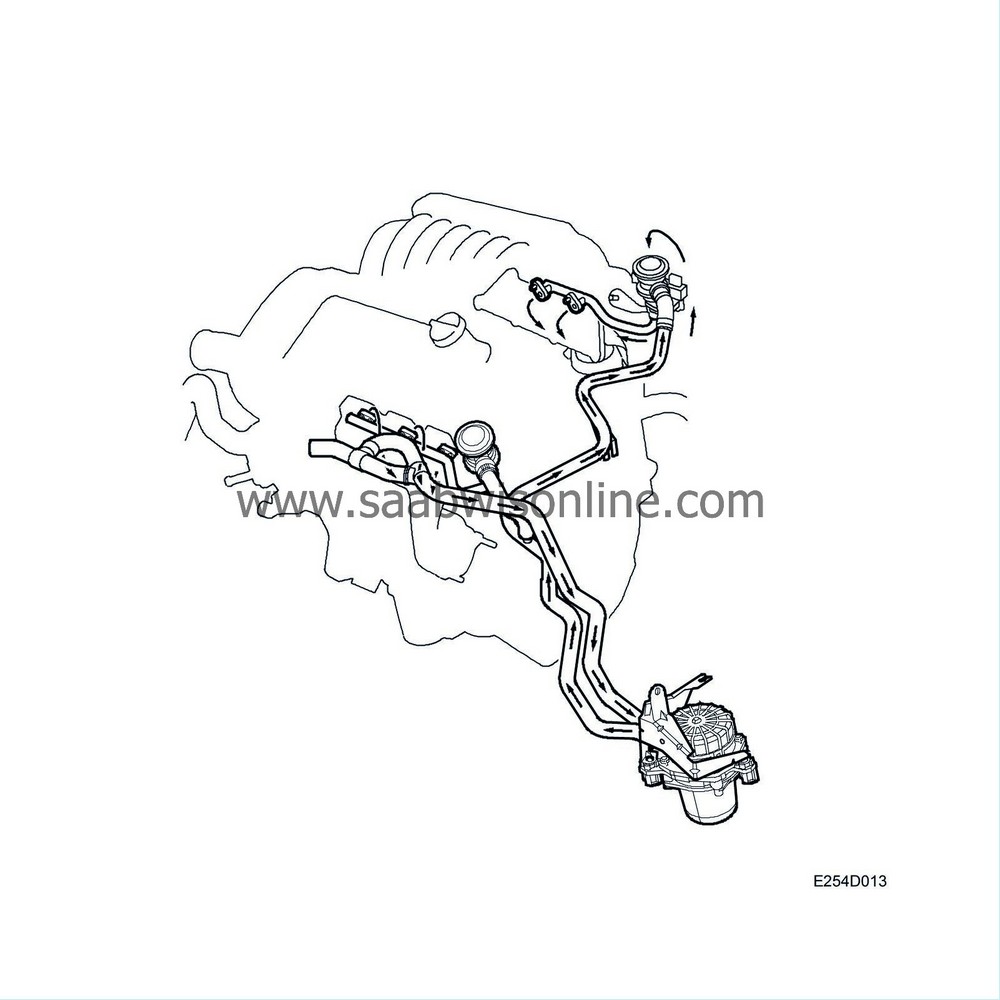

Secondary air injection

| Secondary air injection |

To compensate for this extra air, additional fuel is injected into banks 1 and 2. This addition quantity is added to the normal fuel quantity. Trionic calculates the additional amount of fuel from two matrices; one for the front and one for the rear bank.

If the battery voltage exceeds 16 V, the SAI pump will not start. This is to avoid overloading the pump.

If the mass air flow exceeds 700 mg/combustion the SAI pump will not start. Normal combustion is completely sufficient to heat up the catalytic converter.

The SAI pump starts when the engine is started if the temperature of the charge air and coolant is between -9°C and +30°C, and the battery voltage and mass air flow within the limits specified above.

Before the SAI pump starts the engine must complete a number of combustion cycles. This is delay is determined by the coolant temperature and can vary between 40 and 75 cycles.

The SAI pump will continue to run for a further 15 combustion cycles after the system no longer requests SAI. This is to avoid the unnecessary emission of hydrocarbons once the SAI function has been turned off.

If the charge air or coolant temperature is below +30°, the engine must have been switched off for at least 15 minutes for the SAI pump to start when the car is restarted. This presupposes that the pump has been active during the previous driving cycle.

Check valves prevent exhaust gasses leaking through the SAI system. The valves, one on each cylinder bank, shut when the pump stops.