Throttle control

| Throttle control |

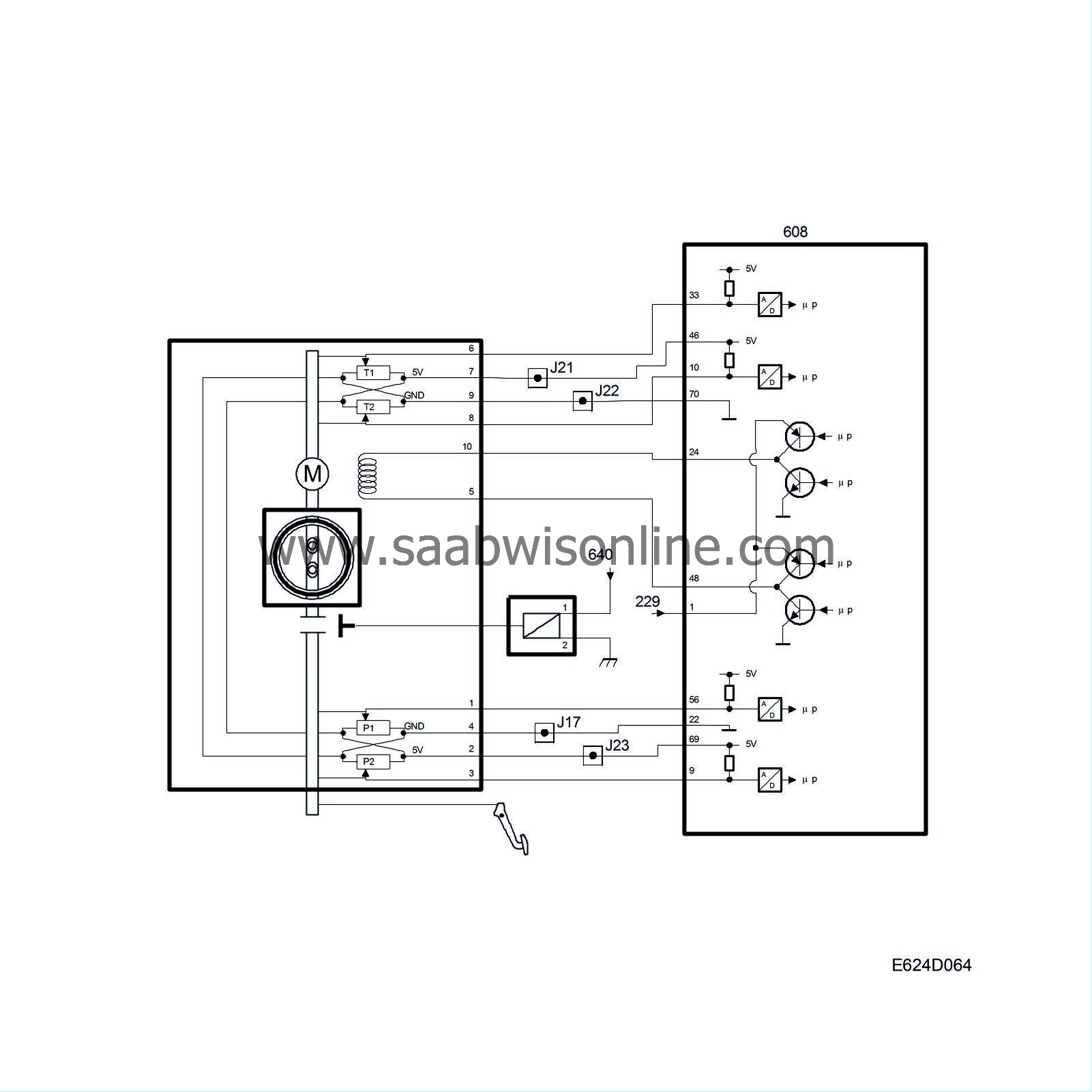

| 1. |

Pedal arm with mounting for accelerator cable (rotates pedal position sensors).

|

|

| 2. |

Return spring on pedal arm (not visible, located behind the pedal arm).

|

|

| 3. |

Pedal position sensors (2 potentiometers)

|

|

| 4. |

Motor (brushless DC motor, rotates throttle spindle and disc, throttle position sensor and throttle arm).

|

|

| 5. |

Throttle

|

|

| 6. |

Throttle arm

|

|

| 7. |

Return spring for throttle arm

|

|

| 8. |

Throttle position sensors (2 potentiometers)

|

|

| 9. |

Limp-home solenoid (activated 5 times in succession on limp-home and each time the ignition is turned on if a diagnostic trouble code that puts the throttle into limp-home mode is stored in the control module memory. If the throttle is put into limp-home mode, the toothed disc will be disengaged).

|

|

| 10. |

Toothed disc (spring loaded by the throttle arm return spring and released by the limp-home solenoid when the throttle goes into limp-home mode. The disc must be reset manually after repair and deletion of the diagnostic trouble code).

|

|

| 11. |

Air after throttle (nipple for purging the EVAP canister).

|

|

| 12. |

Air after throttle (nipple for connecting crankcase ventilation).

|

|

| 13. |

Air before throttle (nipple for connecting to control valve for the turbocharger bypass valve).

|

|

| 14. |

(Not used).

|

|

| 15. |

Pre-heating (2 nipples for coolant circulation to reduce risk of ice forming).

|

|

| 16. |

10-pin connector (2 for motor, 2 for 5V, 2 for ground, 2 for pedal sensor outputs and 2 for throttle position sensor outputs).

|

|

The throttle valve is turned by a brushless throttle motor supplied with a 600 Hz PWM signal from control module pins 24 and 48. The control module can turn the throttle valve in both directions by reversing the motor poles. The PWM ratio increases as the throttle valve moves further away from its nominal value.

Two throttle position sensors are connected to the throttle spindle. The sensors consist of potentiometers which are supplied with 5 V from control module pins 46 and 69, which are internally connected to each other in the throttle body, and grounded via control module pins 22 and 70 which are also connected to each other inside the throttle body.

The voltage from sensor 1 is connected to control module pin 33 and increases with the throttle position. The voltage from sensor 2 is connected to control module pin 10 and decreases with the throttle position. The sum of the two sensor voltages is therefore always about 5 V.

The voltage from sensor 1 is used by the control module as a value for the current throttle position.

The air mass control requests a certain air mass/combustion. The throttle control converts this value into a requested value for throttle position sensor 1 and compares this with the sensor's current value.

The difference gives rises to a throttle motor PWM signal with a polarity which turns the throttle valve until its current value corresponds to that requested.

If a major fault should occur in the throttle control, the control module will ground pin 36 and the limp-home solenoid will operate. The solenoid, which is located on the throttle body, then connects the pedal cable to the throttle spindle. The throttle motor is de-energized and the throttle is then controlled directly from the accelerator pedal.

The limp-home solenoid is first activated for 1 s and then for 4 x 0.5 s.

| Important | ||

|

The solenoid may be supplied with current for short periods only as it is extremely low-ohmic. |

||

When the total air mass/combustion requested by the system has been calculated, it must be realized first by the throttle and then, if necessary, by the turbo control.

The requested air mass/combustion is corrected by the air density before the throttle. Thinner air requires a larger throttle angle to achieve the same air mass/combustion. The density of the air is calculated on the basis of the charge air pressure and the temperature of the intake air.

The value is then converted into a requested voltage for throttle position sensor 1. The throttle motor turns the throttle valve until the current sensor voltage corresponds to that requested.

The control module then checks that the current air mass/combustion corresponds to that requested. If necessary, fine adjustment of the throttle position is performed.

If a safety-related fault occurs in the throttle control system, the throttle will go into limp-home mode. The CHECK ENGINE lamp then comes on immediately and the diagnostic trouble code must be cleared with the diagnostic tool.

| Diagnostics |

| • |

DTC P1230 is generated if there is a fault in the circuit to any of the throttle position sensors. The software has been changed during MY02 in order to make the diagnosis less sensitive to disturbances that normally occur. It is therefore essential that the throttle body is not changed if the control module is programmed with the old software version. See fault diagnosis for more information.

|

|

| • |

DTC P1231 is generated after intermittent breaks in the circuit to one of the throttle position sensors normally caused by contaminants on the potentiometer surfaces. See fault diagnosis for more information.

|

|

| • |

If a throttle motor fault or a mechanical fault occurs, diagnostic trouble codes P1240, P1251-P1253, P1260-P1261, P1263 or P1264 will be generated.

|

|

| • |

If an internal control module fault occurs which affects the throttle control system, diagnostic trouble codes P1601-P1611, P1613-P1614 or P1621 will be generated.

|

|

| • |

If a break or short-circuit occurs between the control module output and the relay for the limp-home solenoid, diagnostic trouble codes P1670-P1671 will be generated.

|

|

Most of the above faults will cause the throttle control system to go into limp-home mode.

| Important | ||

|

When the throttle control system is in limp-home mode, the fault is stored in the control module memory. Each time the ignition is switched on, the limp-home solenoid is activated for 1 s and then for 4 x 0.5 s to ensure that the mechanism is not reset before the fault has been rectified. Repair work must therefore be carried out in the following order: |

||

| 1. |

Rectify the fault.

|

|

| 2. |

Delete the DTCs.

|

|

| 3. |

Reset the limp-home mechanism.

|

|

|

If this sequence is not followed, it is highly likely that the car will leave the workshop with the throttle control system still in limp-home mode. When the system detects that it is in mechanical limp-home mode, diagnostic trouble code P1260, P1263 or P1251 will be generated. |

||

|

Silicone sprays must not be used on the electrical or mechanical parts of the throttle body. |

||

|

The throttle body must not be washed. |

||

| Turning the throttle spindle manually |

If you intend to increase engine speed from the engine bay and accidentally turn the throttle spindle instead of the pedal position sensor arm, fuel shut-off will be activated and diagnostic trouble code P1263 will be generated. The throttle control system will not go into limp-home mode, nor will the CHECK ENGINE lamp come on.

However, if the throttle spindle is turned manually while the starter motor is cranking the engine (such as during a compression test) or during the first 5 seconds after starting, diagnostic trouble code P1251 will be generated and the system will go into limp-home mode.

| Other points |

| • |

The system controls the current air mass/combustion so that it corresponds to the requested value. It is perfectly normal for the throttle valve not to be fully open despite the accelerator being pressed fully down.

|

|

| • |

Apart from internal control module faults, faults in the throttle control system are always localized in the throttle body or its electrical leads. The main relay must also supply control module pin 1 with current.

A fault occurring in the supply of current from the main relay to control module pin 1 will cause main relay diagnostic trouble code P1640 to be generated, the throttle to close and the engine to stop. |

|

| • |

There is no difference in accelerator sensitivity when in limp-home mode.

|

|

| • |

The system is self-calibrating.

|

|

| Note | ||

|

A short circuit in the 5V supply will put the system in limp-home mode and may be due to a fault in the wiring harness or in a sensor supplied with 5V. |