Valve adjustment

| Valve adjustment |

| To remove |

|

||||||||||||||||||||||

| Important | ||

|

Be particulary observant regardning cleanliness when working on the fuel system. Loss of function may occur due to very small particles. Prevent dirt and grime from entering the fuel system by cleaning the connections and plugging pipes and lines during disassembly. Use 82 92 948 Plugs, A/C system assembly. Keep components free from contaminants during storage. |

||

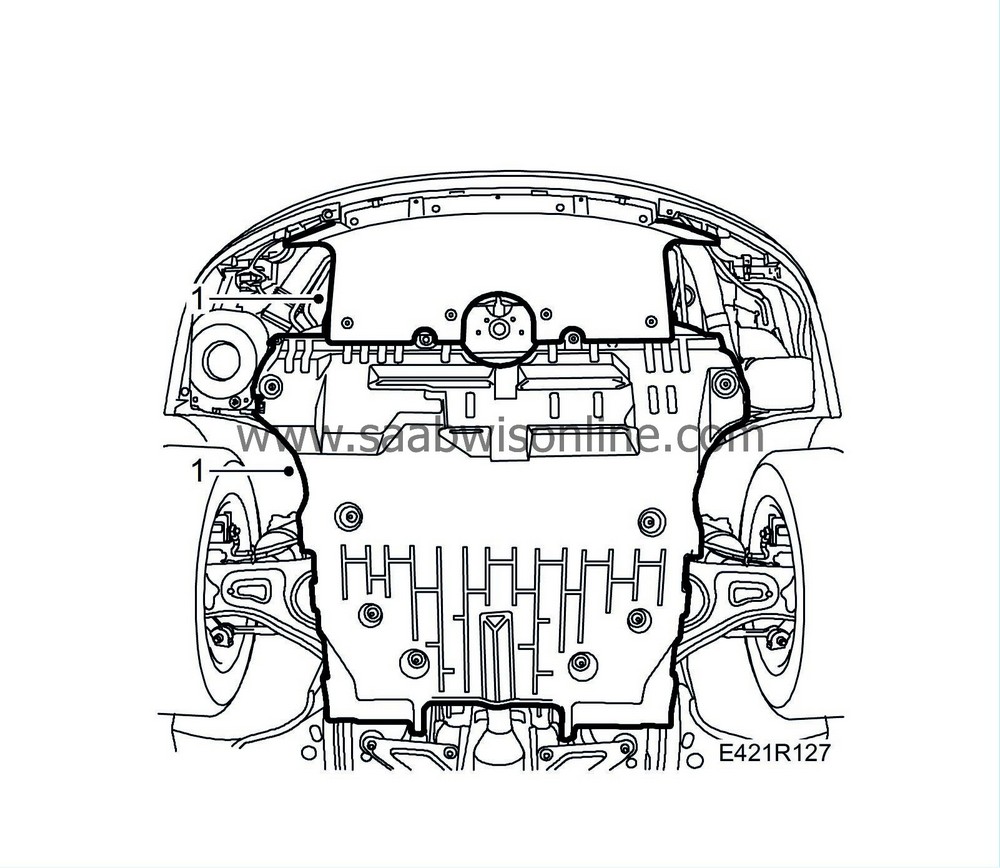

| 1. |

Raise the car and remove the lower engine cover.

|

|

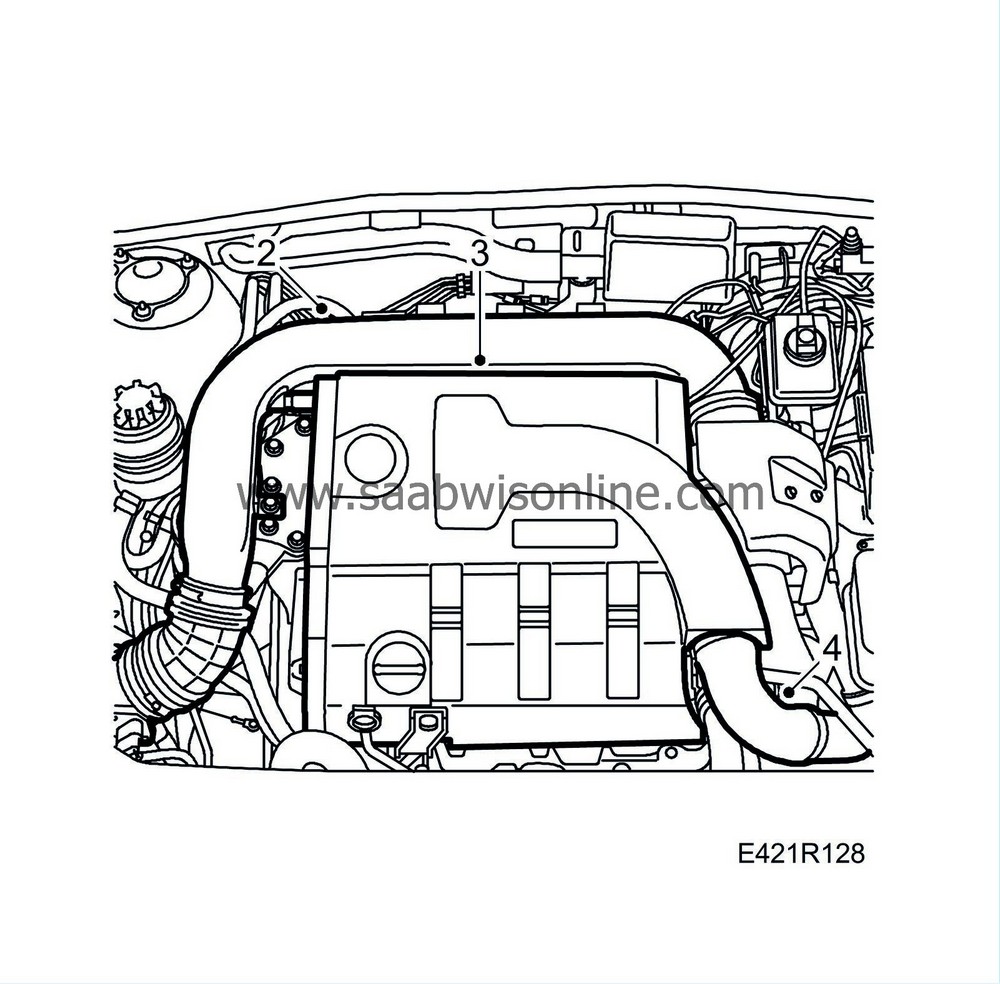

| 2. |

Lower the car and remove the intake manifold with mass air flow sensor from the turbocharger.

|

|

| 3. |

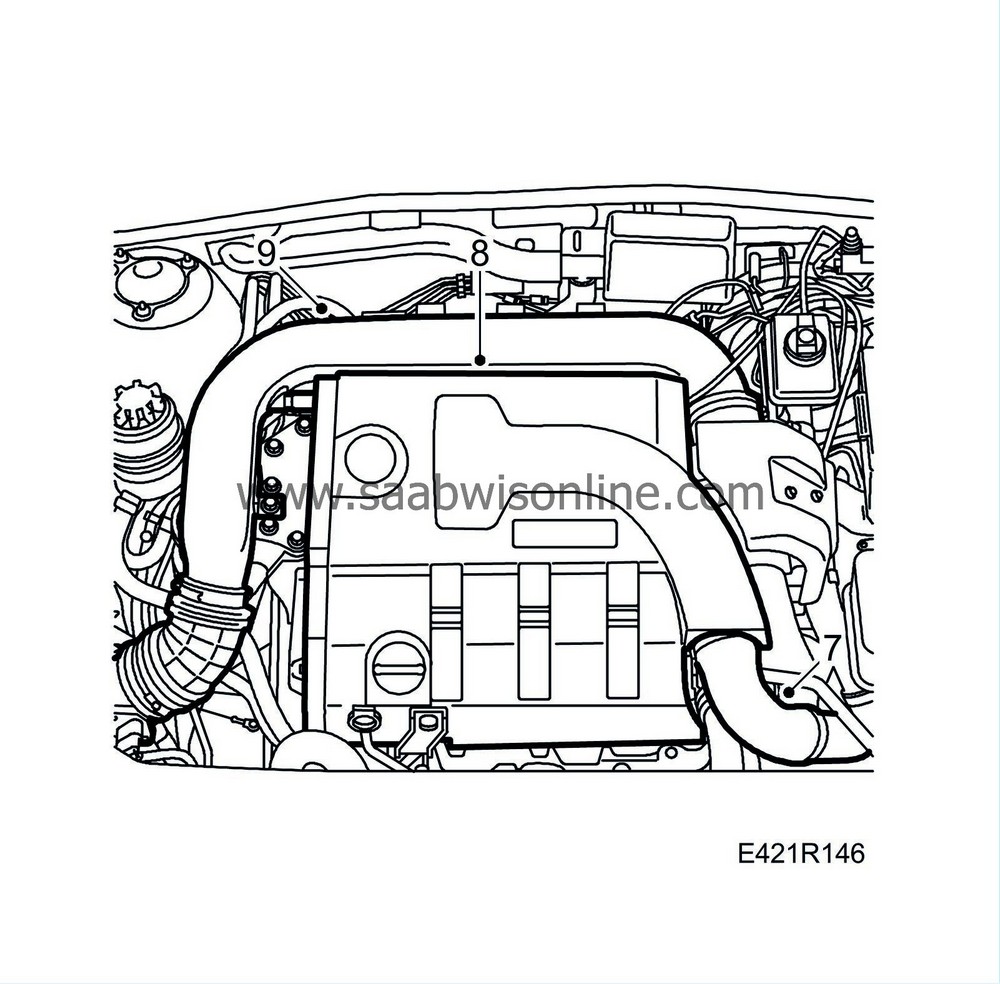

Remove the upper engine cover.

|

|

| 4. |

Detach the turbo pressure hose from the intake manifold.

|

|

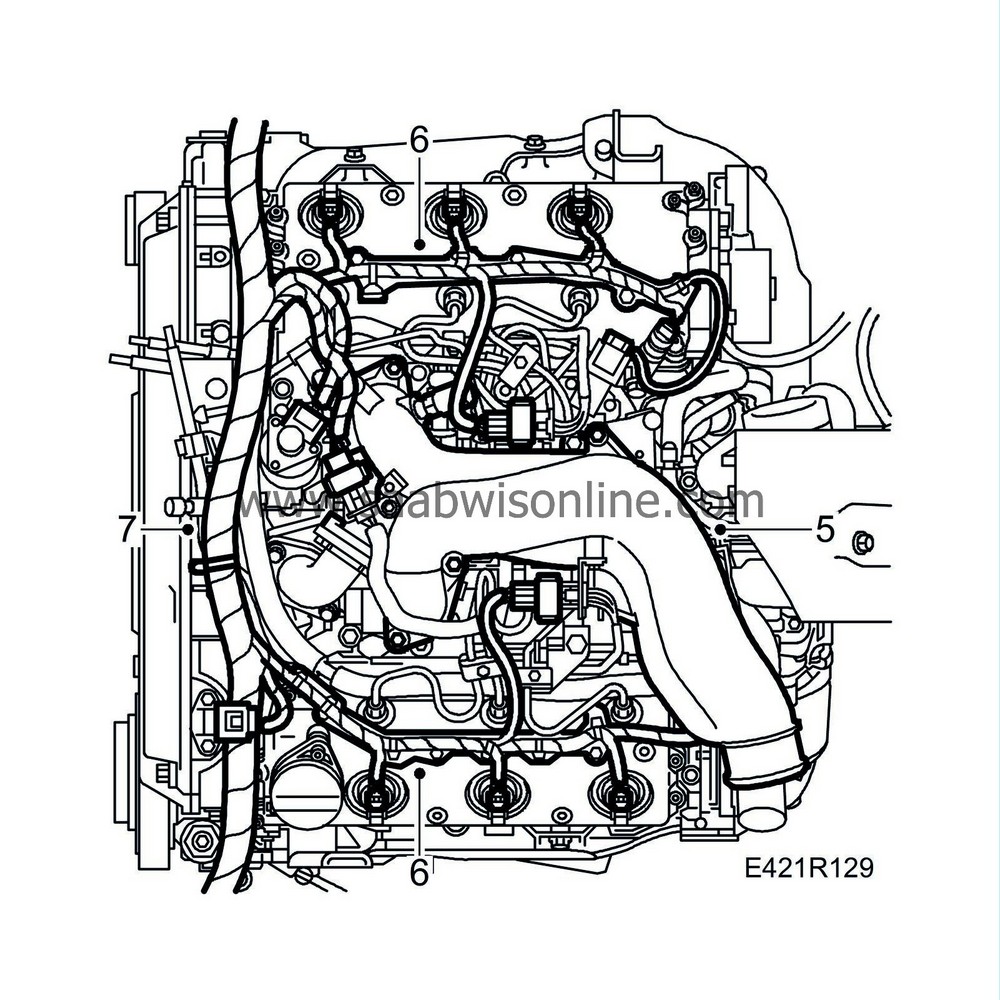

| 5. |

Remove the upper intake manifold.

|

|

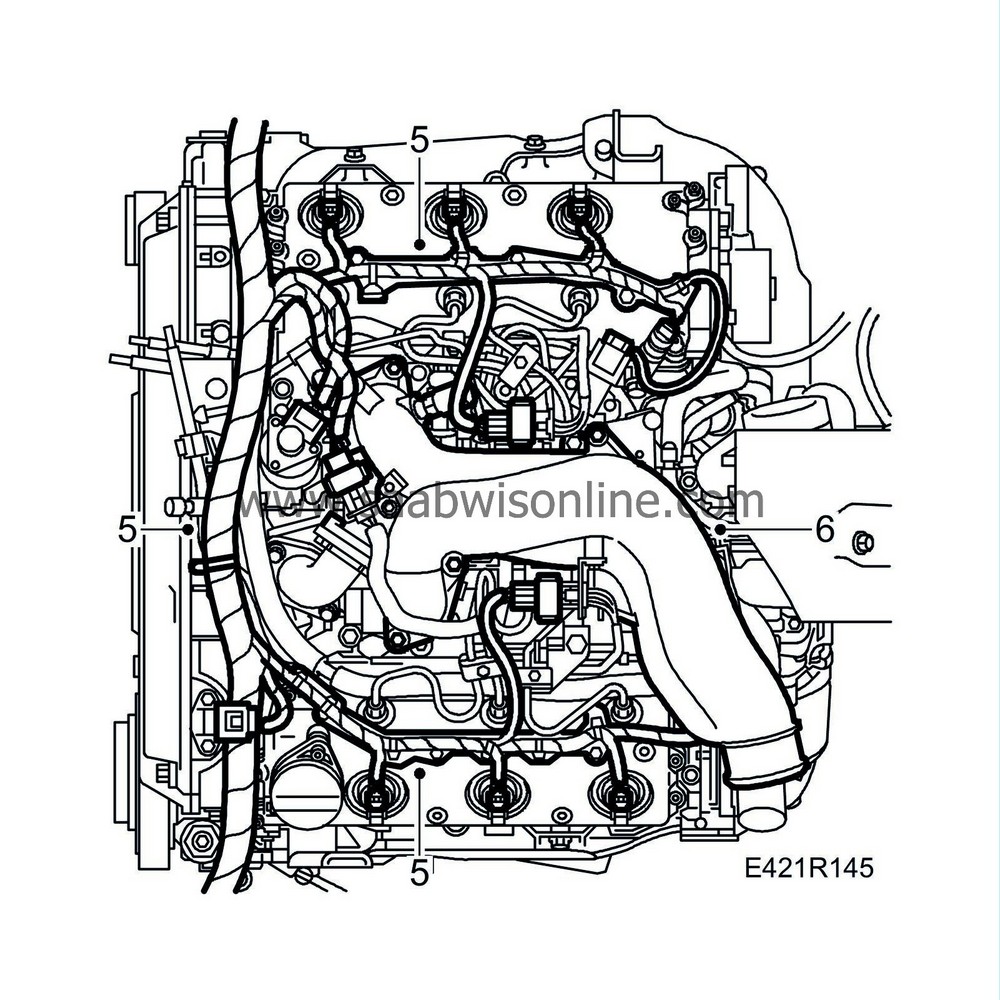

| 6. |

Unplug the connectors for the injectors and the coolant temperature sensor; detach the charge air pressure sensor, the camshaft position sensor, the turbo vacuum clock and the EGR valve. Remove the cable ducts from the camshaft covers.

|

|

| 7. |

Free the wiring secured to the fuel feed and fuel return pipes.

|

|

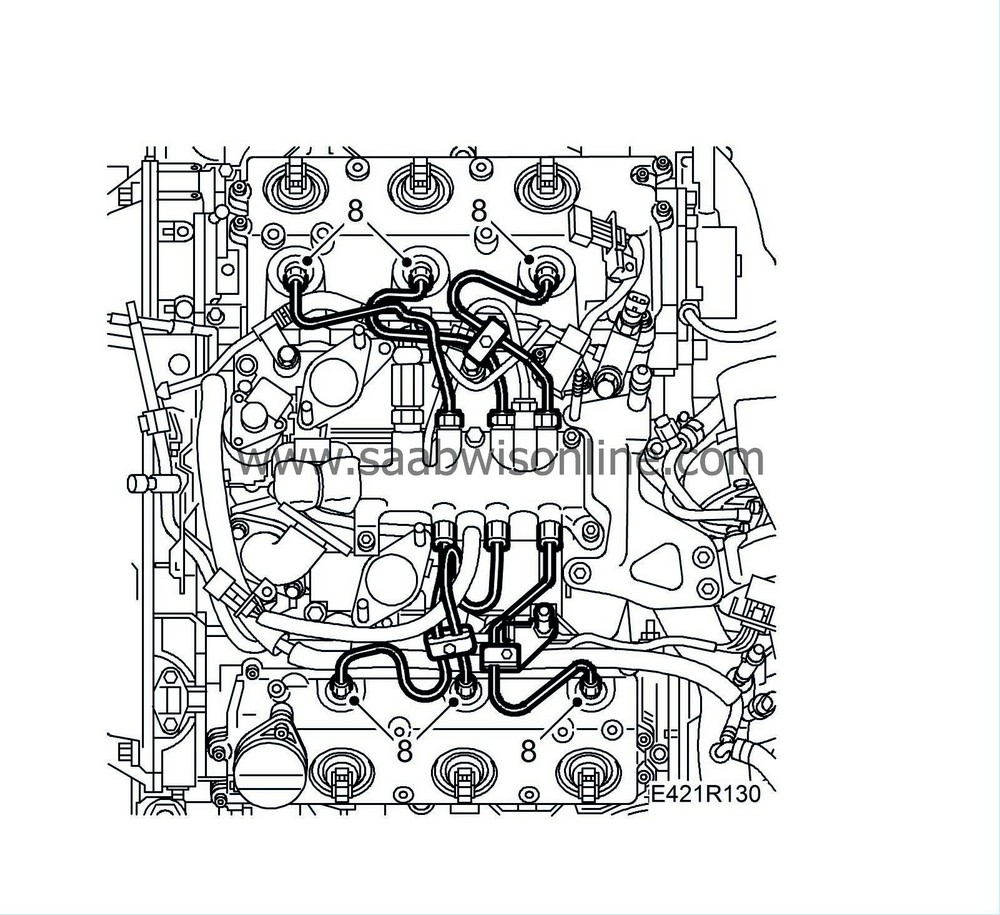

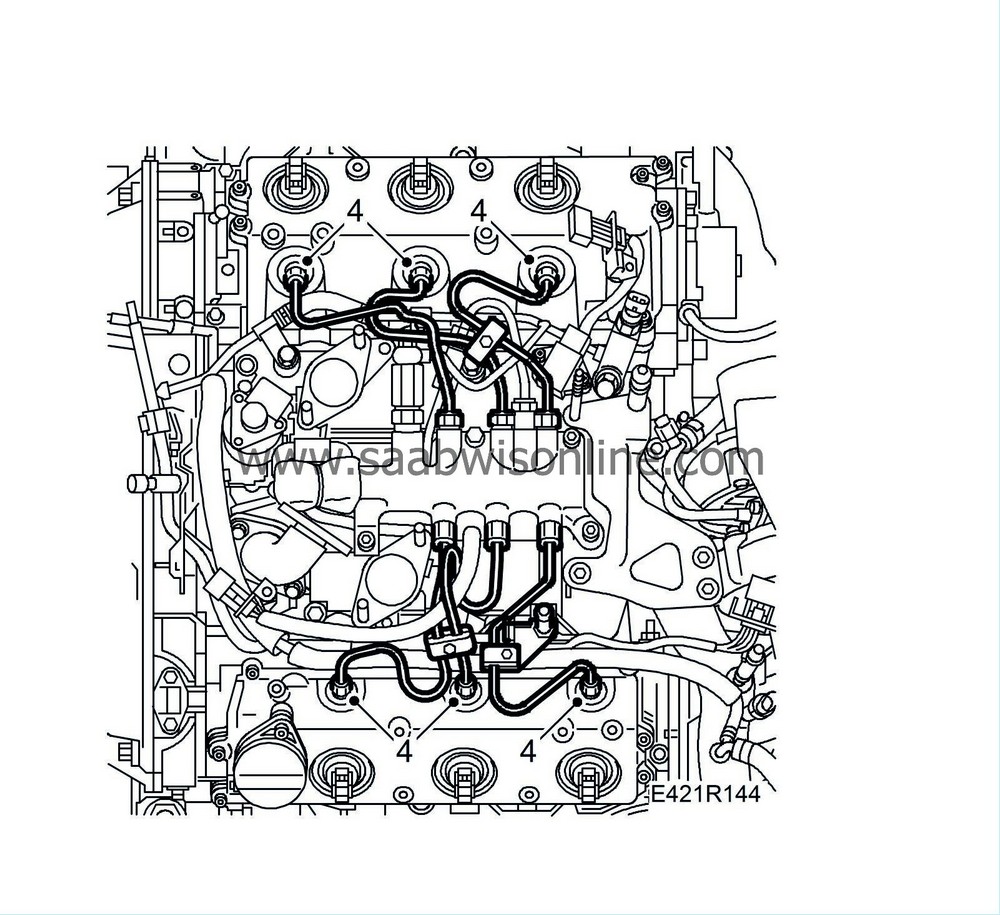

| 8. |

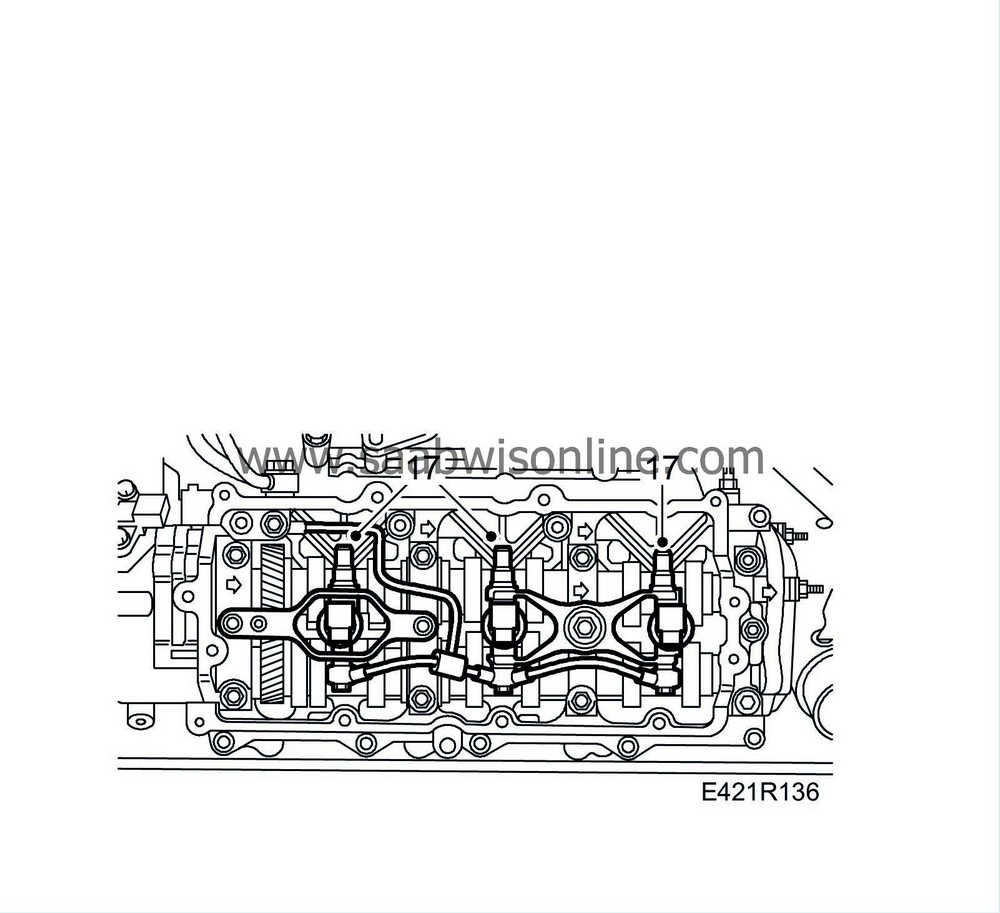

Remove the fuel injection pipes.

|

|||||||||

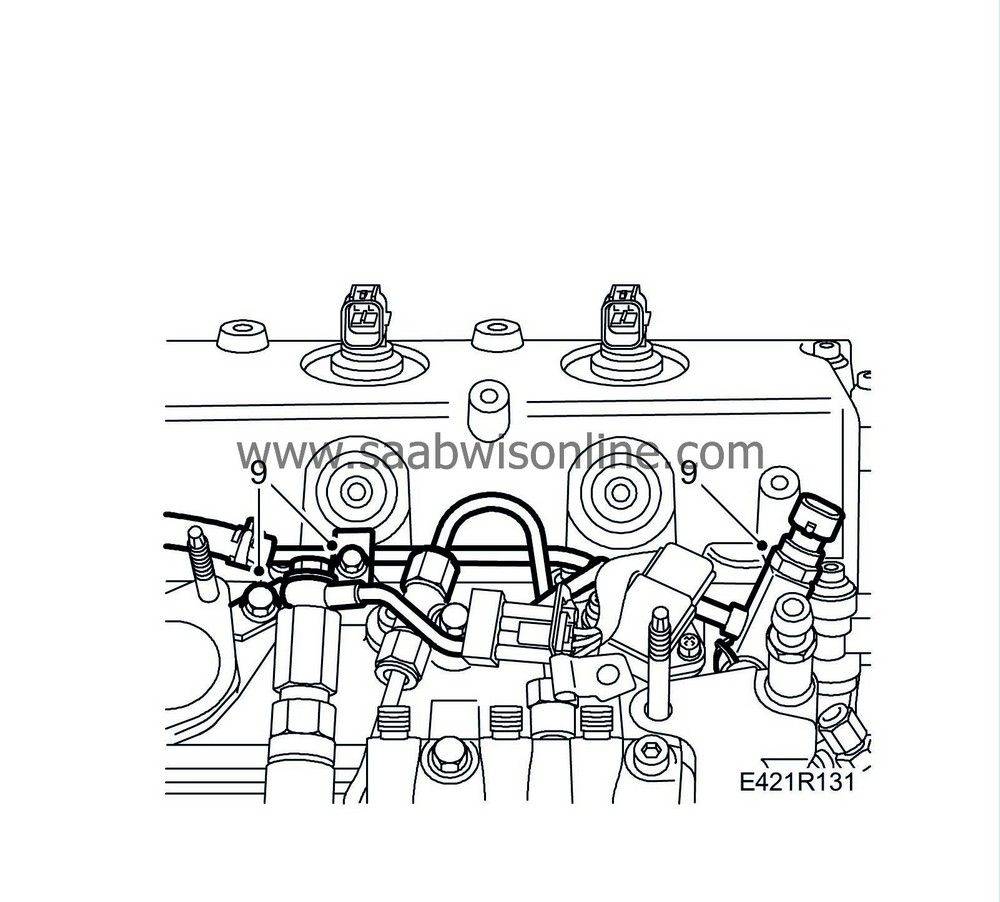

| 9. |

Detach the rear bank's fuel return pipe with mounting from the camshaft frame and the fuel rail. Move the pipes aside.

|

|

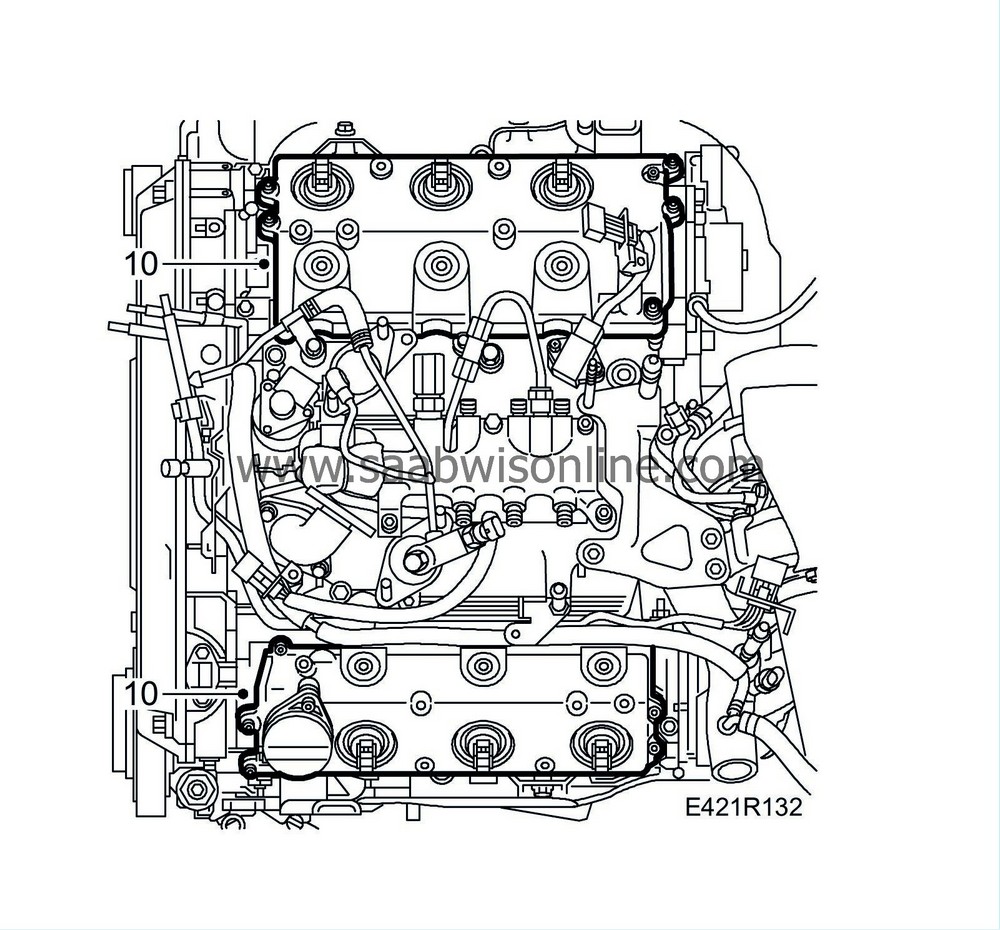

| 10. |

Remove the camshaft covers from the cylinder banks.

|

|

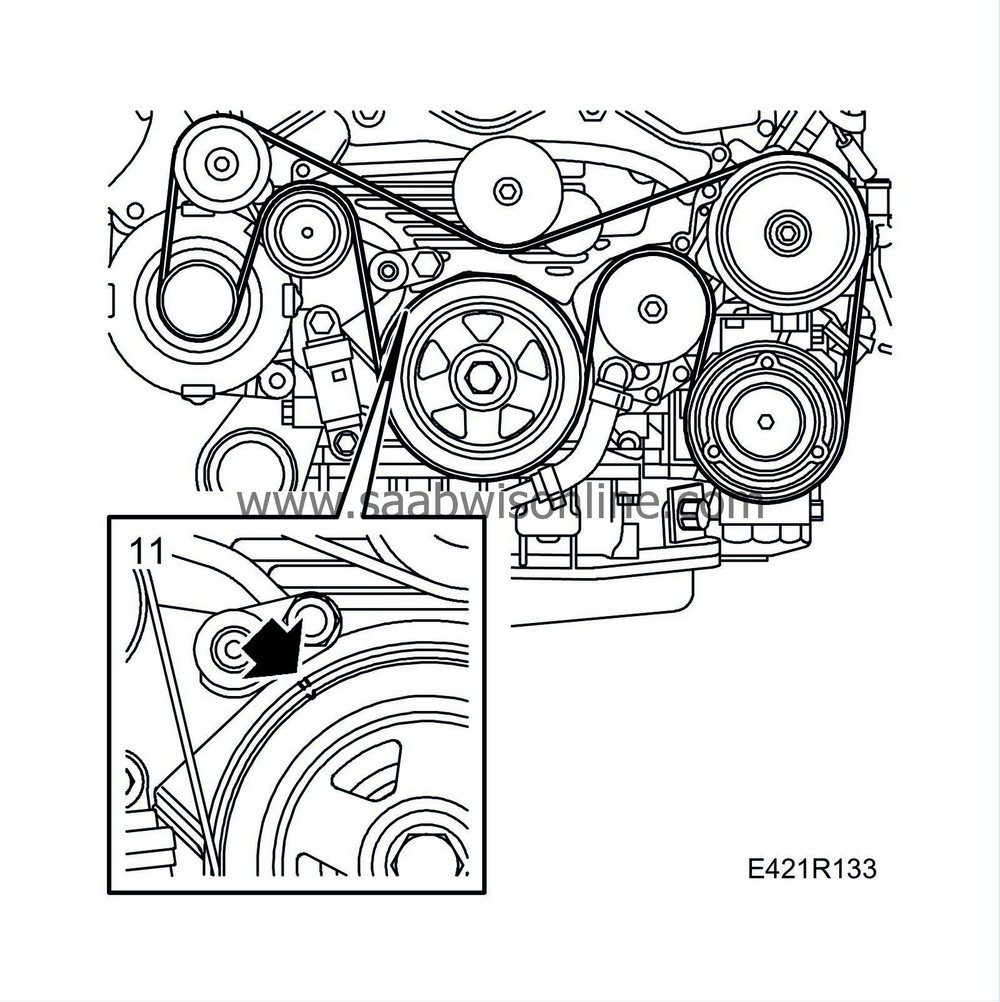

| 11. |

Zero the engine by turning the crankshaft in the engine's direction of rotation so that the mark on the crankshaft pulley aligns with the mark on the timing cover.

|

|

| 12. |

Check that no cylinder 1 valves are loaded by camshaft lobes.

|

|

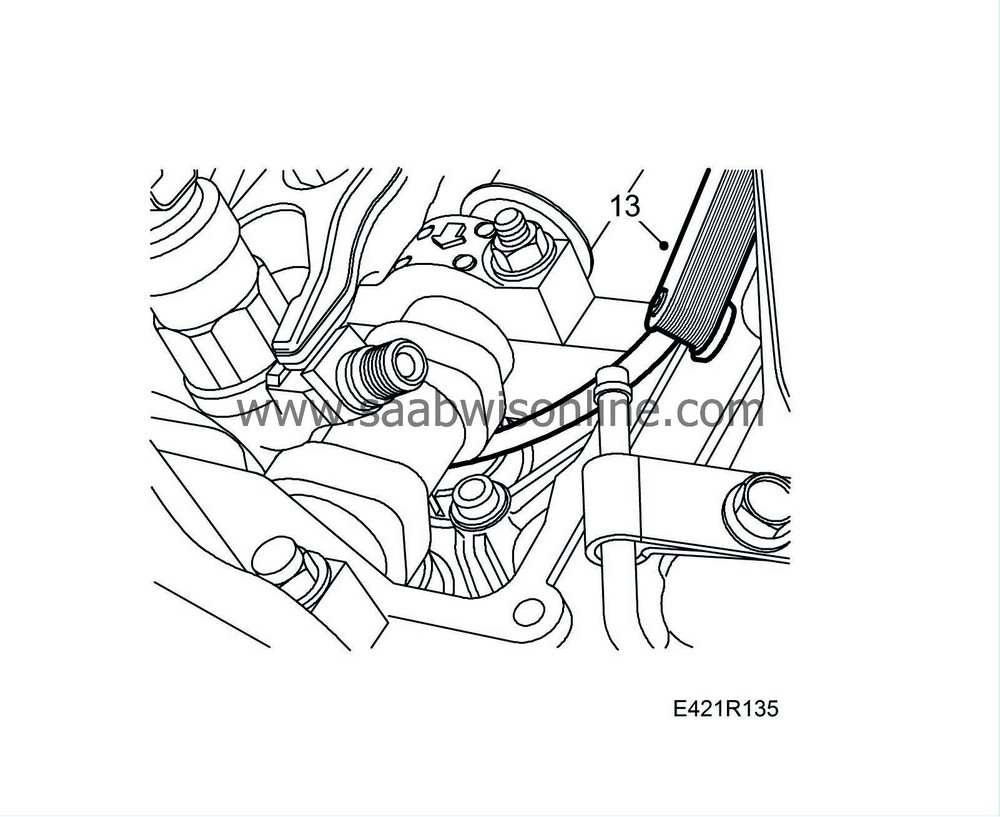

| 14. |

Rotate the crankshaft 1 revolution in the engine's direction of rotation so that the mark on the crankshaft pulley aligns with the mark on the timing cover.

|

|

| 15. |

Check that no cylinder 4 valves are loaded by camshaft lobes.

|

|

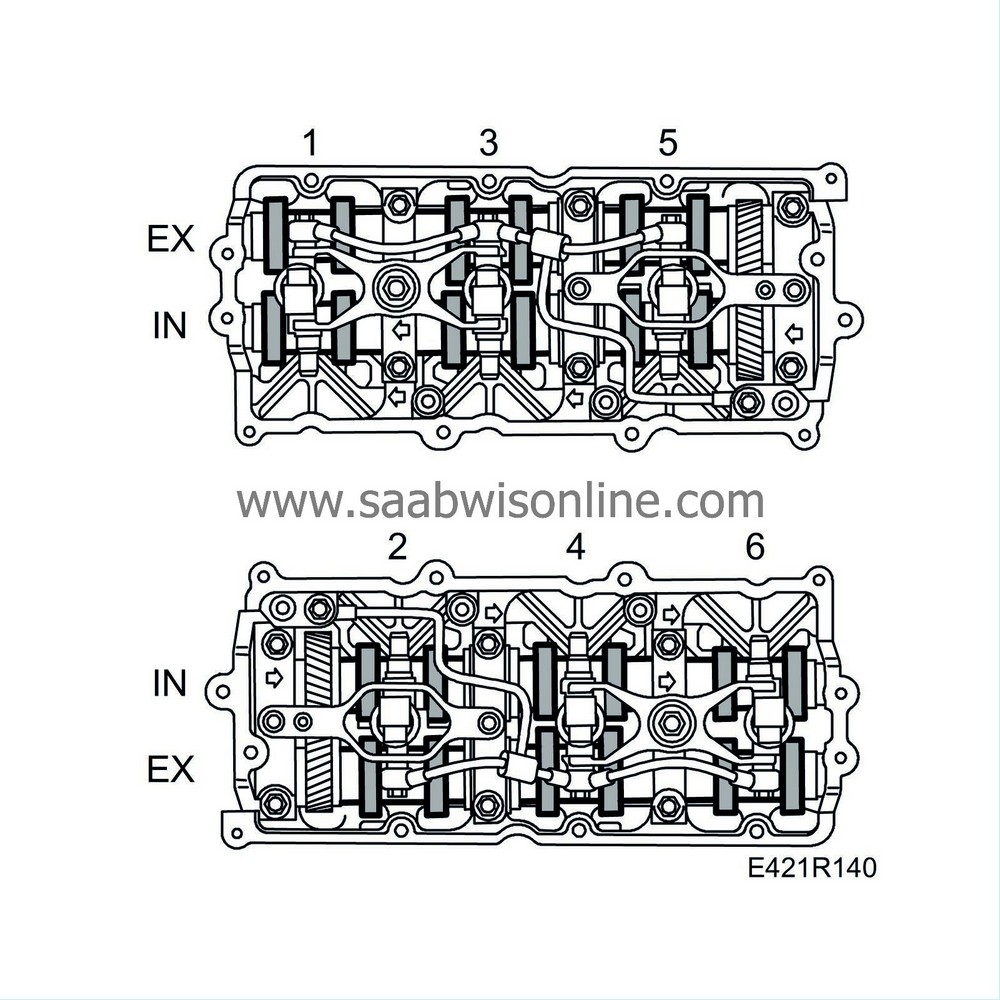

| 16. |

Use a feeler gauge to check the valve clearance of each cylinder. Begin with the intake valves of cylinders 2, 3 and 4. Continue with the exhaust valves of cylinders 4, 5 and 6. Note the valve clearances in the table.

|

|

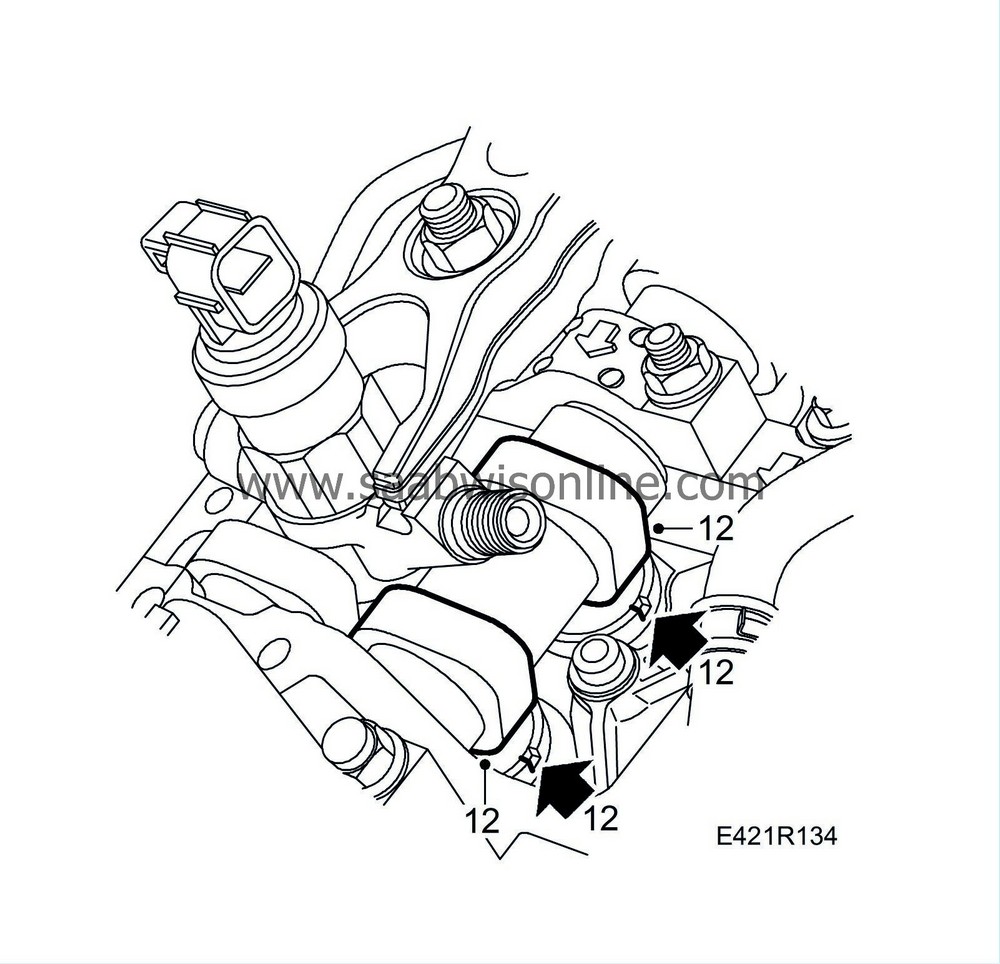

| 17. |

If adjustment is necessary, remove the injector with fuel return pipe at the valve needing adjustment.

|

|

| 18. |

Rotate the crankshaft in the engine's direction of rotation until the cam lobes of the valve in question are perpendicular to the cylinder plane.

|

|

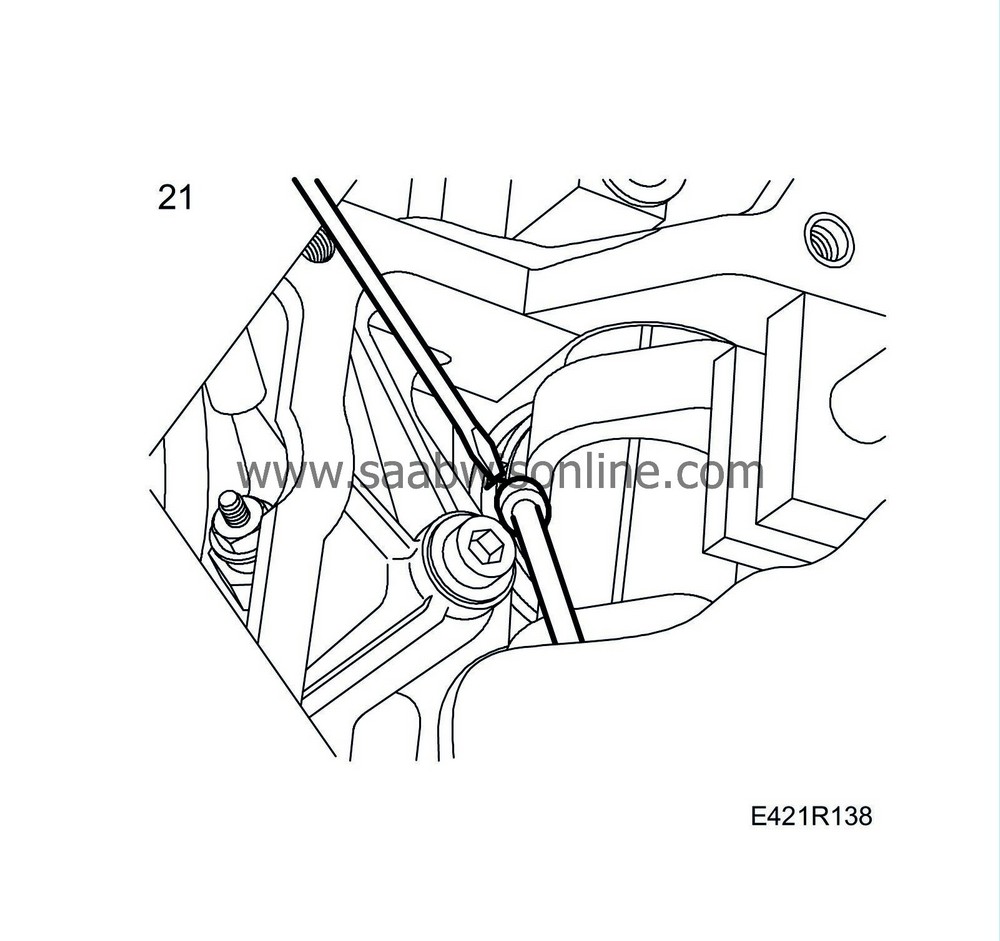

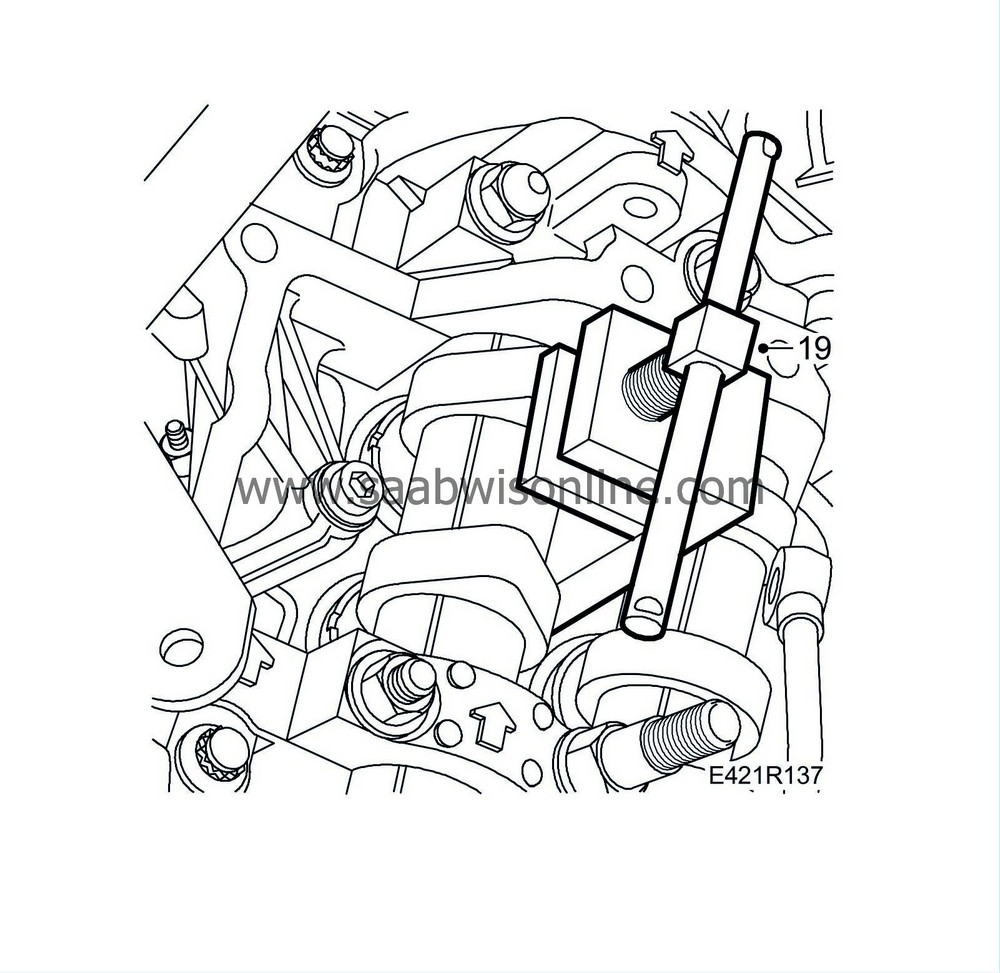

| 19. |

Use

83 95 857 Adjustment tool, exhaust valves

for the exhaust valves and

83 95 840 Adjustment tool, inlet valves

for the inlet valves. Use a screwdriver to turn the tappet so that the tappet groove is accessible.

|

|

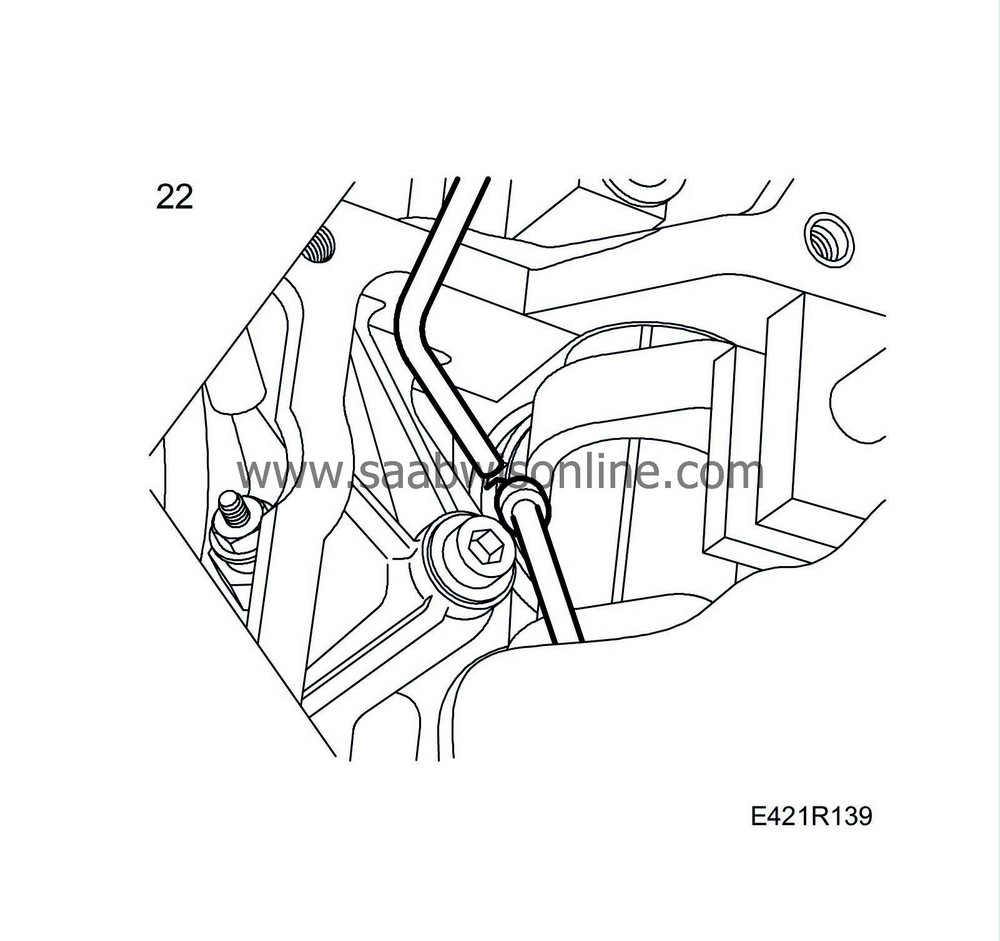

| 20. |

Fit the unloading tool and press down the tappets. Check that the tool is correctly fitted so that it does not press on the adjuster shim.

|

|

| To fit |

| 1. |

Fit the fuel return pipe and injectors using new seals.

|

|

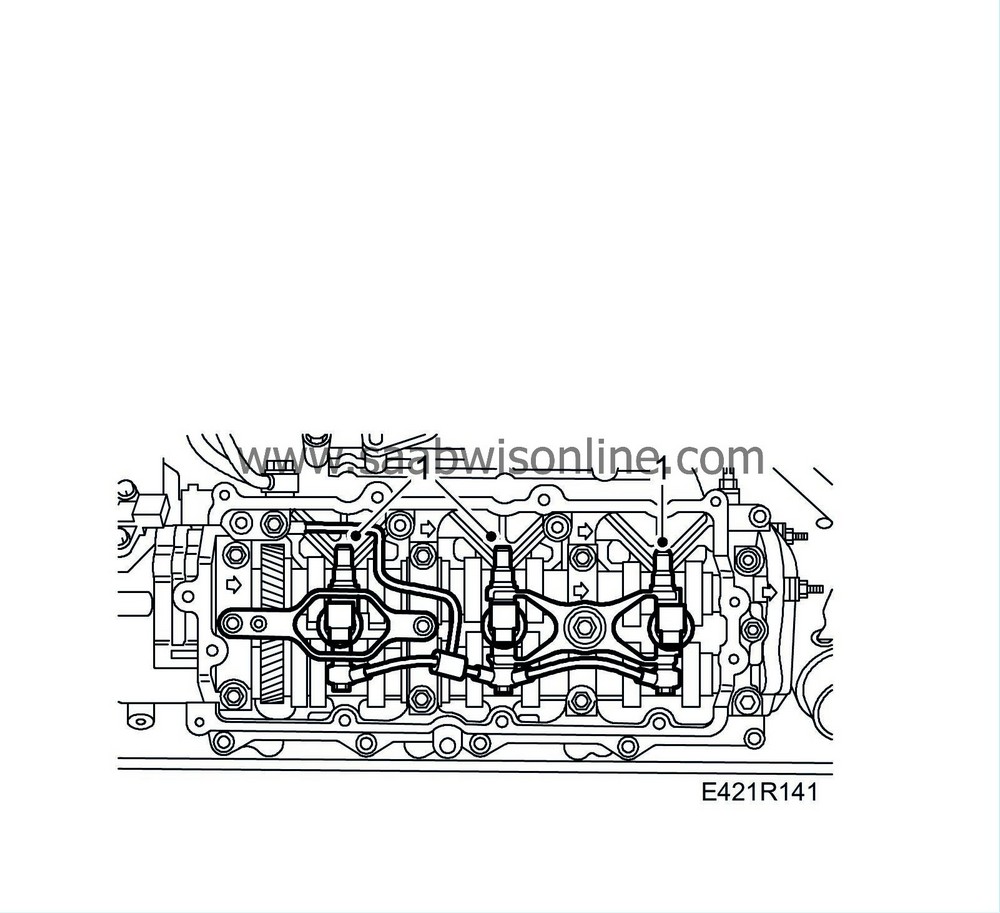

| 2. |

Fit the camshaft covers using new seals; see

Replacing camshaft cover seals

. Apply flange sealant, part no. 87 81 841, to the corners of each cover as illustrated.

|

|

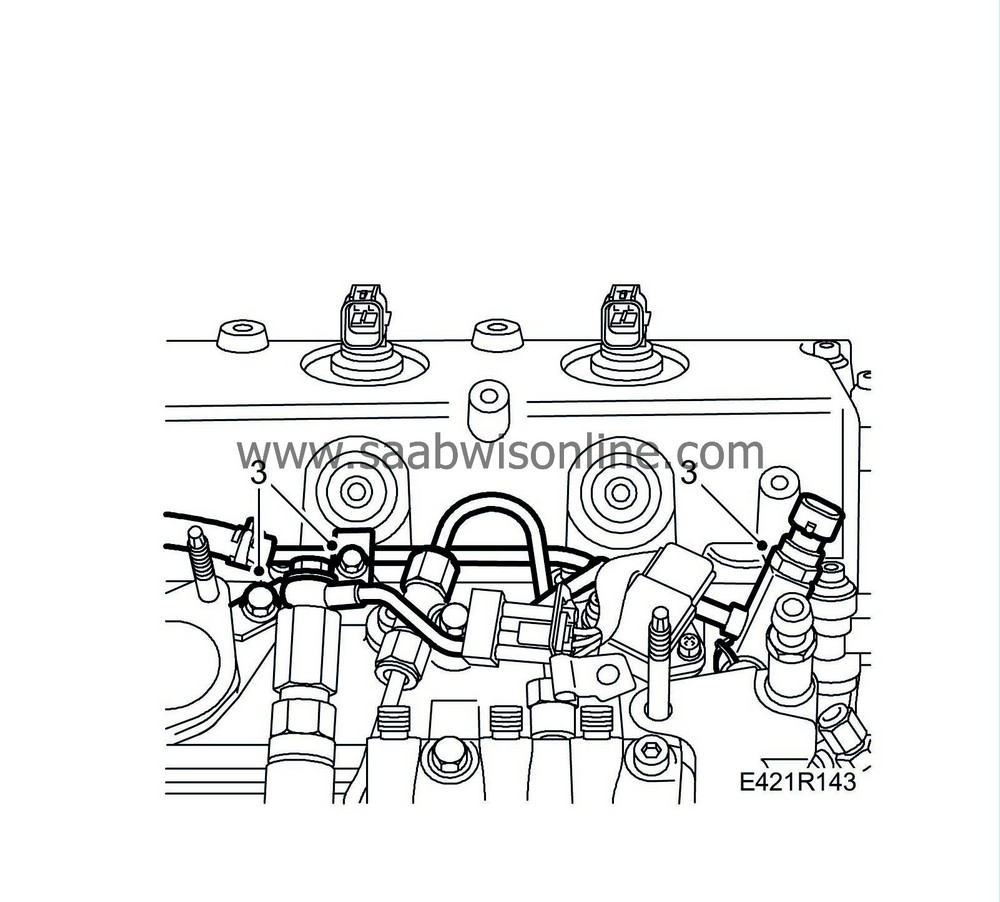

| 3. |

Fit the fuel return pipe and its mounting to the rear cylinder bank.

|

|

| 4. |

fit the injection pipes. Make sure that the wiring between the injection pipes to cylinders 2 and 4 is correctly situated.

|

|

| 5. |

Fit the cable ducts and plug in its connectors.

|

|

| 6. |

Fit the upper intake manifold using new seals.

|

|

| 7. |

Fit the turbo pressure hose to the upper intake manifold.

|

|

| 8. |

Refit the upper engine cover.

|

|

| 9. |

Fit the intake manifold with mass air flow sensor to the turbo.

|

|

| 10. |

Bleed the fuel system as described in

Bleeding the fuel system.

|

|

| 11. |

Clear any DTCs.

|

|

Warning

Warning