Subframe, petrol engines

| Subframe, petrol engines |

This method is used when the same subframe is to be refitted.

| To remove |

| 1. |

Remove the engine cover.

|

|

| 2. |

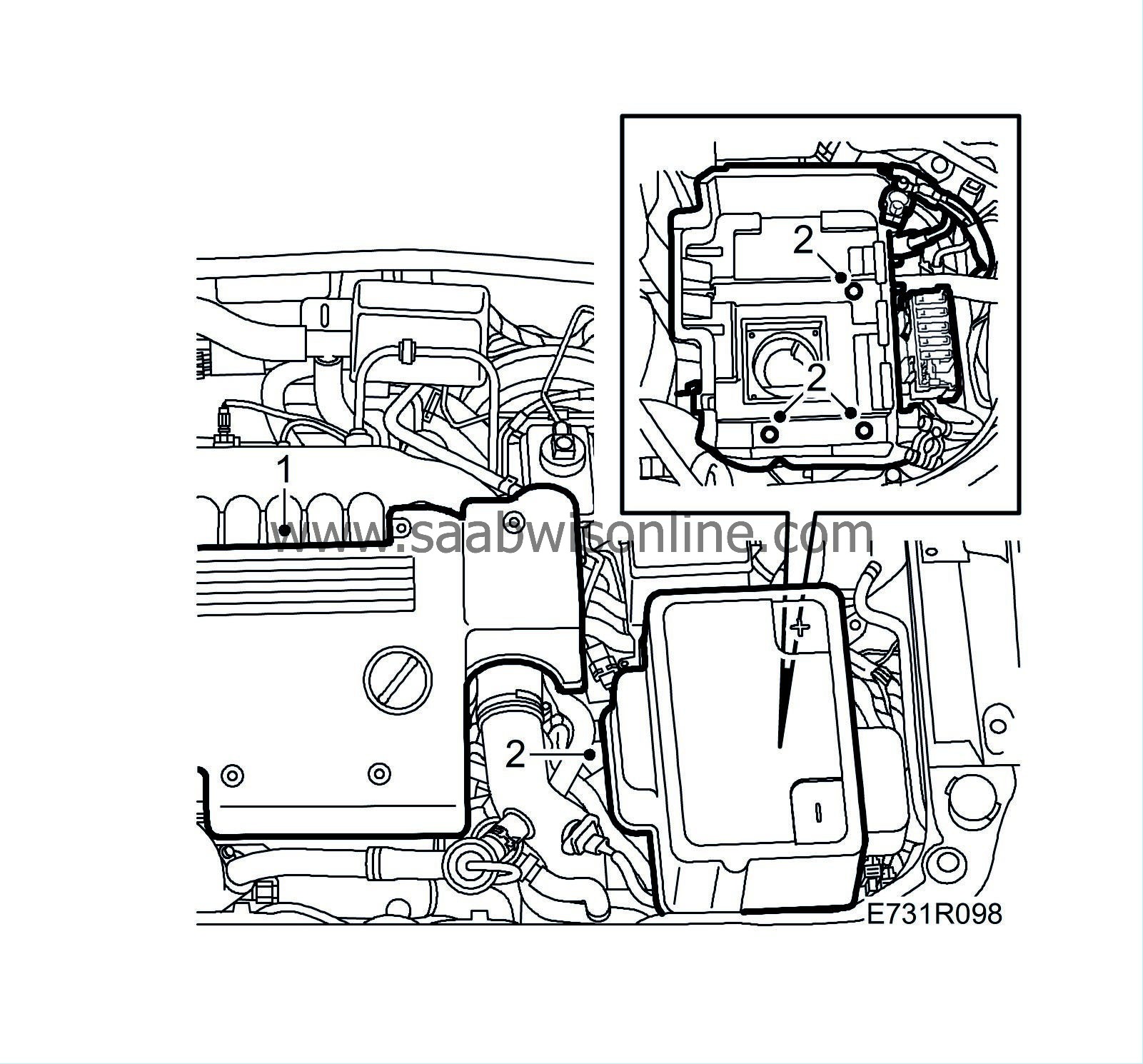

V6:

Remove the battery cover, battery and battery tray.

|

|

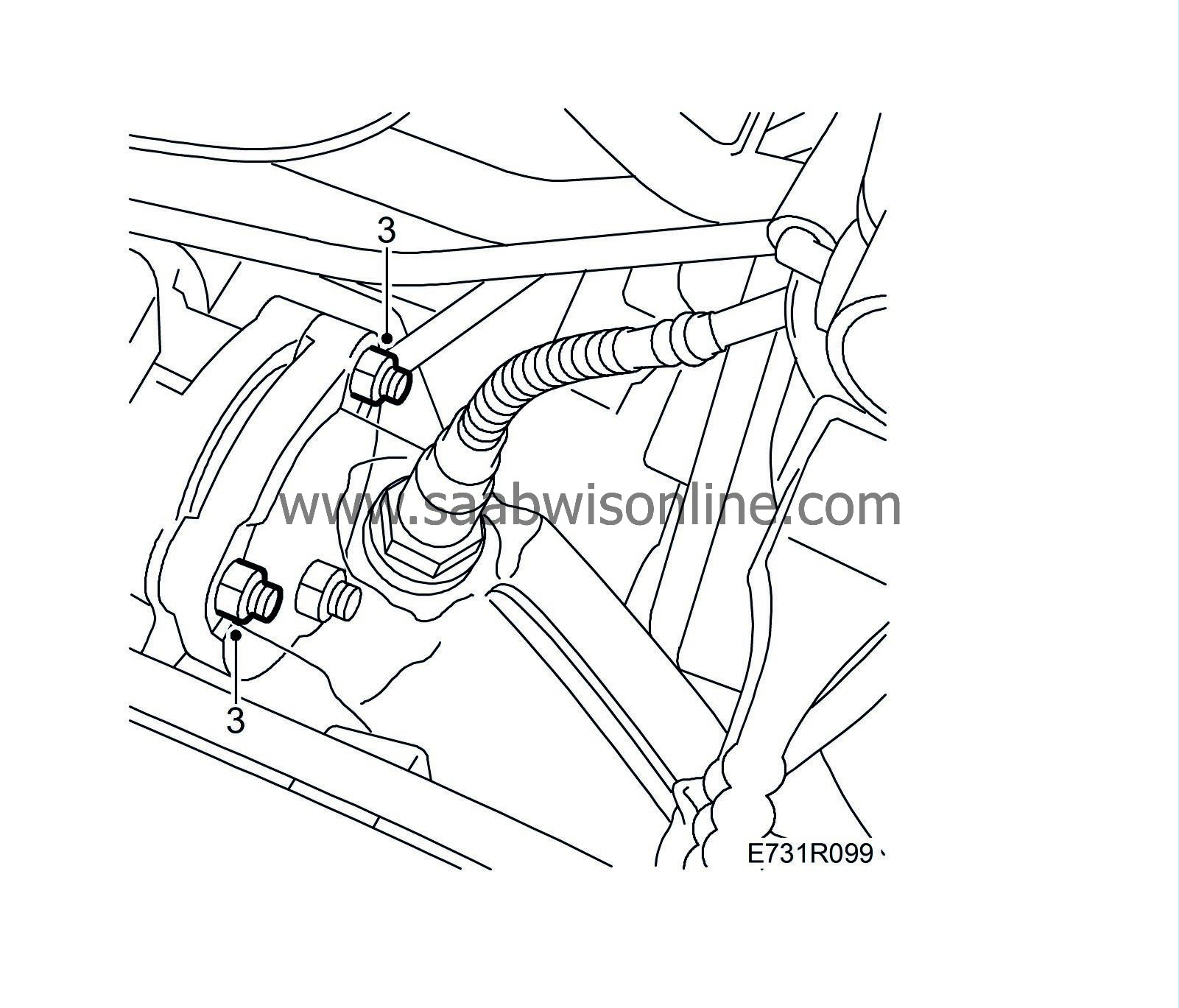

| 3. |

R4:

Remove the two upper nuts from the exhaust pipe flange.

|

|

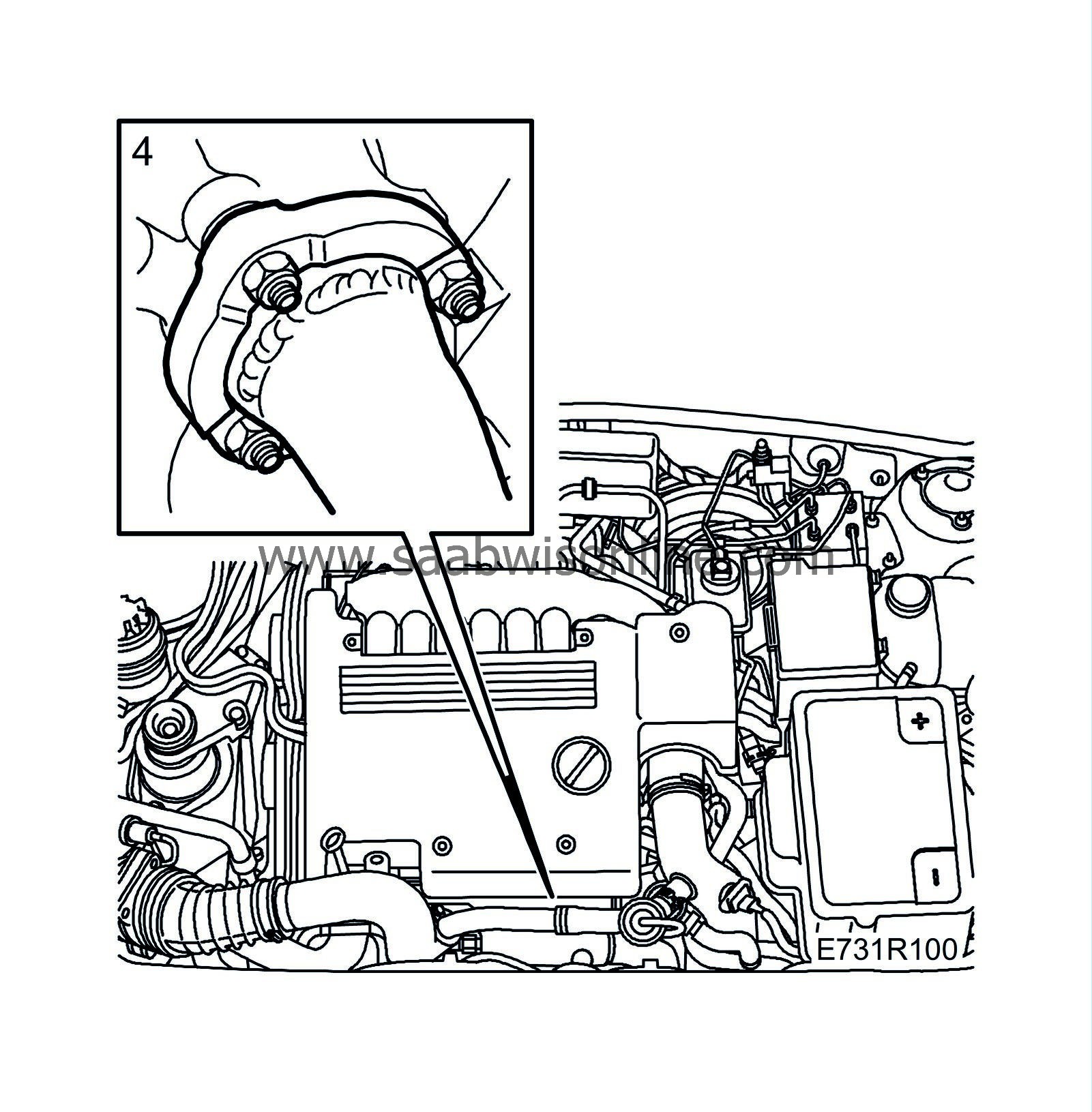

| 4. |

V6:

Remove the exhaust pipe from the front cylinder beam.

|

|

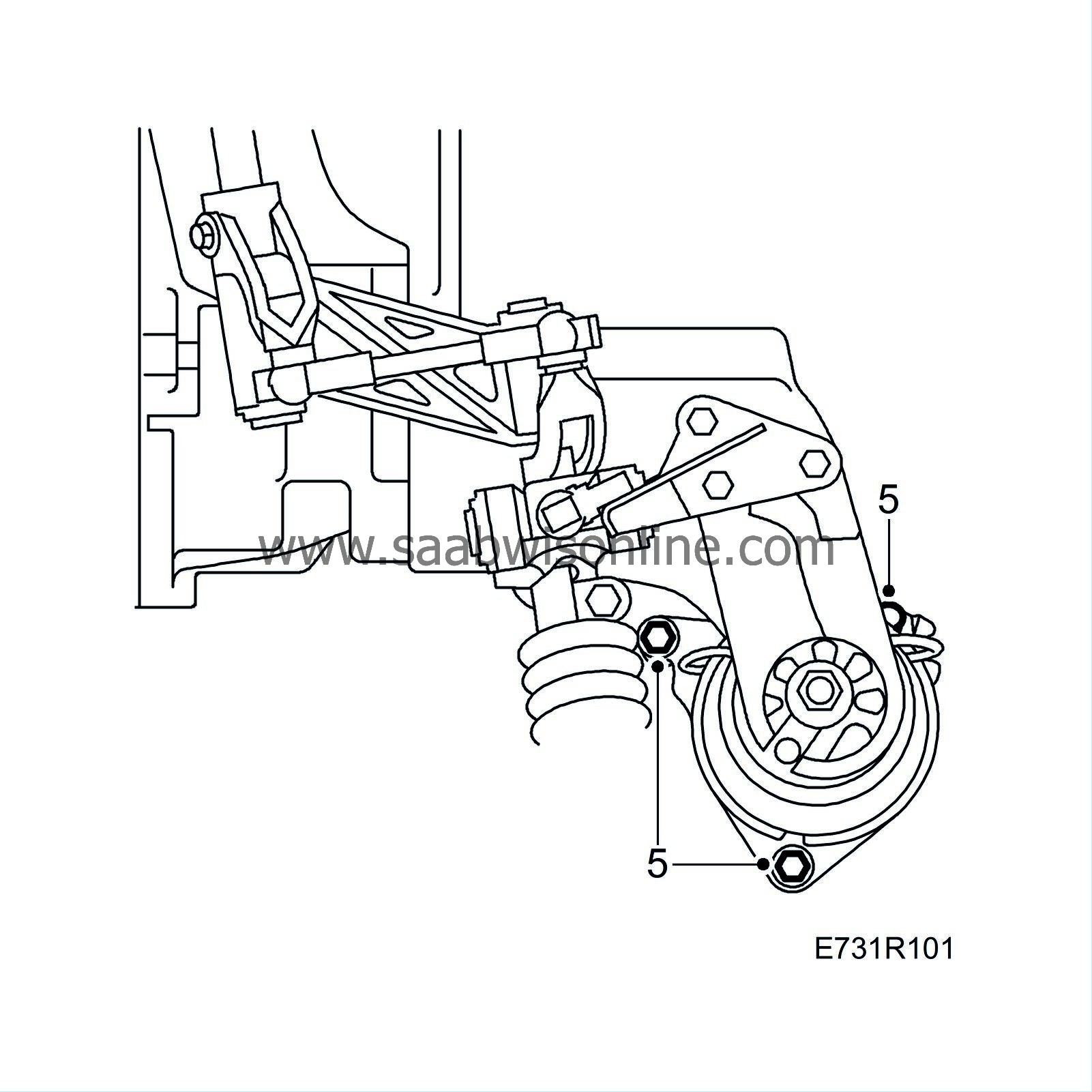

| 5. |

MAN:

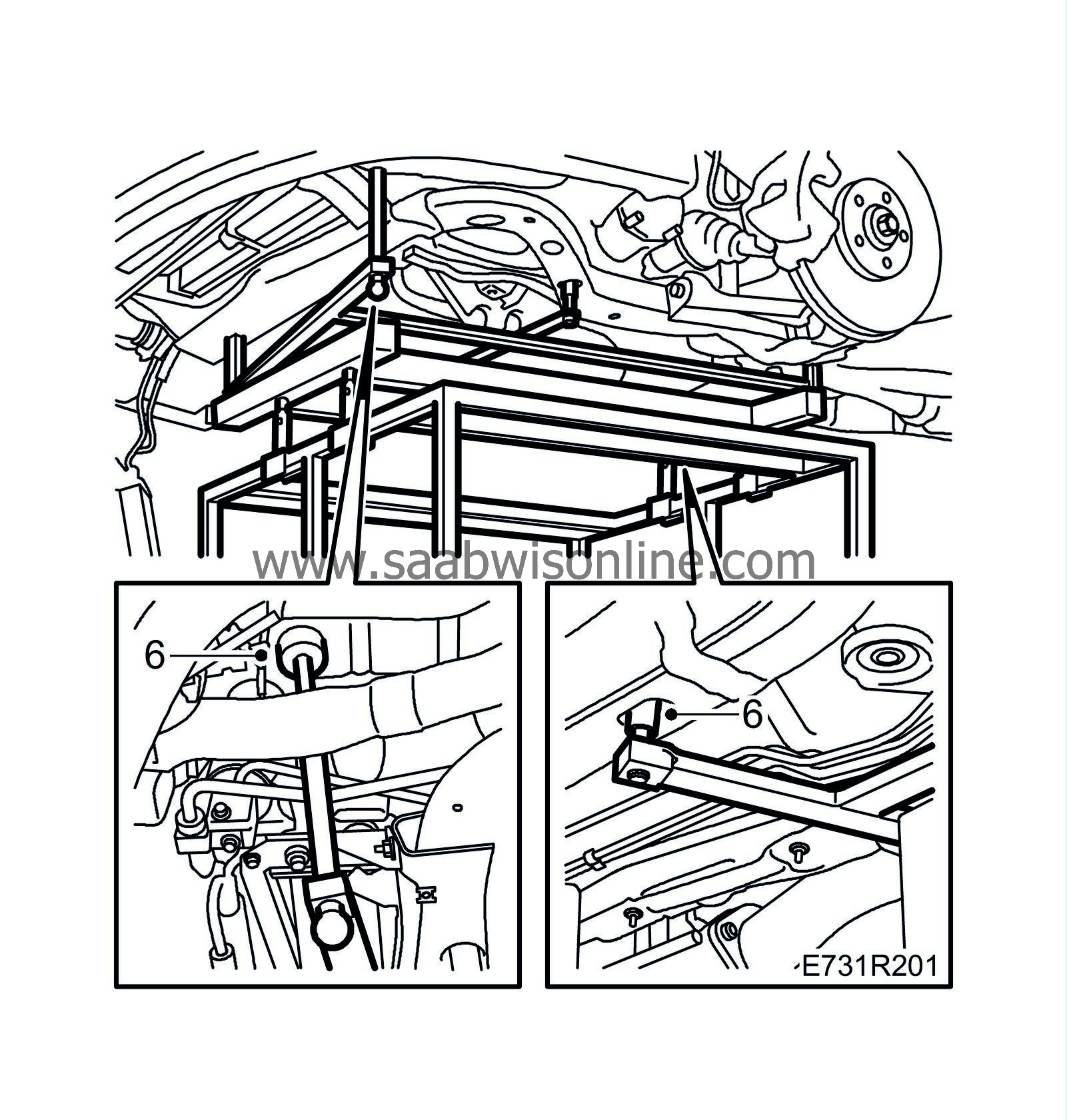

Undo the bolts holding the rear engine pad to the subframe.

AUT: Remove the nut of the rear engine mounting and slacken the two visible bolts holding the rear engine pad.

|

|

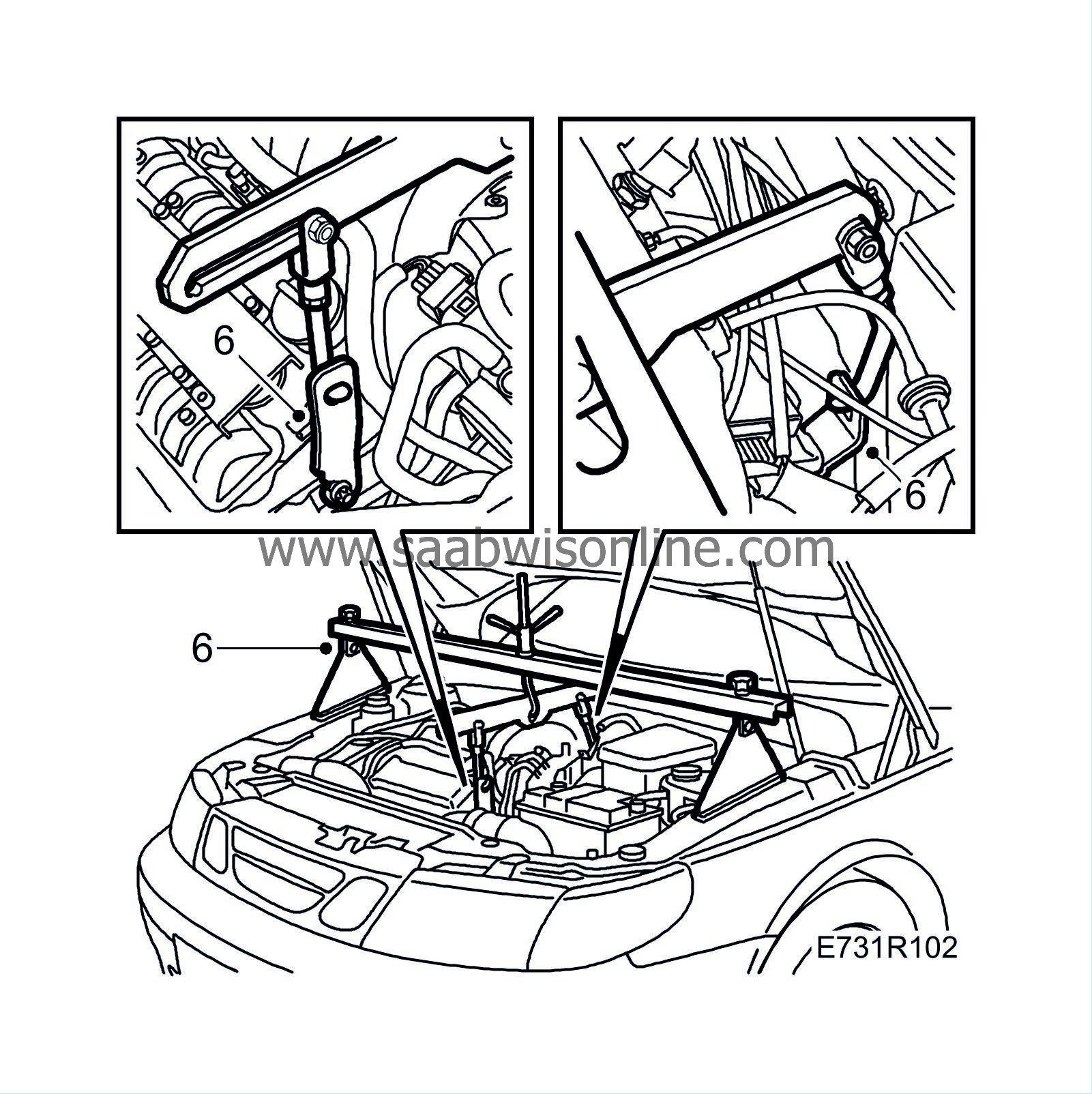

| 6. |

V6 engine:

Fit lifting eyes, one on the back of the cylinder head and one forward on the front (undo one existing bolt first). Fit

83 95 287 Holder

.

Position 83 94 850 Lifting beam on the wings and fit the hook in the engine's rear lifting eyebolt.

|

||||||||||

| 7. |

Hang a

83 95 212 Strap

over the radiator assembly without tightening it.

|

|

| 8. |

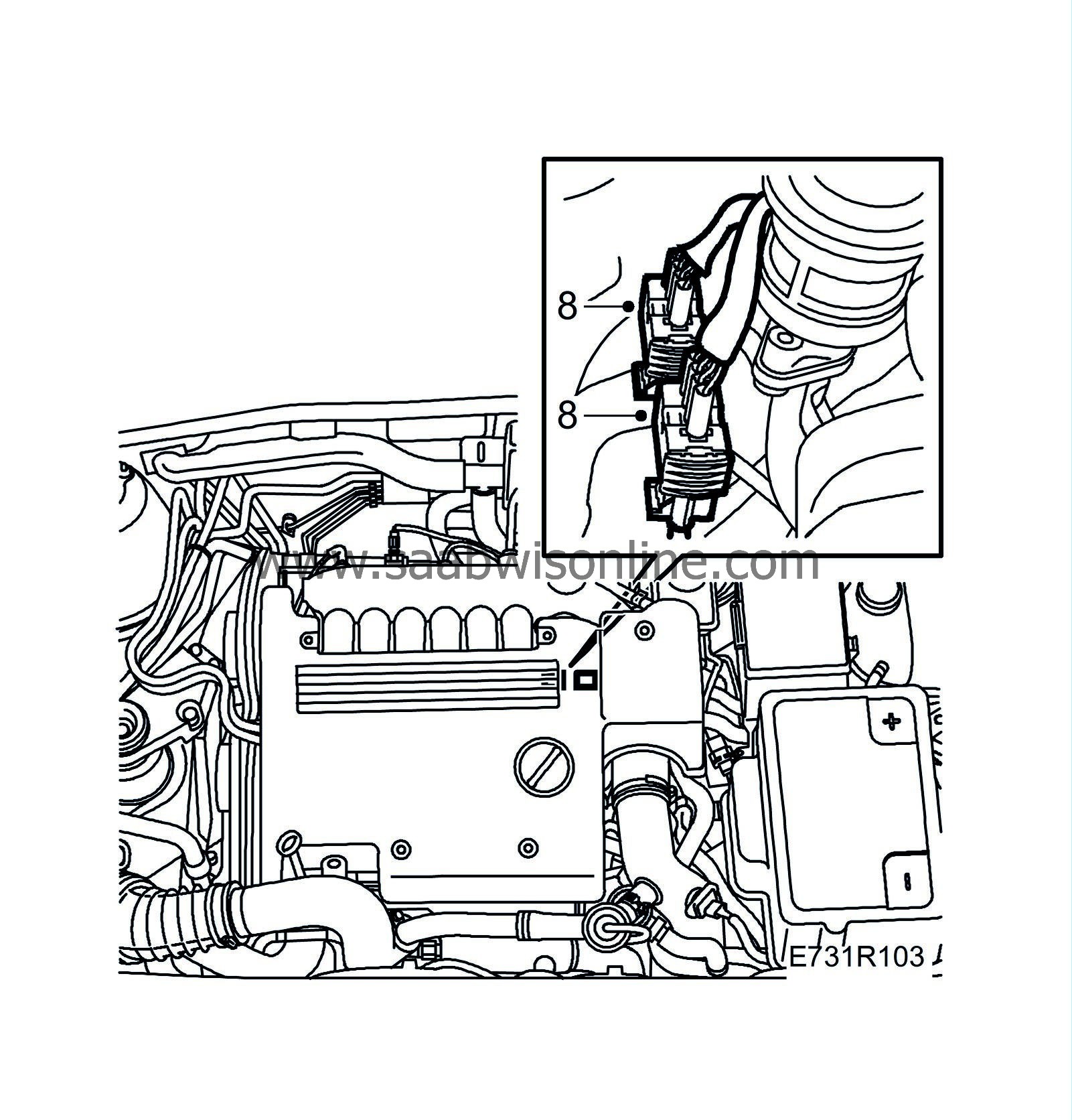

Unplug the connector from the oxygen sensor and rear oxygen sensor if fitted and remove any fasteners.

|

|

| 9. |

Raise the car and remove the front wheels.

|

|

| 10. |

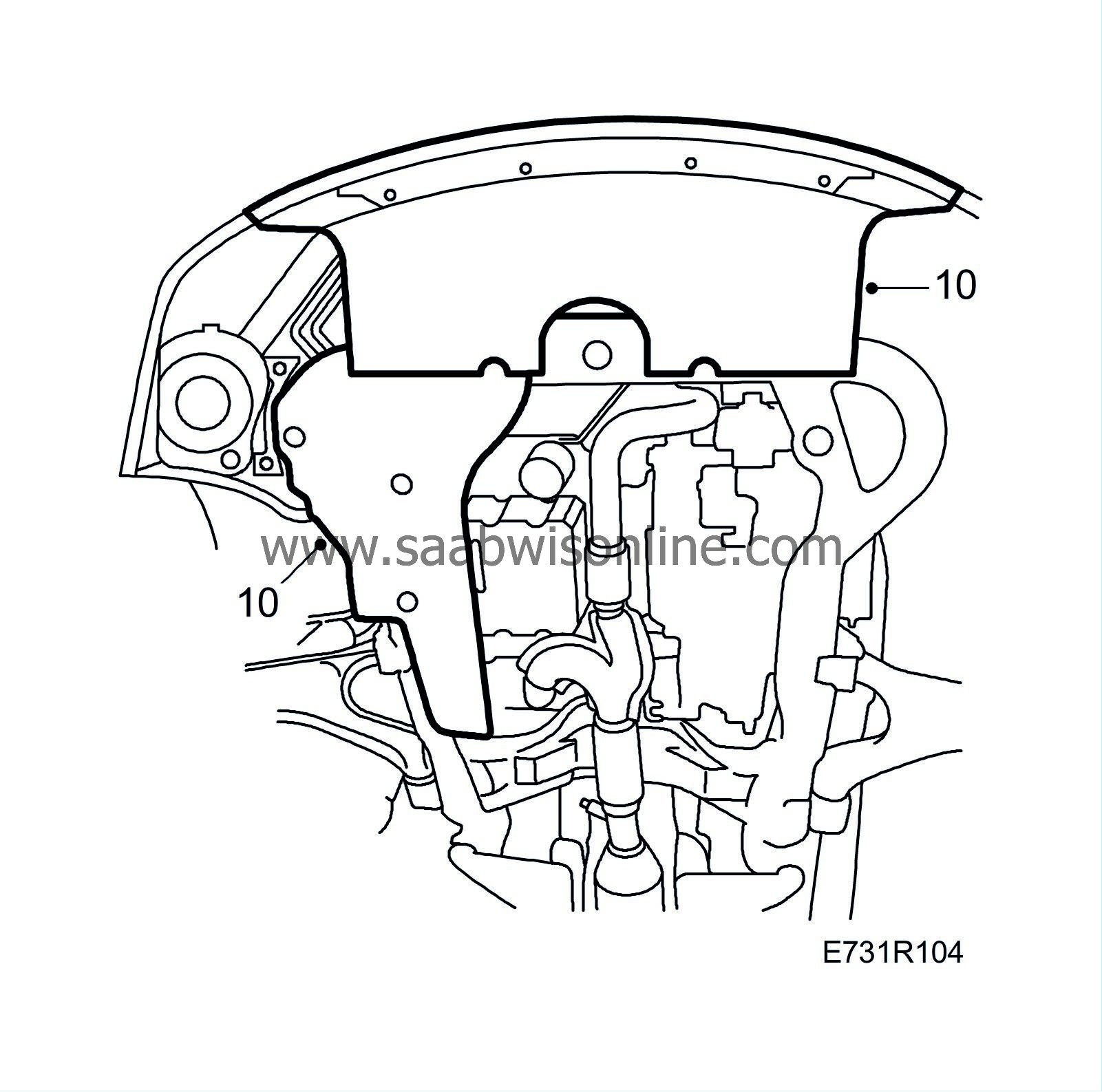

Remove the air shields.

|

|

| 11. |

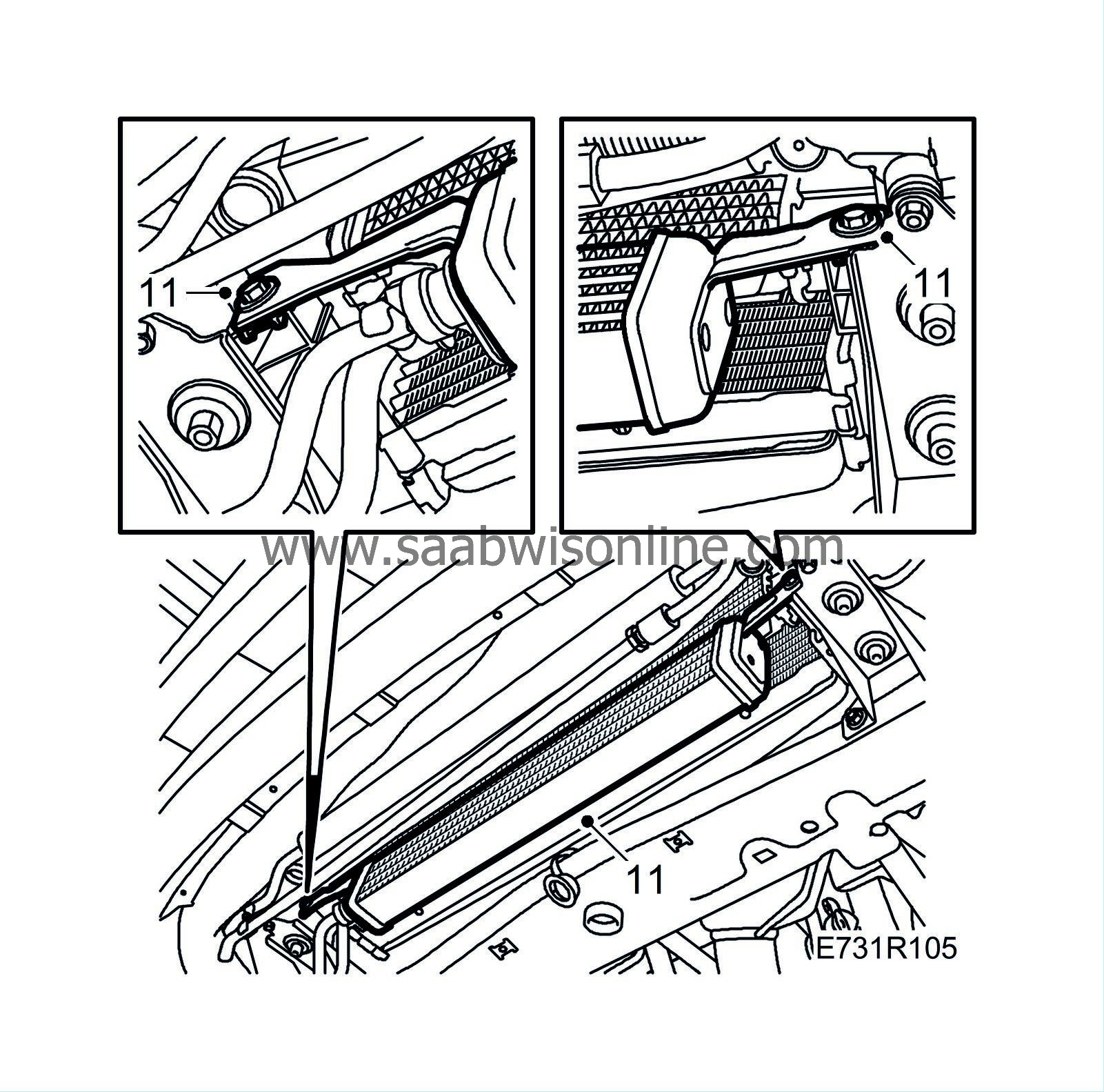

R4:

Undo the engine oil cooler and allow it to hang from the hoses.

V6: Remove the wind deflector.

|

|

| 12. |

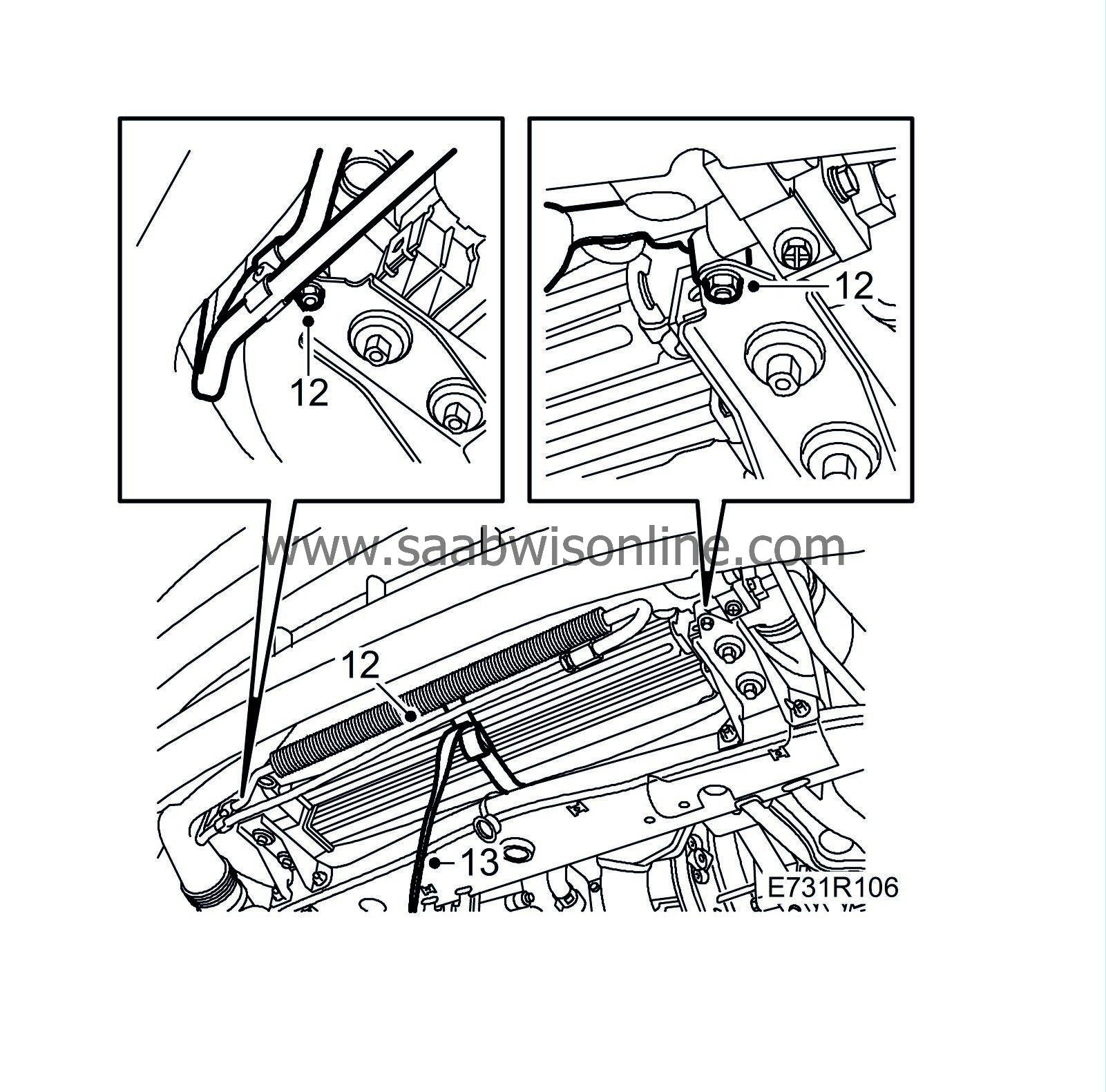

Remove the retaining screws on the power steering cooling coil.

|

|

| 13. |

Pull the strap tight round the radiator member and radiator assembly.

|

|

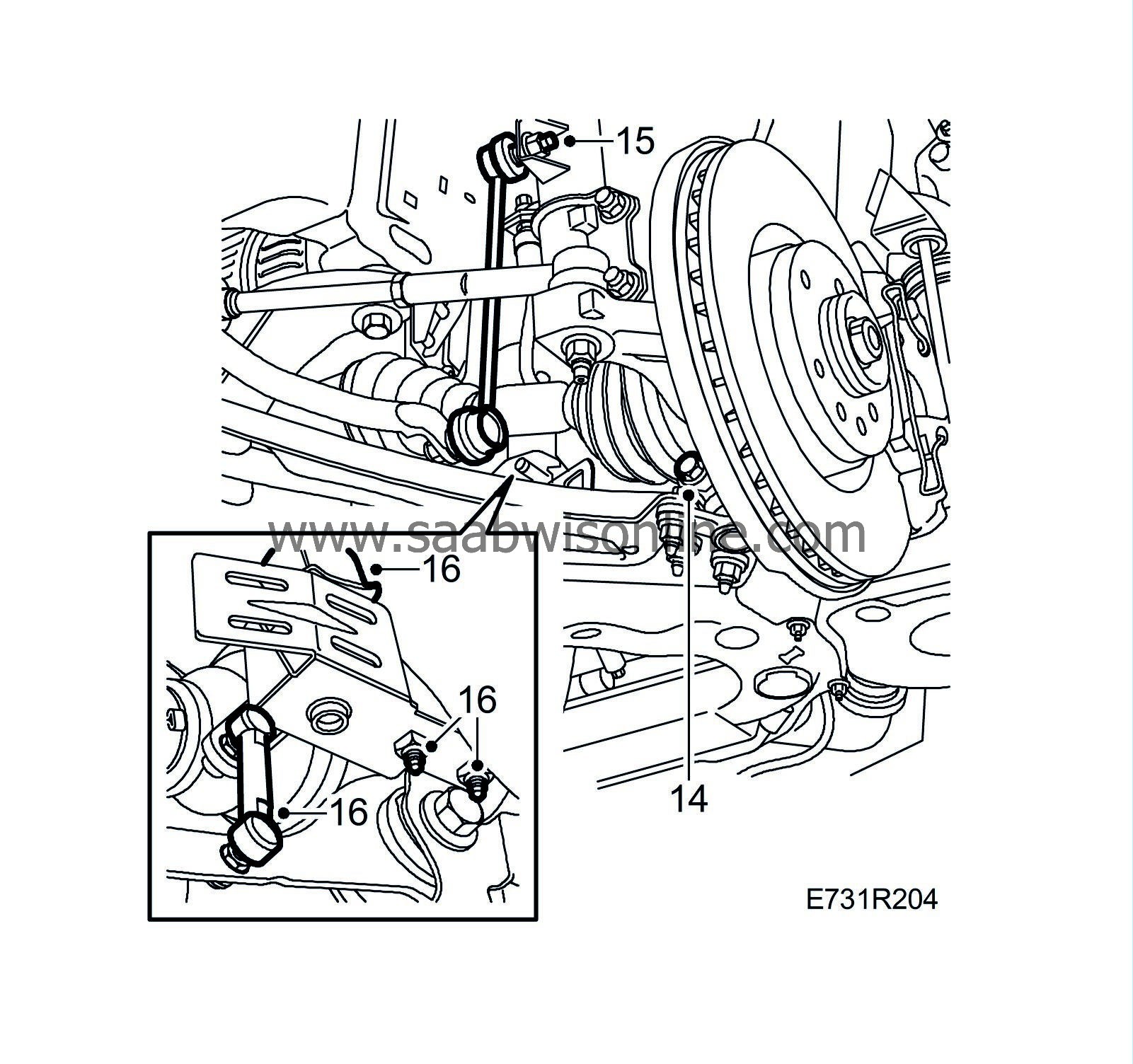

| 14. |

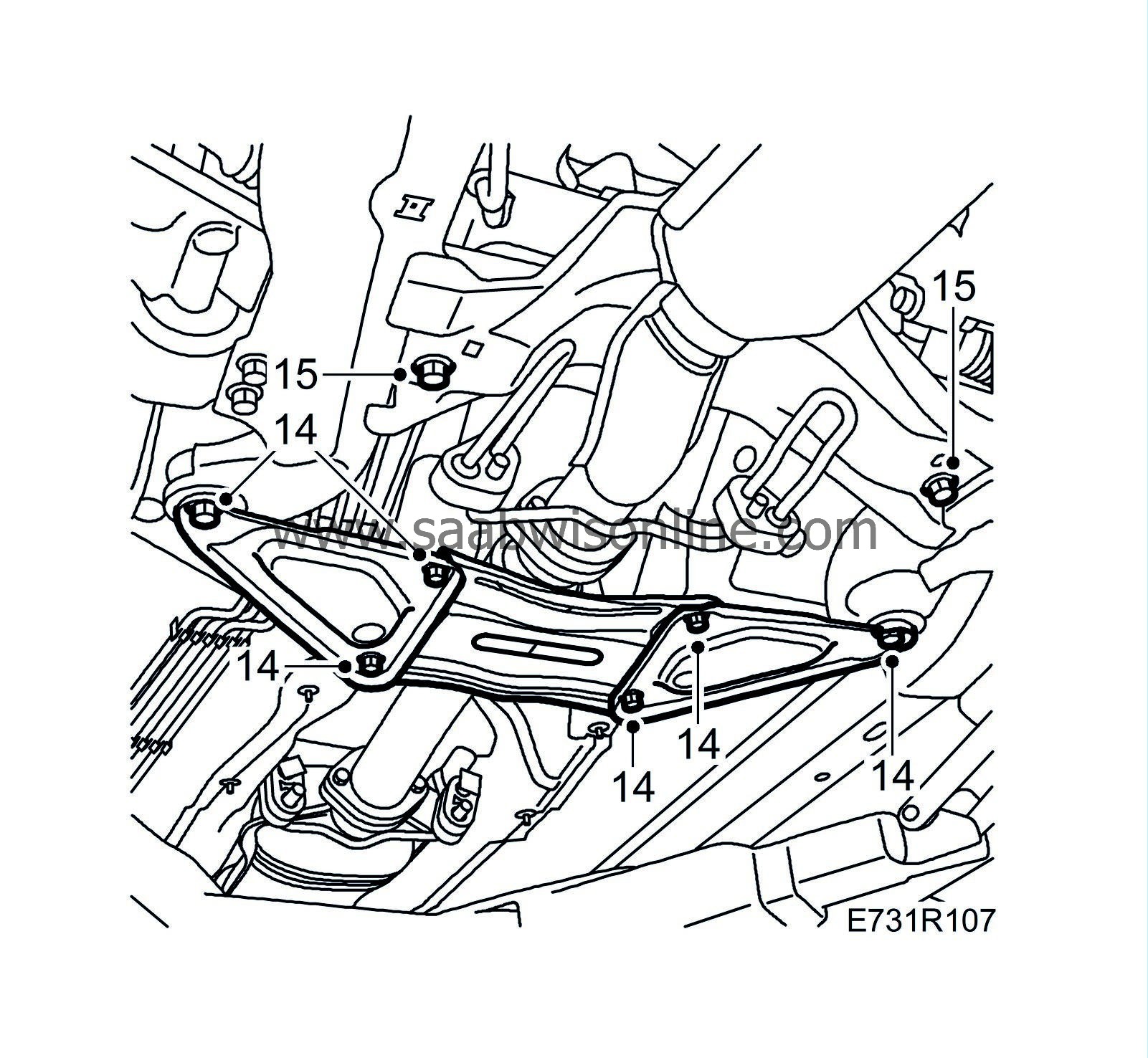

Remove the rear subframe mounting reinforcement.

|

|

| 15. |

Remove the two steering gear retaining bolts.

|

|

| 16. |

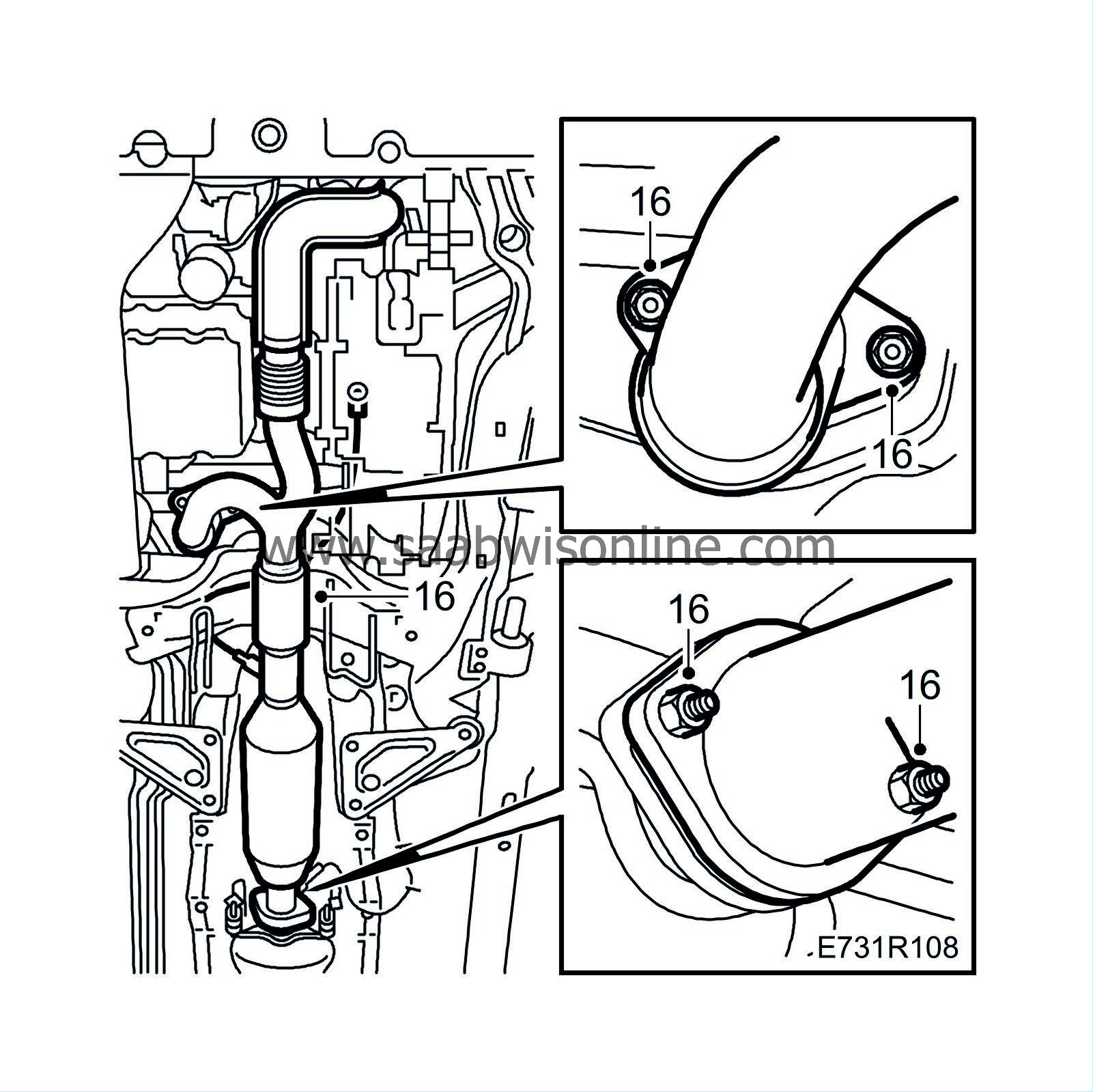

Remove the front part of the exhaust pipe.

|

|

| 17. |

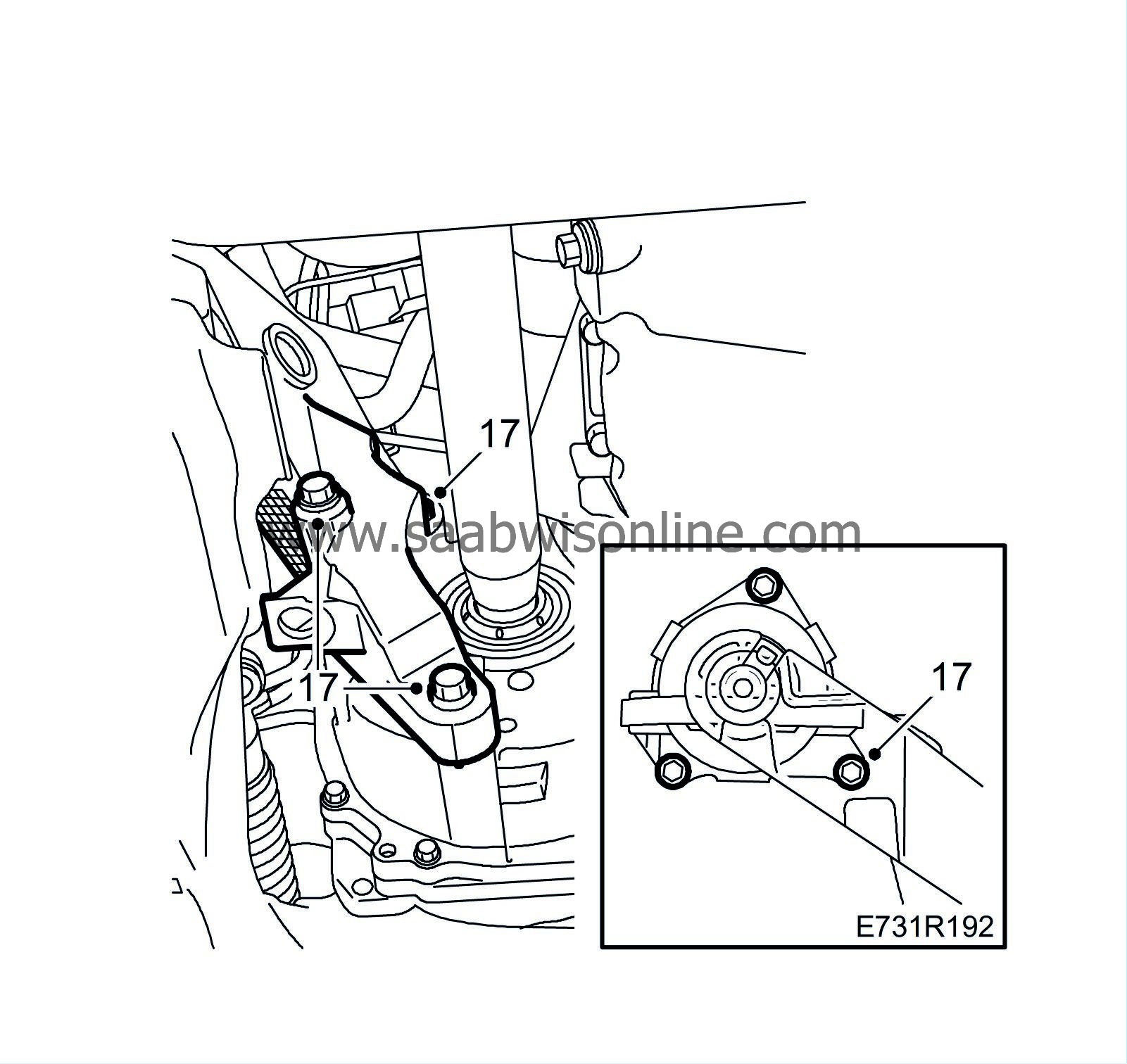

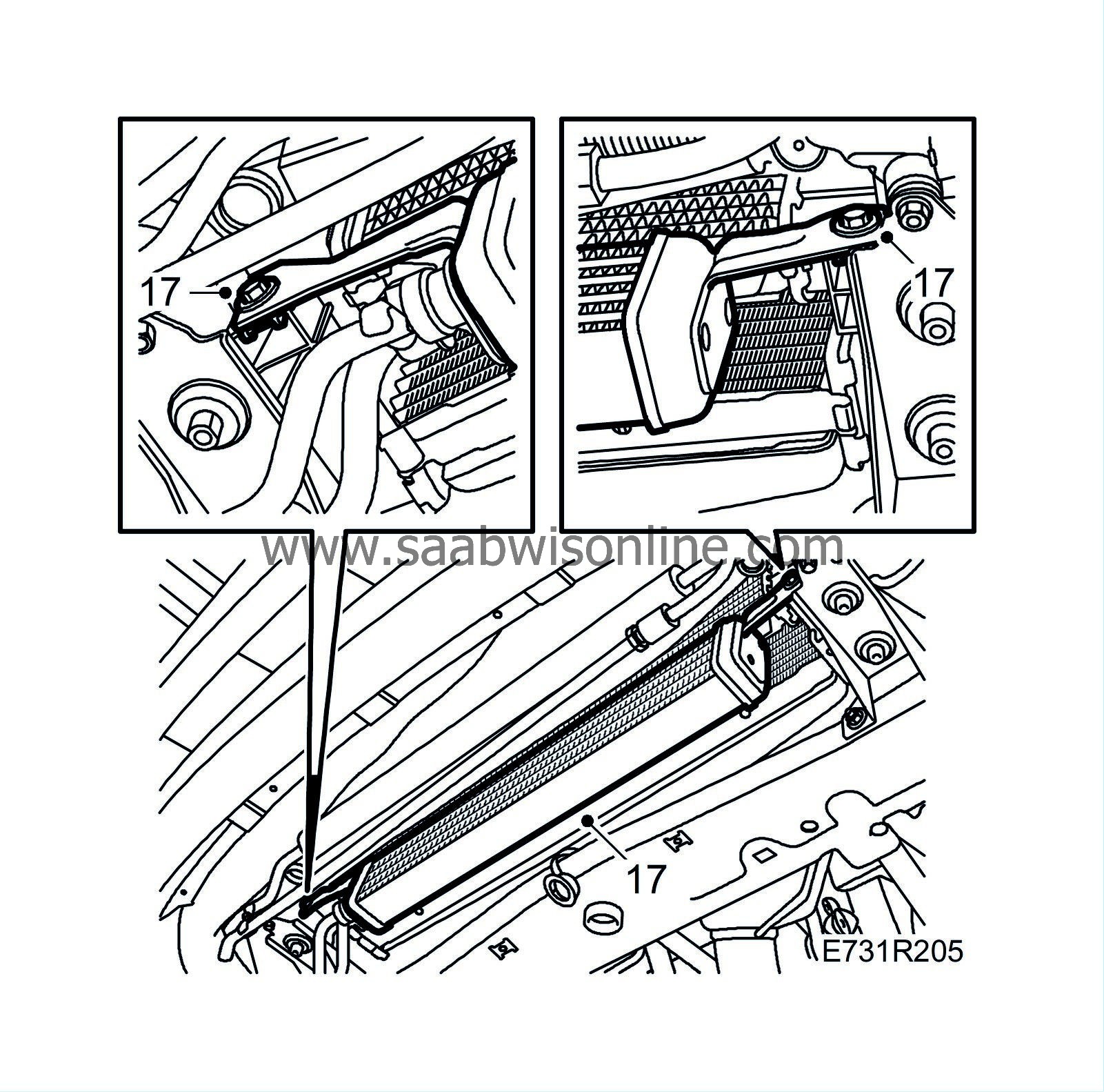

AUT:

Remove the rear engine bracket and the engine pad.

|

|

| 18. |

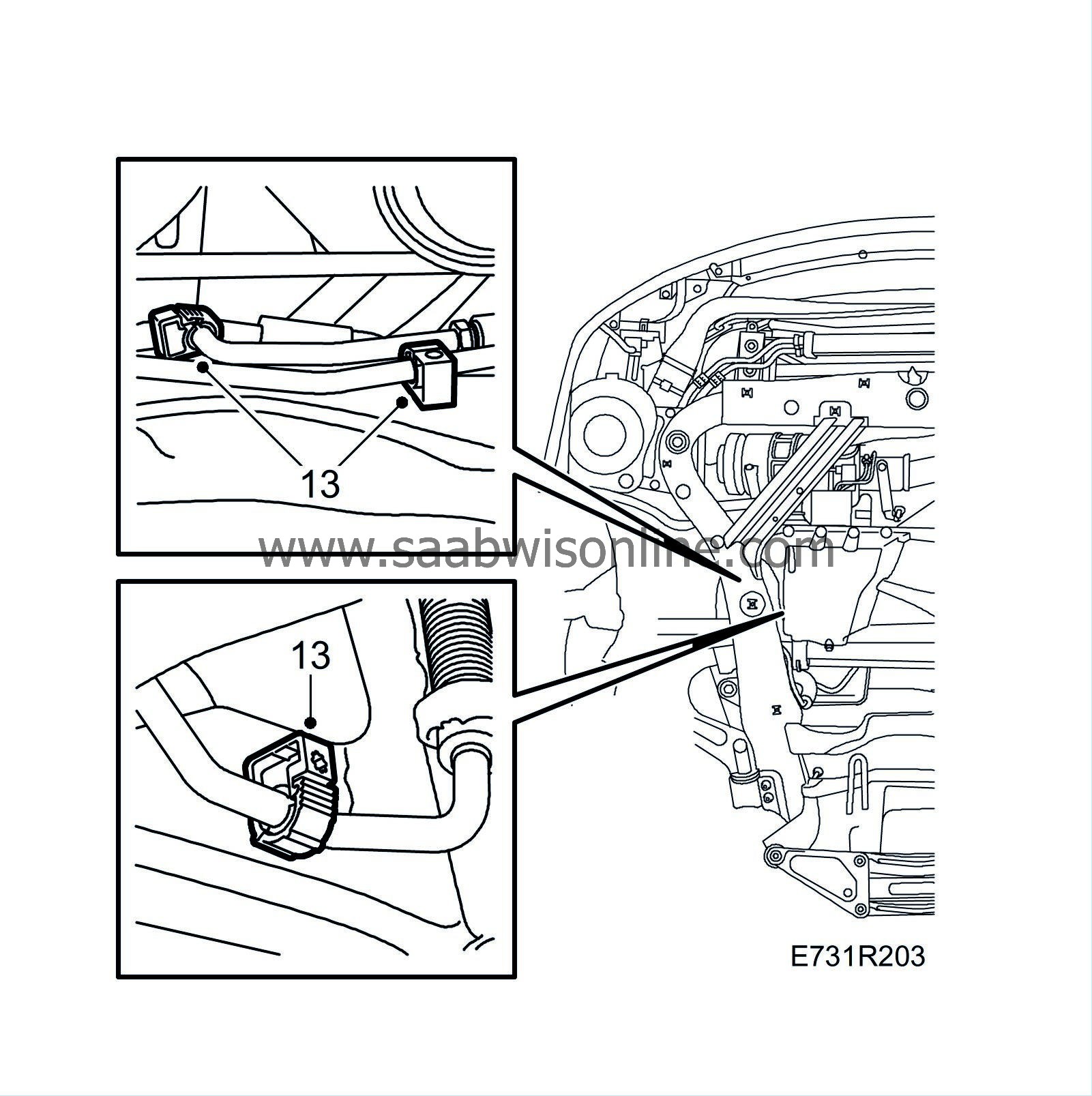

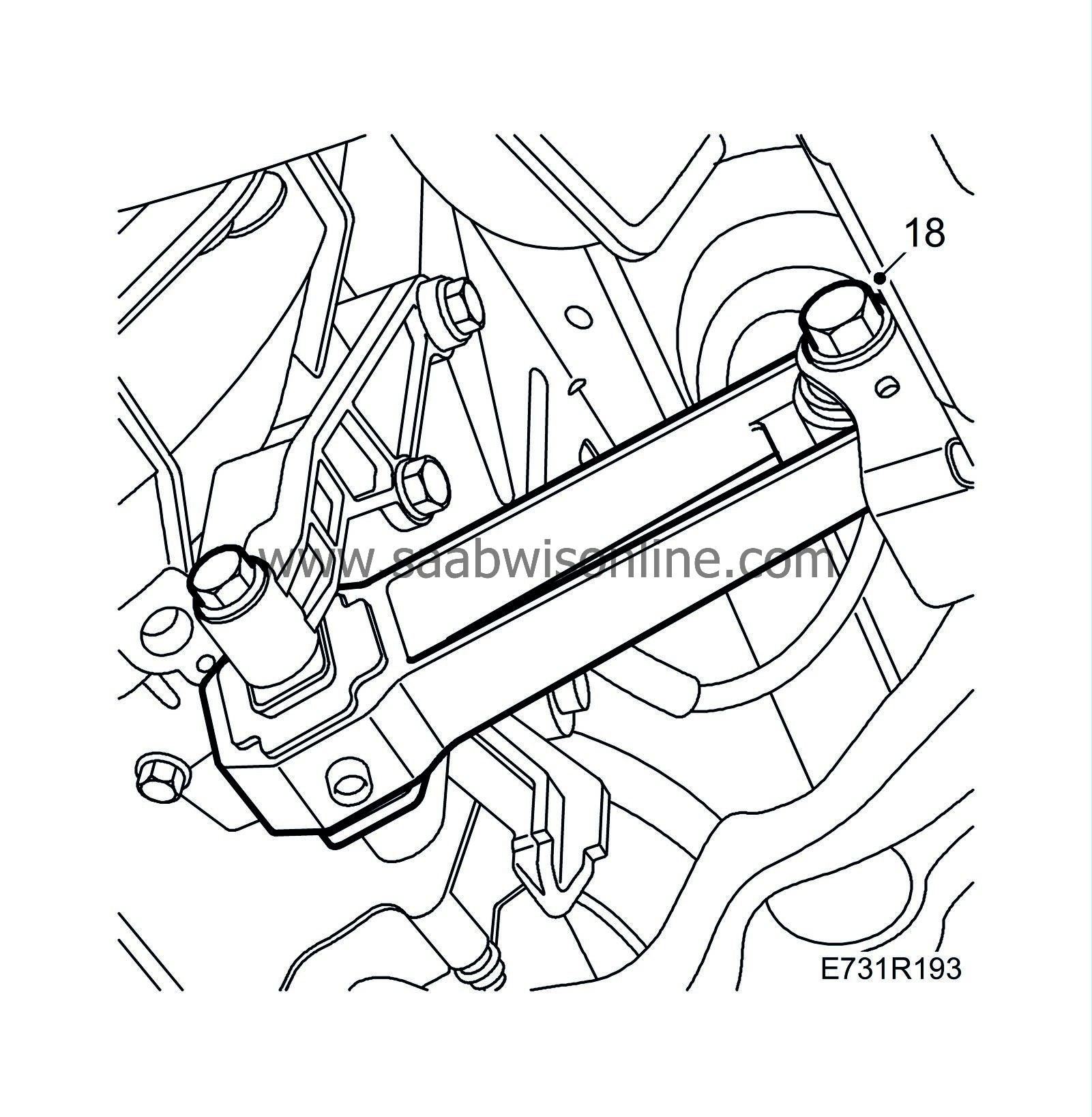

Detach the gearbox torque arm from the subframe.

|

|

| 19. |

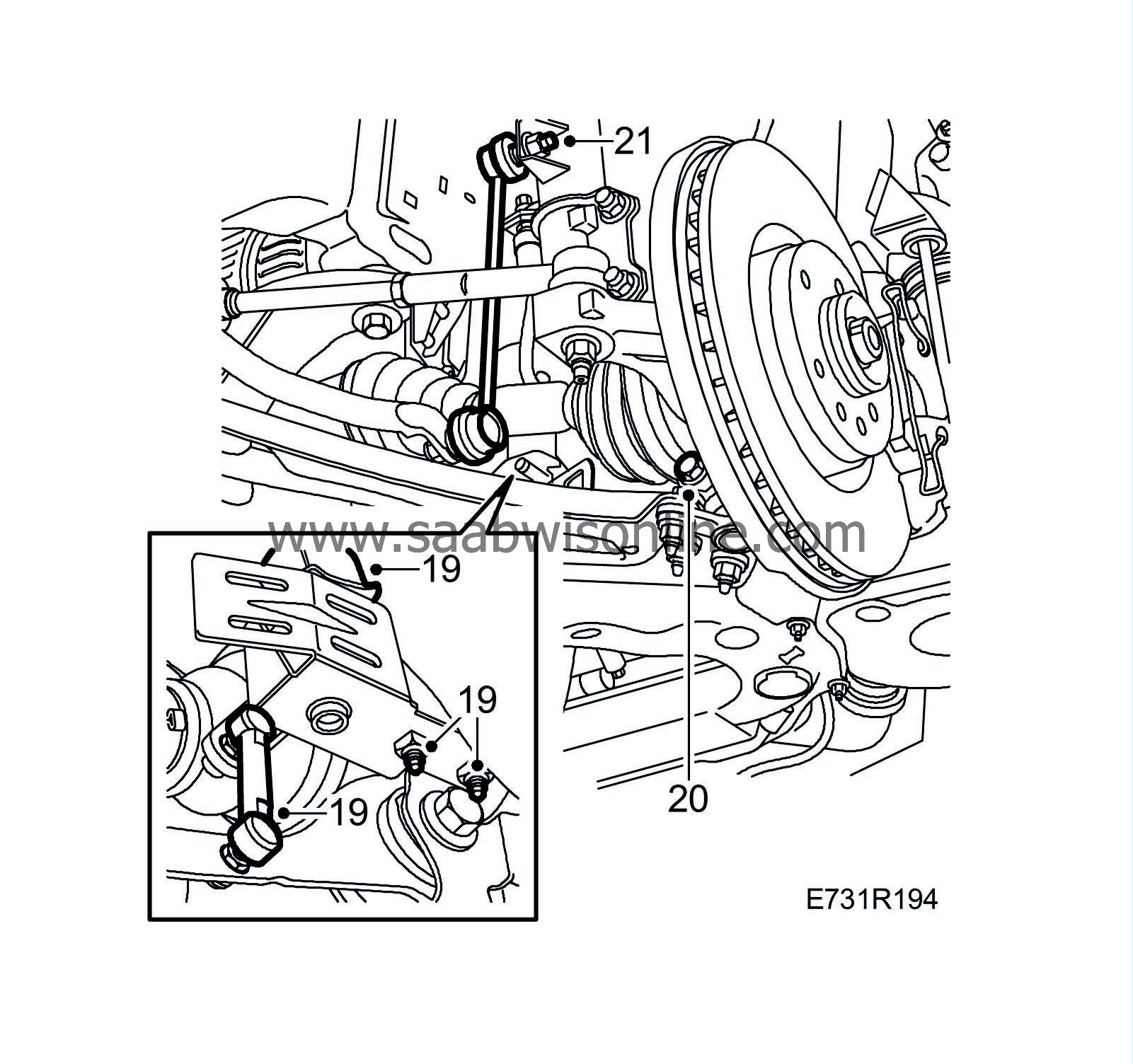

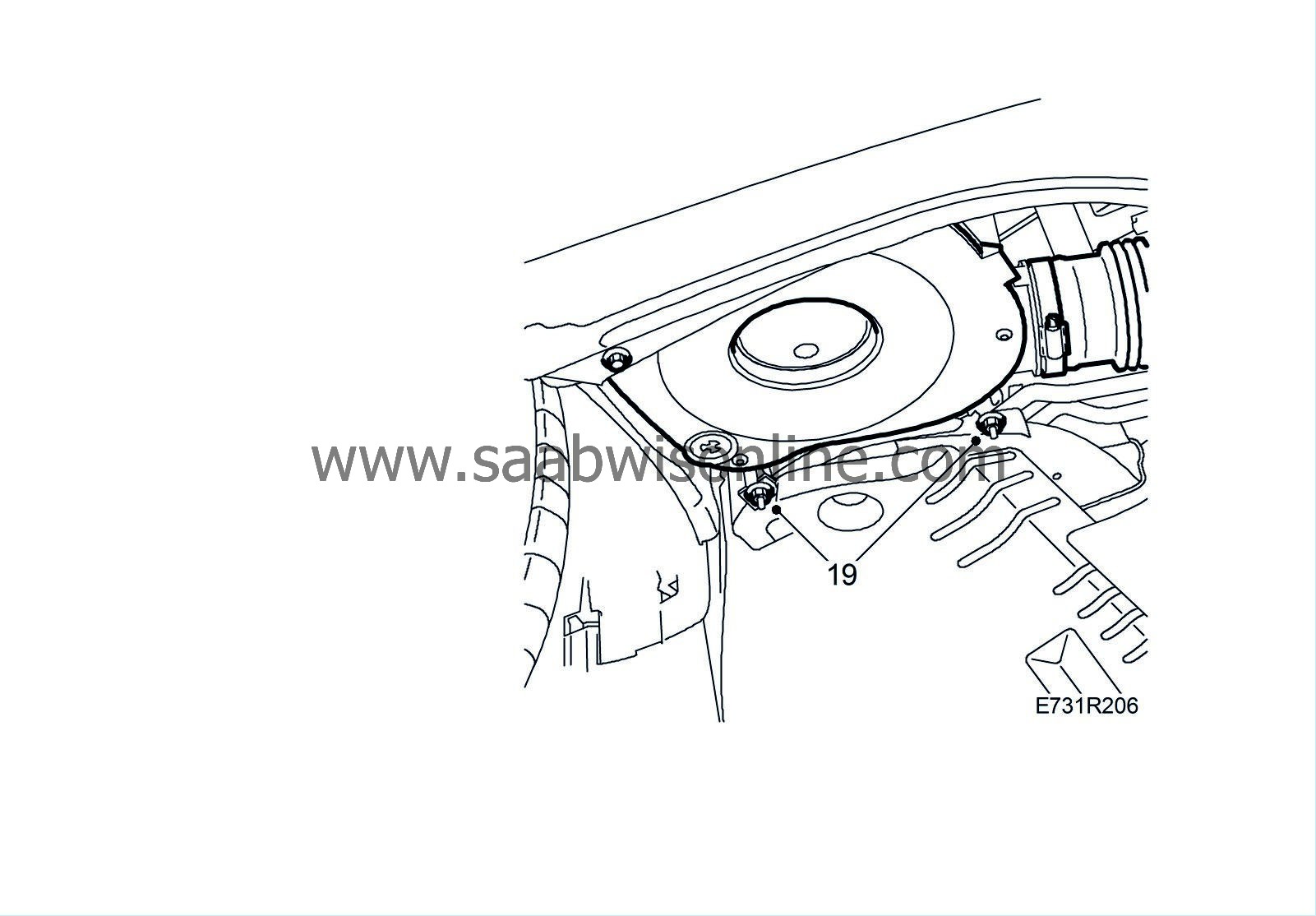

Cars with xenon headlamps:

Detach the level sensor for the xenon headlamps from its mounting and place it to one side.

|

|

| 20. |

Detach the suspension arms from the steering swivel member.

|

|

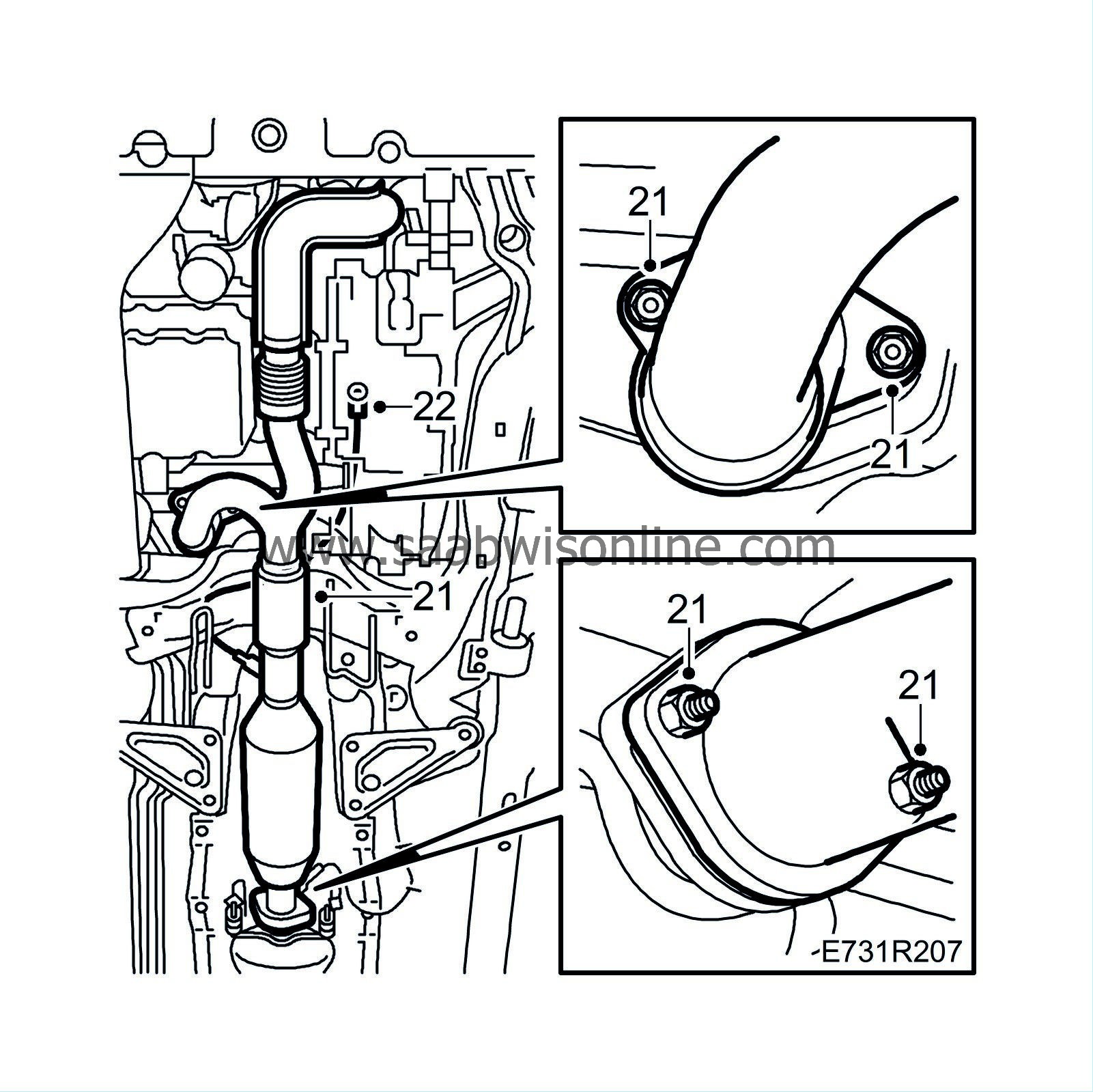

| 21. |

Remove the anti-roll bar from the MacPherson strut.

|

|

| 22. |

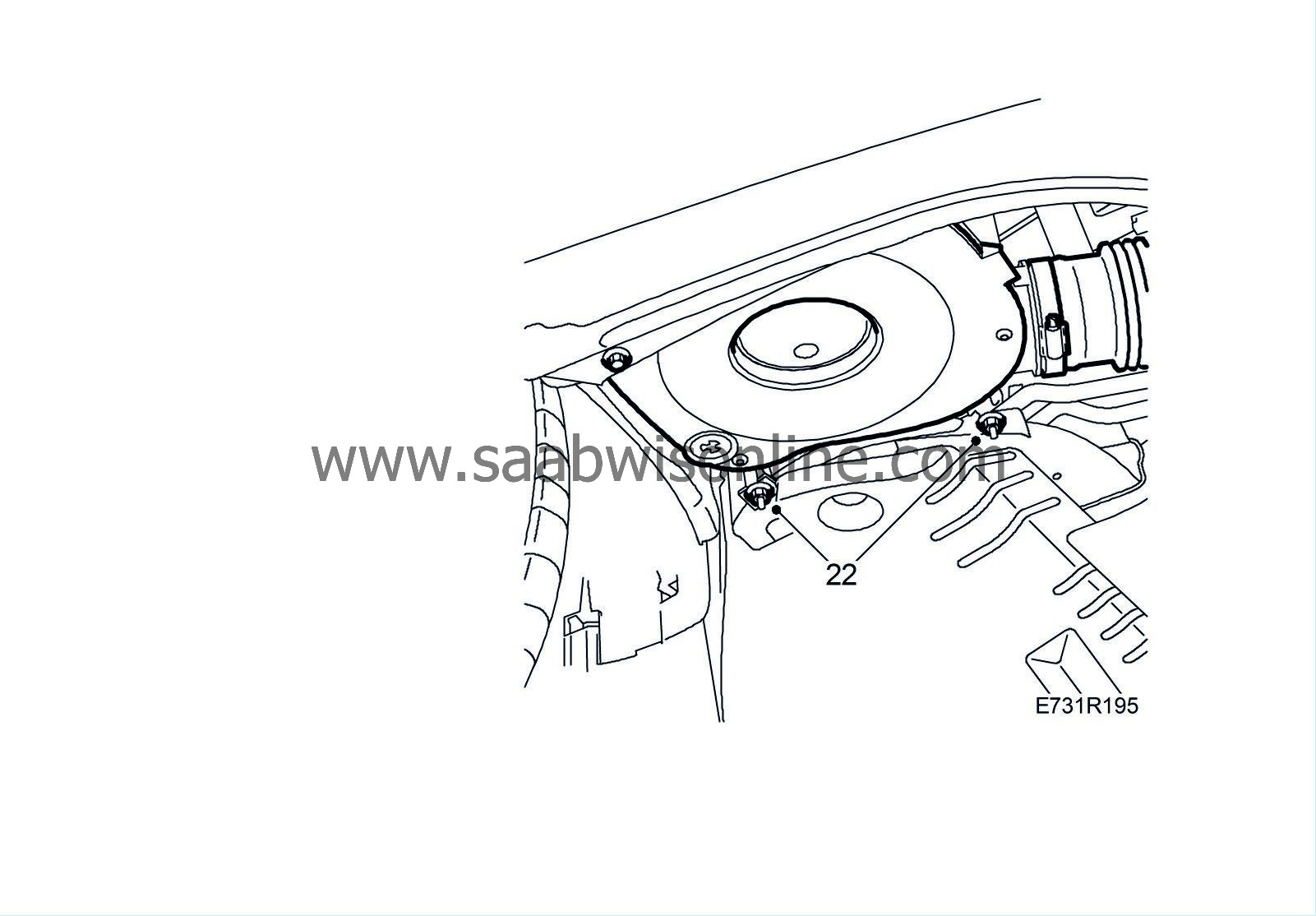

Unscrew the air cleaner retaining nuts from the subframe.

|

|

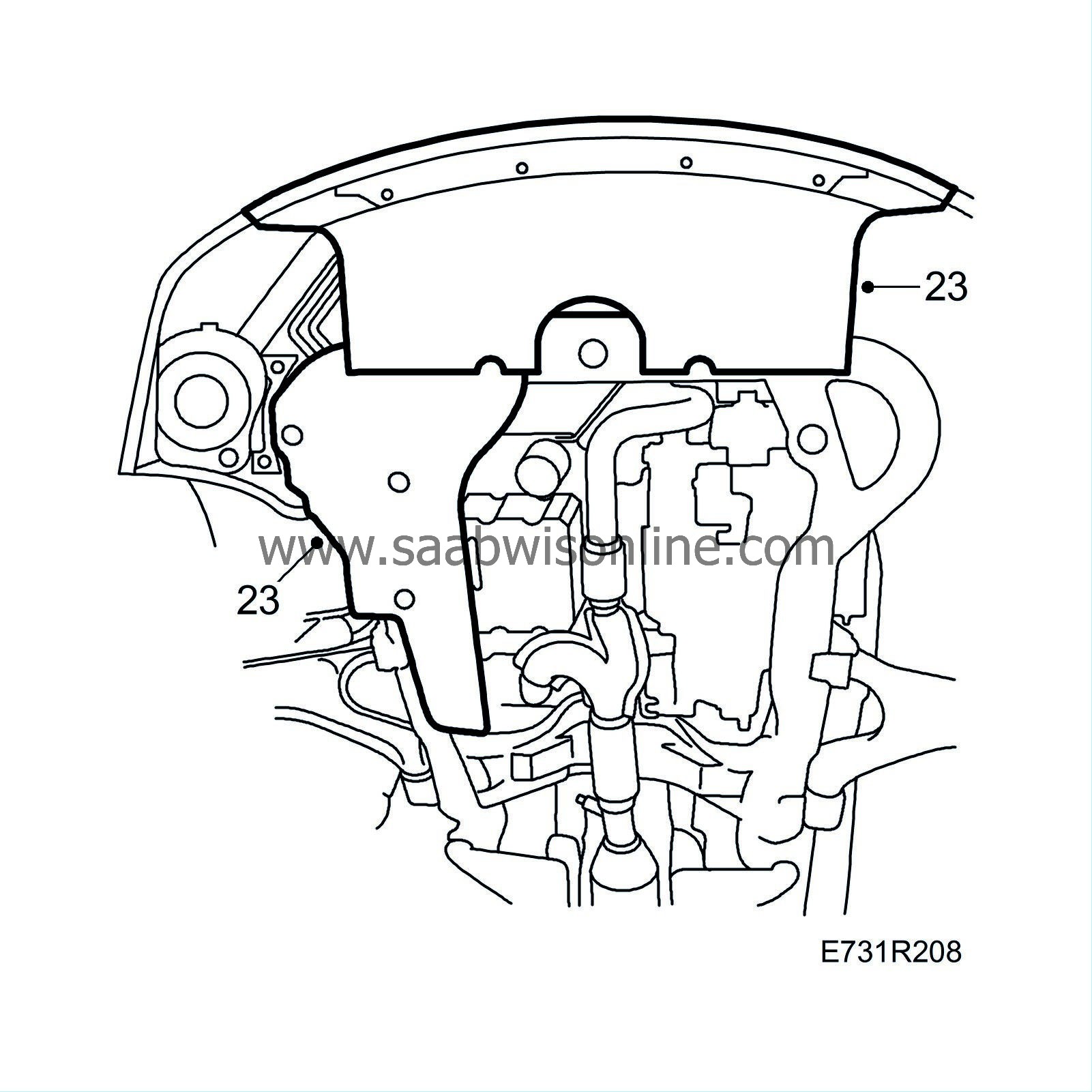

| 23. |

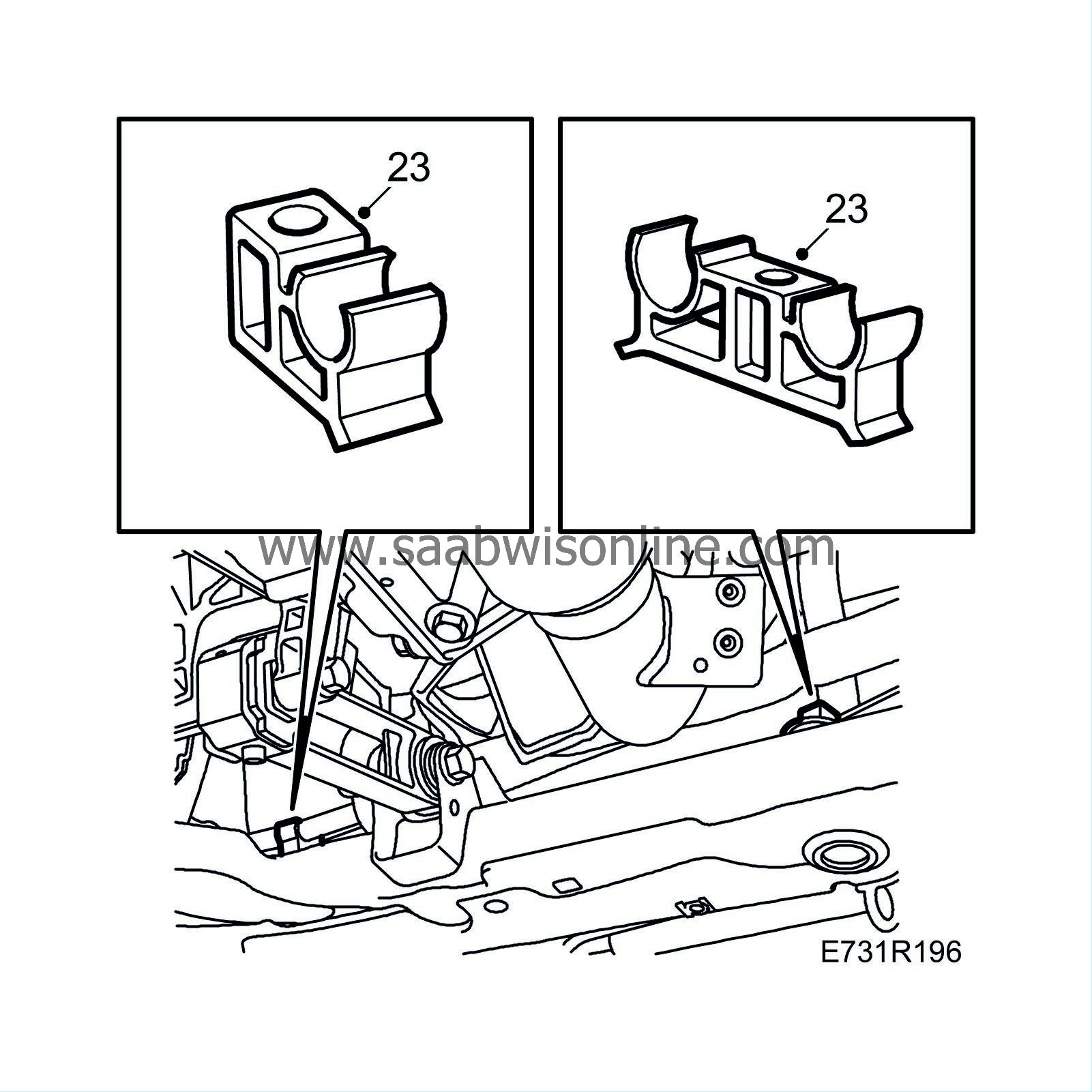

Remove the A/C pipes from their mountings.

|

|

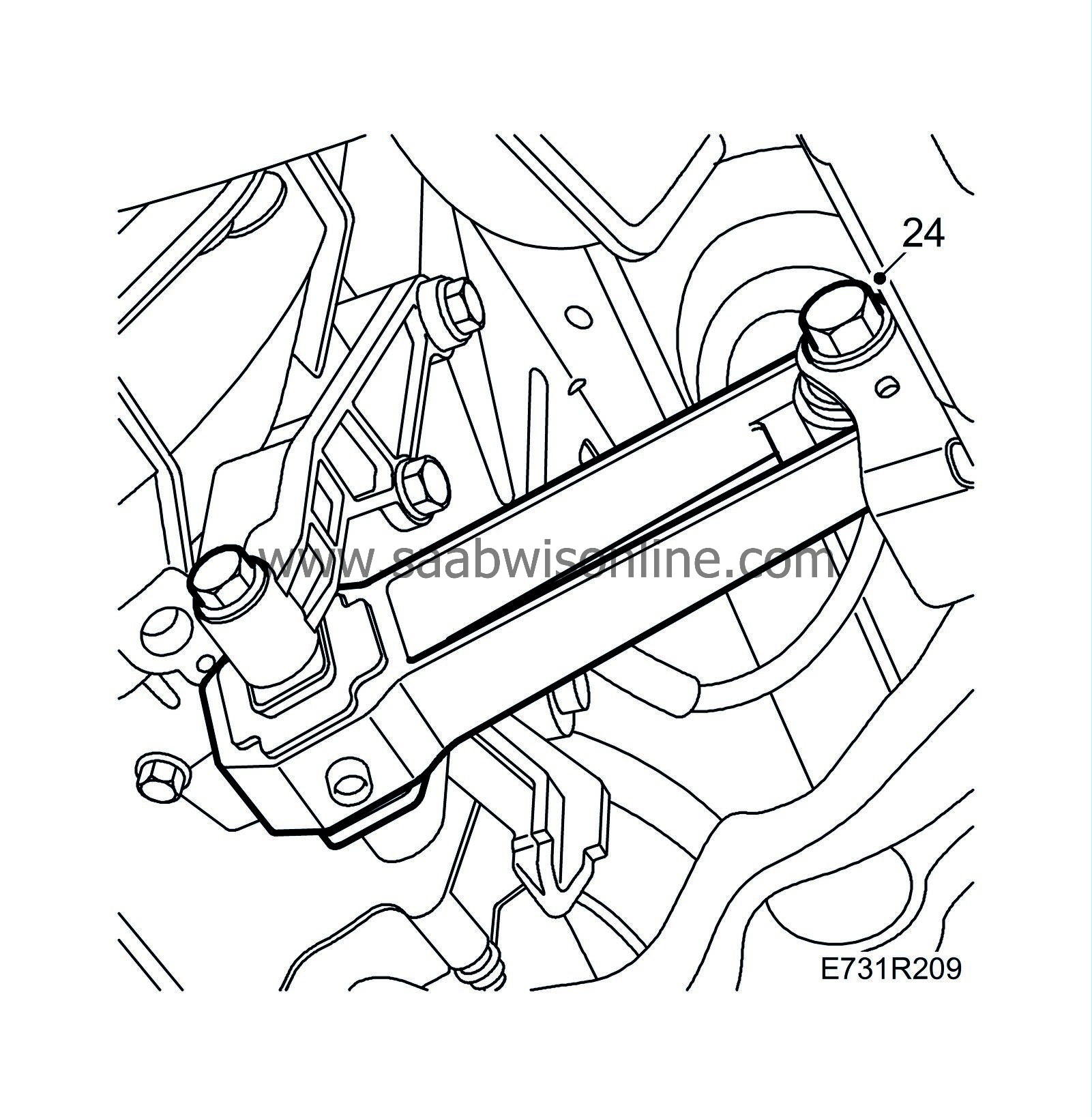

| 24. |

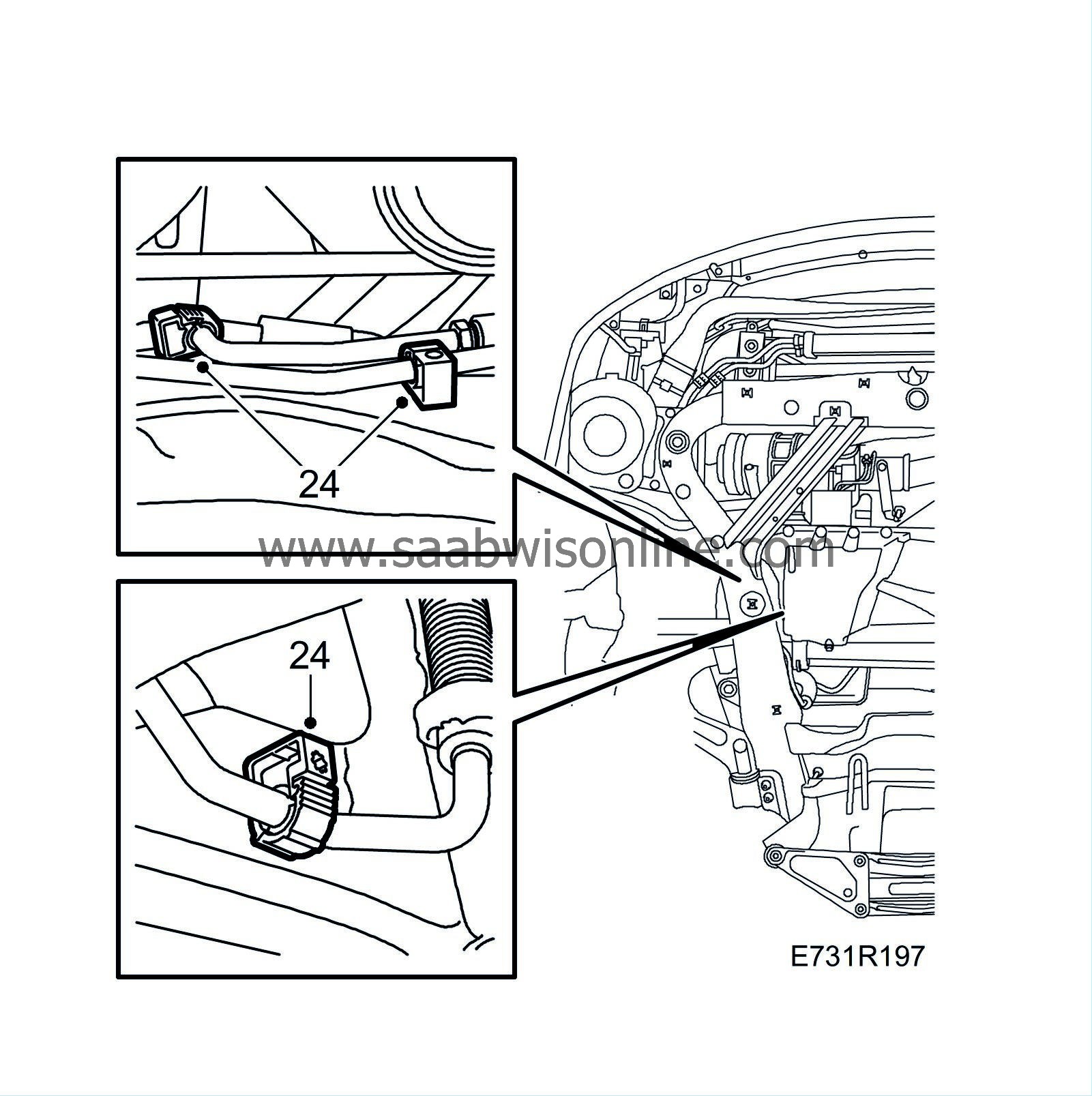

Remove the power steering pipe from clip.

|

|

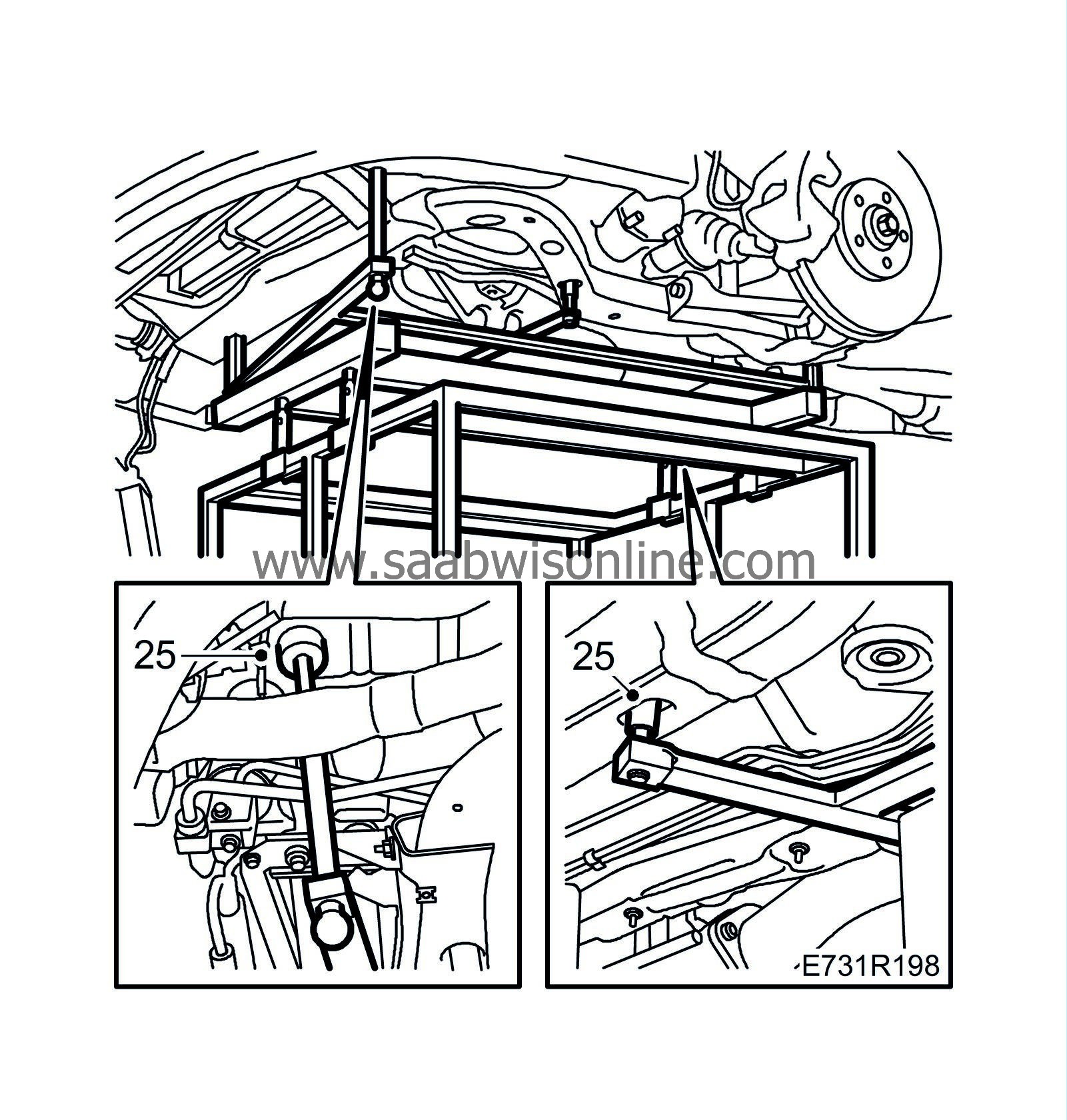

| 25. |

Place

83 95 311 Lifting trolley

with

83 94 801 Parent fixture

,

intermediate stay 83 95 170

,

basic fixture 83 95 188

and

jig 83 95 196

underneath and remove the remaining subframe retaining bolts.

|

|

| 26. |

Lower the subframe.

|

|

| To fit |

| 1. |

Lift up the subframe carefully. Make sure the rubber gaiters for the inner universal joint drivers do not knock the centre mountings on the subframe before the subframe is resting against the body.

|

|

| 2. |

Fit the power steering pipe into the clip.

|

|

| 3. |

Guide the radiator assembly guide pins into the subframe.

|

|||||||

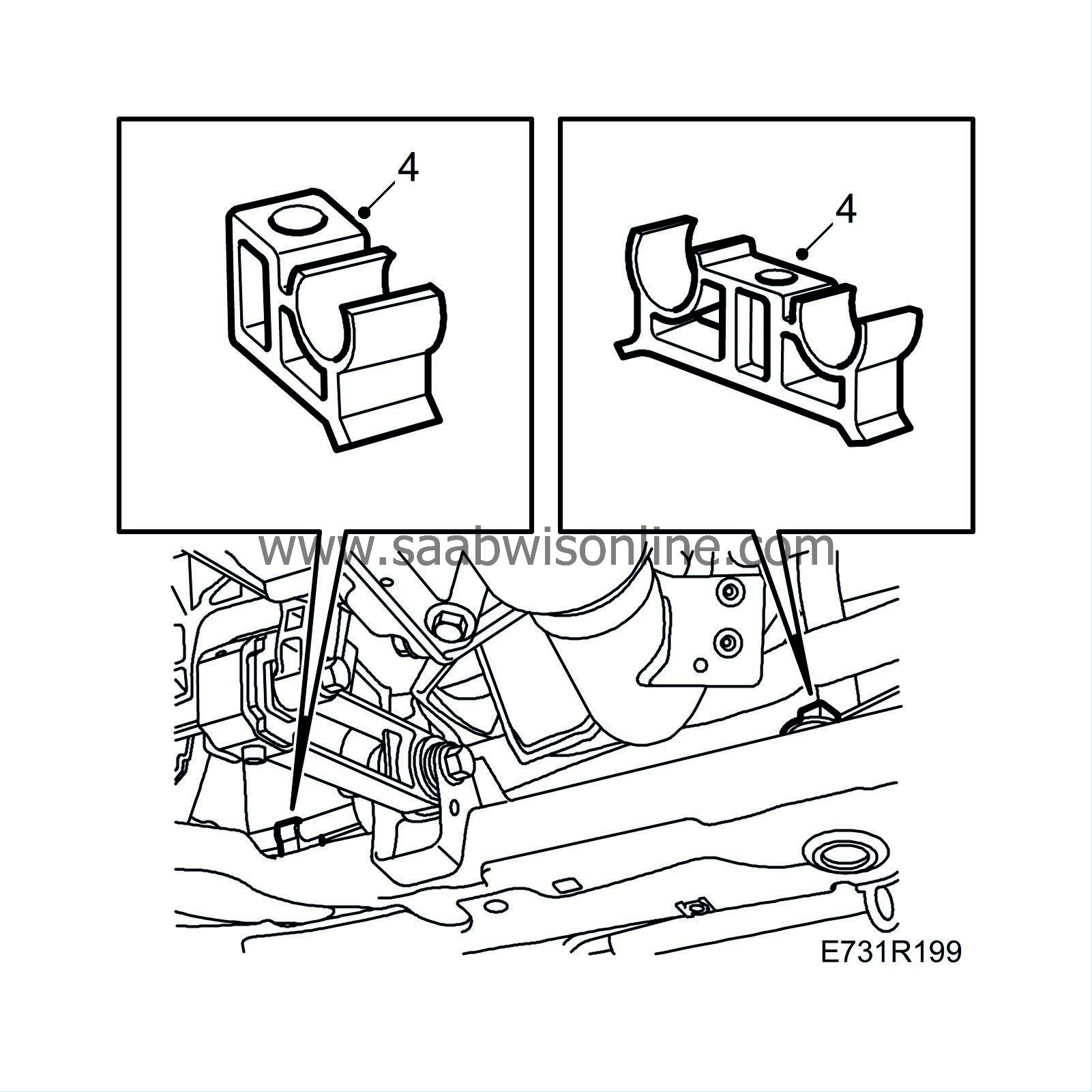

| 4. |

Guide the A/C pipes into their holders on the subframe.

|

|

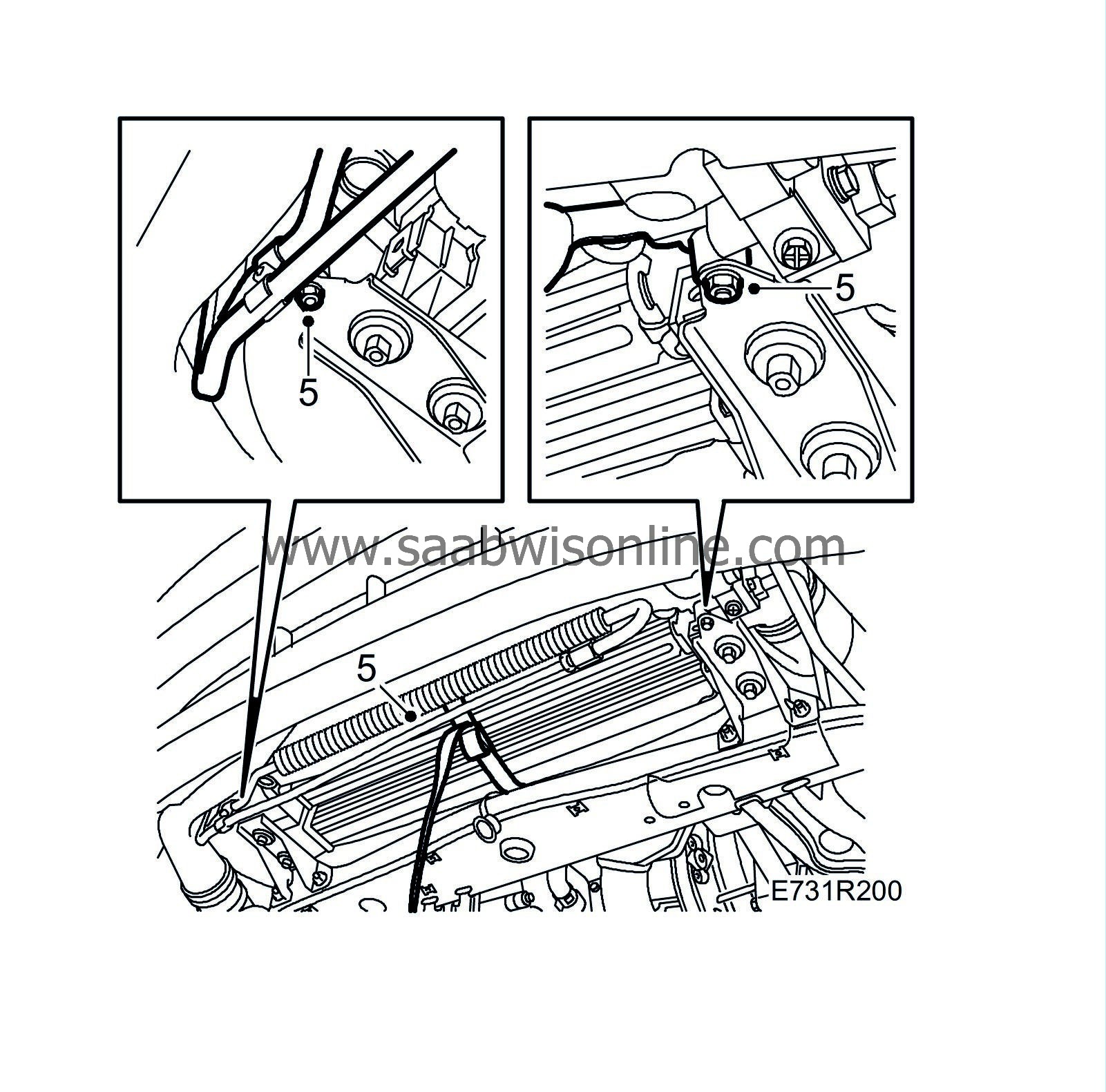

| 5. |

Fit the power steering coolant pipe.

|

|

| 7. |

Fit the bolts to secure the subframe and the rear support plates. Tighten the bolts just enough so that the subframe does not move out of its position when the lifting trolley and fixture are removed.

|

|||||||

| 8. |

Lower the lifting trolley and move it out of the way.

|

|

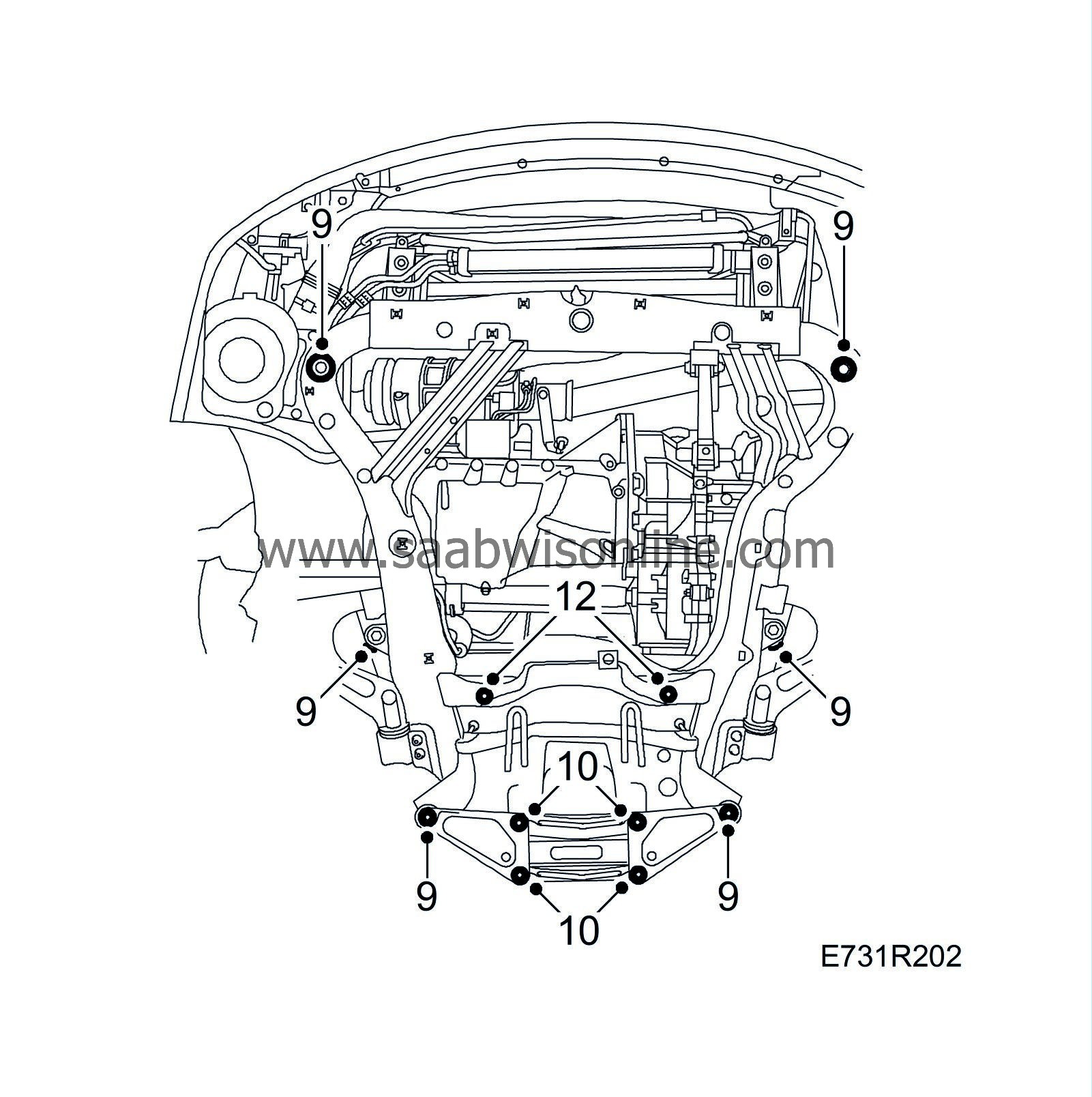

| 9. |

Tighten the subframe bolts.

Tightening torque: 100 Nm +45° (74 lbf ft +45°).

|

|

| 10. |

Tighten the reinforcement at the subframe's rear attachment point.

Tightening torque: 65 Nm (50 lbf ft). |

|

| 11. |

Remove the strap.

|

|

| 12. |

Tighten the steering gear's retaining bolts.

Tightening torque: 95 Nm (70 lbf ft). |

|

| 14. |

Fit the ball joints to the steering swivel member.

Tightening torque: 49 Nm (36 lbf ft).

|

|

| 15. |

Fit the anti-roll bar support to the MacPherson strut.

Tightening torque: 90 Nm (65 lbf ft). |

|

| 16. |

Cars with xenon headlamps:

Fit the level sensor for the xenon headlamps.

|

|

| 17. |

R4:

Fit the engine oil cooler.

|

|

| 18. |

V6:

Fit the air shield.

|

|

| 19. |

Fit the nuts for the air cleaner.

|

|

| 20. |

Cars with automatic gearbox:

|

|

| • |

Insert the bolts of the rear engine pad.

|

| • |

Lower the car and tighten the engine pad bolts from above.

Tightening torque: 24 Nm (18 lbf ft) |

| • |

Raise the car and attach the engine bracket to the gearbox.

Tightening torque: 60 Nm (44 lbf ft). |

| 22. |

Run the oxygen sensors' cables into the engine bay.

|

|

| 23. |

Fit the air shields.

|

|

| 24. |

Tighten the bolts securing the gearbox torque arm to the subframe.

Tightening torque: 90 Nm +90° (66 lbf ft +90°).

|

|||||||

| 25. |

Fit the wheels. See

Wheels

.

Lower the car to the floor. |

|

| 26. |

Remove the lifting beam.

|

|

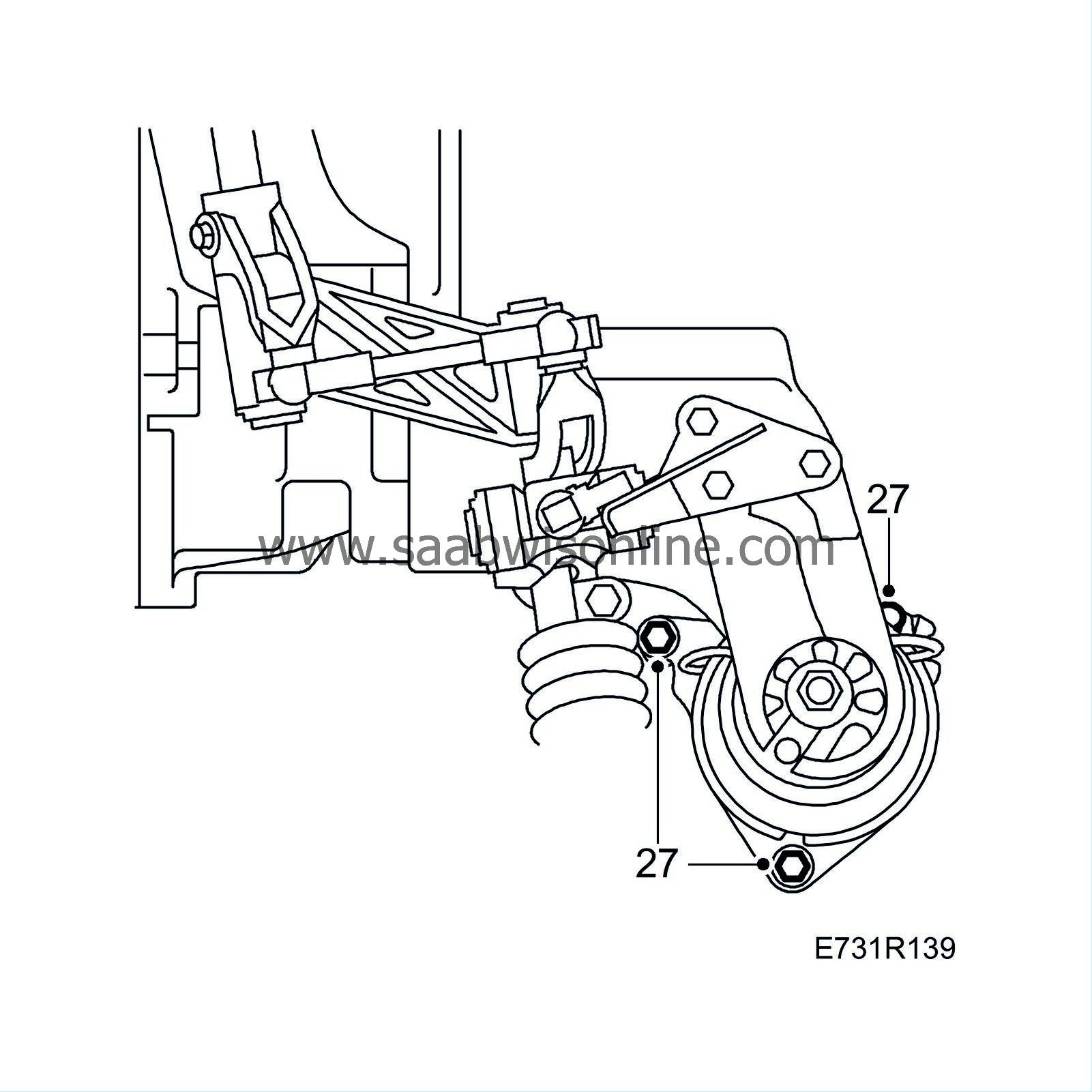

| 27. |

Man:

Tighten the bolts holding the rear engine pad to the subframe.

Tightening torque: 25 Nm (18 lbf ft). Aut: Fit the rear engine pad nut. Tightening torque: 47 Nm (35 lbf ft).

|

|

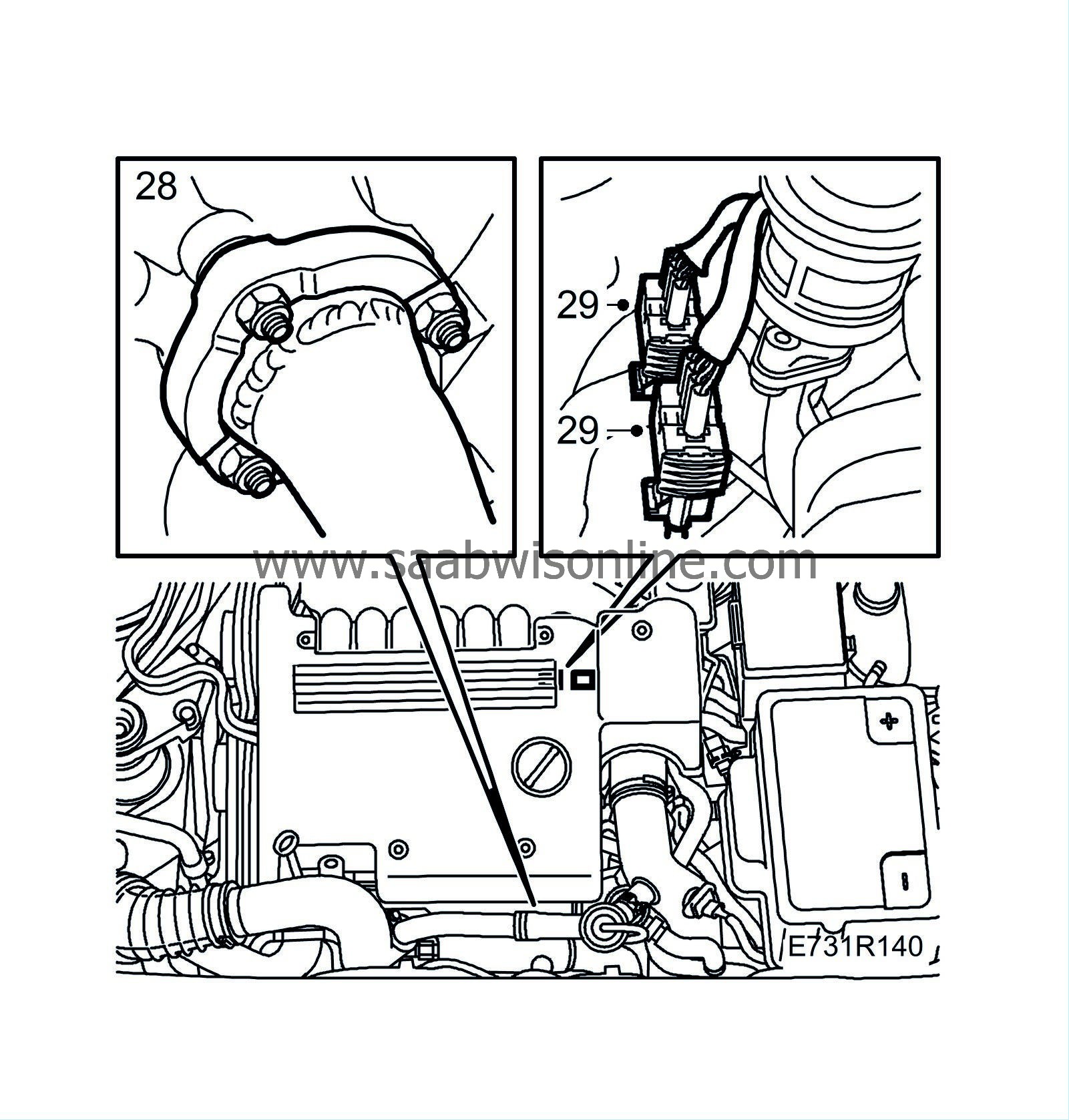

| 28. |

Fit the exhaust pipe to the turbocharger.

Tightening torque: 25 Nm (18 lbf ft).

|

|

| 29. |

Plug in the front heated oxygen sensor's connector and that of the rear heated oxygen sensor, if fitted, and secure the cable at suitable places.

|

|

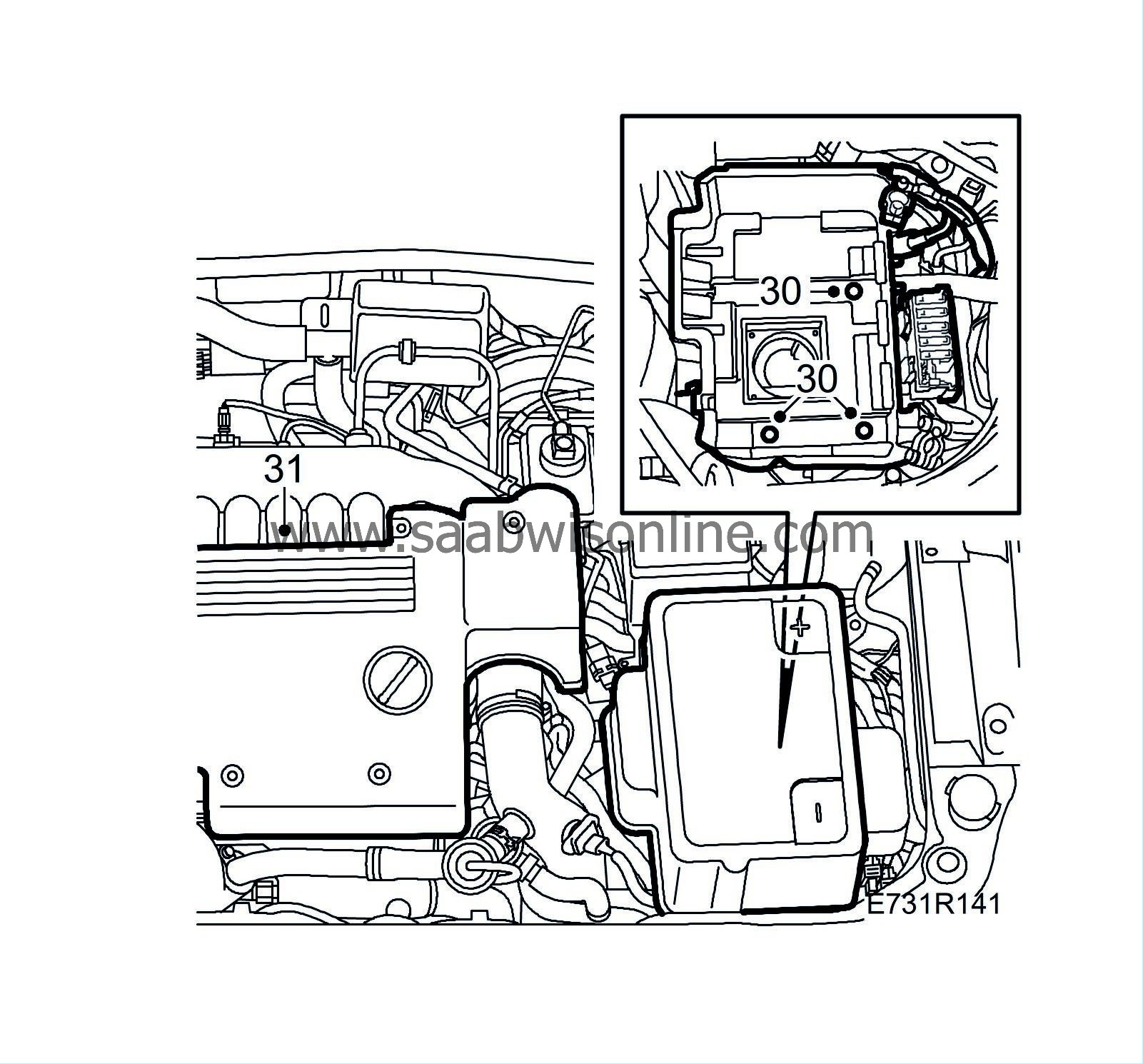

| 30. |

Fit the battery tray, battery and battery cover.

|

|

| 31. |

Fit the engine cover.

|

|

| 32. |

Perform a road test and check the position of the steering wheel on a level surface and adjust as necessary.

|

|