Untraceable faults in PSG16 despite diagnostic trouble code being generated

Symptom: Untraceable faults in PSG16 despite diagnostic trouble code being generated

|

|

Untraceable faults in PSG16 despite diagnostic trouble code being generated

|

Background

The car may have fault symptoms where a diagnostic trouble code for an electrical fault has been generated but the cause of the fault cannot be found despite repeated fault diagnosis.

This can be due to reversed pins in one of the connectors with the engine control module which causes poor contact. The following fault diagnosis encompasses a comprehensive fault diagnosis of the connectors with the engine control module.

Fault symptom

Untraceable faults in PSG16 despite diagnostic trouble code being generated

Conditions

If a diagnostic trouble code arises then each fault diagnosis is used at first. If this is unsuccessful then the following action must be taken.

Diagnostic procedure

|

1.

|

Read the diagnostic trouble codes from the engine management system. Record the diagnostic trouble codes for the continued fault diagnosis.

|

|

2.

|

Check the wiring diagram for the engine management system. Record which pins and connectors belong to the component/function to which the diagnostic trouble codes apply.

|

|

3.

|

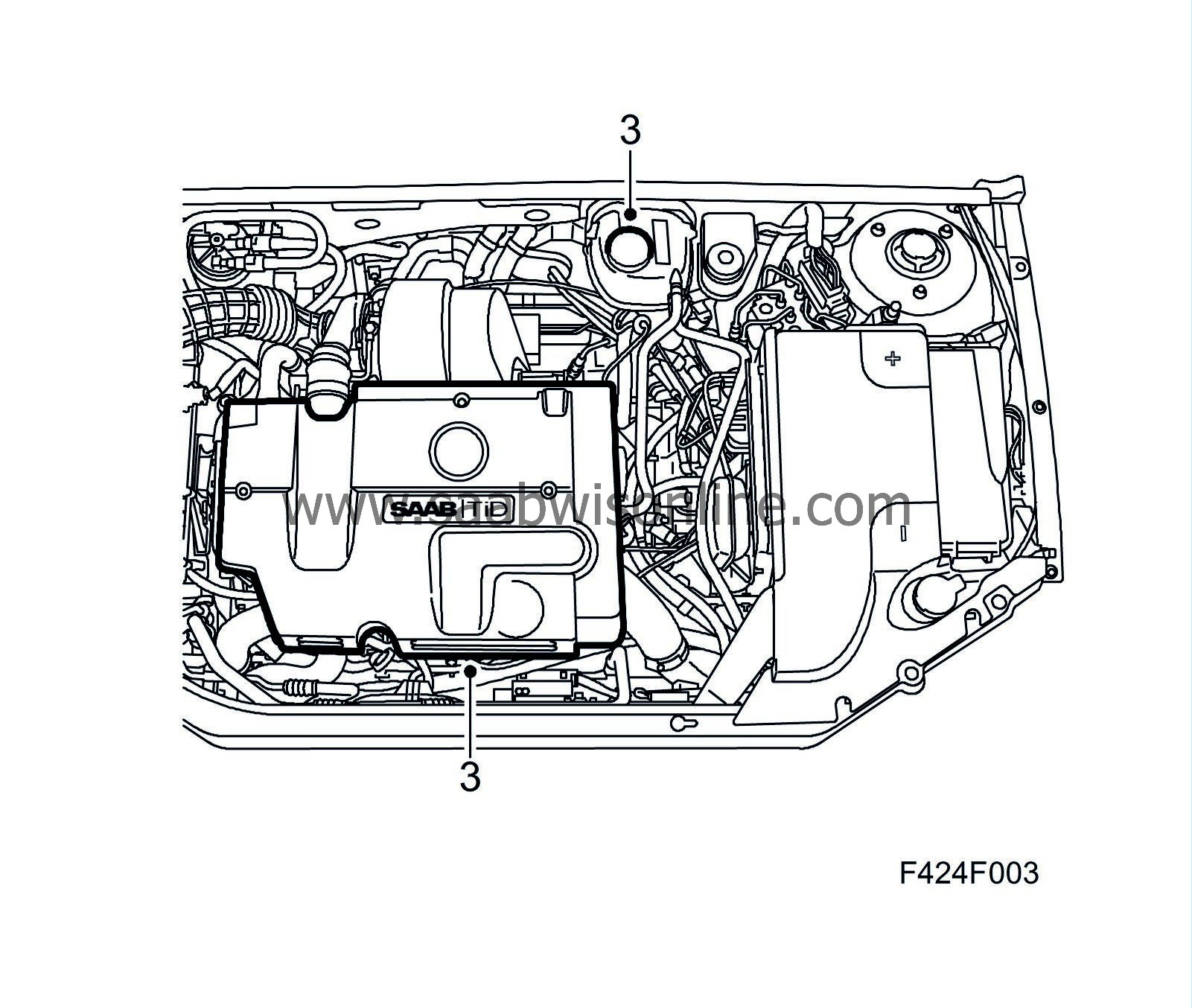

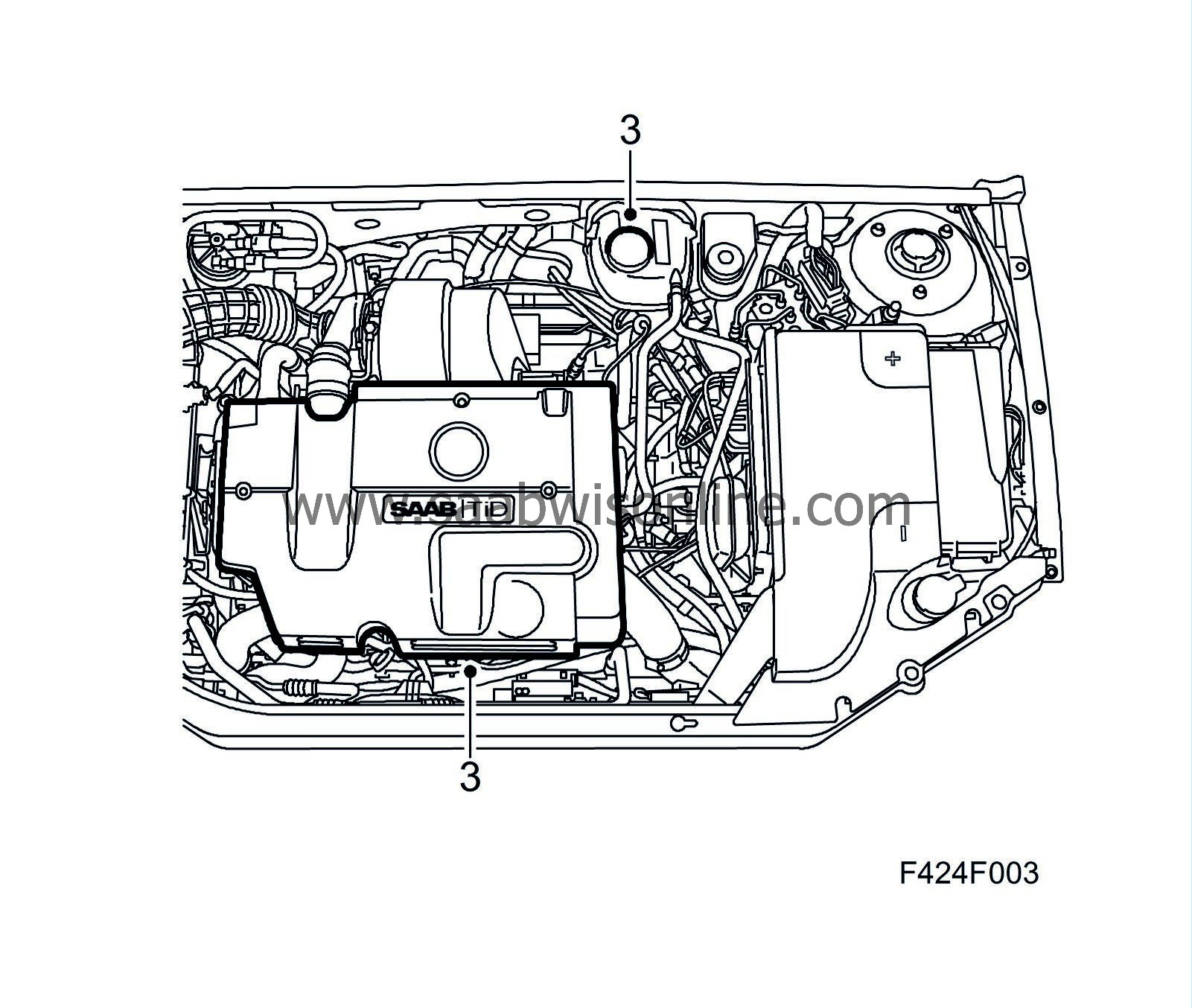

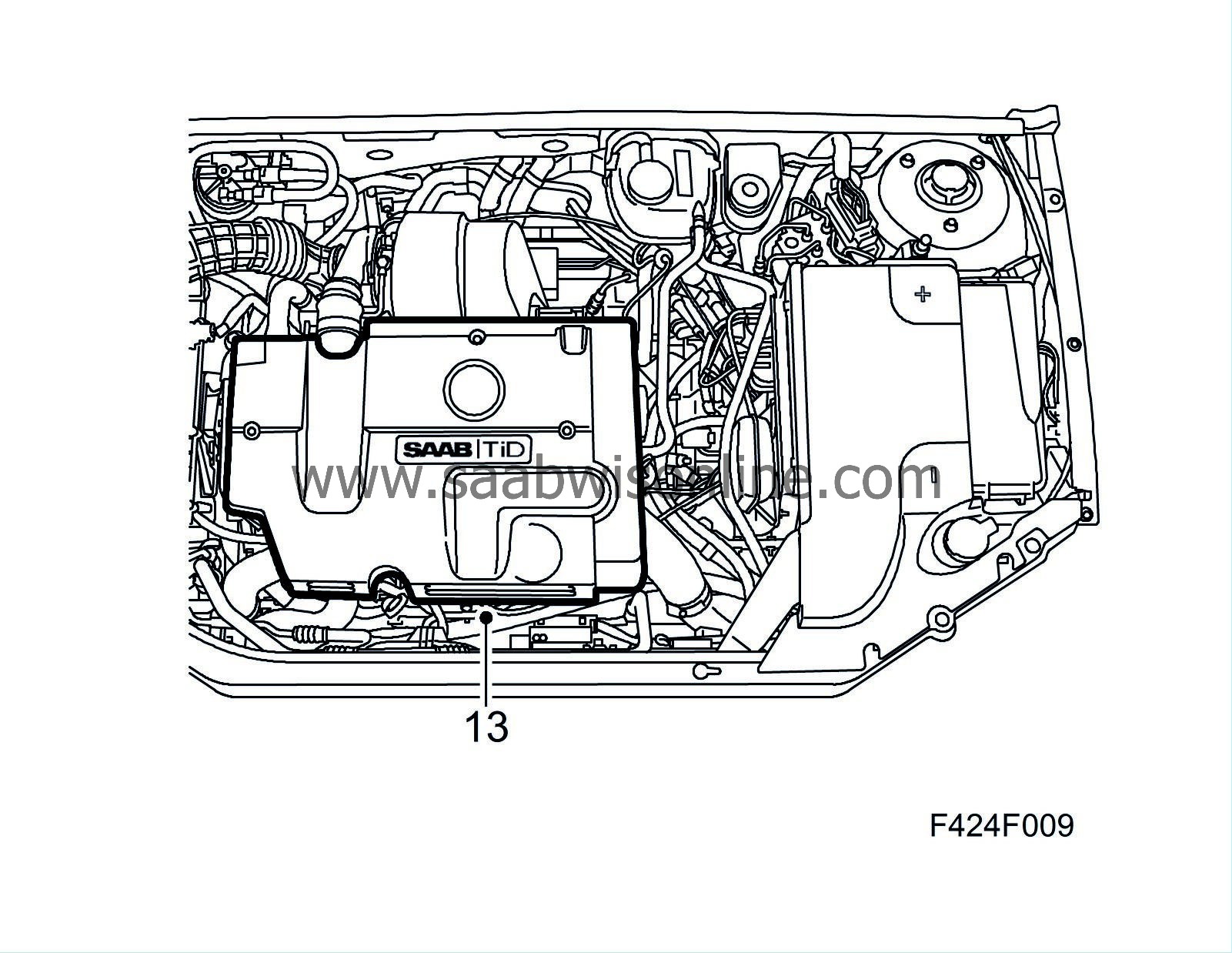

Remove the upper engine cover and undo the expansion tank cap in order to release overpressure in the cooling system.

|

|

4.

|

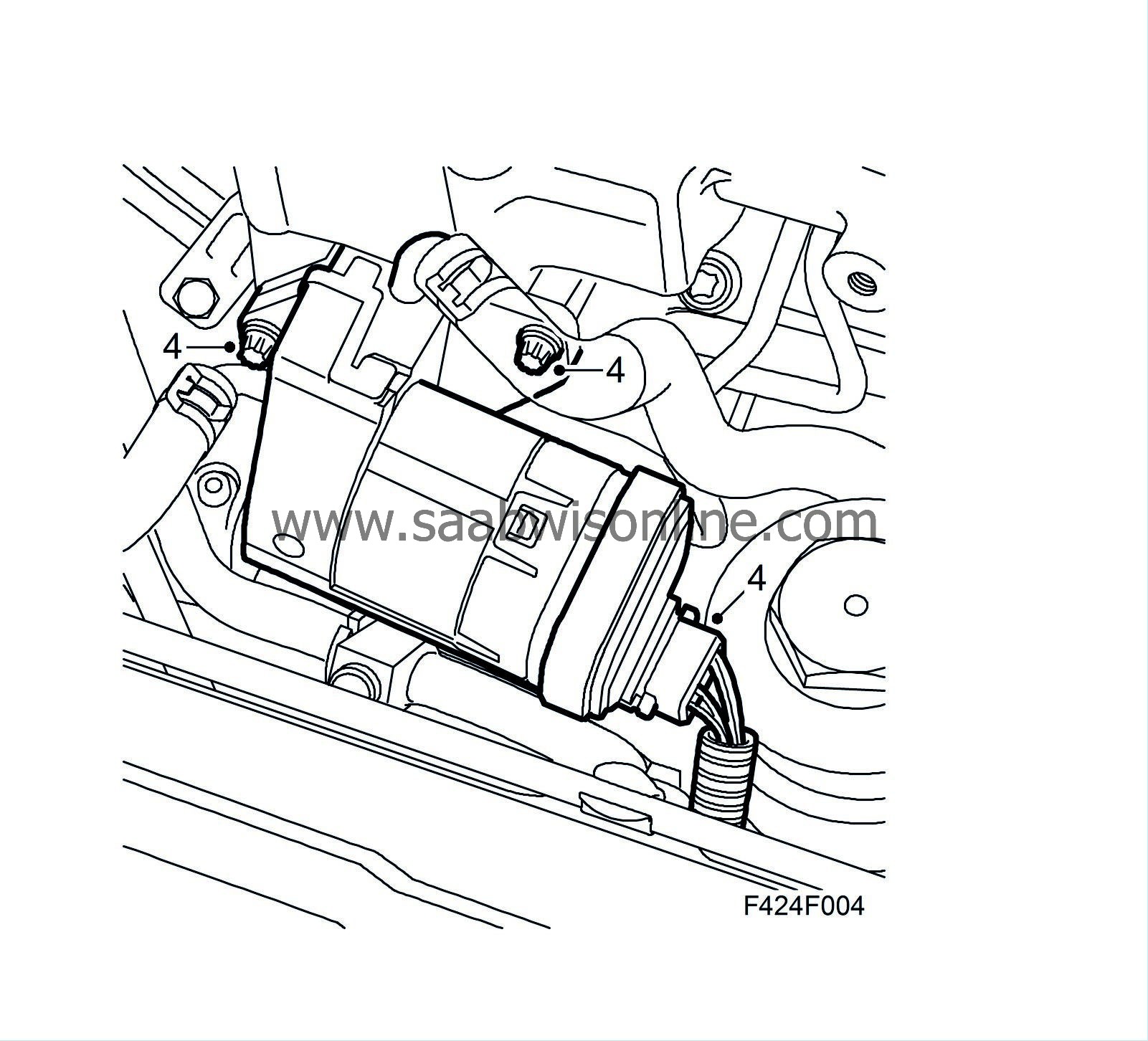

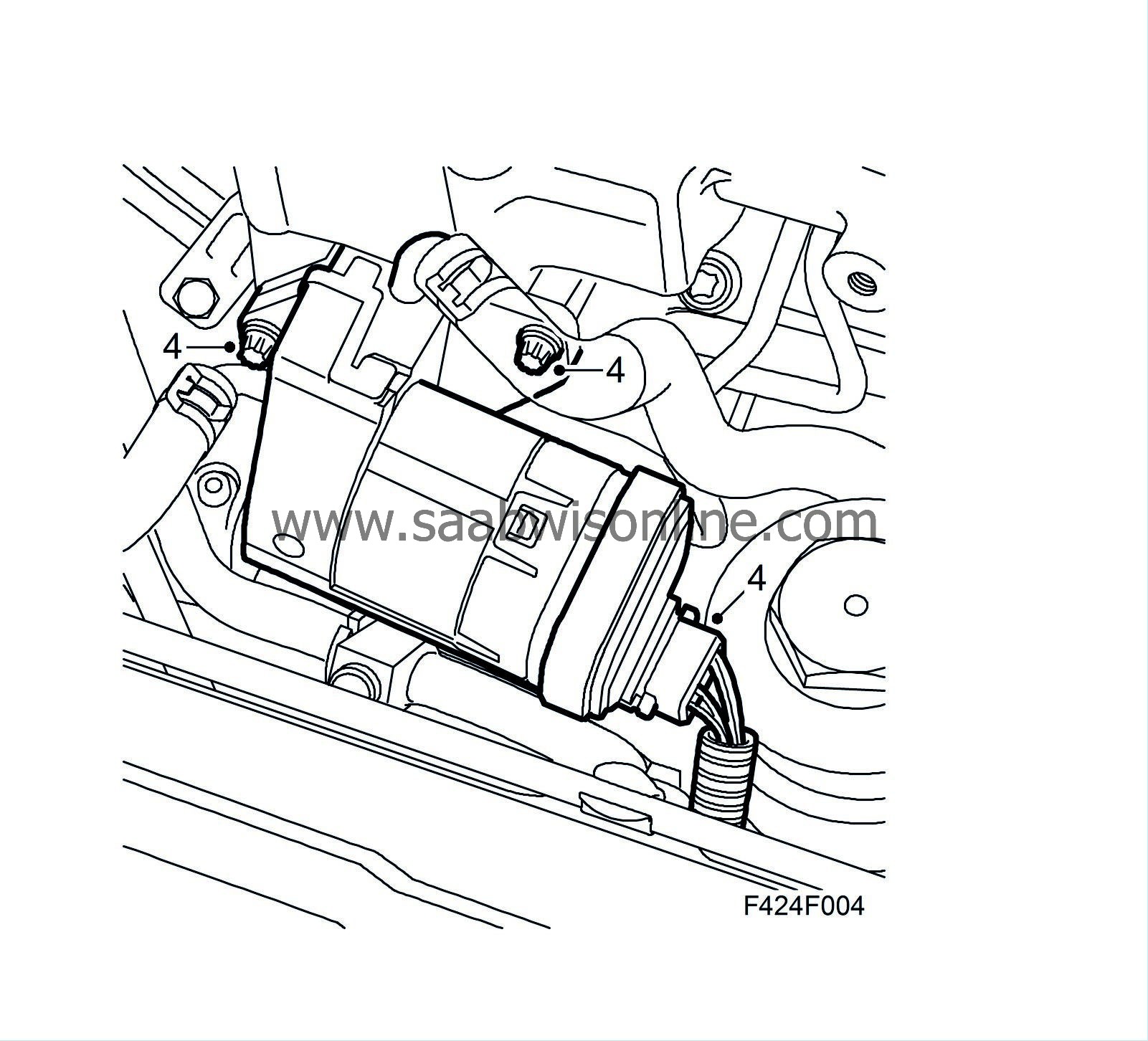

Unplug the connector and remove the EGR valve from the intake manifold.

|

|

6.

|

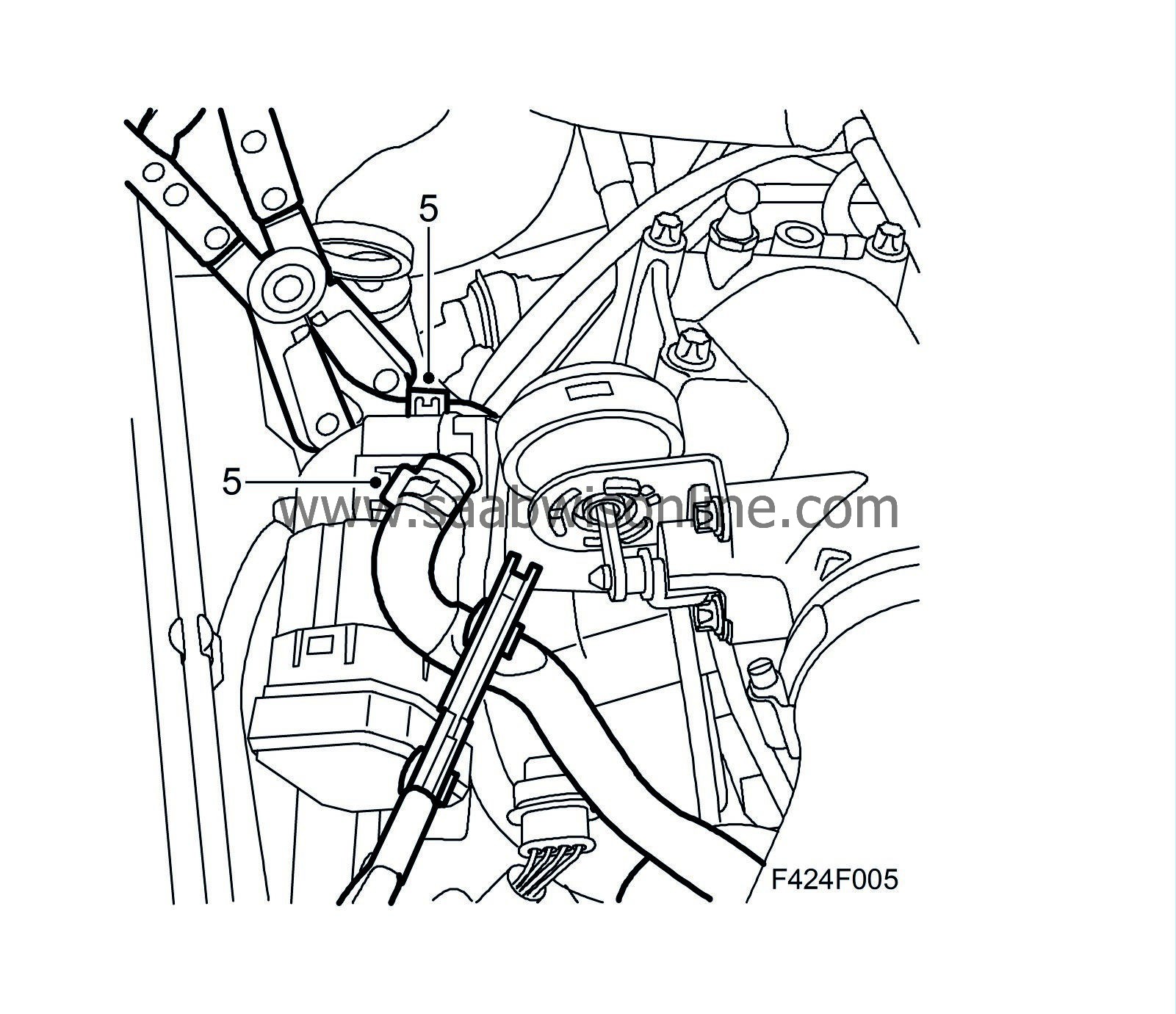

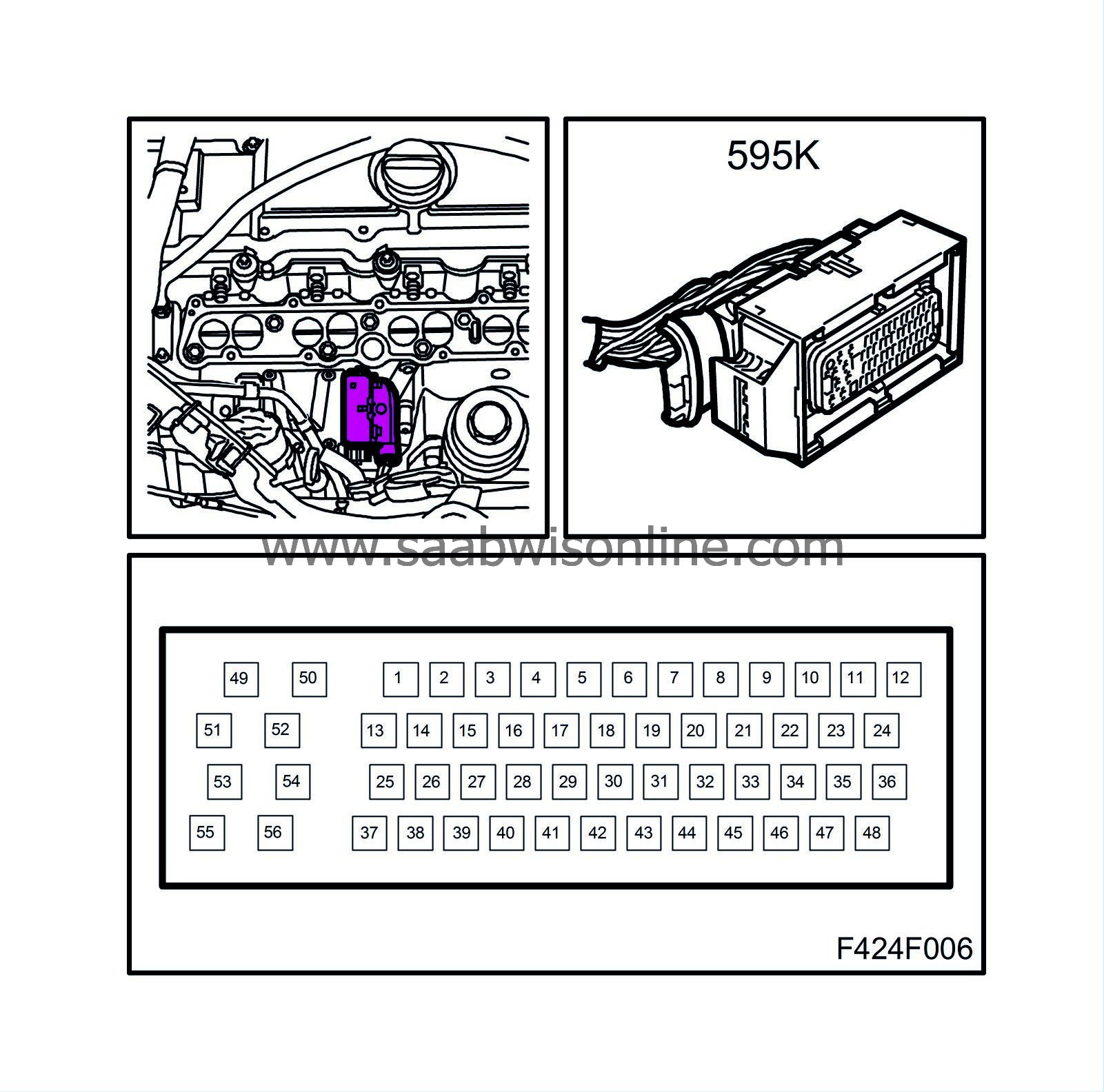

Unplug one or both of the connectors on the engine control module depending on which component/function is the subject of the fault diagnosis.

|

Important

|

|

ESD-SENSITIVE COMPONENT

|

|

Touch a source of ground, e.g. the car body, before unplugging/plugging in component connectors.

Do not touch the pins on the components

.

|

|

When changing control module

|

|

• Keep the new control module in its original packaging for as long as possible.

|

|

• Place the exchanged control module in the return packaging without touching its pins.

|

|

|

|

|

7.

|

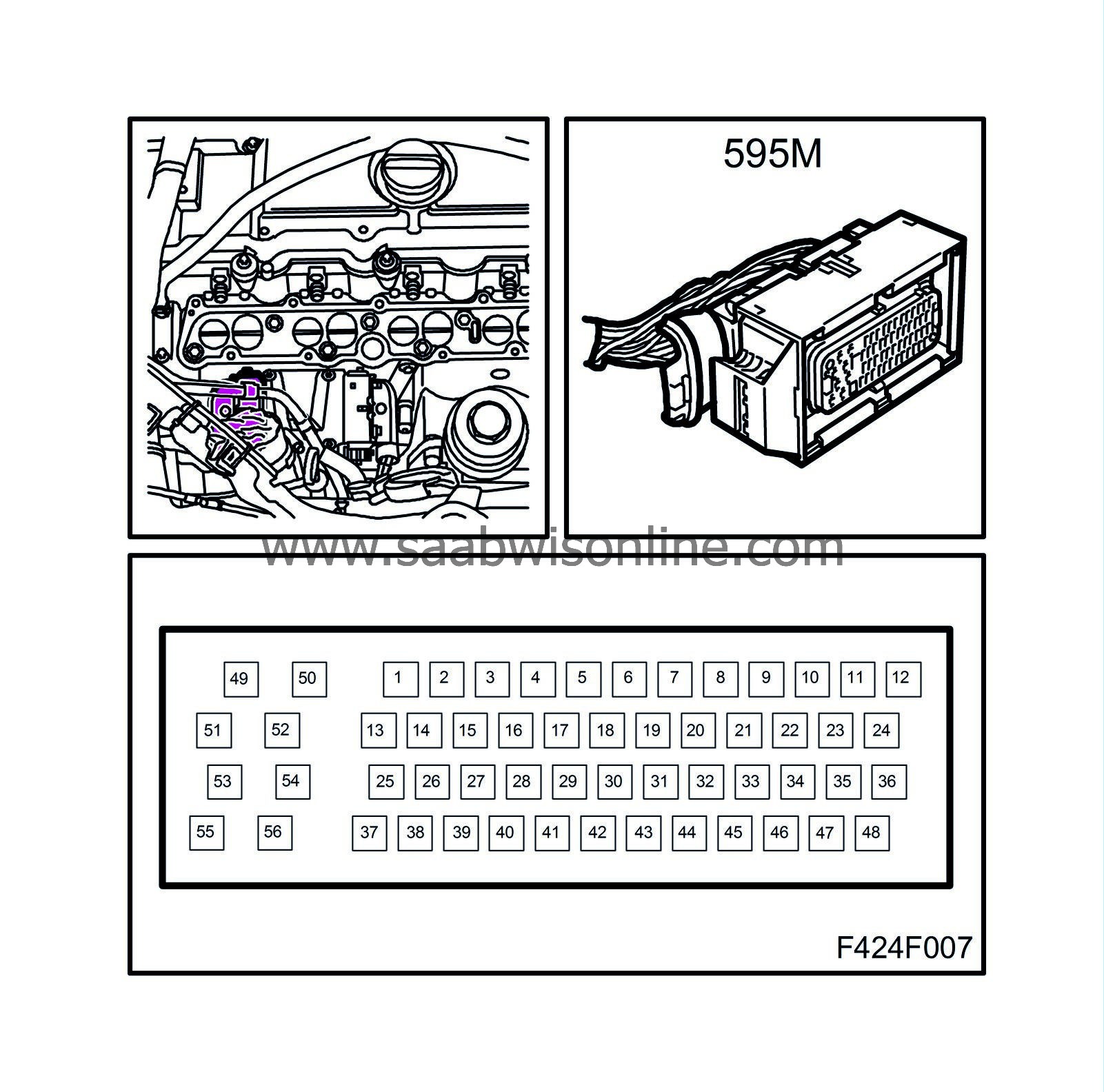

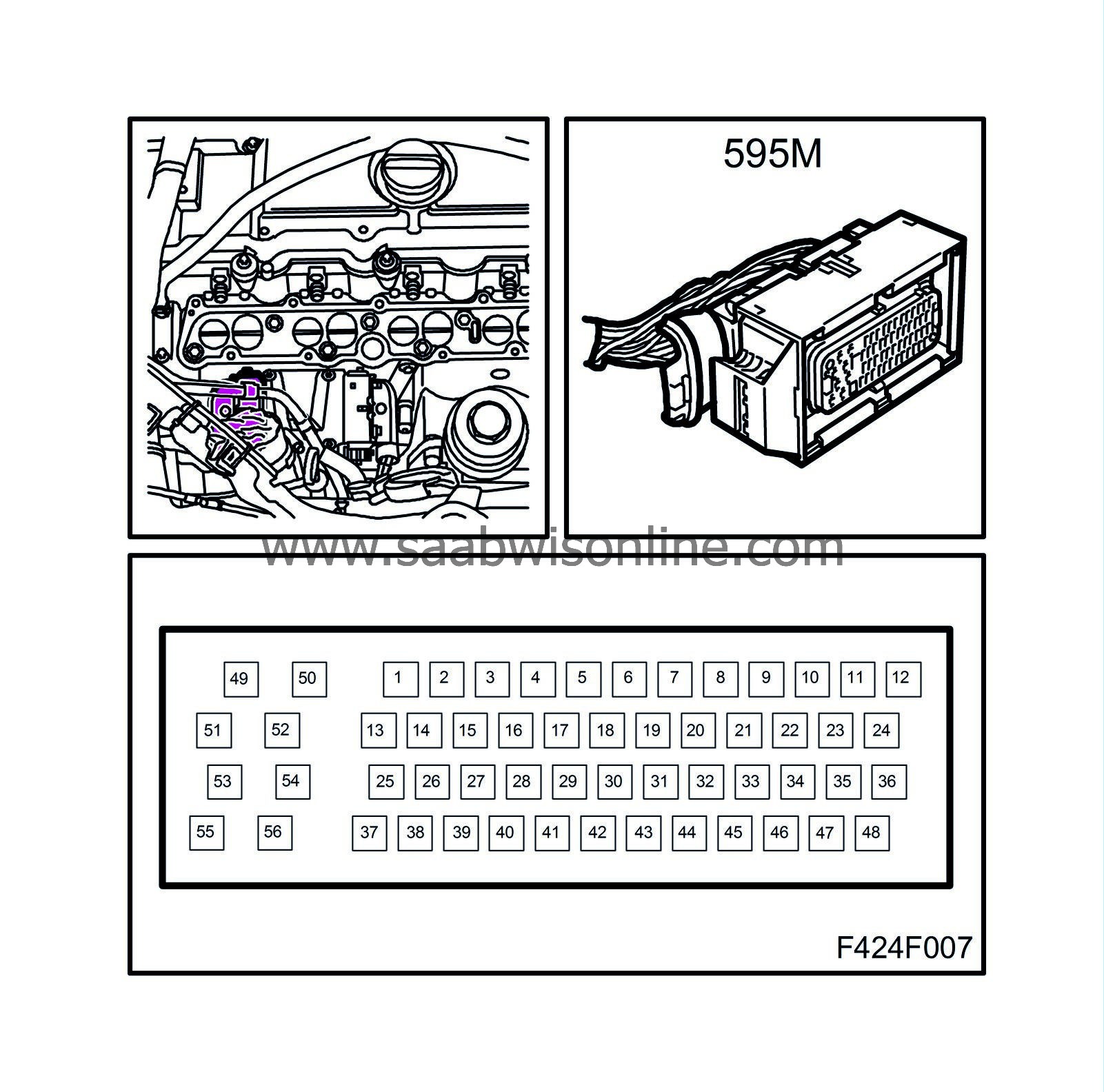

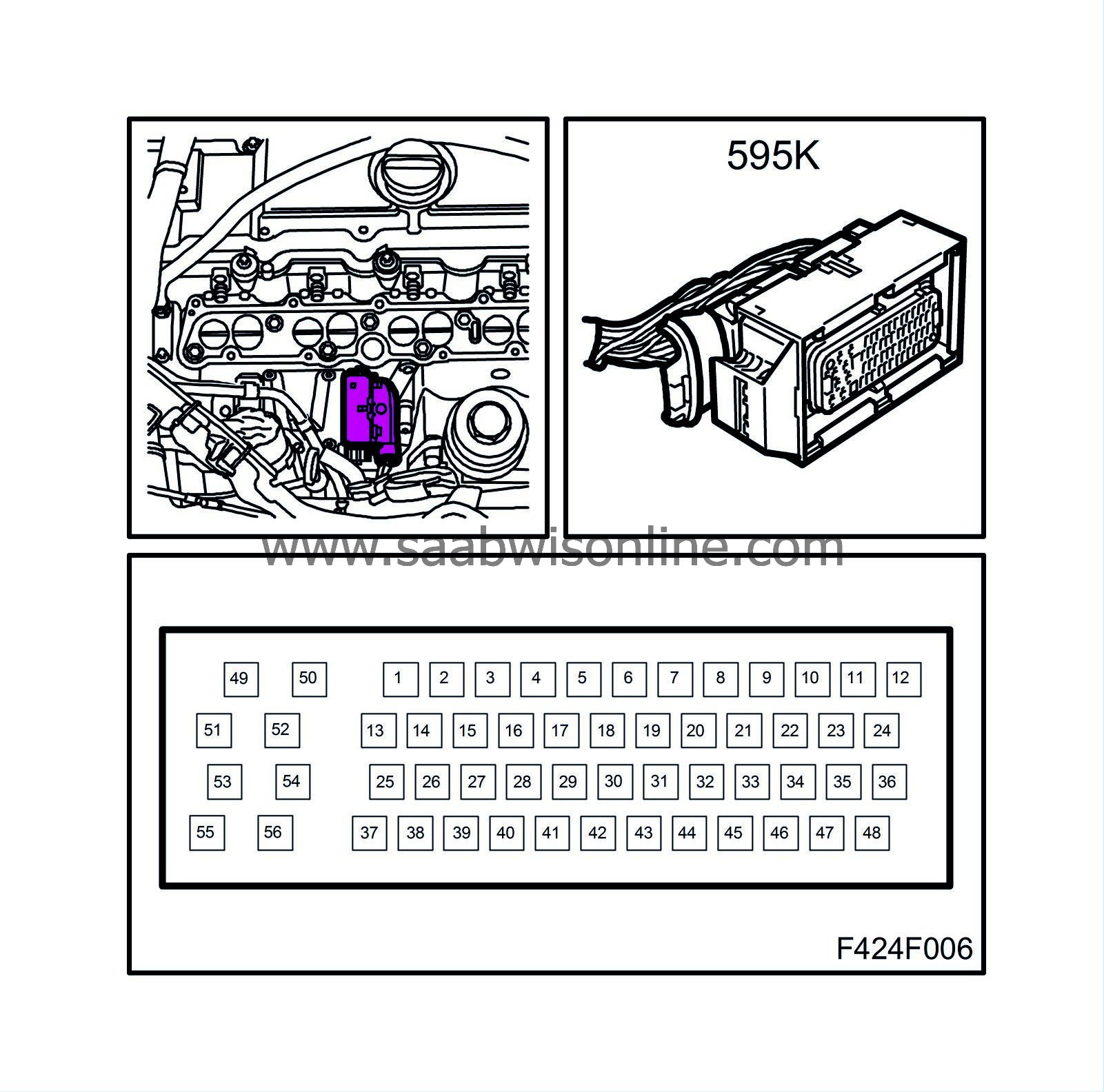

Release the connectors so that the pins which are affected according to the records from step 2 can be checked very carefully.

|

|

8.

|

Use a test cable with pin size 0.6 x 0.6 mm from kit 86 12 731. Guide the test cable pins into the connector's pins to assess the clamping force on the pins in question. In addition, check that the engagement of the pins has the same depth as other pins in the connector.

Poor clamping force and inadequate engagement depth in the connector's pins can cause poor contact.

|

Important

|

|

Incorrect handing or the use of the wrong tool can damage the sleeves in the connector.

|

|

Use a test cable (part no. 86 12 731) of the correct size to avoid damaging the sleeves in the connector.

|

|

|

|

|

9.

|

If a reversed pin or a pin with poor clamping force is detected then the engine's wiring harness must be replaced.

|

|

10.

|

Using a mirror, check that the engine control module pins are straight.

|

Important

|

|

ESD-SENSITIVE COMPONENT

|

|

Touch a source of ground, e.g. the car body, before unplugging/plugging in component connectors.

Do not touch the pins on the components

.

|

|

When changing control module

|

|

• Keep the new control module in its original packaging for as long as possible.

|

|

• Place the exchanged control module in the return packaging without touching its pins.

|

|

|

|

|

11.

|

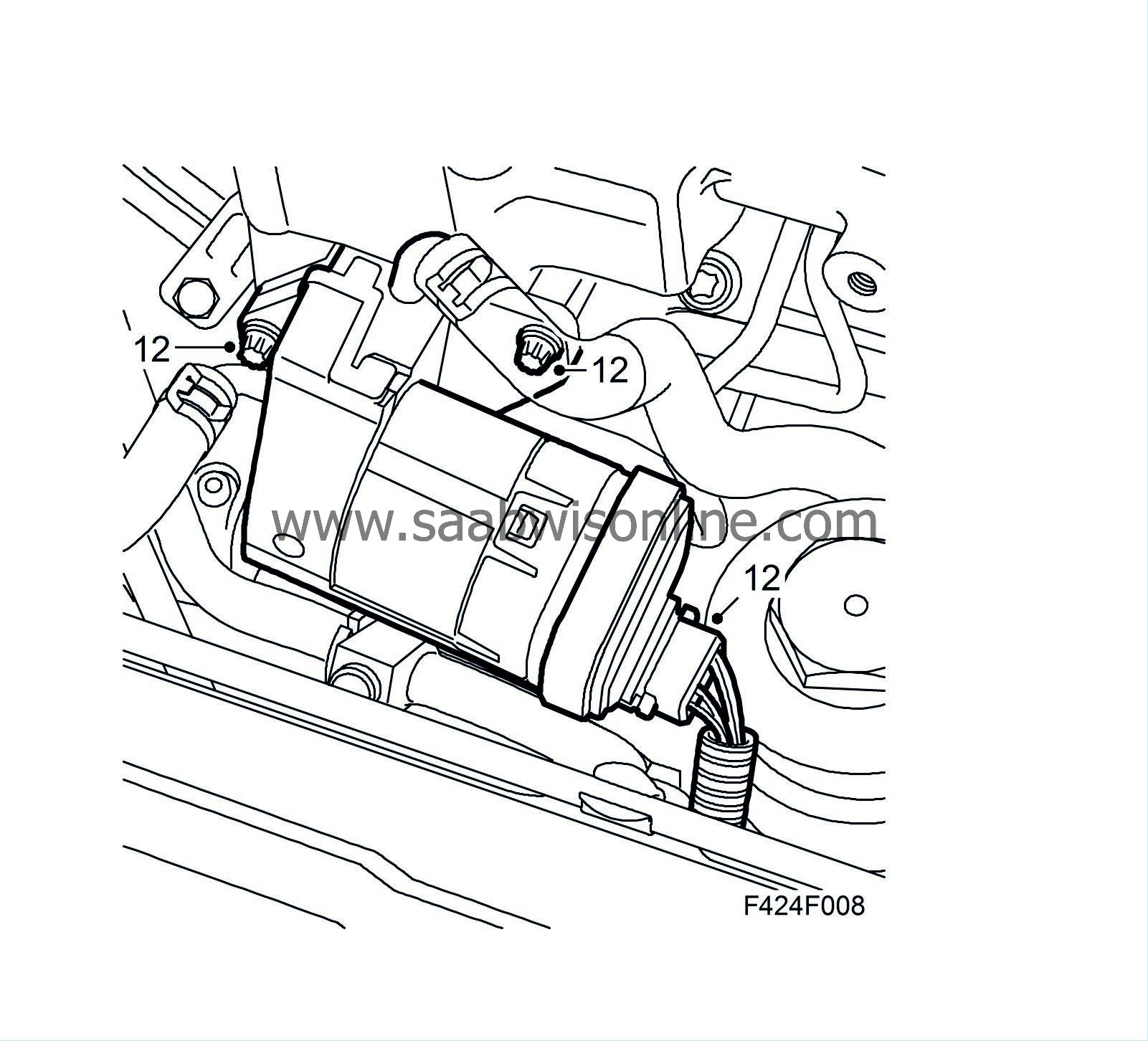

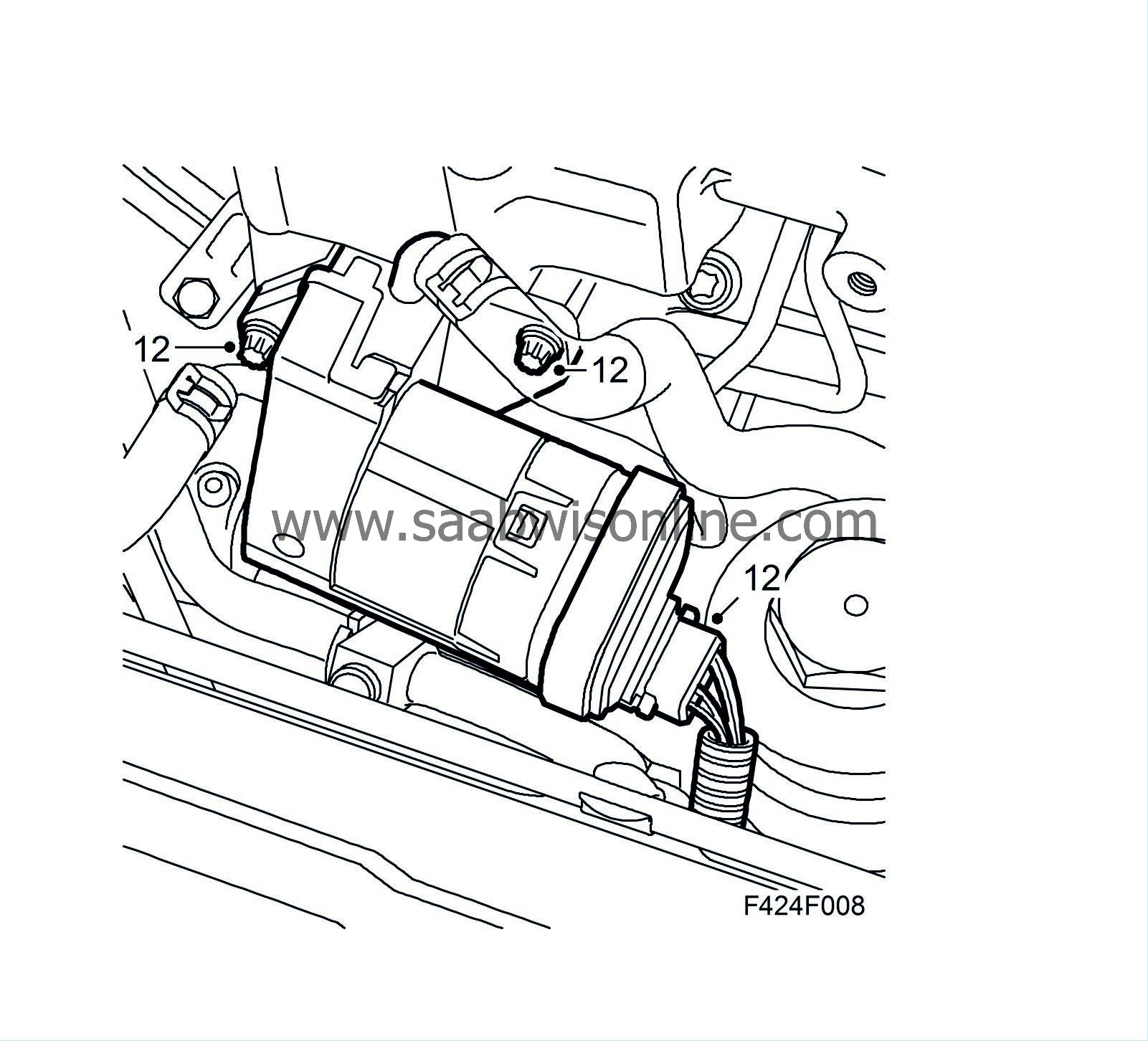

Fit the engine control module connector.

|

|

12.

|

Fit the EGR valve.

|

|

13.

|

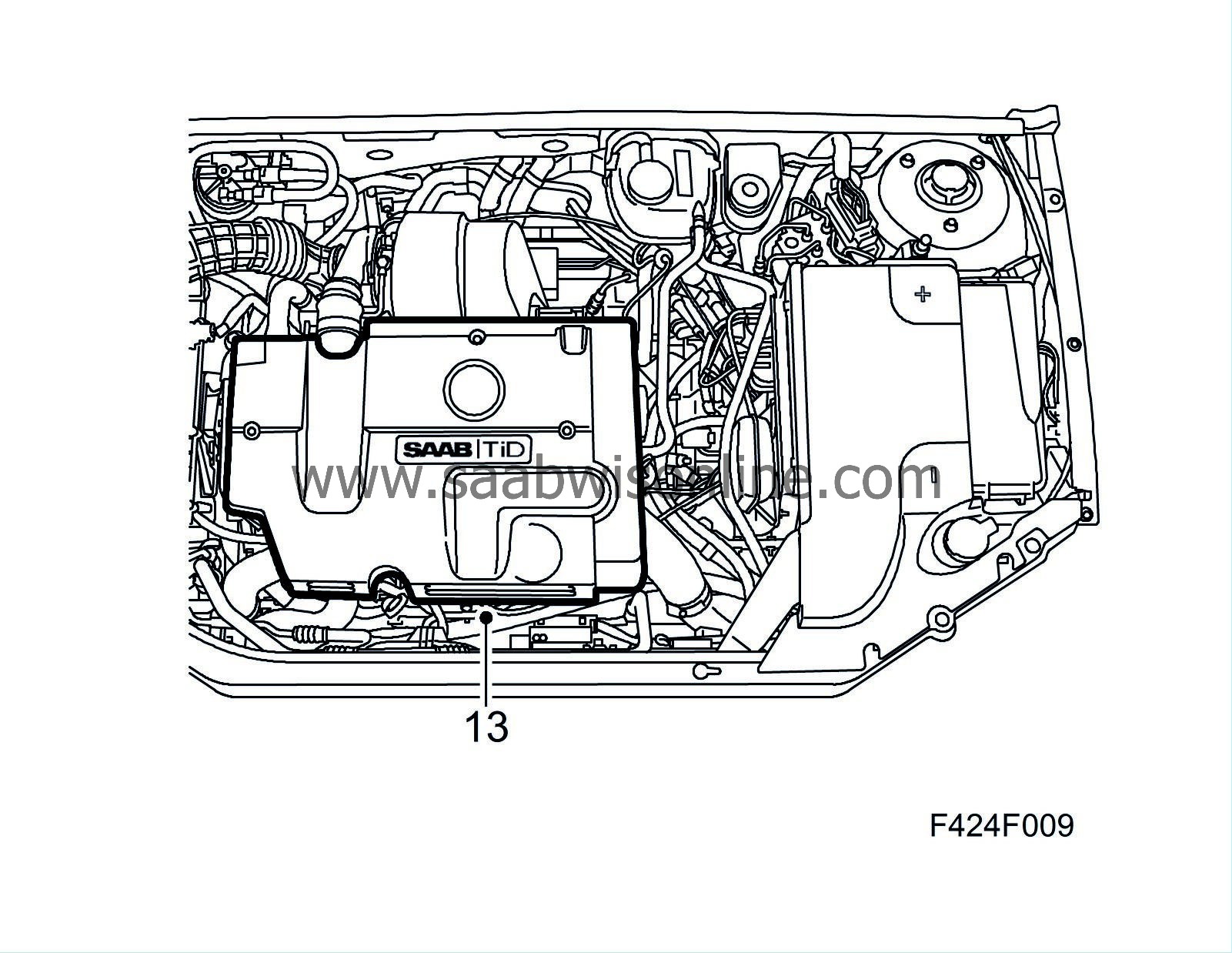

Fit the upper engine cover.

|

|

14.

|

Read the control module software version using Tech 2. If there is a later software version in TIS2000 then this must be programmed into the control module.

|

|

15.

|

Carry out a driving cycle, i.e. run the car with varying engine loads and engine speeds for five minutes.

|

|

16.

|

Using Tech 2, check that the diagnostic trouble code has not returned.

|

|

17.

|

If the problems are not resolved then contact the importer's technical support.

|