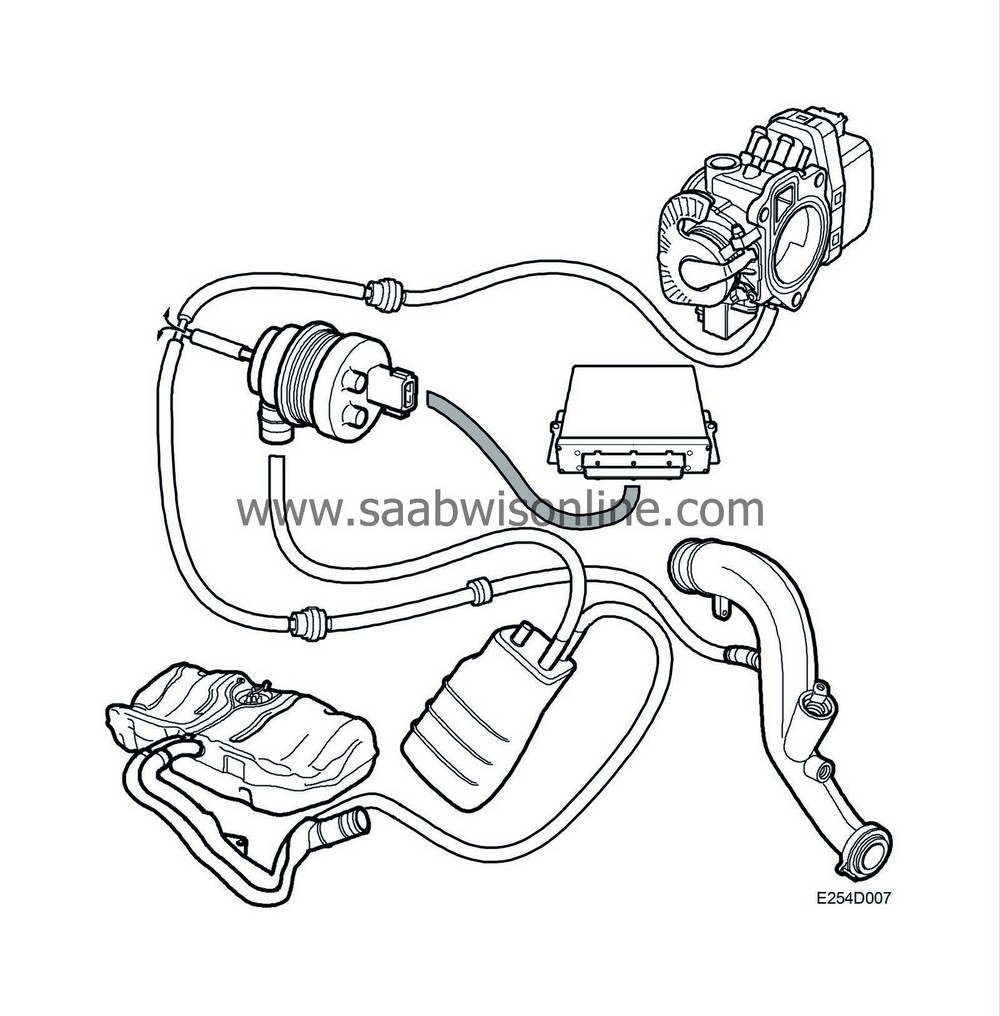

Evaporative emission system, V6

| Evaporative emission system, V6 |

| General |

Hydrocarbons from the fuel tank ventilation pass through a pipe to a container filled with active carbon (evaporative emission container) where they are temporarily stored. Then the fuel fumes are sucked via the EVAP cannister purge valve into the engine and burnt. The EVAP cannister purge valve is controlled by Trionic and the flow is controlled by a pulse ratio so that this flow is always a determined part of the total flow that the engine consumes. For further information about the EVAP cannister purge valve and its control see Group 2 “Engine control system, Trionic V6”, Technical description, Venting

.

.

| Brief description |

Evaporative emission canister

The evaporative emission canister consists of a container with active charcoal, the purpose of which is to store the fuel vapour from the tank. The container has connections for the inlet from the tank and the outlet to the purge valve, and there is also a fresh air inlet. Air is drawn through the opening, passed through the charcoal to clean it, and continues into the intake manifold.To prevent charcoal powder from penetrating the evaporative canister purge valve and causing the valve to leak, the upper part of the evaporative canister is fitted with a fine-mesh screen.

Cleaning the evaporative emission canister

When the engine starts, ambient air is drawn through the evaporative emission canister via the purge valve and a non-return valve into the intake manifold. The petrol vapours are carried with it and burnt in the engine.When the pressure in the intake manifold exceeds barometric pressure, another non-return valve opens and the flushing air is passed to the intake side of the turbocharger. To prevent flow in the wrong direction, two mechanical non-return valves are incorporated into the system.