P1455

Read the instructions below then start the fault diagnostic procedure.

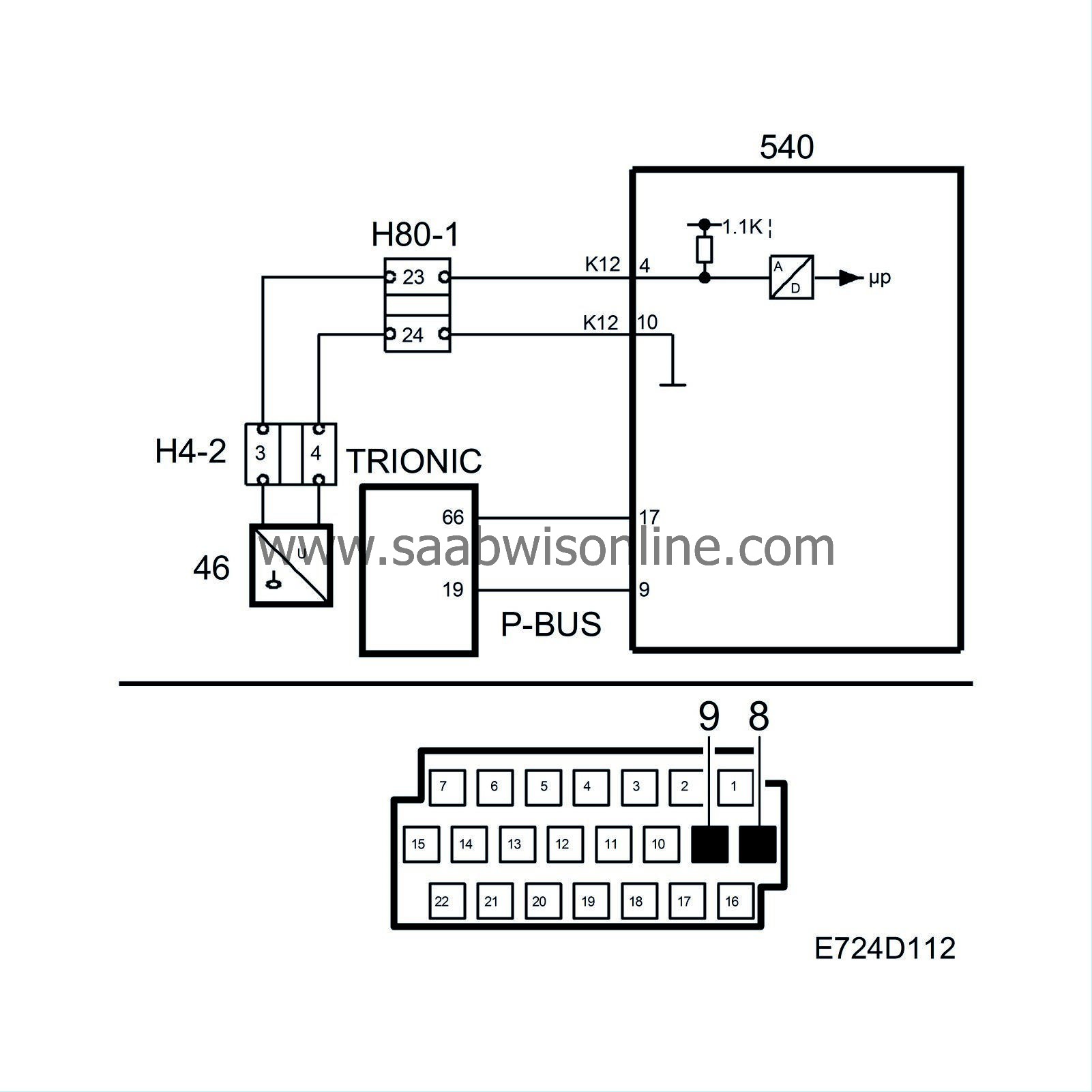

Symptom: CHECK ENGINE. Possible smell of petrol. Possible faulty reading on the fuel gauge in MIU.

| P1455 |

EVAP Purge Valve Circuit. Major leakage in the system at the same time as the fuel level sensor diagnosis has reported a fault.

Fault symptoms

| • |

CHECK ENGINE.

|

|

| • |

Possible smell of petrol.

|

|

| • |

Possible faulty reading on the fuel gauge in MIU.

|

|

On-Board Diagnostics

Type of diagnosis:| - |

Once per driving cycle. Interrupted when fault criteria fulfilled or OK reported. Restarts next driving cycle.

|

|

Test 1, Cold start

Enable criteria:

| - |

Coolant temperature at start between 5-40°C. Difference between coolant temperature and intake air temperature less than 5°C.

If the above conditions are not fulfilled, Test 2 (warm start) will start. Idling speed. Max. one change in status of brake light switch. Purging adaptation higher than -15%. Intake air pressure at least 20 kPa lower than the atmospheric pressure. The vehicle stationary for 5 sec. Fuel volume in tank between 11-54 litres. Battery voltage between 10-16 volts. Tank pressure between -300 to +100 Pa. The diagnosis will start once the above conditions have been fulfilled for more than 5 seconds. If the diagnosis is interrupted then the speed must exceed 0 on one occasion before it is allowed to restart. The diagnosis is divided into 3 phases, A-C: Phase A) Evaporation check The shut-off valve is activated (closed) at the same time as possible purging is stopped for 4.5 sec. Tank pressure is observed, falling pressure reveals leaks in purging valve. Rising pressure of more than 3 Pa/s points to fuel evaporation, in these cases Phase A is repeated. If it becomes apparent that the pressure is rising by more than 3 Pa/s the diagnosis is interrupted, vehicle speed is needed during a certain time for it to be restarted. For pressure increases less than 3 Pa/s then Phase A is complete. The diagnosis continues to Phase B (pressure reduction) Phase B) Pressure reduction Shut-off valve is still closed, the purging valve's pulse ratio is set at 23-24.5% until the tank pressure has reached -600 Pa. This pressure reduction should take no more than max. 30 seconds. Phase C) Pressure retaining The shut-off valve is still closed, the purging valve is closed. The tank pressure is observed for max. 12 seconds. |

|

Test 2, Warm start

Enable criteria:

| - |

The following conditions should be fulfilled for 5 seconds so that the diagnosis can start: Coolant temperature and intake air temperature at start exceeds +40°C and the difference between coolant temperature and intake air temperature is greater than 5°C.

Idling speed. Max. one change in status of brake light switch. Purging adaptation higher than -6%. Tank pressure between -300 to +100 Pa. Inlet air pressure at least 20 kPa lower than the atmospheric pressure. The vehicle stationary. Fuel volume in tank between 11-54 litres. Battery voltage between 10-16 Volts. Tank pressure sensor diagnosis must have reported OK. The diagnosis will start once the above conditions have been fulfilled for more than 5 seconds. The diagnosis is interrupted if the purging adaptation exceeds -8%. If the diagnosis is interrupted then the speed must exceed 0 on one occasion before it is allowed to restart. The diagnosis is divided into 3 phases, A-C: Phase A) Evaporation check The shut-off valve is activated (closed) at the same time as possible purging is stopped for 4.5 sec. Tank pressure is observed, falling pressure reveals leaks in purging valve. Rising pressure of more than 4 Pa/s points to fuel evaporation, in these cases Phase A is repeated. If it becomes apparent that the pressure is rising by more than 4 Pa/s the diagnosis is interrupted, vehicle speed is needed during a certain time to restart. At pressure increases less than 4 Pa/s then Phase A is complete. The diagnosis continues on to Phase B (pressure reduction) Phase B) Pressure reduction Shut-off valve is still closed, the purging valve's pulse ratio is set at 18% until the tank pressure has reached -600 Pa. This pressure reduction should take no more than max. 30 seconds. Phase C) Pressure retaining The shut-off valve is still closed, the purging valve is closed. The tank pressure is observed for max. 12 seconds. |

|

Test 3, Filler cap test

Enable criteria:

| - |

Vehicle speed above 40 km/h. Inlet air pressure at least 25 Pa lower than atmospheric pressure. Mass air flow through engine above 10 g/s and that the mass air flow during the diagnosis remains in the interval 85-150% of the value at the start of the diagnosis. The purging valve's pulse width is between 50-65%. Purging adaptation between -10% to -20%. The fuel volume between 11-40 litres. Tank pressure between -300 to 100 Pa or that the test has commenced.

If the conditions are fulfilled, the shut-off valve is closed and the purging is locked at the value it had in the beginning of the diagnosis (50-65%). If the pressure does not fall to -500 Pa within 6 seconds three times while driving then a fault is reported. |

|

Fault criteria:

Test 1 (Cold start)

| - |

Phase A) Evaporation check

If the pressure falls by more than 27.5 Pa/s then an internal leak in the purging valve has been detected. If the pressure has risen by more than 3 Pa/s then there is major fuel evaporation, Phase A will then be repeated. If it becomes apparent that the pressure is rising by more than 3 Pa/s then the diagnosis is interrupted. So that the diagnosis is restarted the vehicle must be put in motion. For pressure increases less than 3 Pa/s then the diagnosis continues on to Phase B.

|

|

| - |

Phase B) Pressure reduction

If the pressure cannot be reduced to -450 Pa within 15 seconds or if the pressure reaches -450 Pa within 15 seconds but not as high as -600 Pa within a further 15 seconds (30 seconds in total) then a major leakage has been found.

|

|

| - |

Phase C) Pressure retaining

If the pressure rises to -450 Pa within 12 seconds then a small leakage has been found.

|

|

Fault criteria:

Test 2 ( Warm start)

| - |

Phase A) Evaporation check

If the pressure falls by more than 27.5 Pa/s then an internal leak in the purging valve has been detected. If the pressure has risen by more than 4 Pa/s then there is major fuel evaporation, Phase A will then be repeated. If it becomes apparent that the pressure is rising by more than 4 Pa/s then the diagnosis is interrupted. The vehicle must be put in motion before the diagnosis can be restarted. For pressure increases less than 4 Pa/s then the diagnosis continues on to Phase B.

|

|

| - |

Phase B) Pressure reduction

If the pressure cannot be reduced to -450 Pa within 15 seconds or if the pressure reaches -450 Pa within 15 seconds but not as high as -600 Pa within a further 15 seconds (30 seconds in total) then a major leakage has been found.

|

|

| - |

Phase C) Pressure retaining

If the pressure rises to -450 Pa within 12 seconds then a small leakage has been found.

|

|

Generation of diagnostic trouble codes:

| - |

Diagnostic trouble codes are generated when the above fault criteria are fulfilled and the dependents are OK.

In addition for Test 2 (Warm start) the intake air temperature has not been below 5°C. Fuel level, Plausibility diagnosis: Because fuel level is used as an enable criteria in certain diagnosis, then the control module must know that fuel level value is plausible. It works in such a way that Trionic receives the bus message ”Fuel level XX litre" from MIU. While driving Trionic observes the value and as the vehicle is driving it is consuming petrol, Trionic sees that the fuel level value will fall. In Trionic there is a number of filtrations of the value so as to avoid inaccuracies due to for example splashing fuel in the tank and hill starts. The fuel level diagnosis can be said to be a support diagnosis, it does not generate its own diagnostic trouble codes, but if for example the integrity diagnosis has reported a leakage in the purging valve then DTC P0455 is normally generated. If on the other hand the integrity diagnosis has reported the same fault and the fuel level diagnosis at the same time has also reported a fault then DTC P1455 is generated instead. P0441, P1441 are generated if faults are reported during Phase A P0455, P1455 are generated if faults are reported during Phase B P0442, P1442 are generated if faults are reported during Phase C |

|

Fault criteria:

Test 3 (Filler cap test)

| - |

If faults are reported and the engine's starting temperature is between 5-40°C diagnostic trouble code P0455 or P1455 is generated.

|

|

Dependents:

| - |

P0444, P0445, P0501, P0502, P0506, P0507, P1444, P1445, P1576, P1577 and (vehicles equipped with TCS) P1925.

|

|

OK report:

| - |

If all conditions are fulfilled and the diagnoses have been carried out without finding any faults then OK is reported.

|

|||||||

Fault handling:

(For more information, see “Fault diagnosis, general”.)

| - |

Type III.

|

|

Diagnostic help

Fault diagnosis concerns a leak.Functions in the diagnostic tool related to the fault:

| • |

Diagnostic status for the diagnosis.

|

|

| • |

Activate EVAP diagnosis.

|

|

For more information, see “Fault diagnosis, general”.

| Note | ||

|

During the final check of a rectified fault, the diagnostic tool activation command must be used so that Test 1 (cold start) is initiated irrespective of starting temperature. |