Power steering pump, V6 petrol engine

|

|

Power steering pump, V6 petrol engine

|

|

Important

|

|

Scrupulous cleanliness must always be observed when carrying out any work involving hydraulic components.

|

|

|

|

1.

|

Place the car on a lift.

|

|

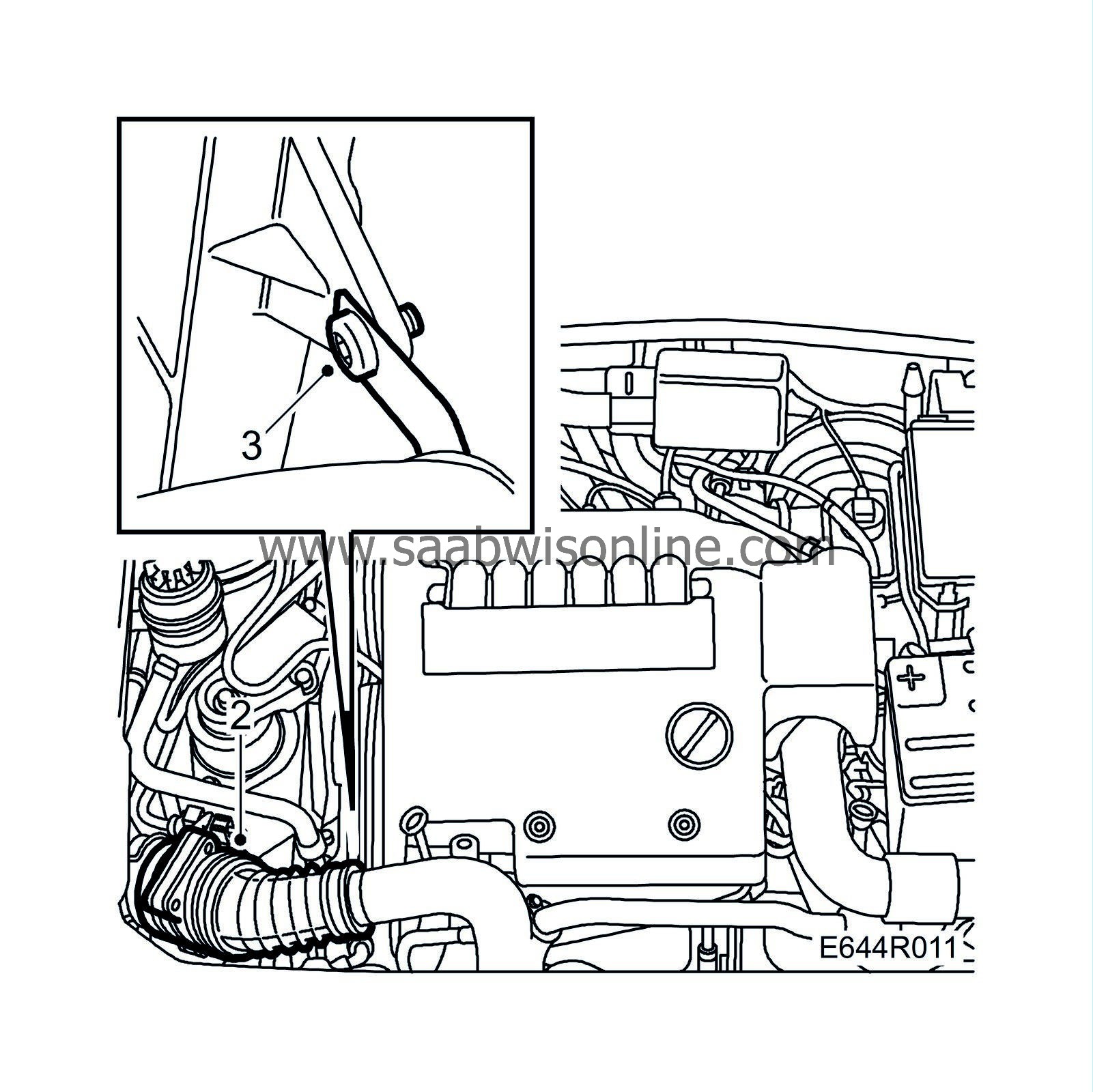

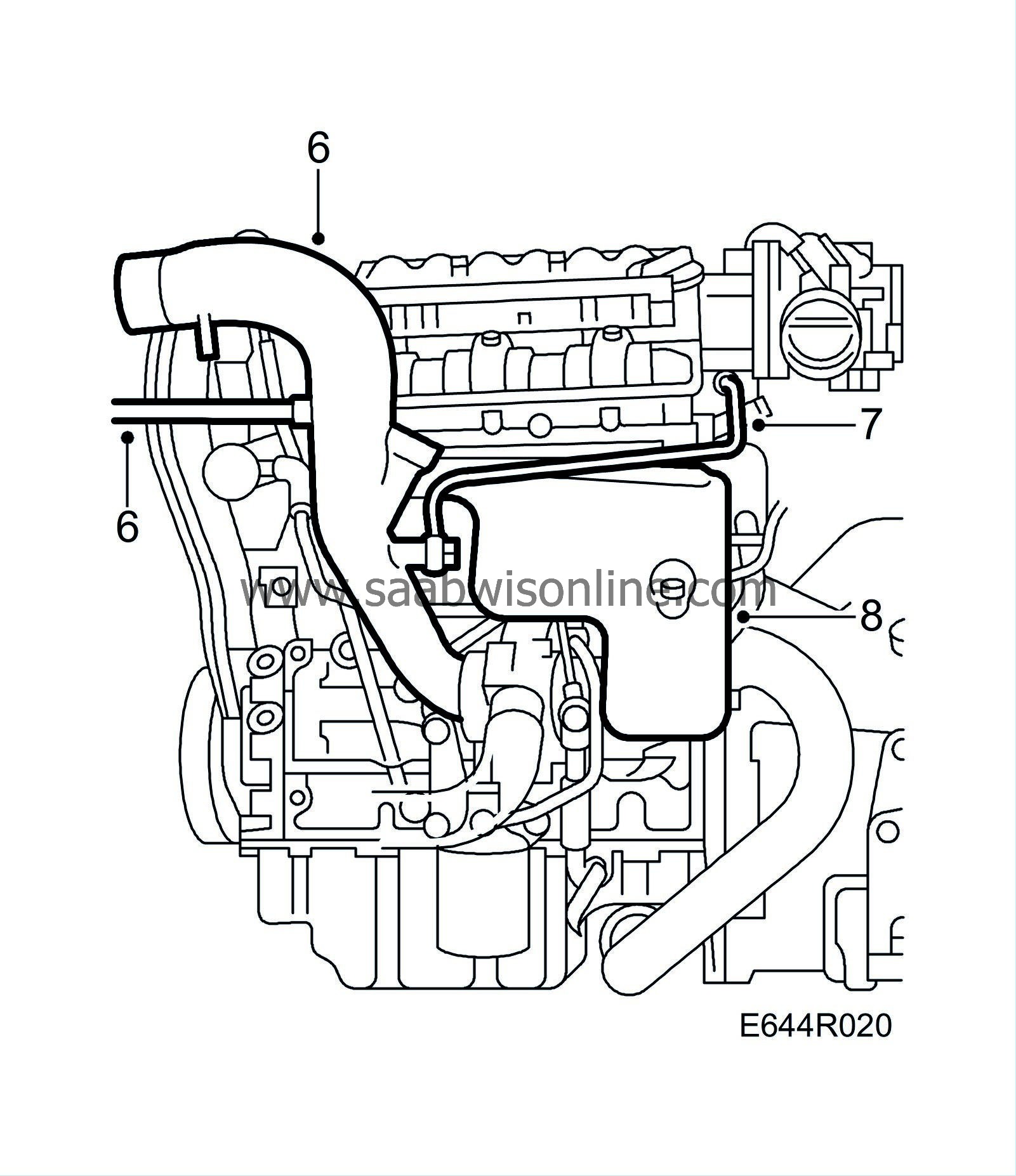

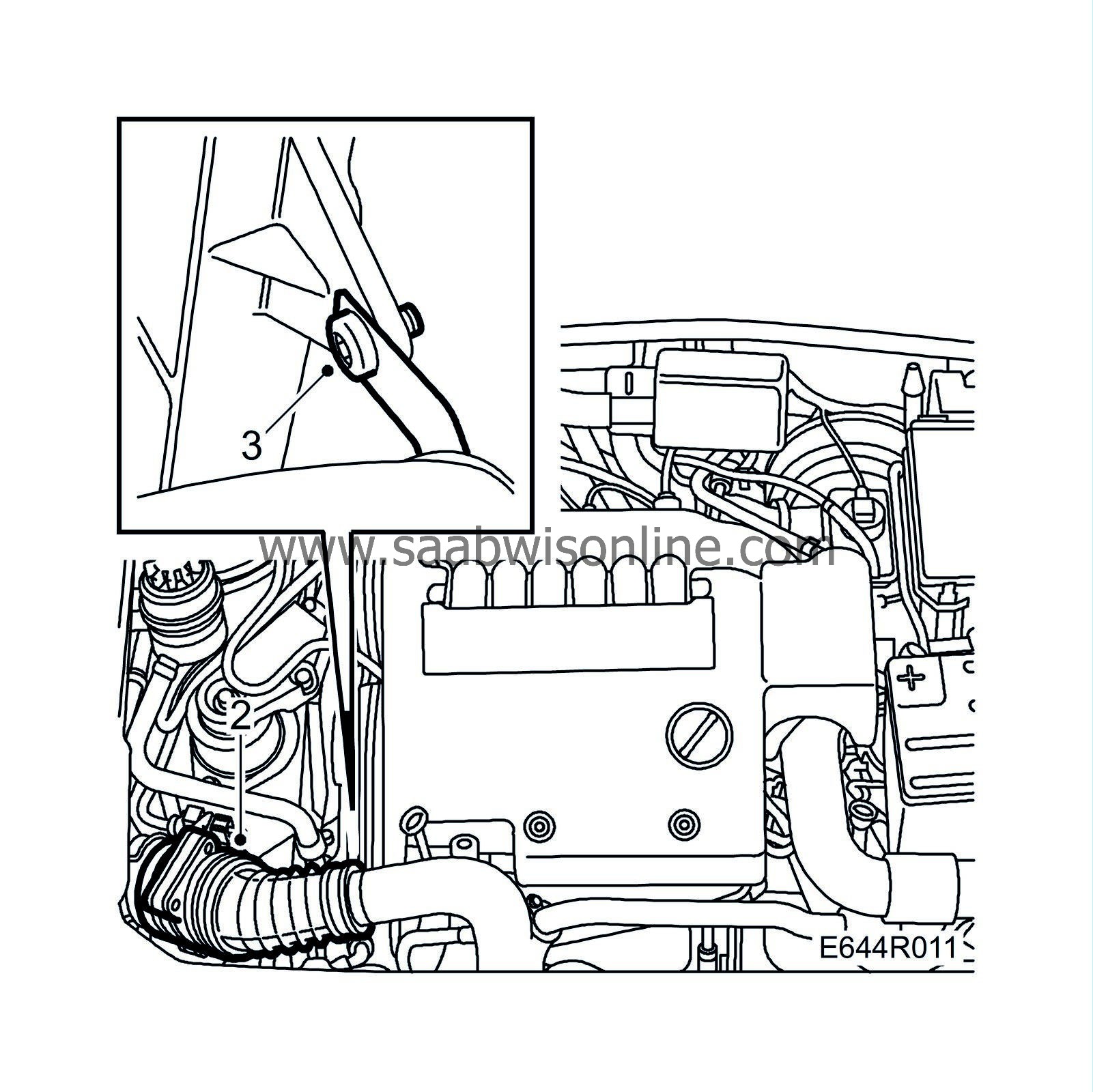

2.

|

Remove the mass air flow sensor with hose.

|

|

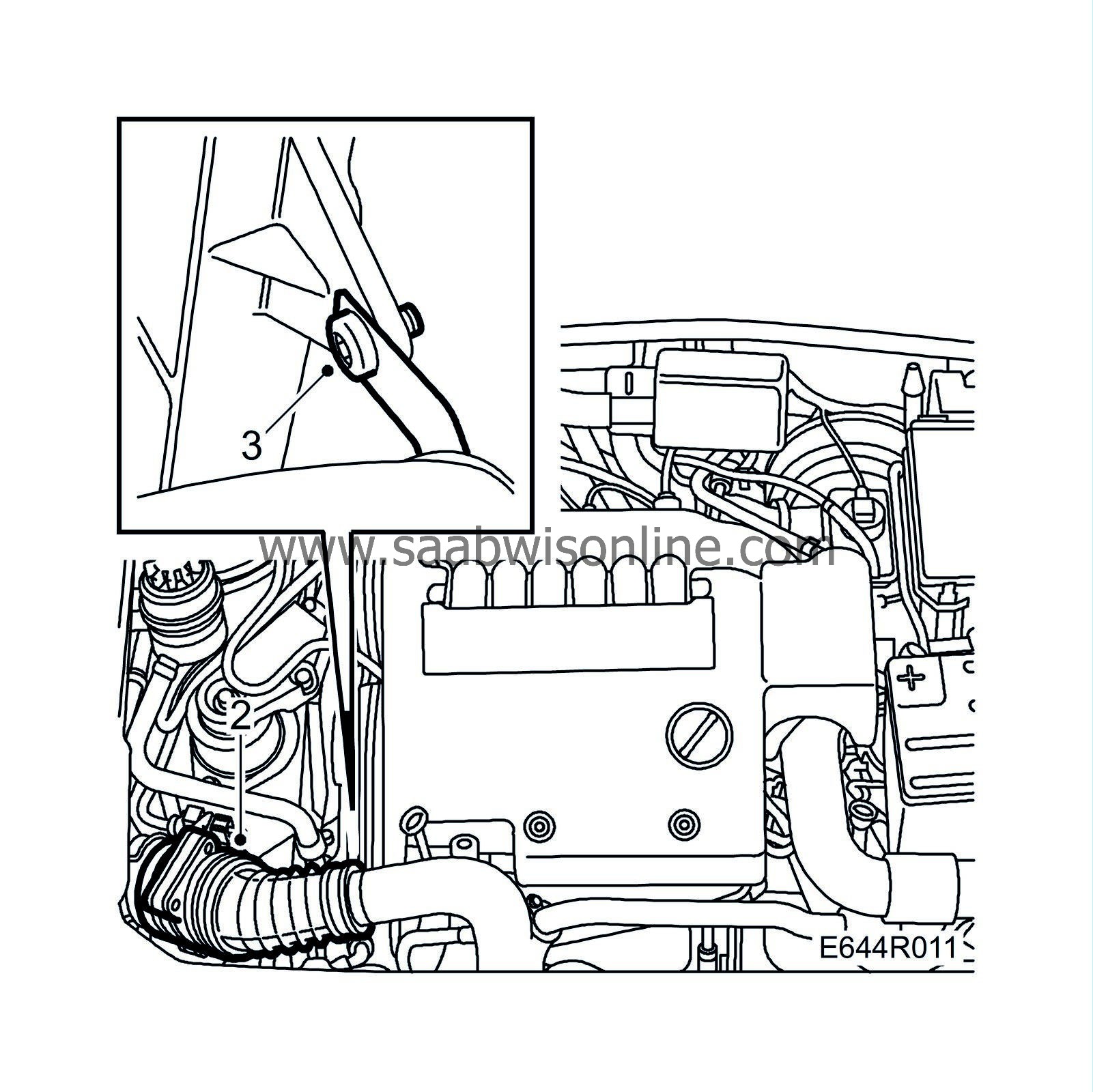

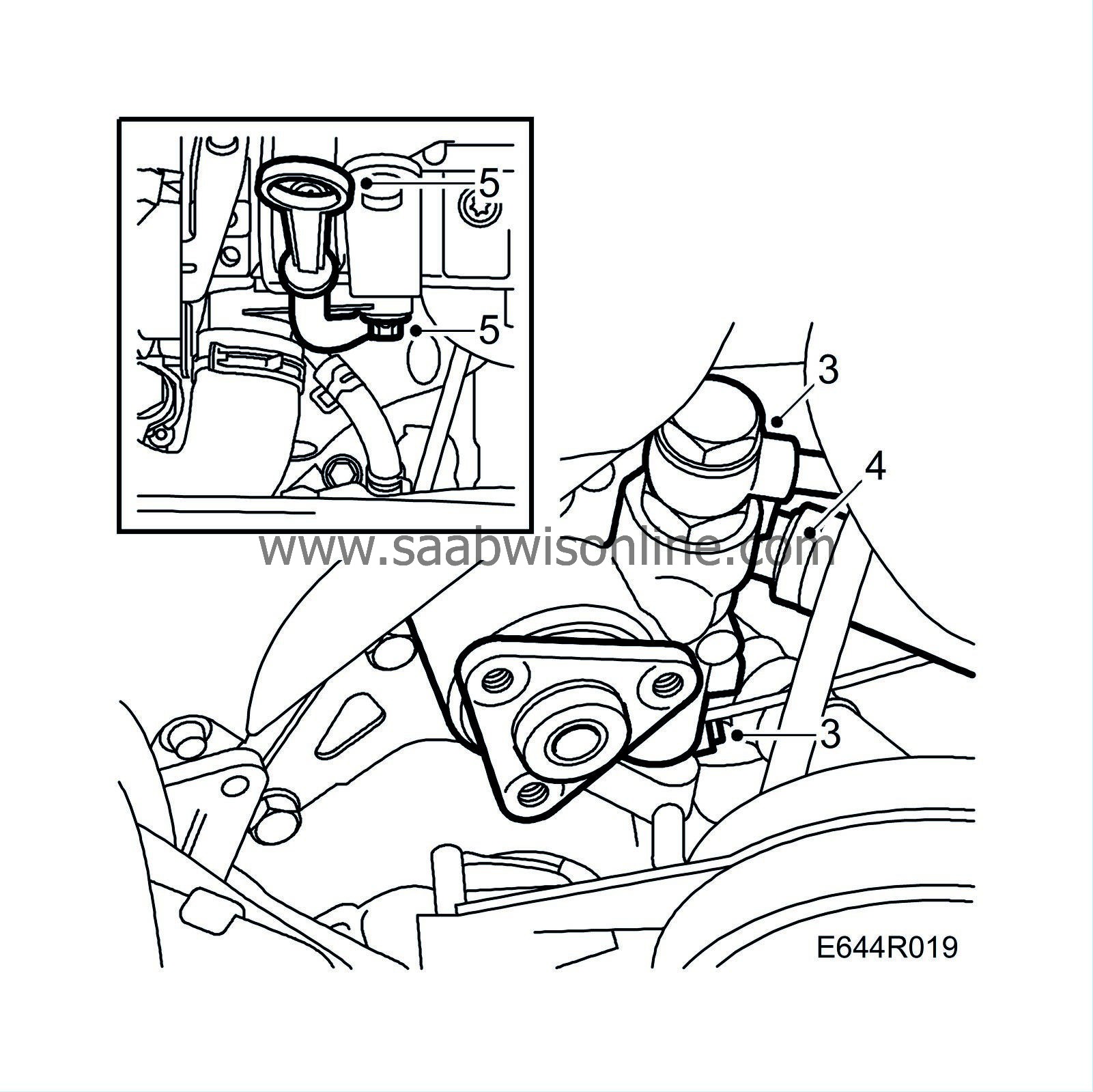

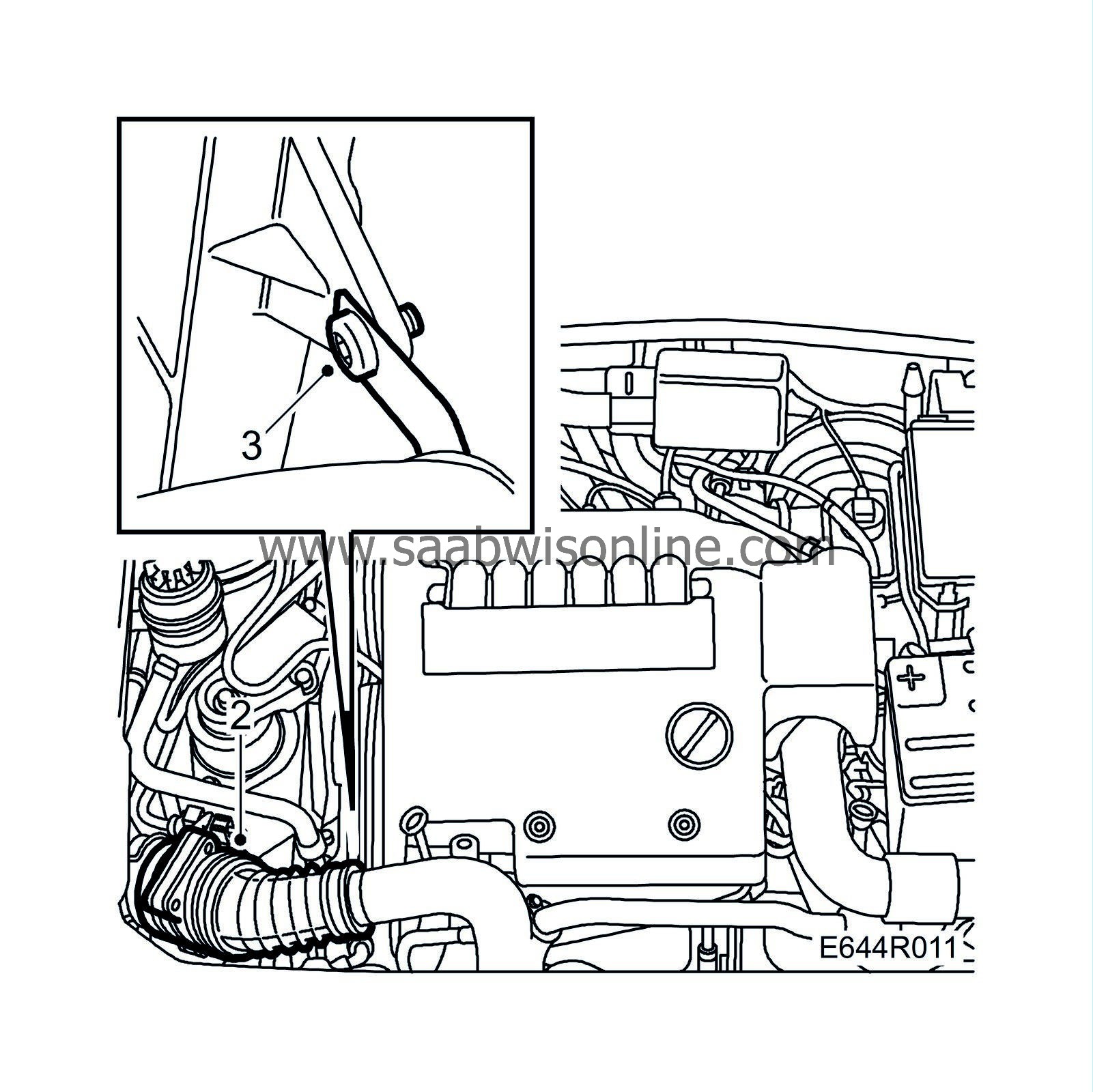

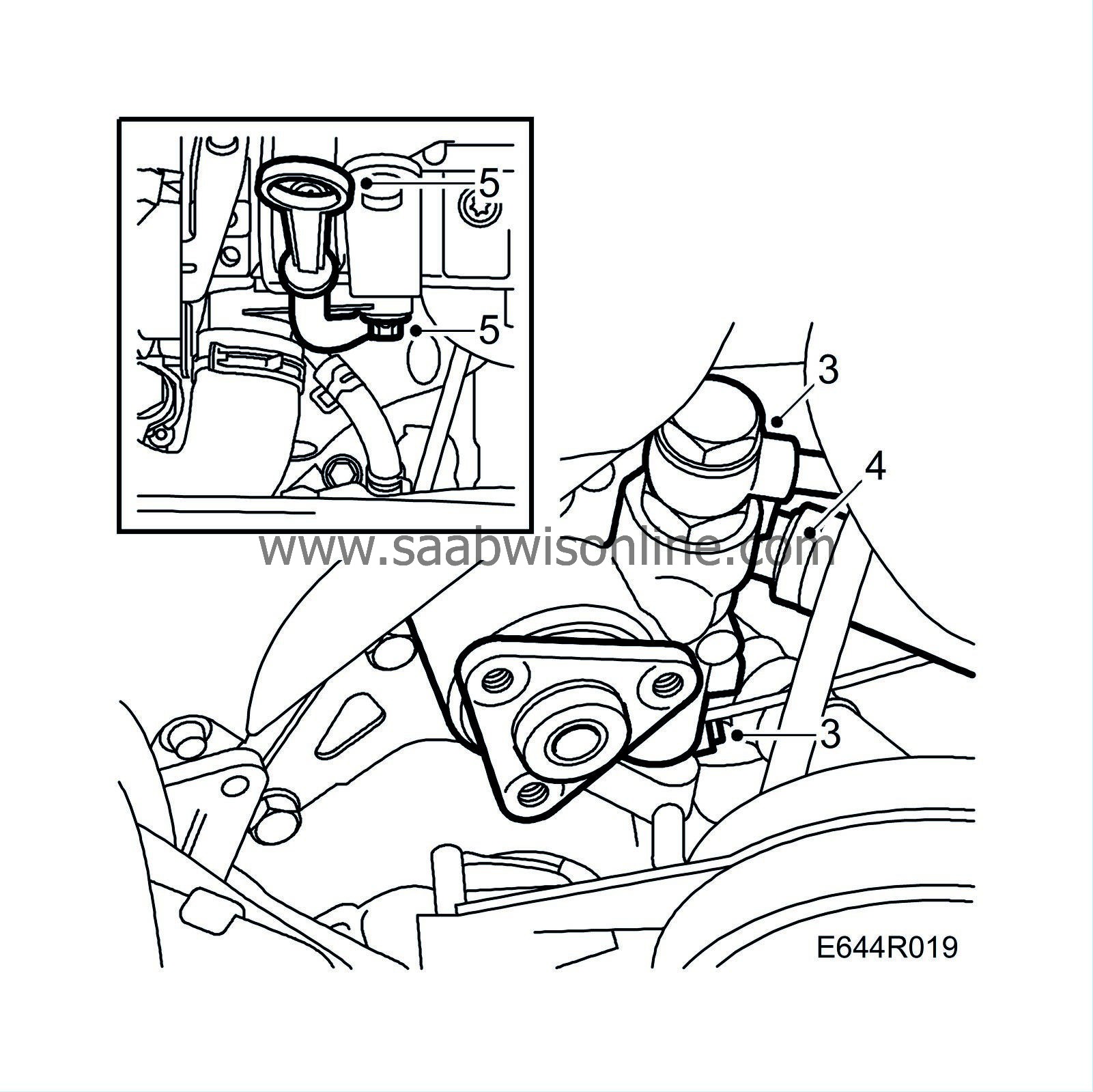

3.

|

Detach the power steering servo hose from the engine mounting bracket.

|

|

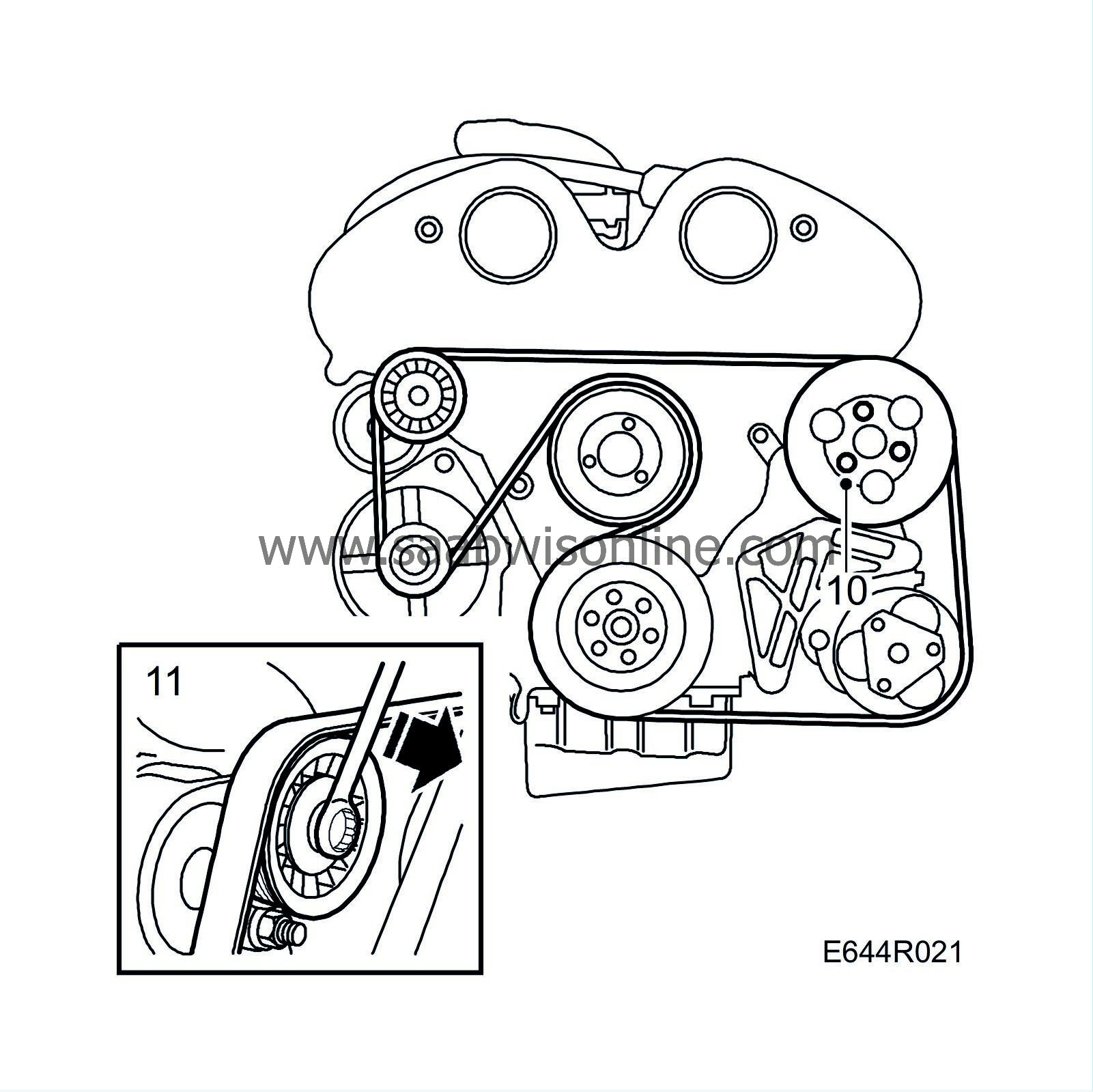

4.

|

Undo the belt pulley bolts slightly.

|

|

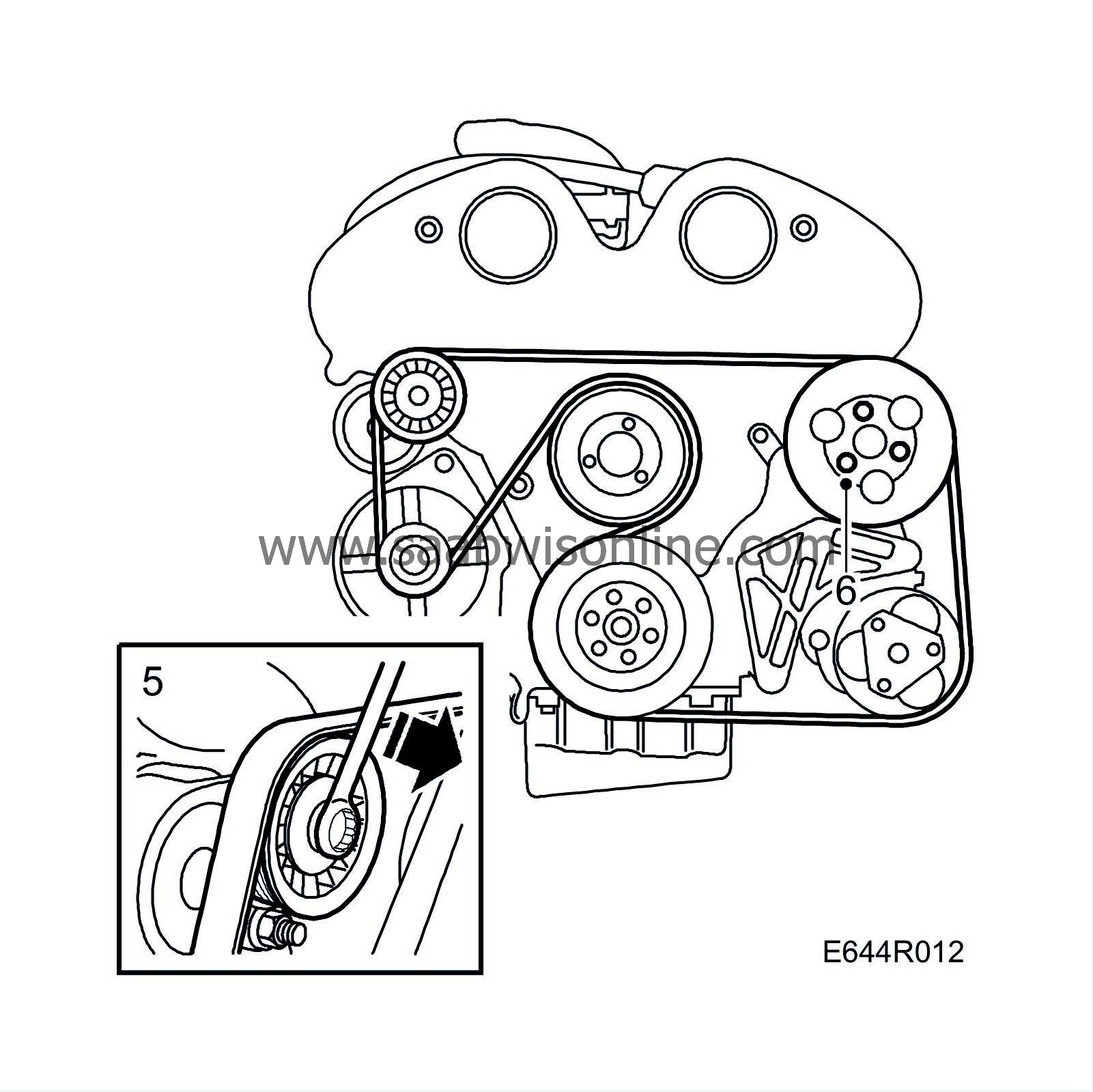

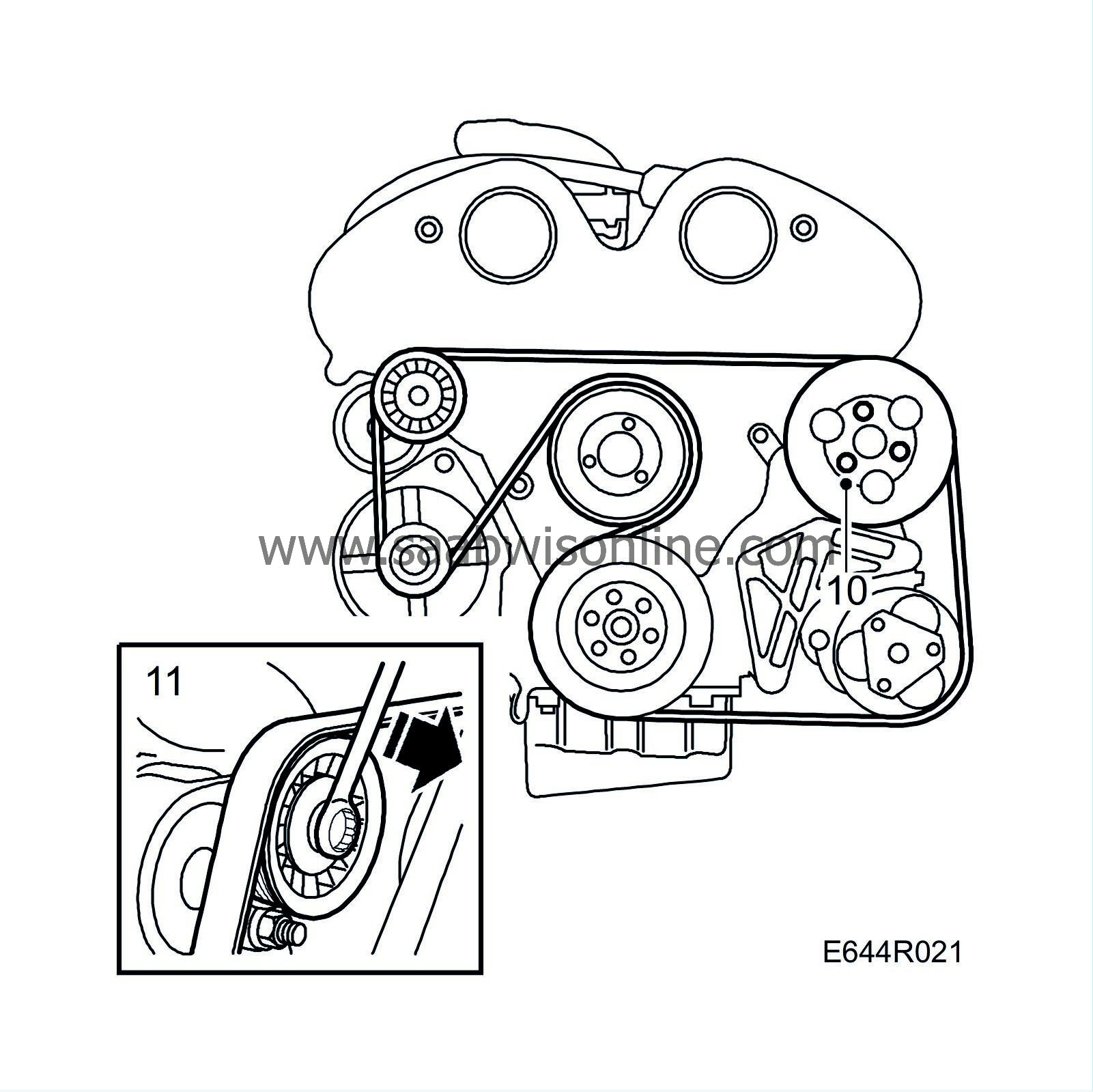

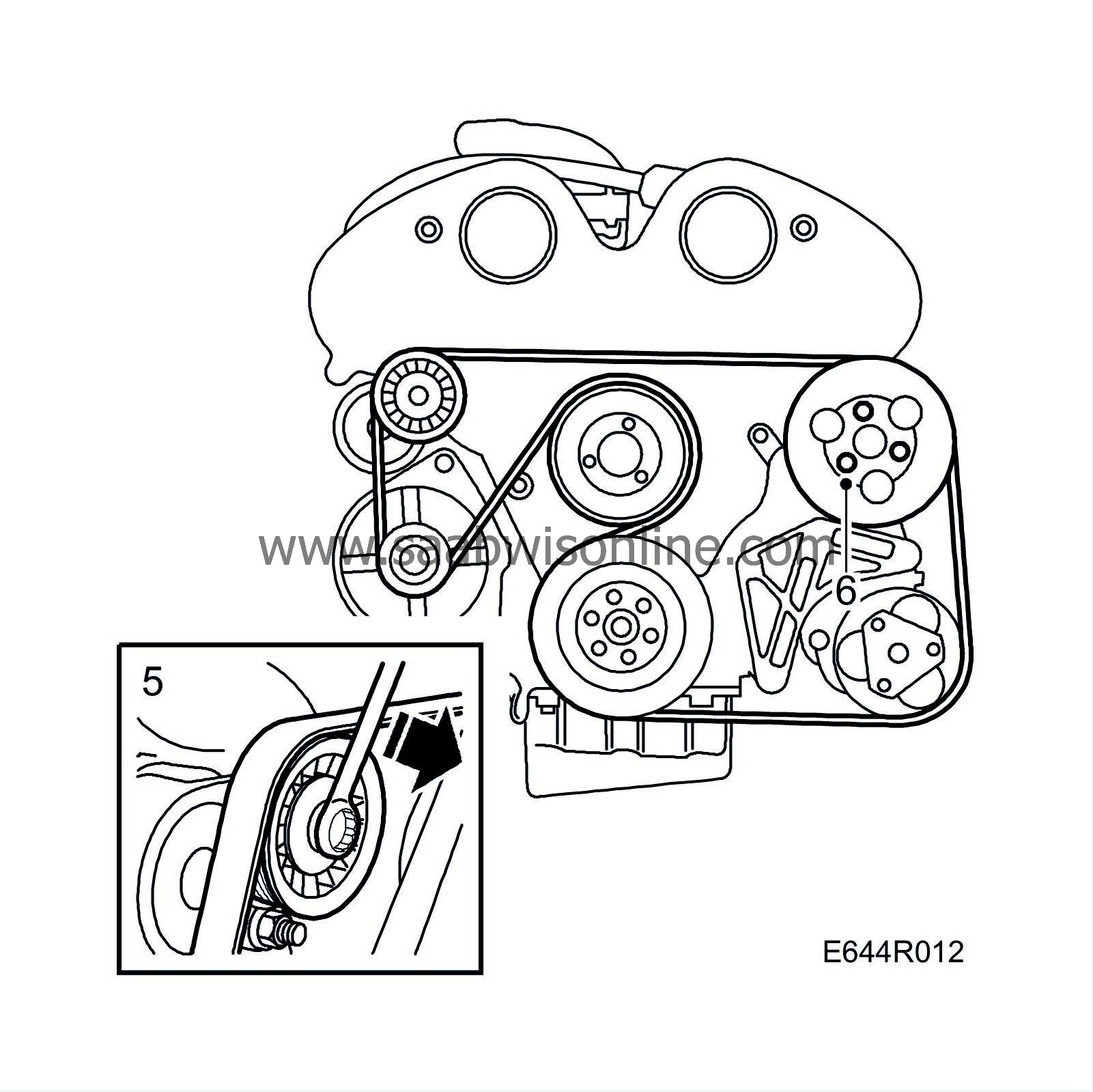

5.

|

Detension the multigroove V-belt and lift it off the servo pump pulley.

|

|

6.

|

Remove the belt pulley.

|

|

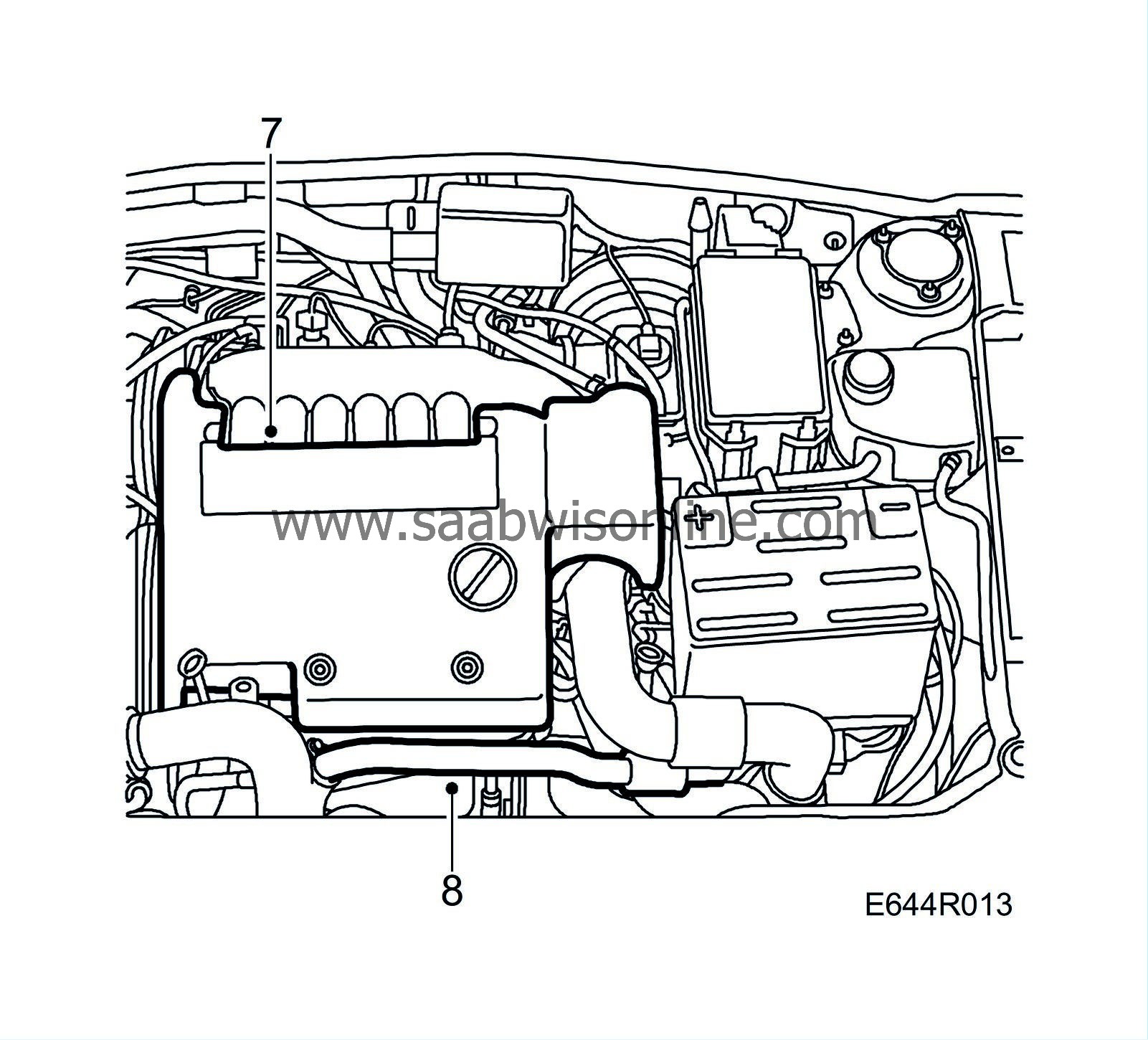

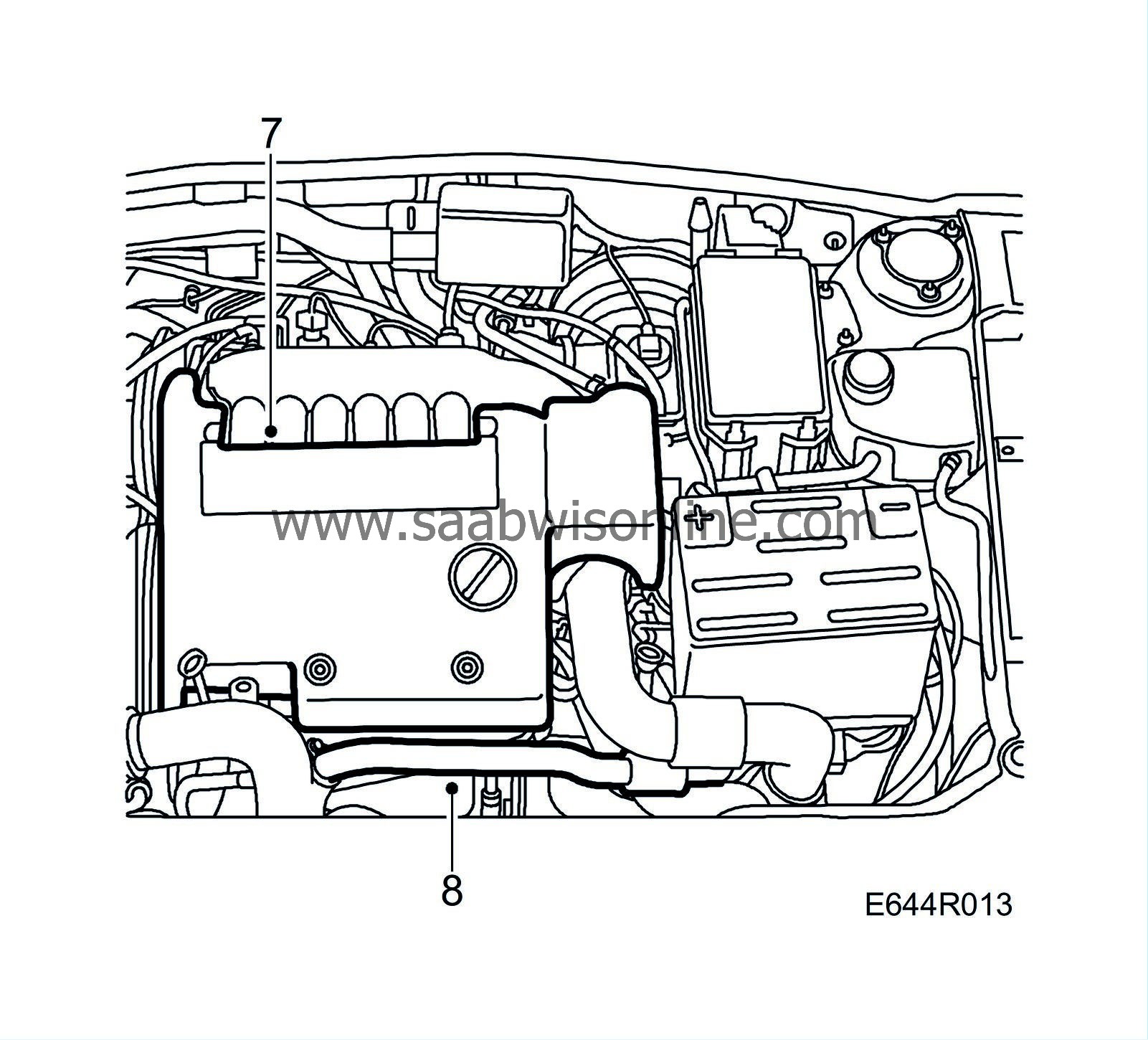

7.

|

Remove the upper engine cover.

|

|

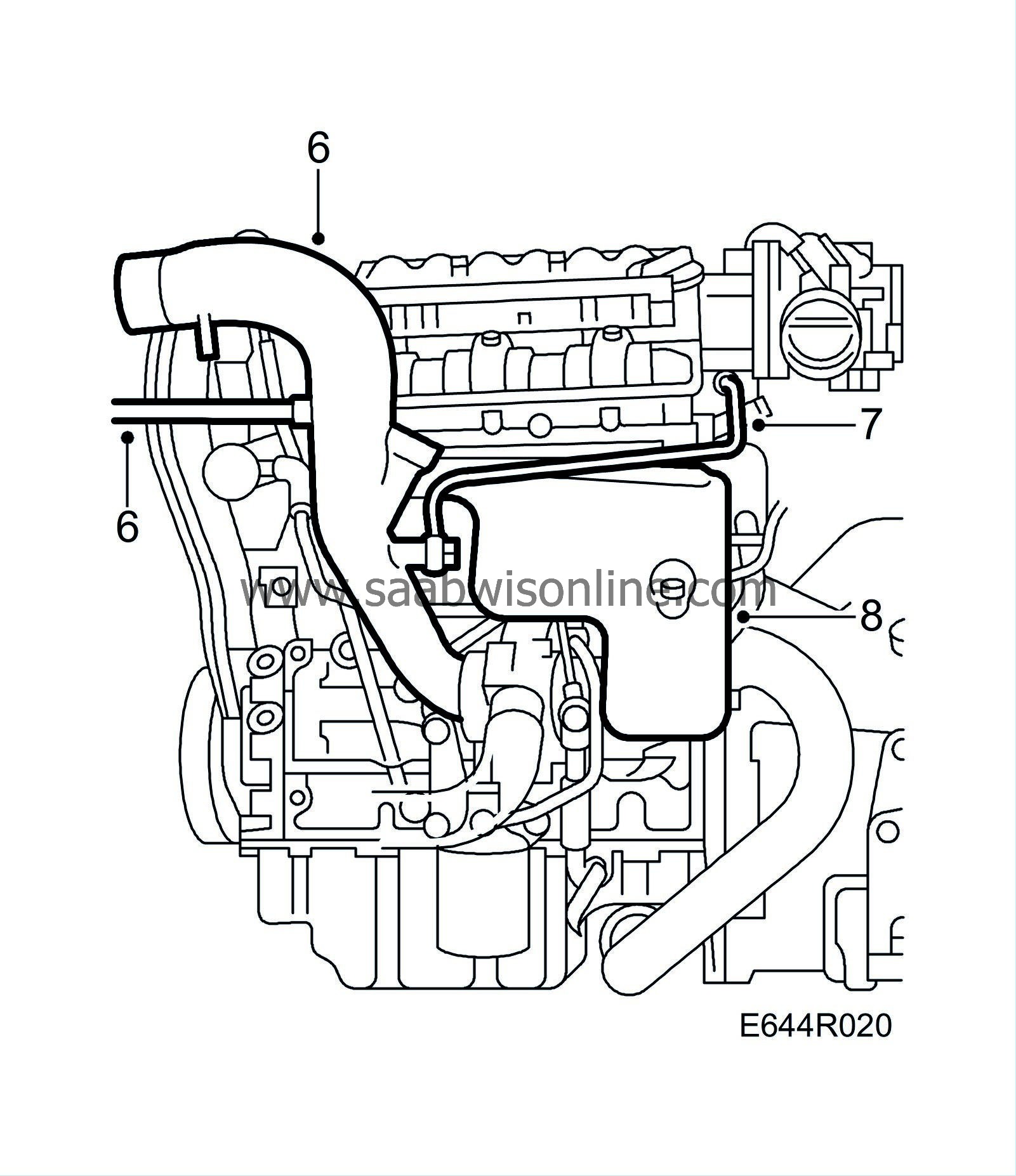

8.

|

Detach the bypass pipe from the turbo inlet pipe and bend it to one side, retrieve the O-ring.

|

Note

|

|

Blow clean around the connection first.

|

|

|

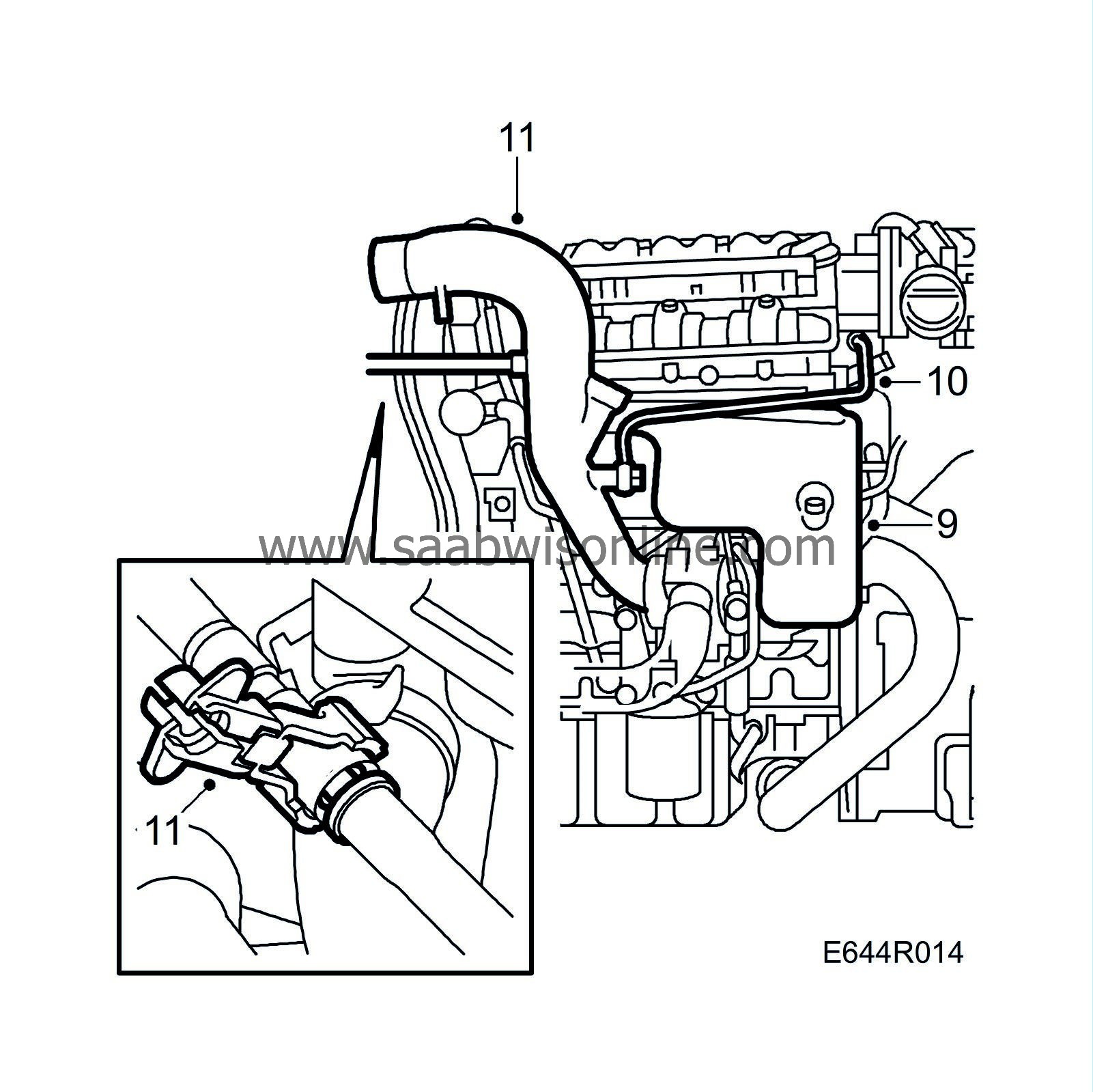

9.

|

Remove the exhaust manifold heat shield.

|

|

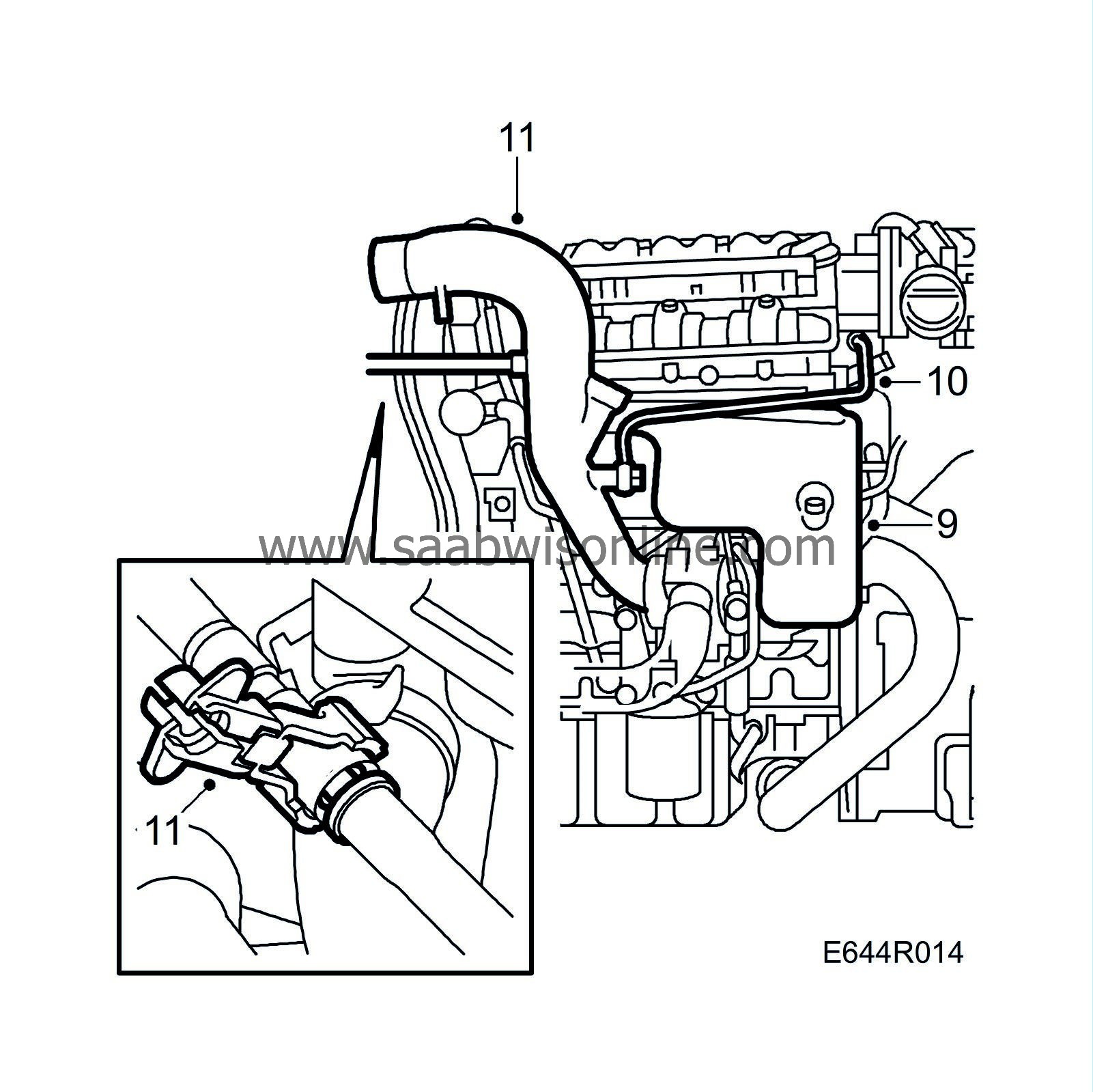

10.

|

Disconnect the crankcase ventilation pipe between the turbo inlet pipe and the cylinder head. Retrieve the sealing washers.

|

|

11.

|

Remove the turbo inlet pipe and disconnect the quick-release coupling on the hose to the EVAP canister, use special tool 83 95 261.

|

|

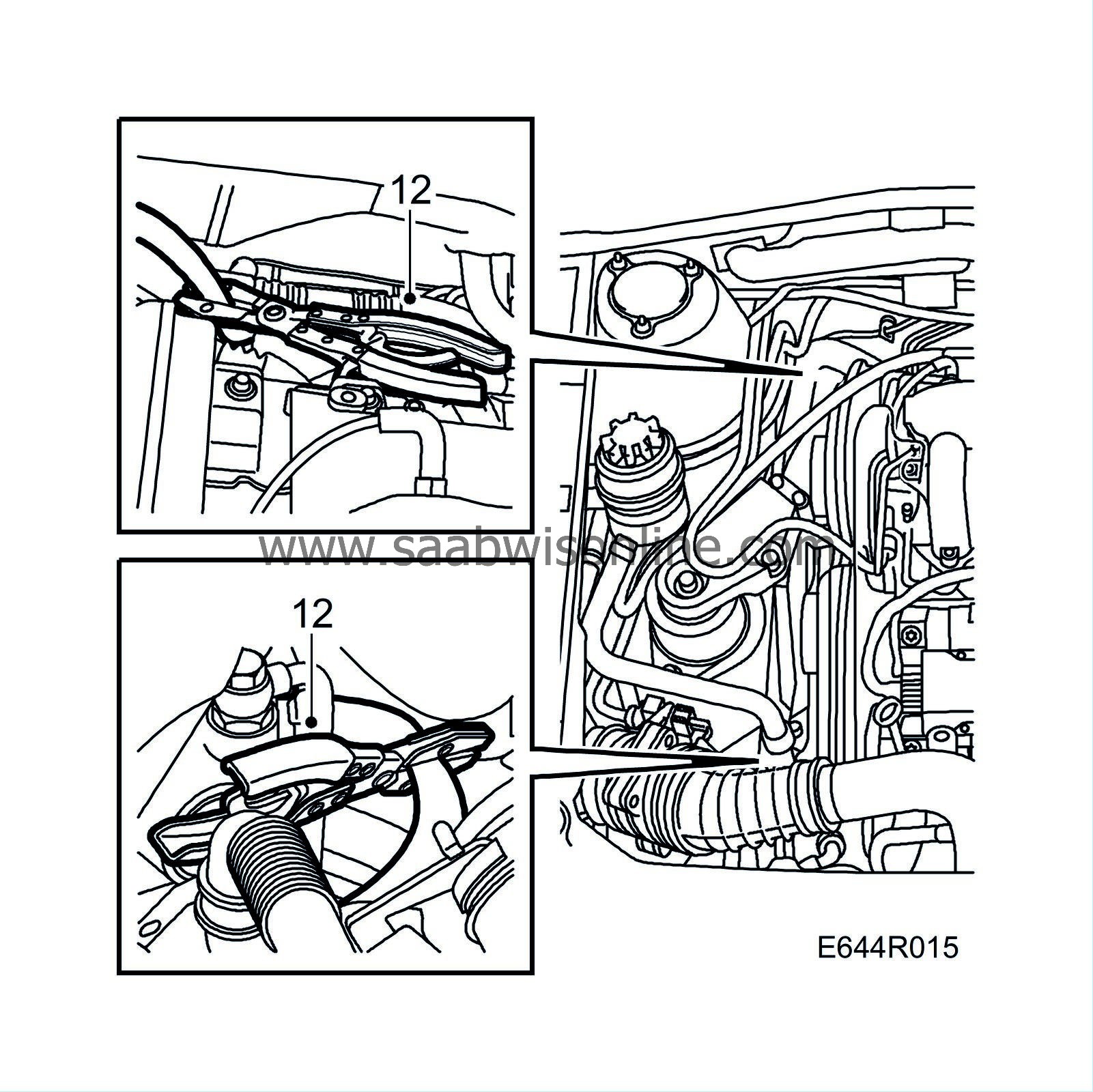

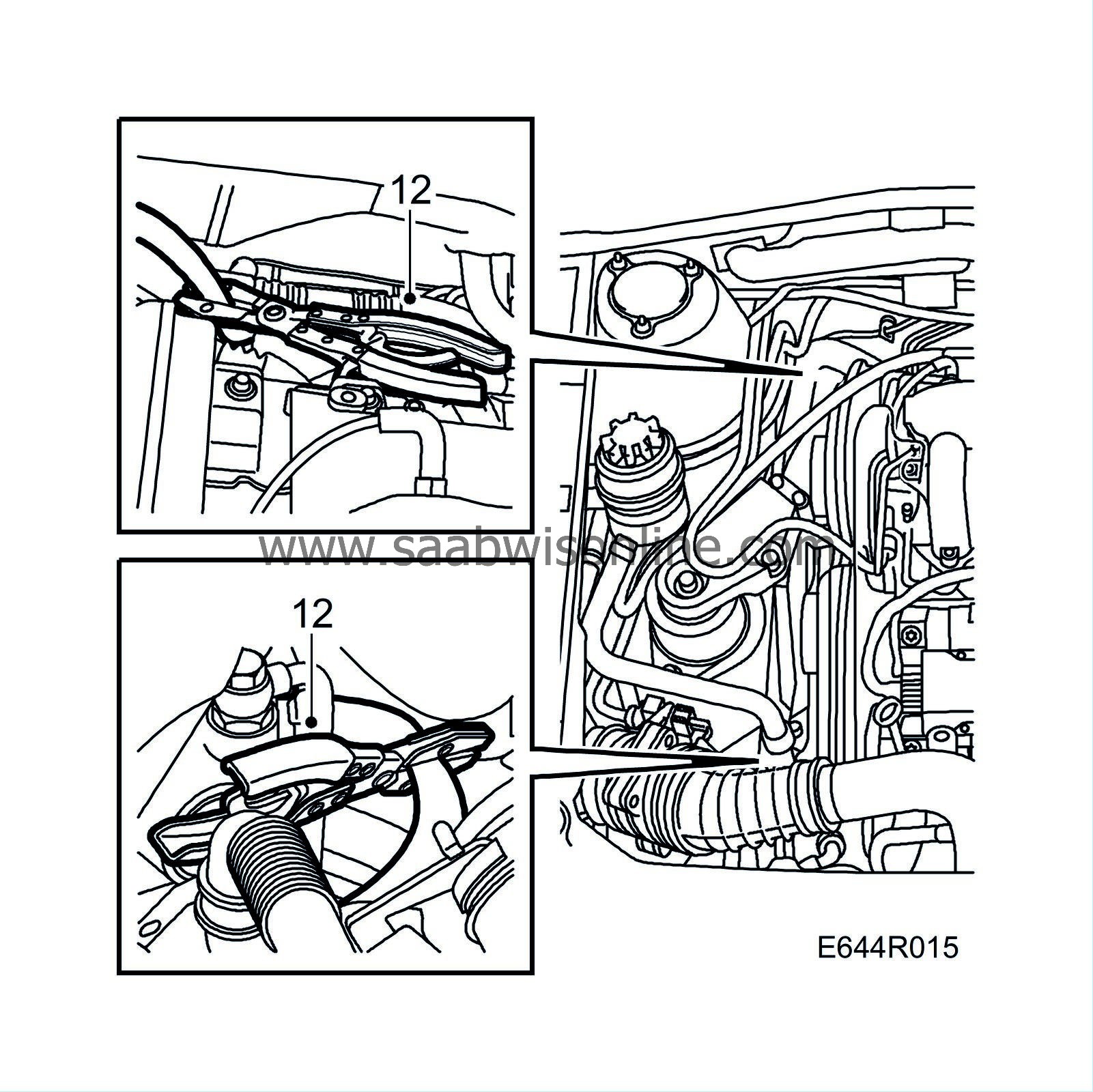

12.

|

Pinch the inlet hose to the power steering pump and return hose to the reservoir with pinch-off pliers 30 07 739.

|

|

13.

|

Disconnect the inlet hose from the pump. Collect any fluid spill.

|

Important

|

|

Power steering fluid must not come in contact with belt pulleys or belts.

|

|

|

|

|

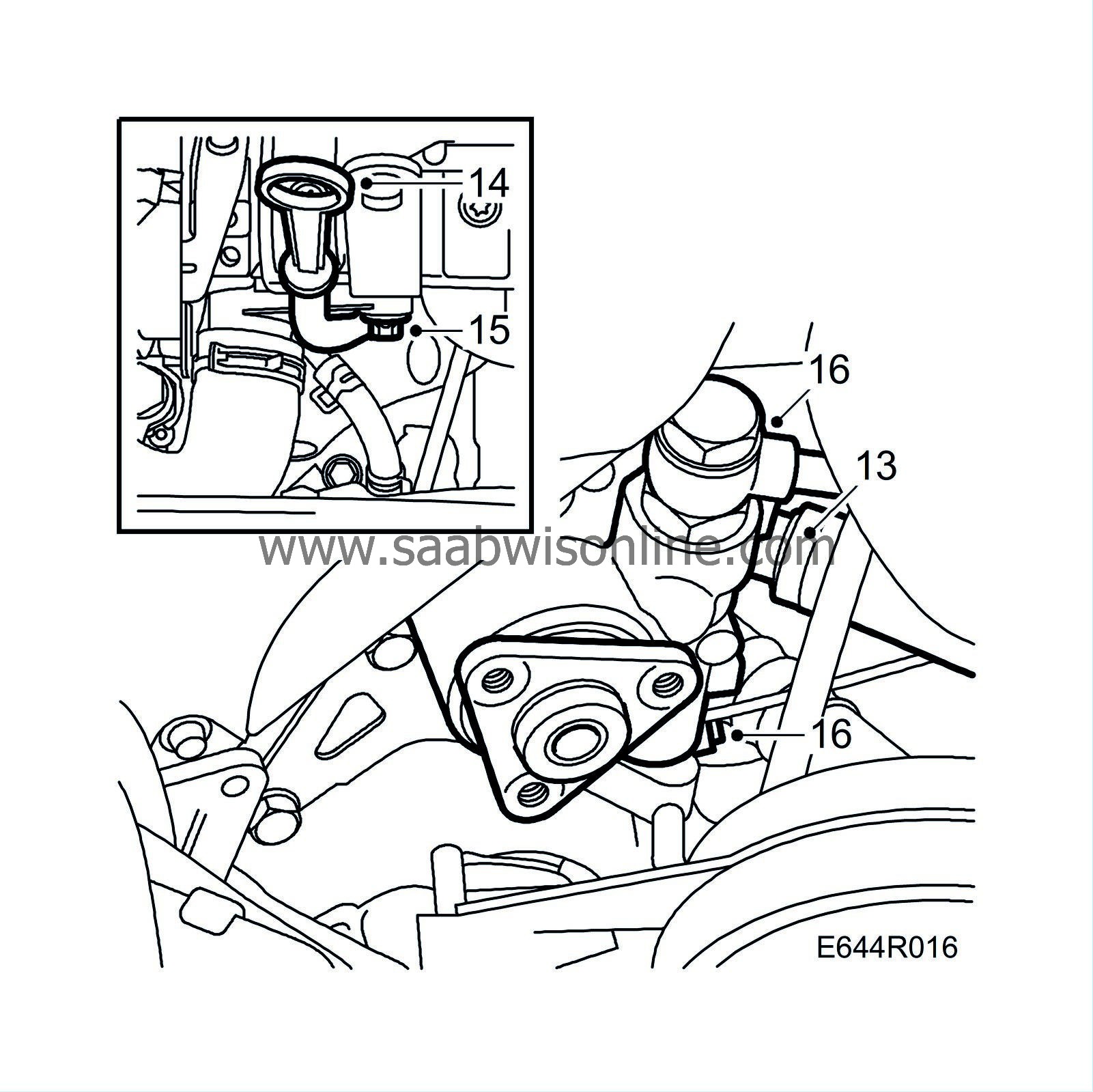

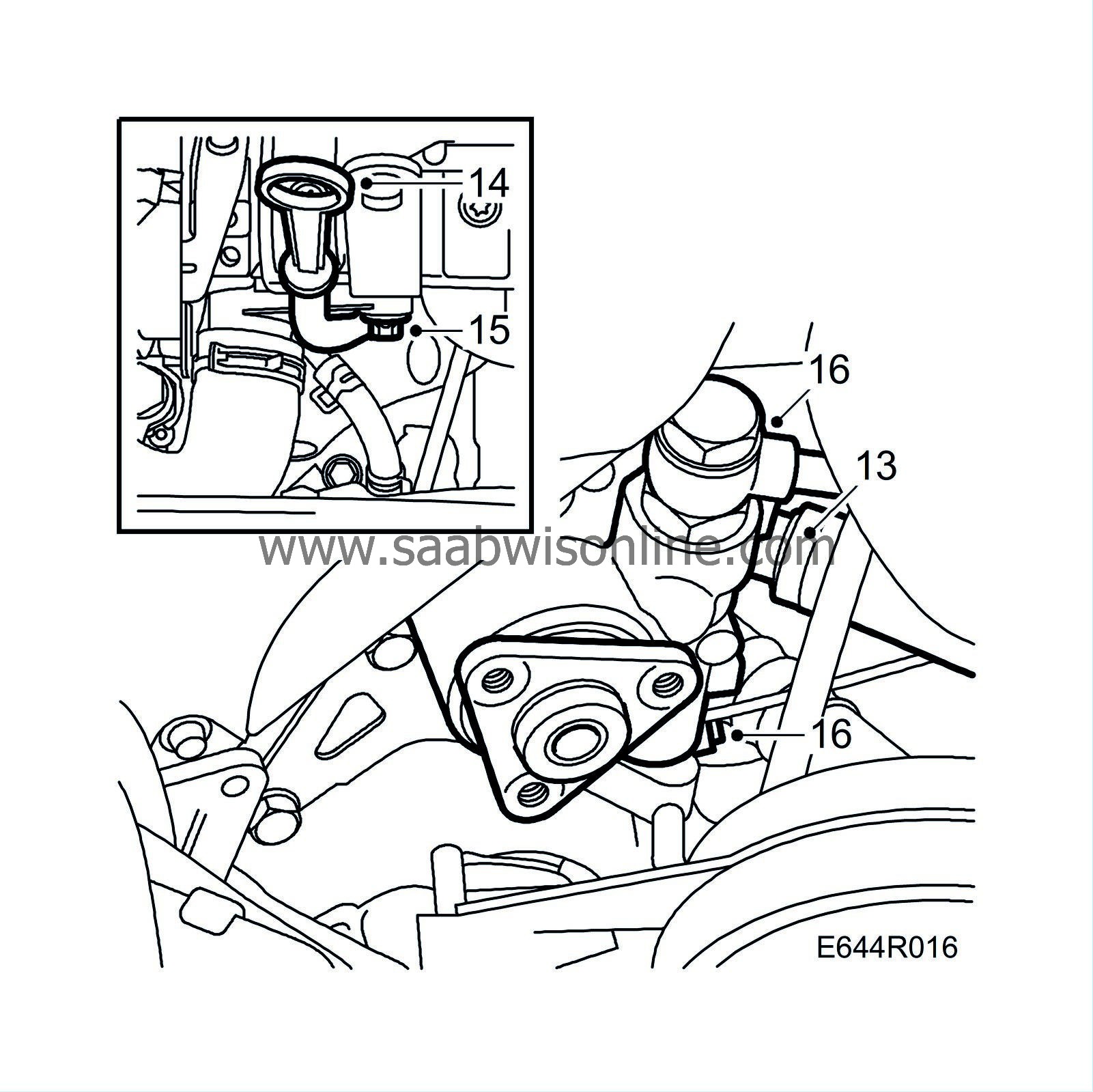

14.

|

Open the filler cap to the cooling system to release any pressure.

Remove the dipstick.

|

|

15.

|

Undo the bracket for the fluid level pipe and pull up the pipe to detach it from the engine. Replace the screw loosely to keep the water pipe in place.

|

Note

|

|

Take care, so that the water pipe does not come away from the thermostat mounting allowing water to run out.

|

|

|

16.

|

Detach the pressure (delivery) pipe from the pump, one bracket and one banjo screw. Collect any fluid spill.

|

|

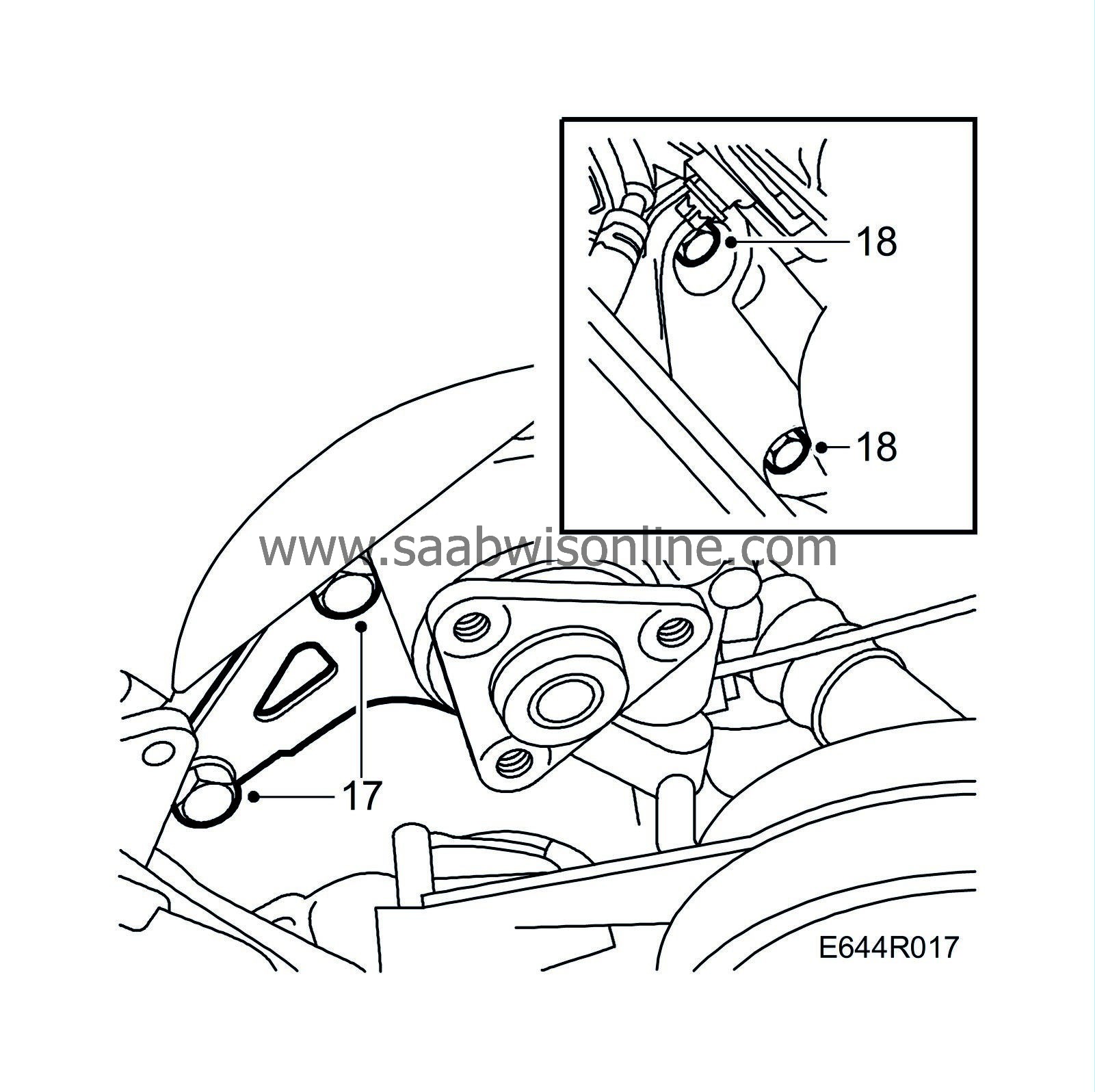

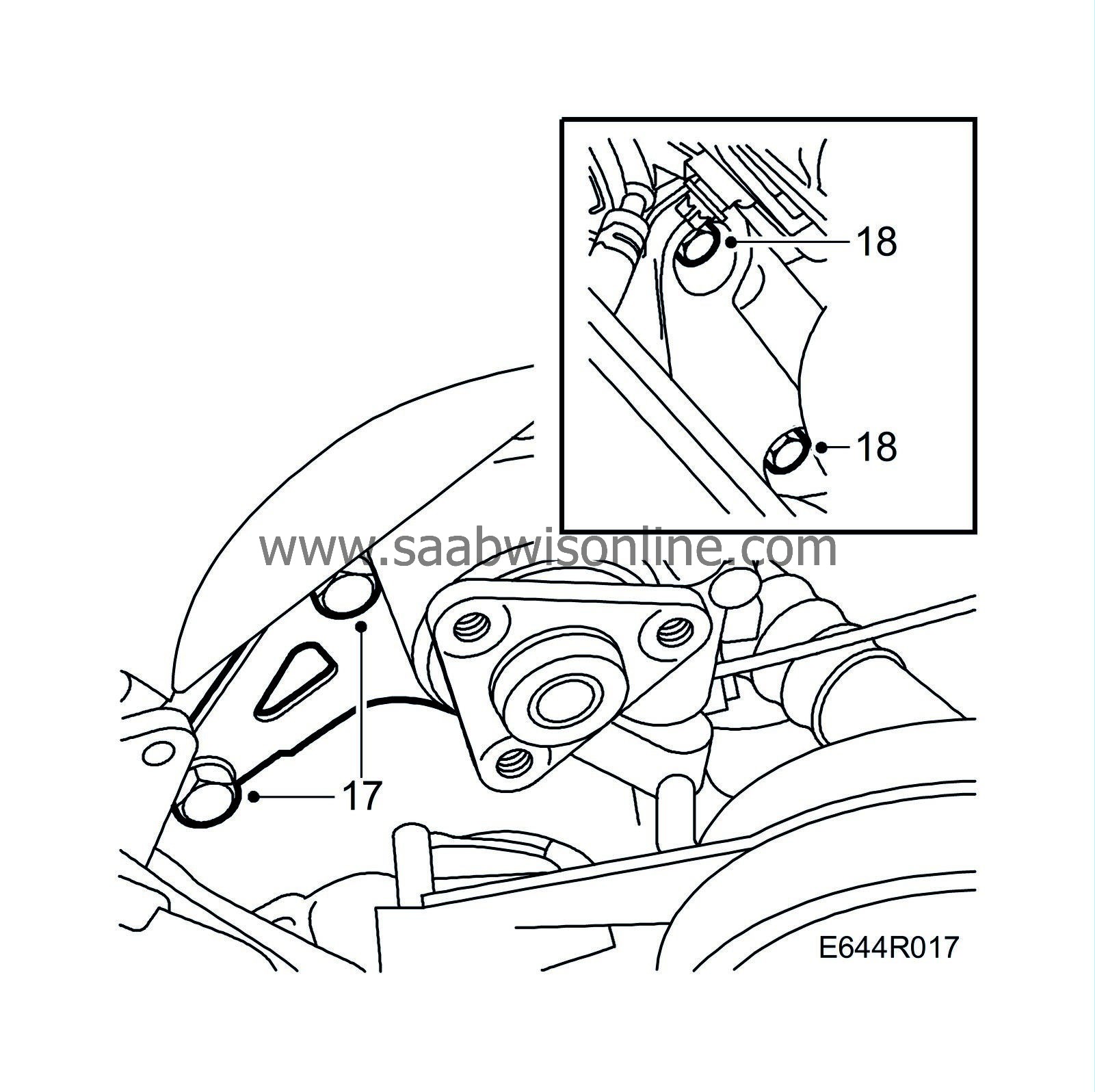

17.

|

Remove the pump bracket, 3 bolts.

|

|

18.

|

Unscrew the 2 pump retaining bolts and lift out the pump.

It may be necessary to undo the engine coolant hose to the turbo and bend the pipe slightly to one side to access the bottom bolt.

|

|

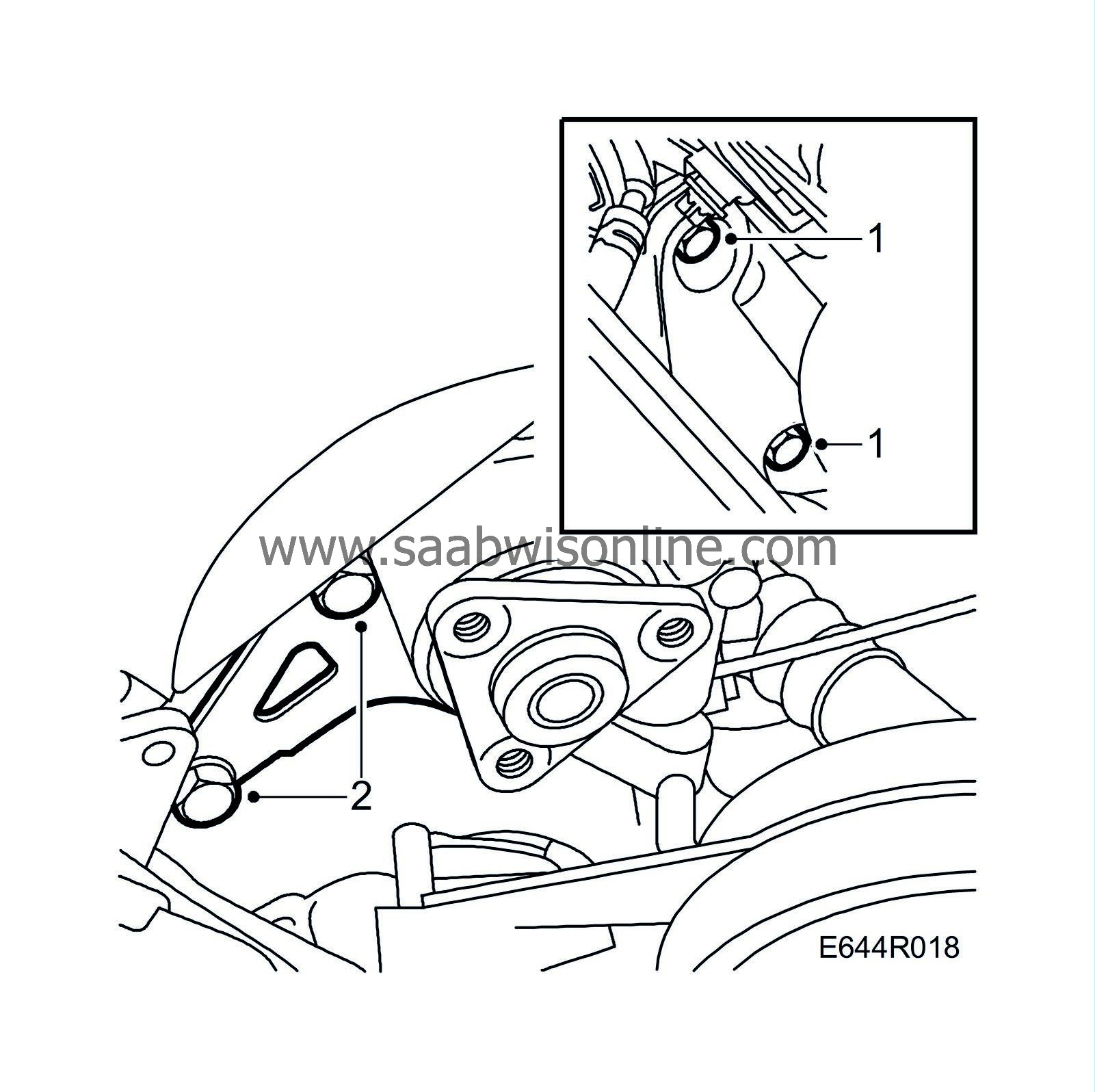

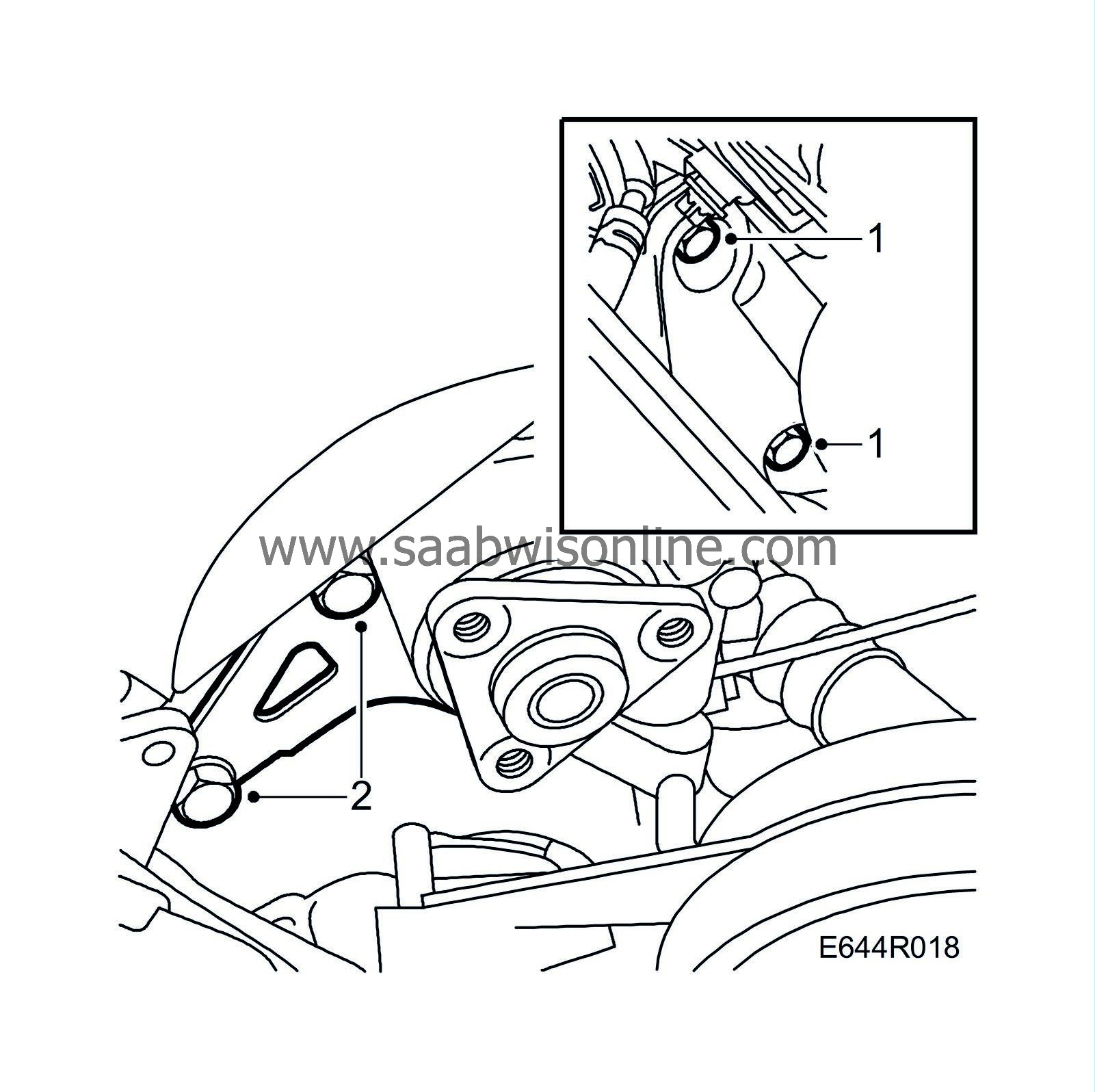

1.

|

Fit the 2 pump bolts and tighten them.

Tightening torque 24 Nm (18 lbf ft)

|

|

2.

|

Screw in and tighten the 3 bracket bolts.

Tightening torque 24 Nm (18 lbf ft)

|

|

3.

|

Connect the pressure (delivery) pipe and tighten the banjo nipple on the pump using new seals.

Tightening torque 30 Nm (22 lbf ft)

Screw the pipe mounting lug to the bracket.

|

|

4.

|

Connect the inlet pipe and tighten the hose clip.

Remove the pinch-off pliers.

|

|

5.

|

Fit the fluid level pipe.

Lubricate the O-rings with petroleum jelly, part no. 30 06 665, and press the pipe in place. Fit the screw for the level pipe bracket.

Insert the dipstick.

|

|

6.

|

Fit the turbo inlet pipe and tighten the V-clip.

Tightening torque 3 Nm (2 lbf ft)

Press together the quick-release coupling on the hose to the EVAP canister.

|

|

7.

|

Fit the crankcase ventilation pipe to the turbo inlet pipe using new sealing washers.

Tightening torque 24 Nm (18 lbf ft)

|

|

8.

|

Fit the heat shield to the front exhaust manifold.

|

|

9.

|

Connect and tighten the turbo bypass pipe with an O-ring.

Tightening torque 8 Nm (6 lbf ft).

|

|

10.

|

Fit the belt pulley.

Tightening torque 20 Nm + 30° (15 lbf ft + 30°)

|

|

11.

|

Take the strain off the belt tensioner and fit the belt. Ensure the belt is fitted correctly on all the belt pulleys.

|

|

12.

|

Fit the power steering servo hose to the engine mounting bracket

|

|

13.

|

Fit the mass air flow sensor with hose and plug it in.

|

|

14.

|

Fit the engine cover.

|

|

16.

|

Check for leakage around the connectors on the pump. Check also the integrity of the cooling system.

|

|

17.

|

Raise the car and wipe off any fluid spill on the right-hand engine cover under the car.

|

|

18.

|

Lower the car and road test.

|