Fuel injection, basic function

|

|

Fuel injection, basic function

|

|

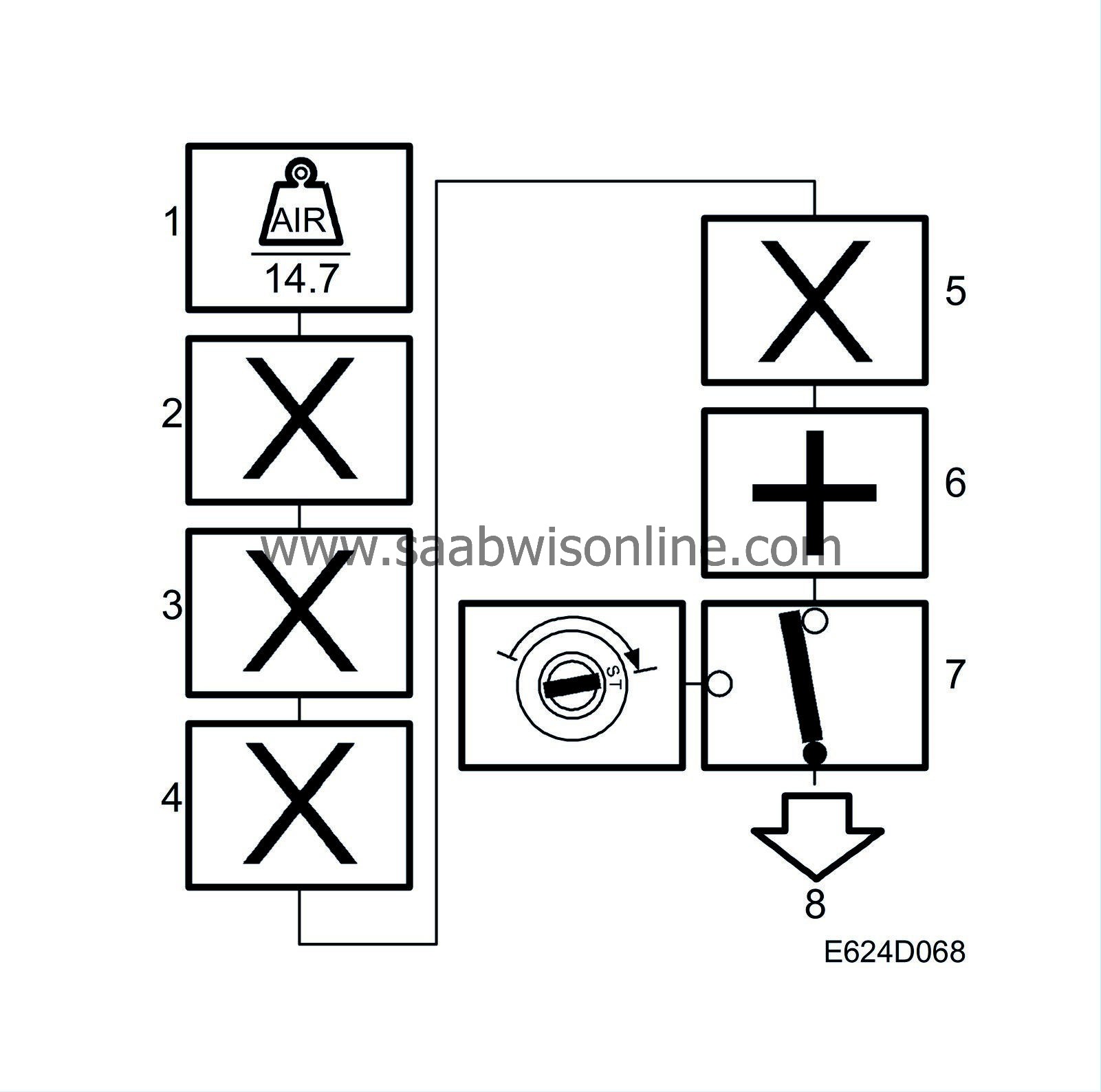

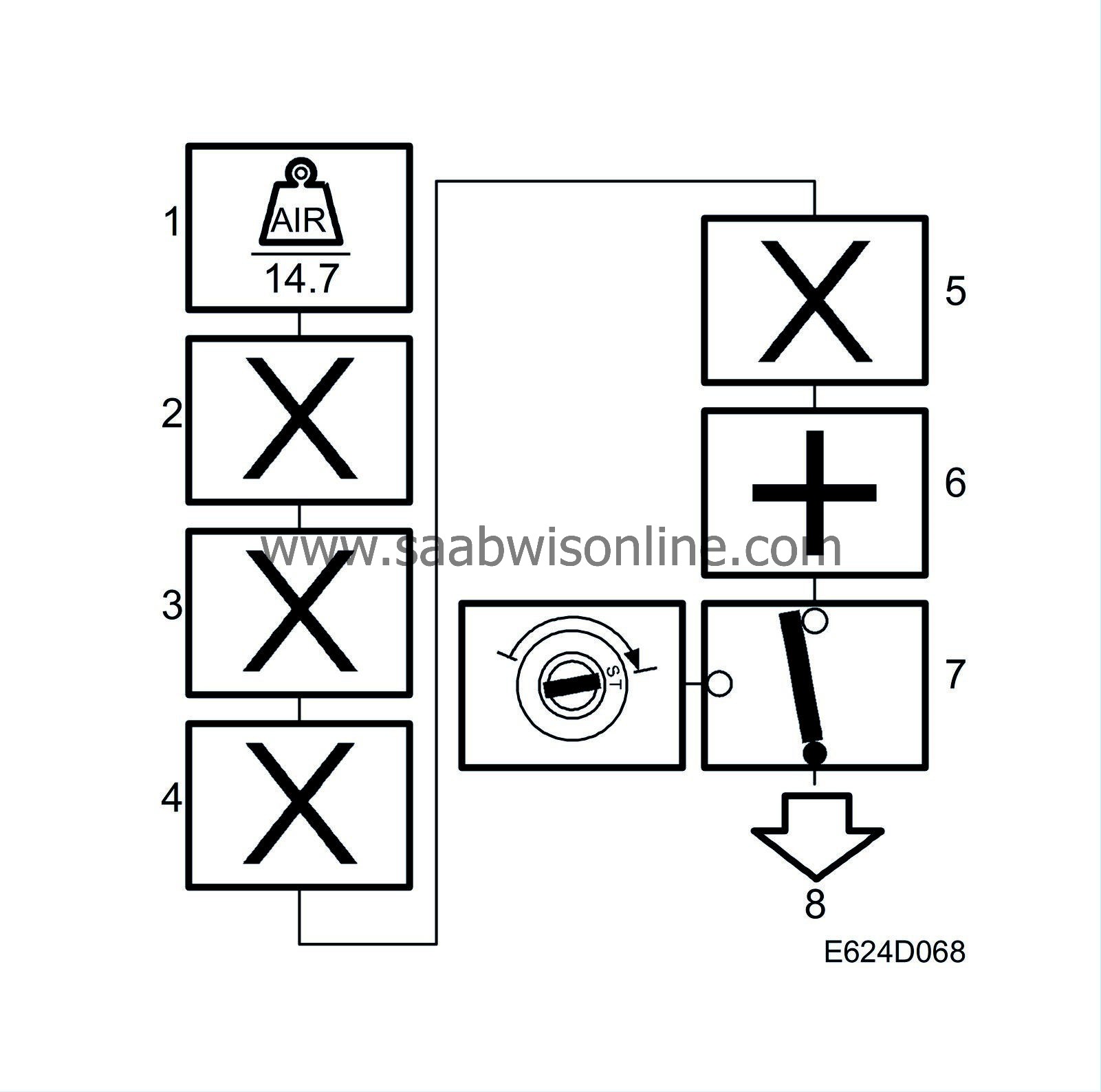

1.

|

Basic calculation of fuel mass/combustion

The current air mass/combustion is divided by 14.7 and sent to box 2. The unit is now mg fuel/combustion.

|

|

2.

|

Compensation

In the case of a cold engine, shortly after starting, rapid load changes, knocking or a high load, the current value is multiplied by a compensation factor.

|

|

3.

|

Closed loop

The closed loop control system value is also used as a multiplier. The value is sent to box 4.

|

|

4.

|

Correction for purging

Multiply by the value for purging adaptation. The value is sent to box 5.

|

|

5.

|

Multiplicative adaptation

The multiplicative adaptation value is also used as a multiplier and the new value sent to box 6.

|

|

6.

|

Additive adaptation.

The additive adaptation value is added. If the engine is running the new value is sent via box 7 to box 8.

|

|

7.

|

Starting fuel quantity

If the engine still has not started the starting fuel is selected. The value is sent to box 8 via box 7.

|

|

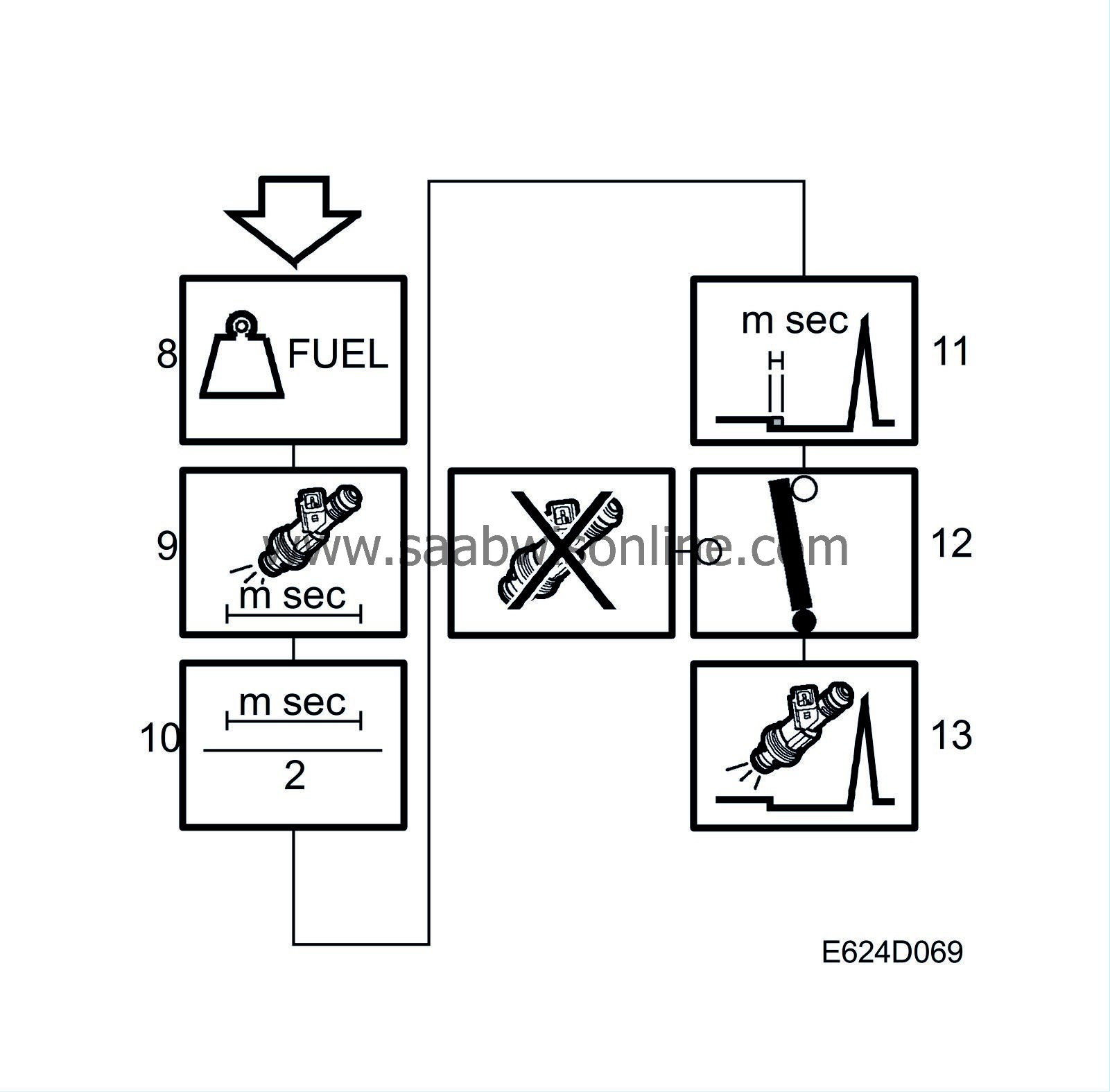

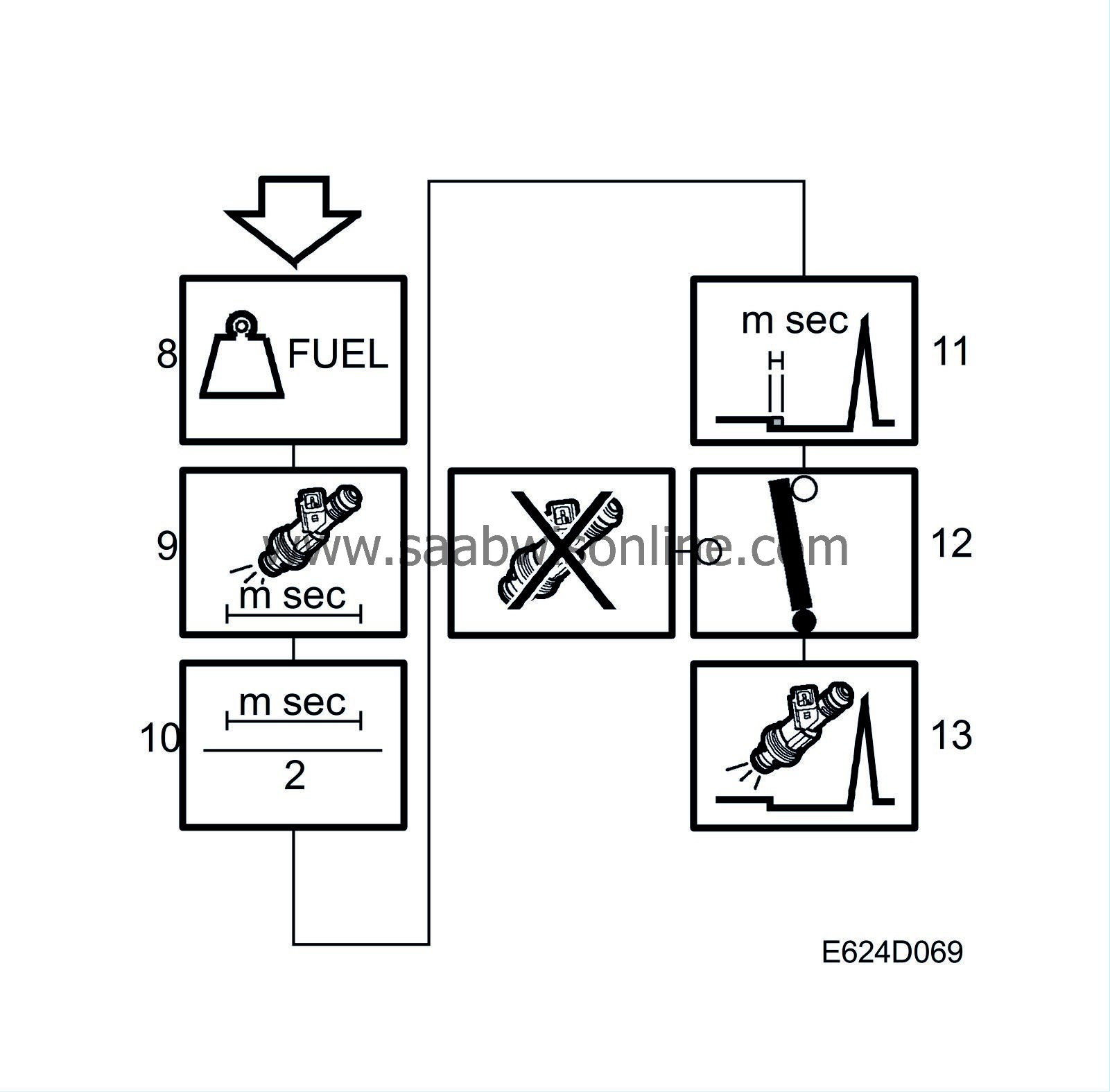

8.

|

Fuel mass/combustion to be injected

Fuel mass/combustion is the fuel mass that is to be supplied to the engine. The value is sent to box 9.

|

|

9.

|

Injector opening time

Converts the value into the time the injector must be open and the new value is sent to box 10.

|

|

10.

|

Injection twice per combustion

Before the camshaft position has been detected, injection takes place twice/combustion. Injection duration is then divided by two. Current value is sent to box 11.

|

|

11.

|

Voltage-dependent needle lift time added

Add the injector duration delay, which is voltage dependent. The value is sent to box 12.

|

|

12.

|

Fuel shut-off

If fuel shut-off is not active, the value will be sent to box 13.

|

|

13.

|

Activation of injector

At a specific crankshaft angle, the microprocessor controls the transistor for the injector that is next in the firing order.

|