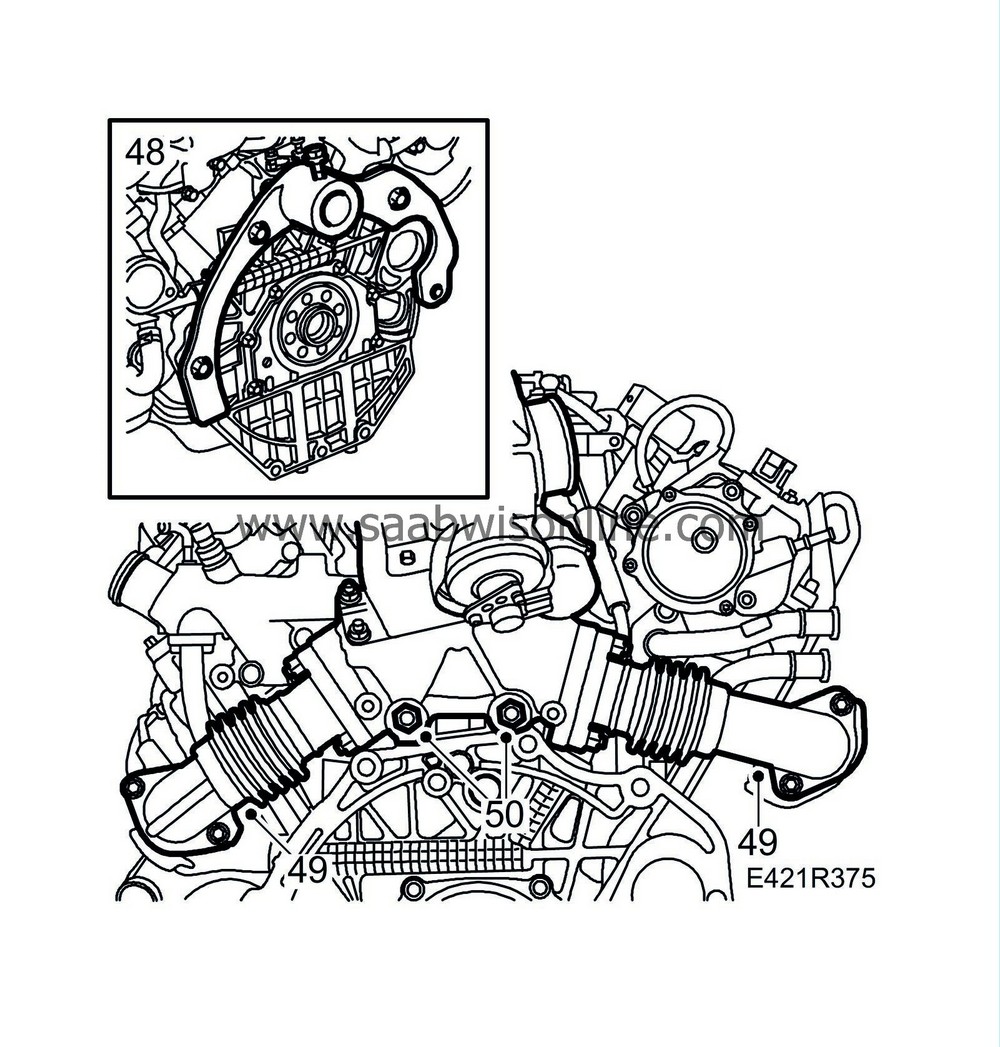

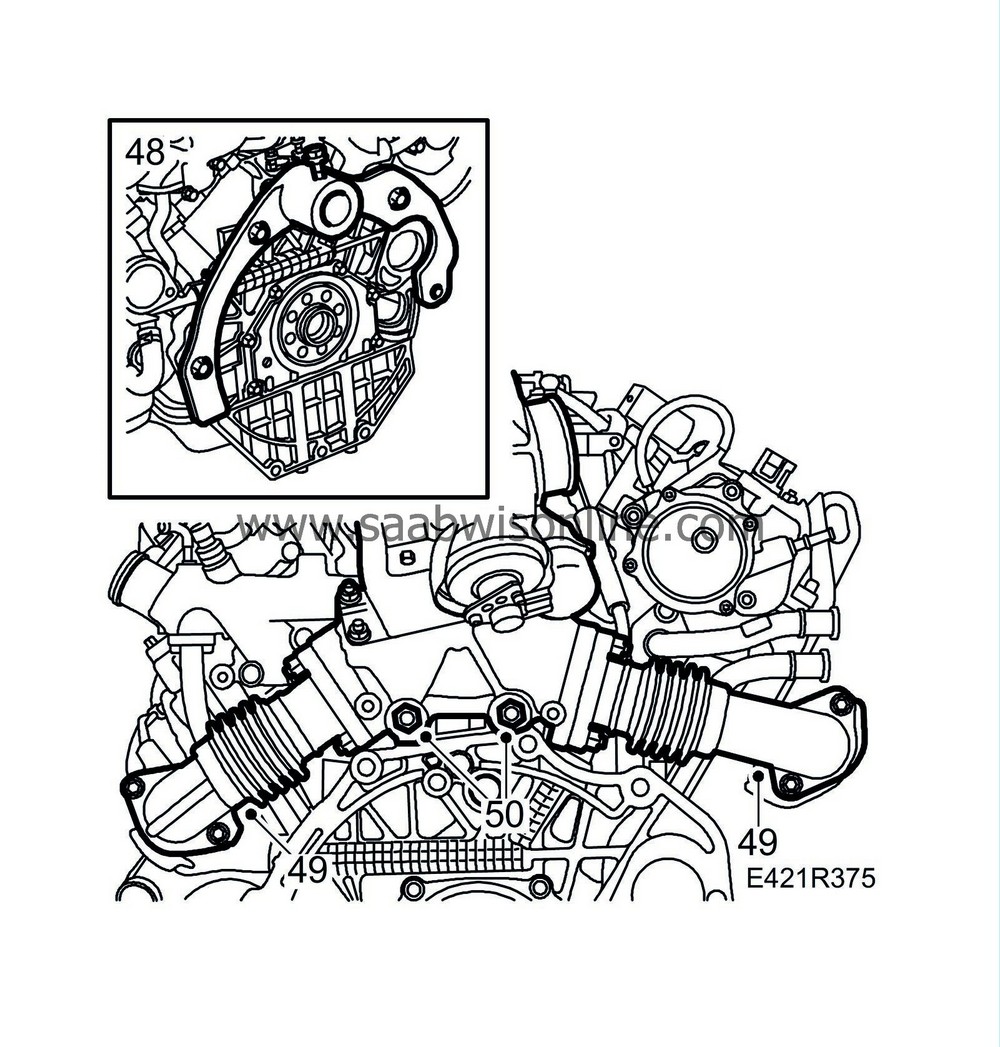

48.

|

Loosen the engine from the stand and remove bracket 83 94 751 from the engine.

|

|

49.

|

Fit the turbocharger with pipe as one unit.

Tightening torque, turbocharger's nuts 21 Nm (15 lbf ft)

|

|

50.

|

Fit the pipes of the exhaust manifold and the two large screws under the turbo.

Tightening torque: 52 Nm (38 lbf ft)

|

|

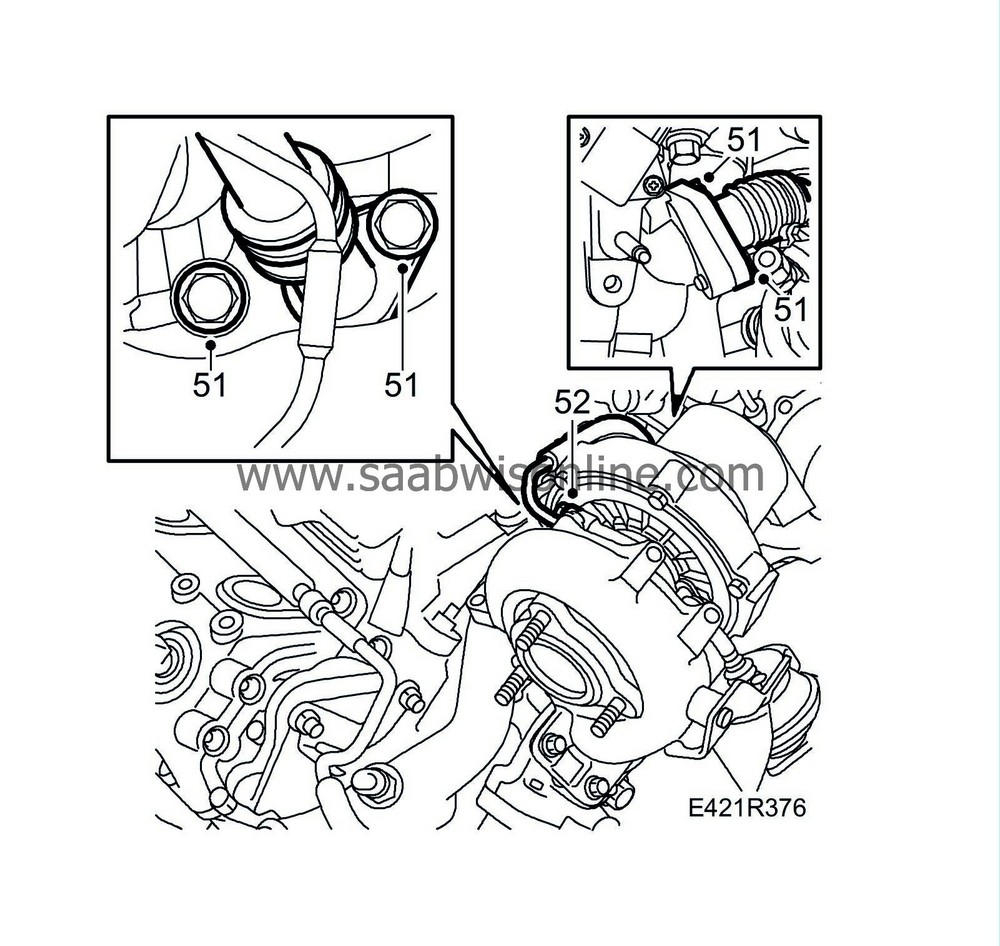

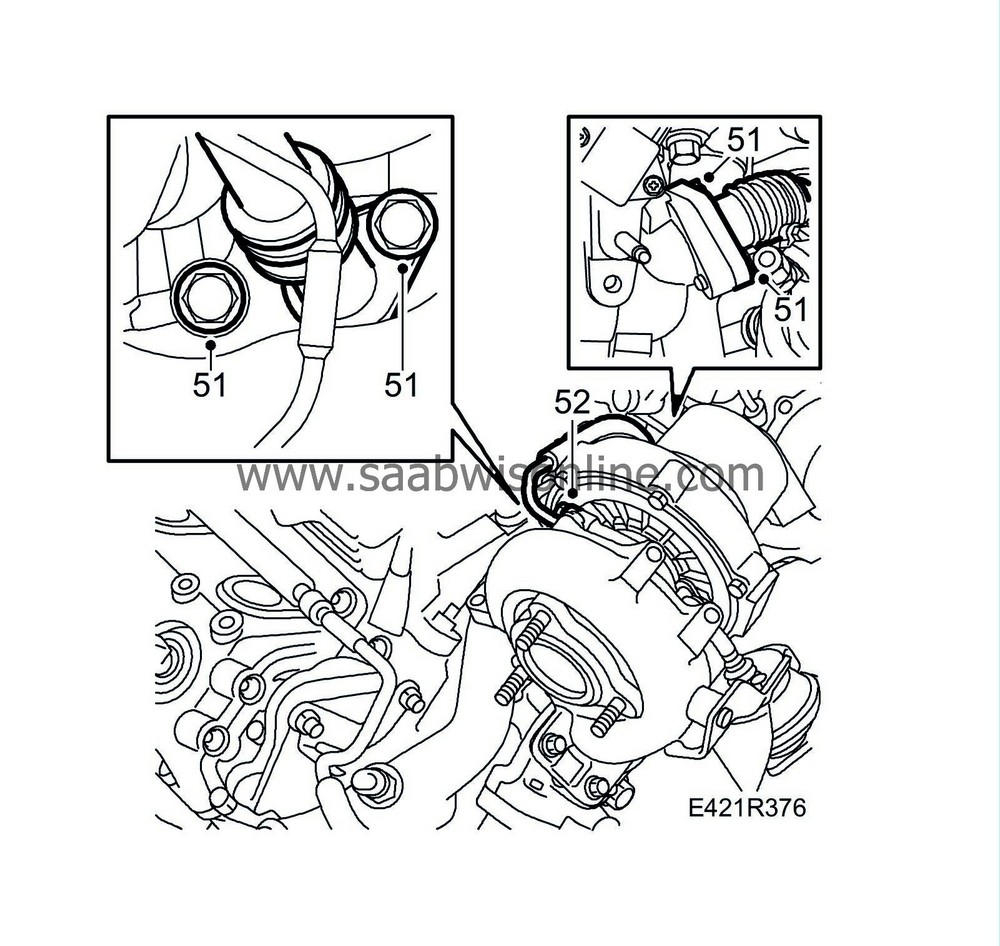

51.

|

Fit the oil pipe on the cylinder block and the EGR pipe.

|

|

52.

|

Fit the turbo bracket and the turbo's water pipe.

|

|

53.

|

Fit the heat shields on the exhaust manifold and turbo pipe.

|

|

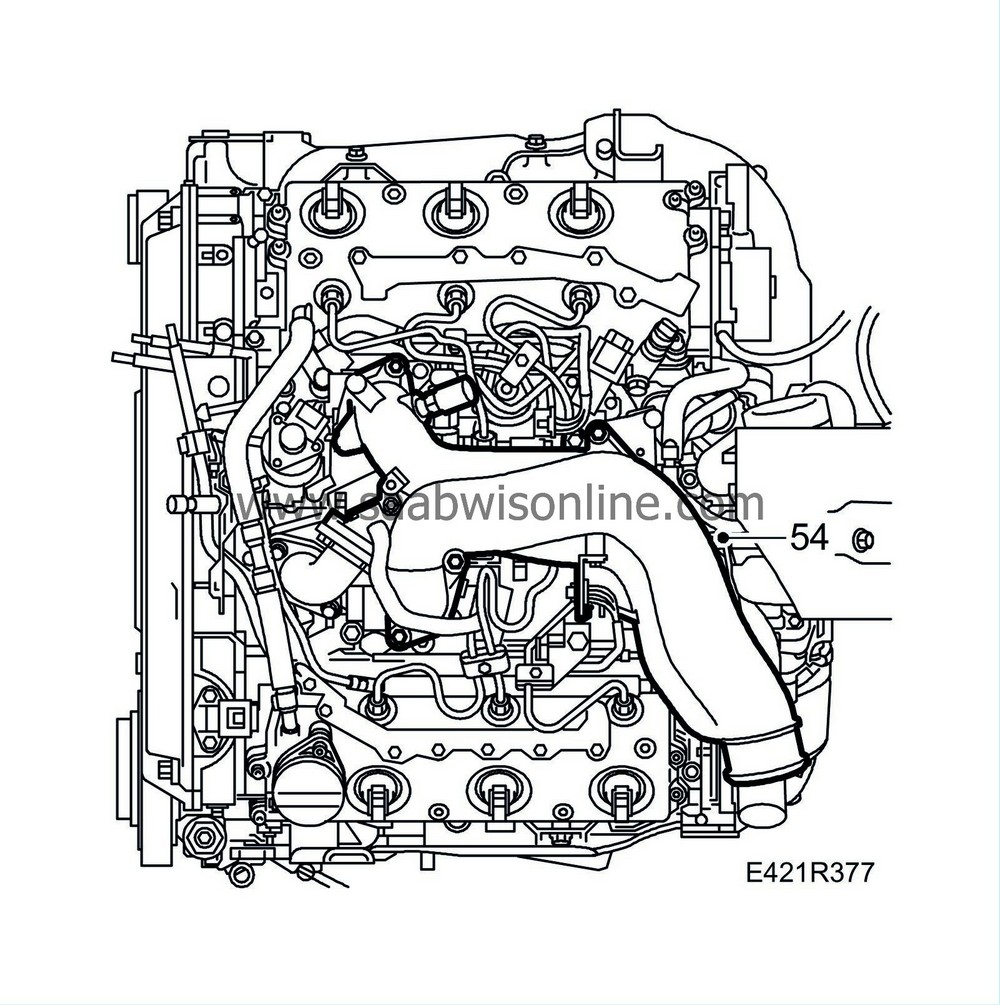

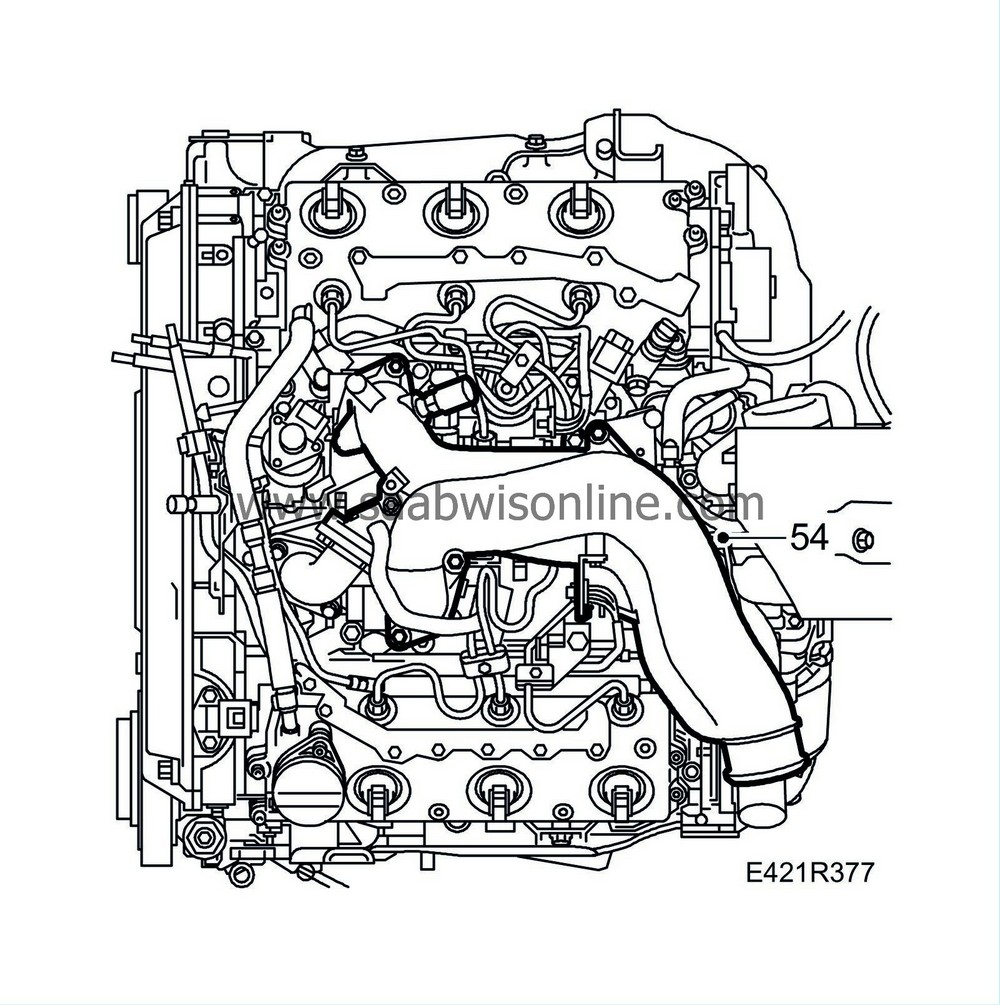

54.

|

Fit the upper intake manifold.

|

|

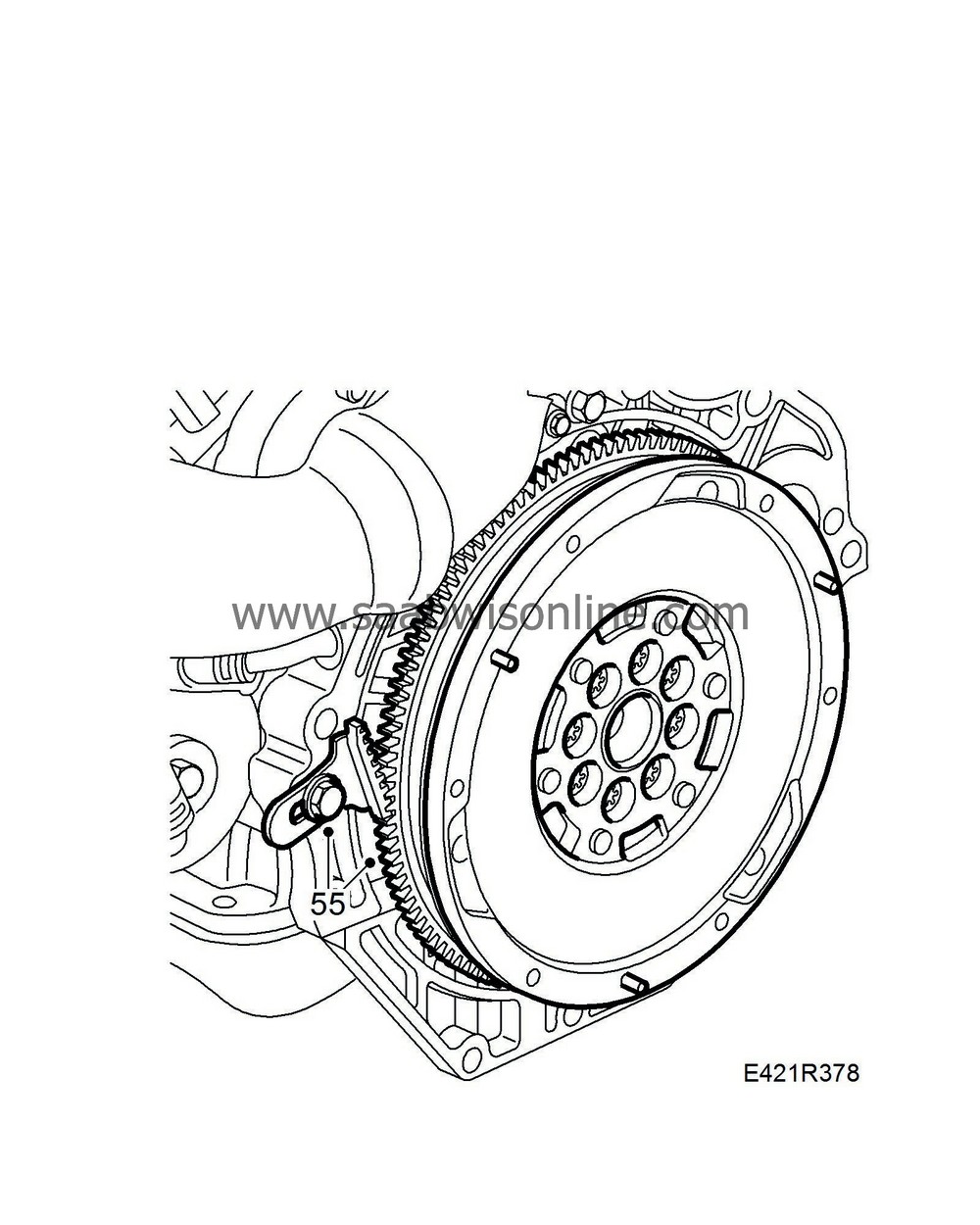

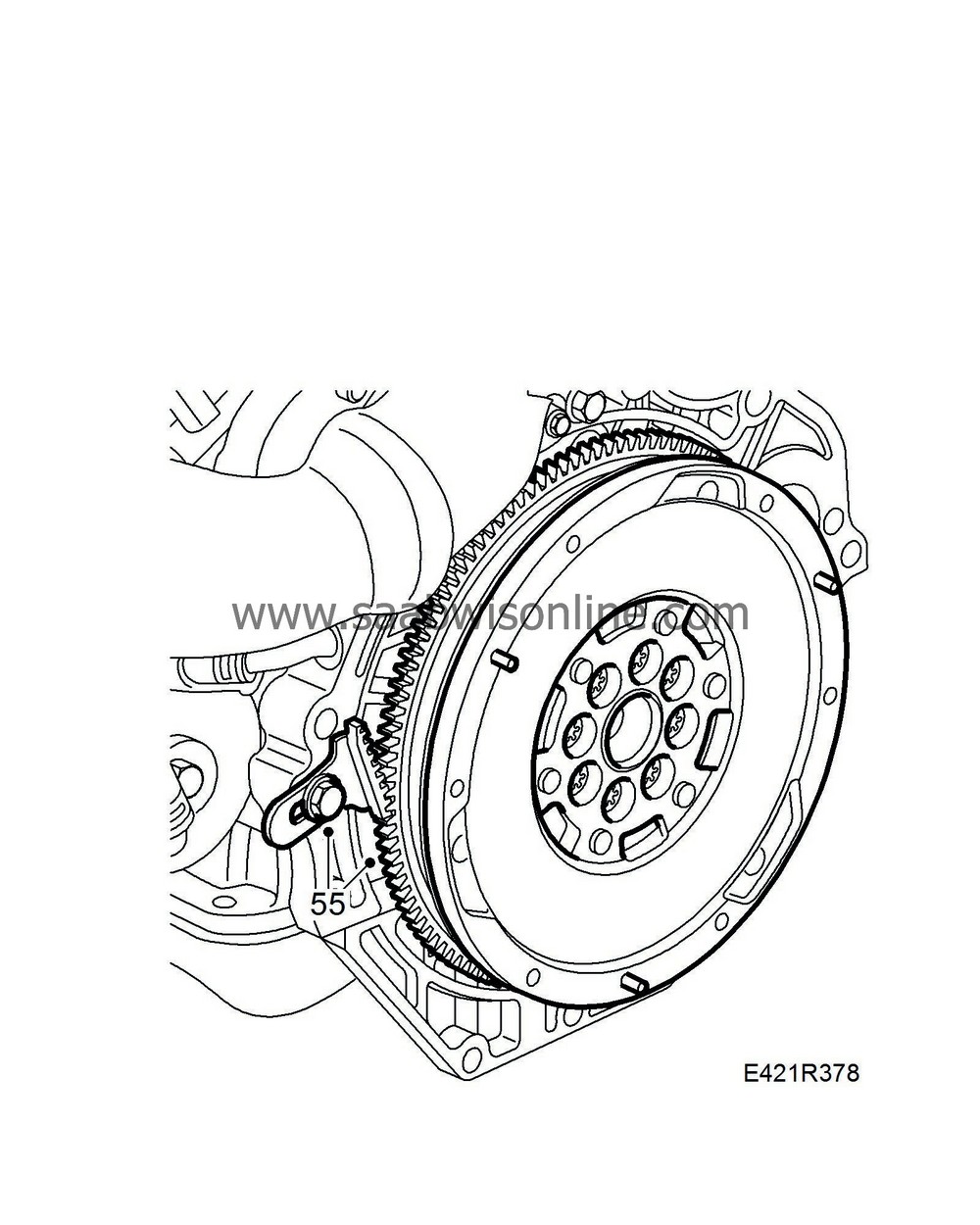

55.

|

Fit the flywheel. Tighten the bolts alternately.

Tightening torque: 118 Nm (87 lbf ft)

|

|

56.

|

Fit the gearbox and other equipment. See

Engine on subframe, removing - fitting

.

Tightening torque, side bolts and upper bolts 70 Nm (52 lbf ft)

Tightening torque, bottom bolts 40 Nm (30 lbf ft)

|