To fit

| To fit |

| 1. |

Lubricate the primary shaft splines, see

List of lubricants and sealing compounds

.

|

|

| 2. |

If the slave cylinder is new or empty of brake fluid, it must be bled, see

Bleeding the slave cylinder

.

|

|

| 3. |

Fit

83 95 162 Protective collar, drive shafts

in the right-hand shaft seal in the gearbox to protect the seal when the gearbox is refitted.

|

||||||||||

| 4. |

Lift the car.

|

|

| 5. |

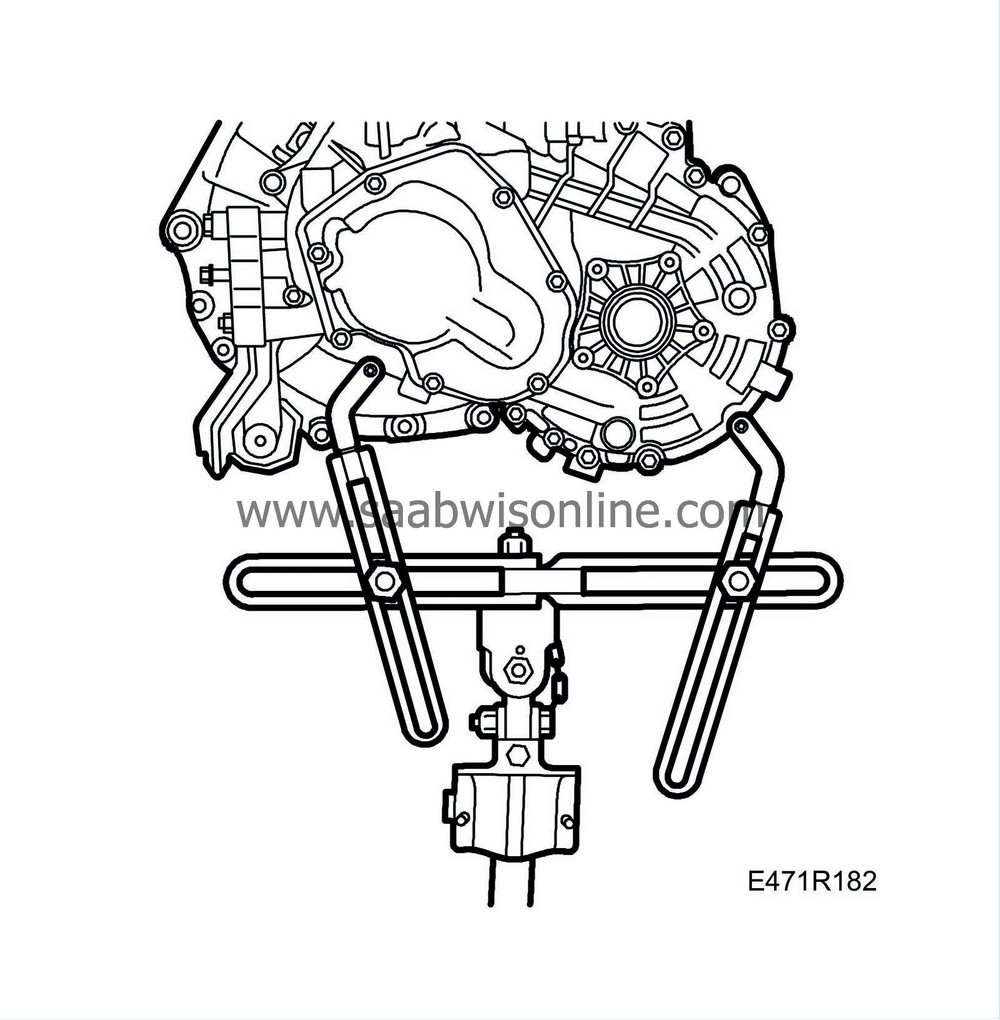

Connect lifting tool

87 92 608 Holder for single-column lift

.

|

|

| 6. |

Adjust the lifting tool so that its centre is in line with the gearbox centre and splitting plane.

|

|

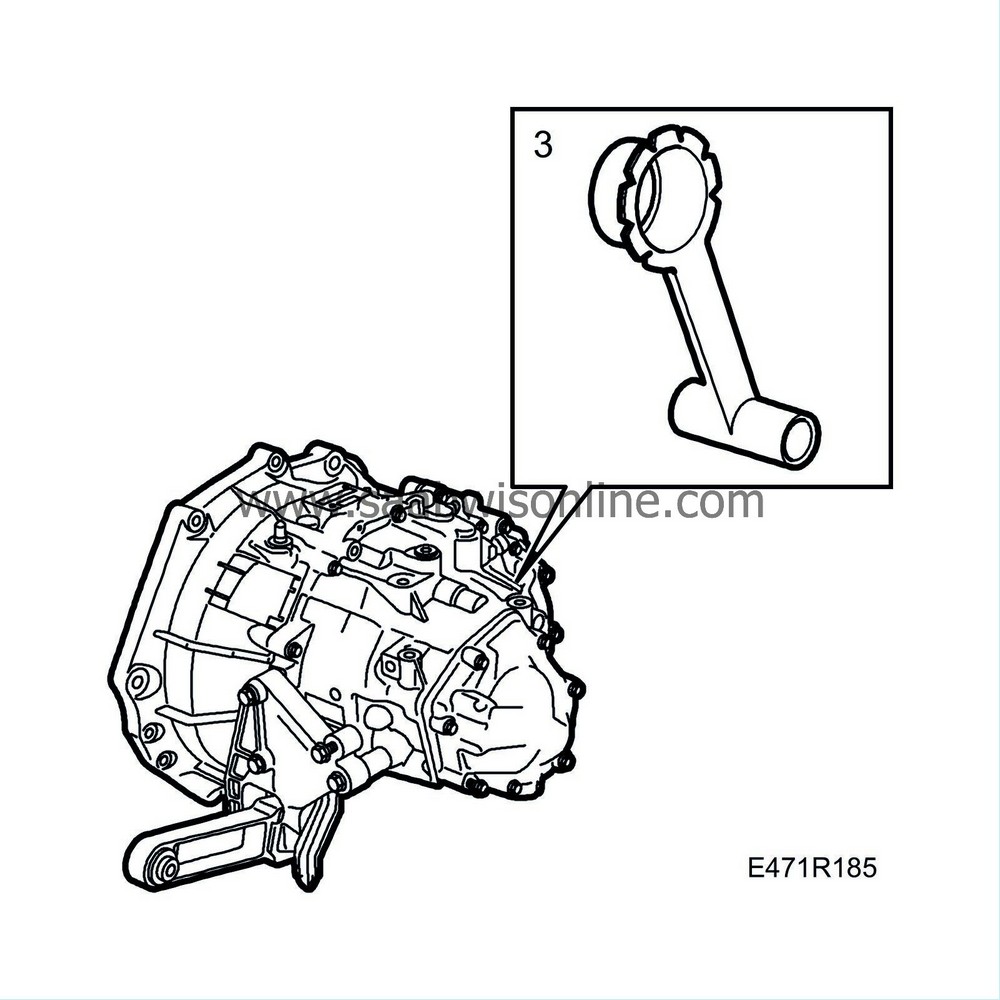

| 7. |

Fit the gearbox using the lifting tool on a column jack.

|

||||||||||

| 8. |

Insert the remainder of the gearbox. Turn the crankshaft if necessary to seat the gearbox correctly.

|

|

| 9. |

B235R:

Fit the protective plate behind the flywheel. Fit the bolts between the gearbox and oil sump, and the bolts to the protective plate.

Tightening torque Gearbox - oil sump 40 Nm (30 lbf ft) |

|

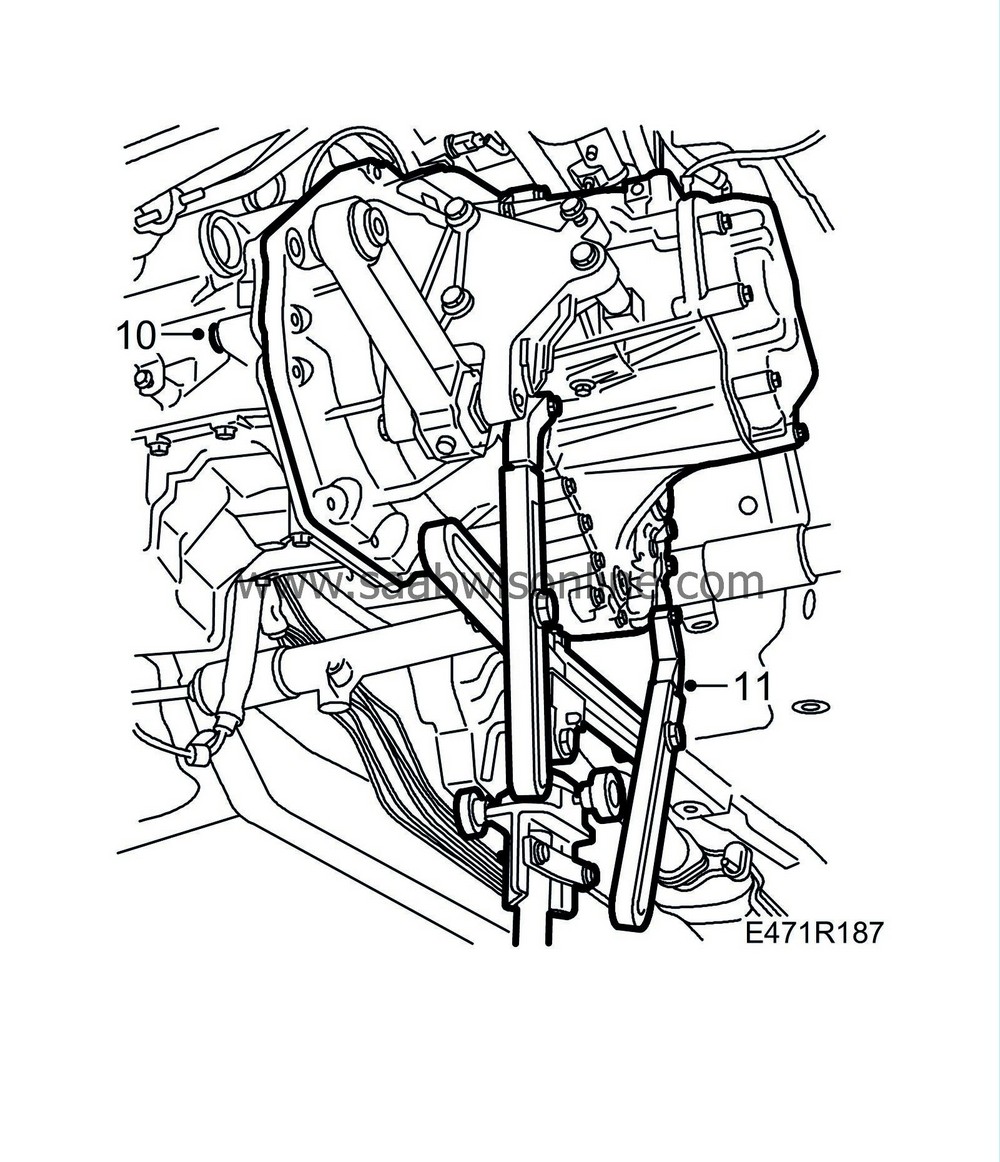

| 10. |

Tighten the lowest bolts between the engine and gearbox.

Tightening torque 70 Nm (50 lbf ft) |

|

| 11. |

Remove the lifting tool from the gearbox and lower the jack.

Refit the gearbox bolts. Tightening torque: 24 Nm (18 lbf ft) |

|

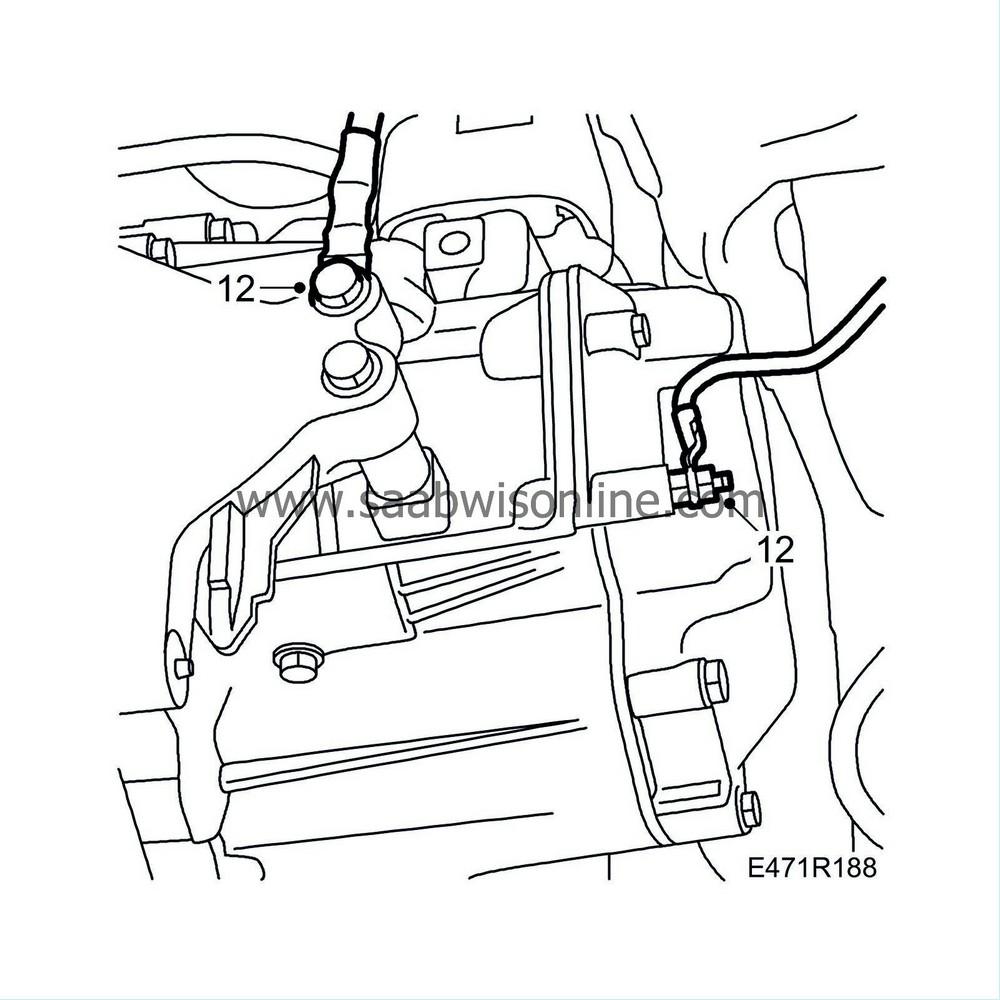

| 12. |

Fit the ground leads to the mounting and gearbox.

|

|

| 13. |

Fit

83 95 162 Protective collar, drive shafts

to the left-hand shaft seal.

|

|

| 14. |

Ensure that the driver is clean and then insert the driver in the tool.

|

||||||||||

| 15. |

Insert the remainder of the shaft until the circlips engage.

|

|

| 16. |

Lower the car to the floor.

|

|

| 17. |

Fit the gearbox mounting.

Tightening torque: 40 Nm (30 lbf ft) |

|

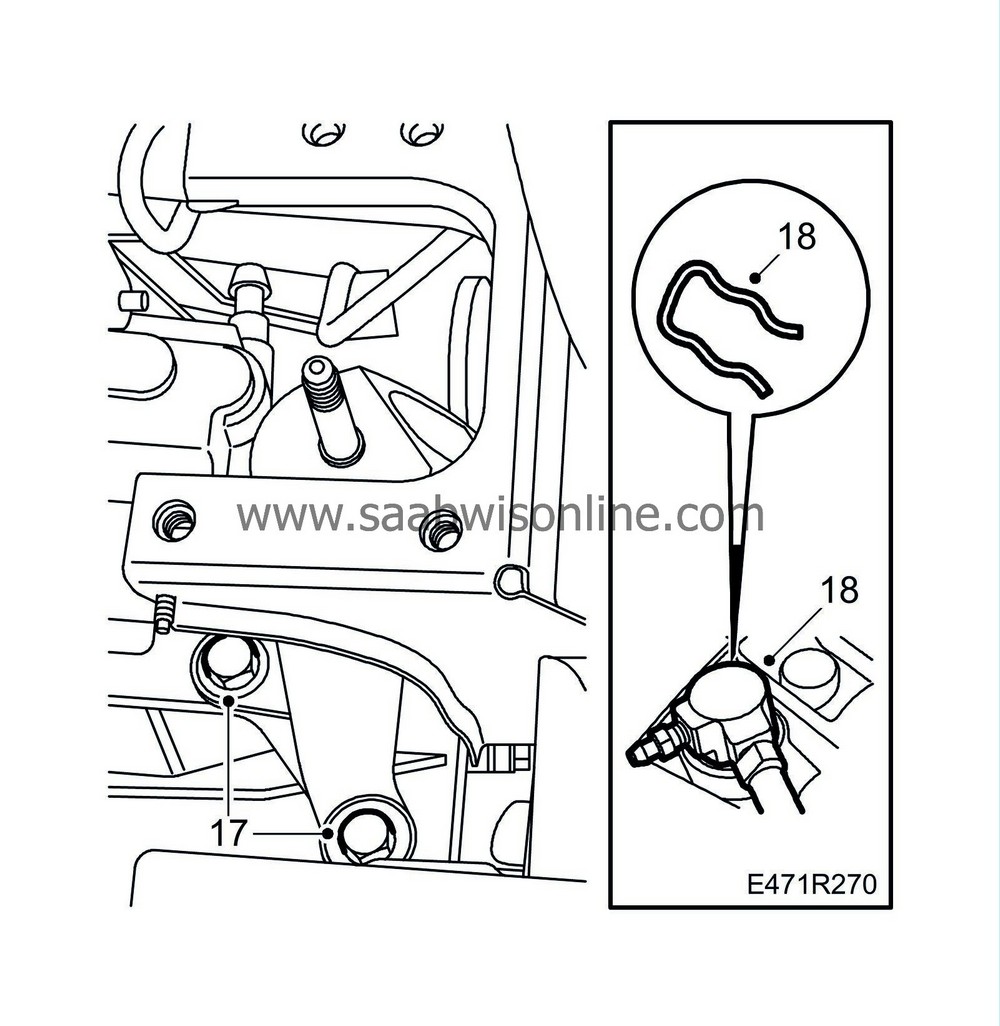

| 18. |

Connecting the coupling pipe to the gearbox and fit the circlips, checking that the pipe fixing to the body is tight.

|

|

| 19. |

Lift the unit.

|

|||||||

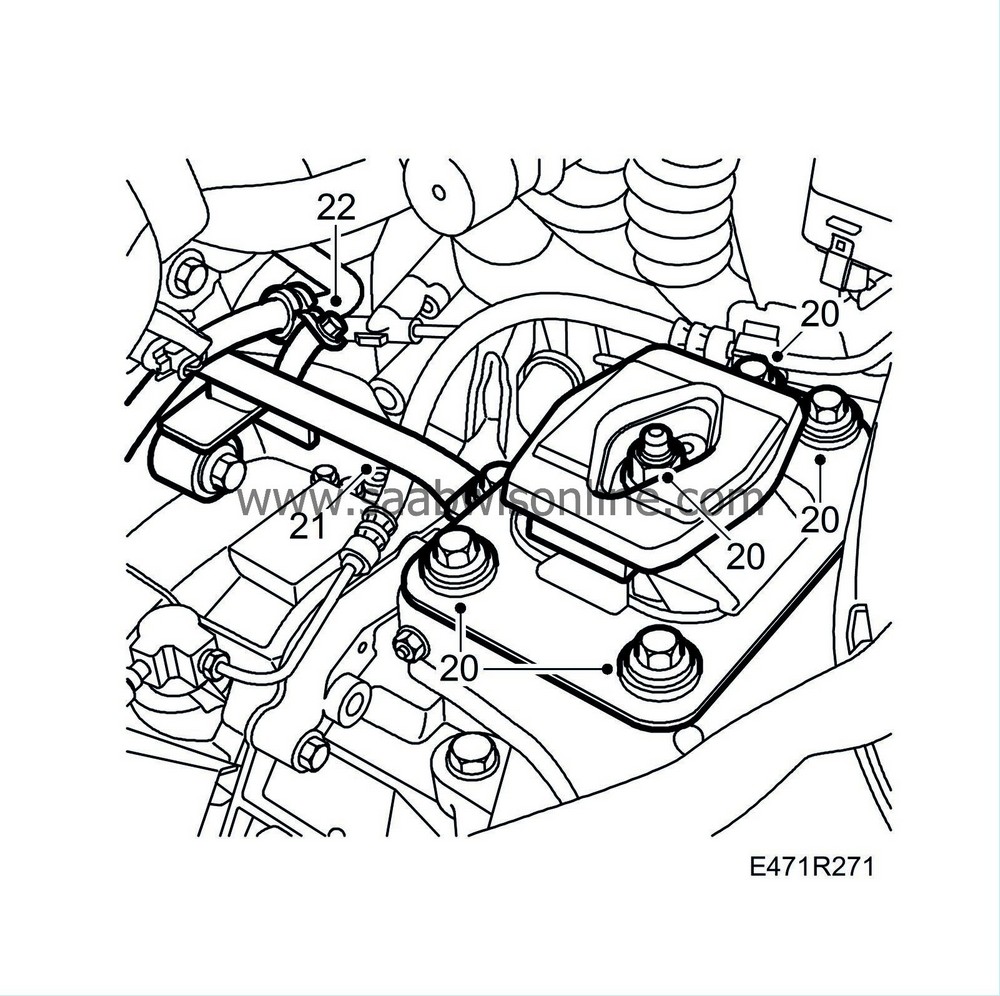

| 20. |

Tighten the left-hand engine cushion to the body and gearbox, first inserting all bolts and nuts.

Tightening torque Engine cushion - gearbox 85 Nm (62 lbf ft) Engine cushion - body 60 Nm (45 lbf ft) |

|

| 22. |

Fit the clip to the starter motor cable.

|

|

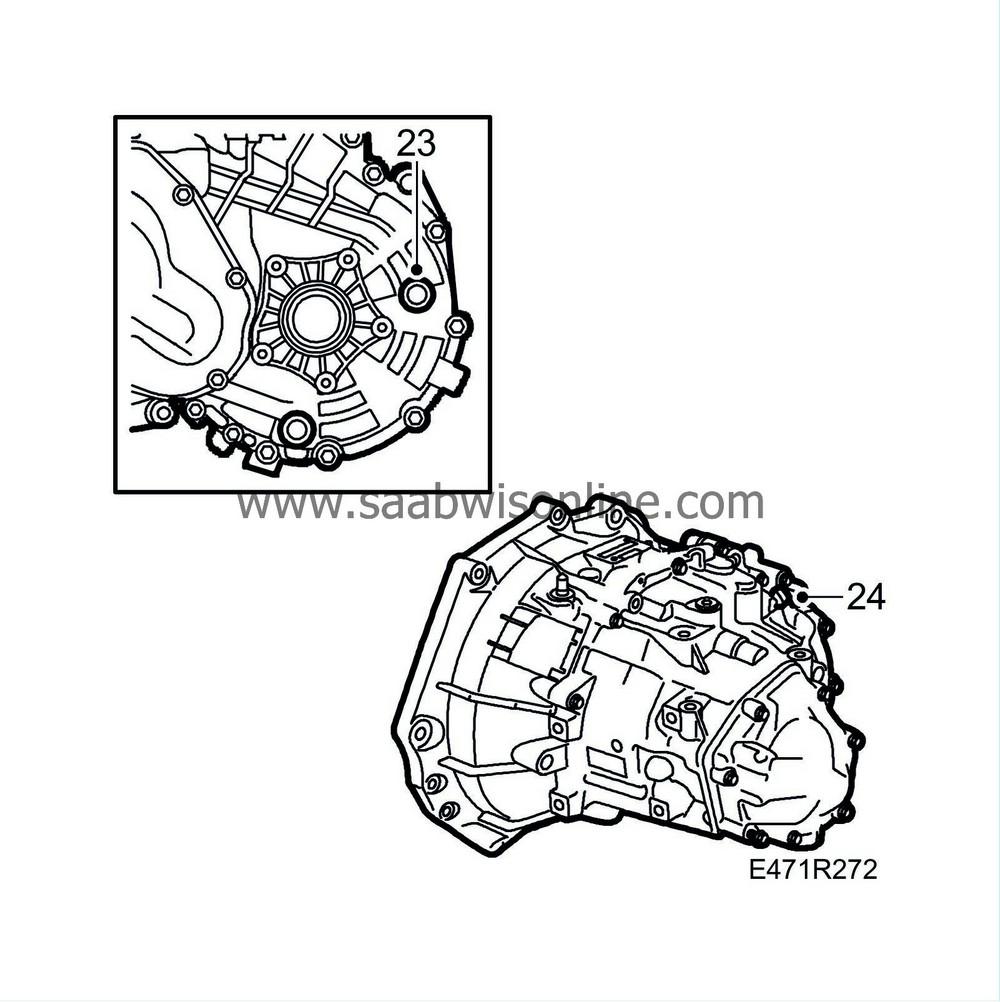

| 23. |

Add oil to the gearbox to the correct level. Use mounting tool

87 92 590 Tool, oil level plug

. Tighten level plug, drain plug and filling plug.

Tightening torque: 50 Nm (37 lbf ft)

|

|

| 24. |

Connect the line to the reversing light switch.

|

|

| 25. |

Check that the radiator core guide pins are correctly fastened to the radiator bar.

|

|

| 26. |

Suspend the oil cooler.

|

|

| 27. |

Raise the car and move the trolley lift with subframe below the car.

|

|

| 28. |

Carefully raise the subframe.

|

|||||||||||||||||||

| 29. |

Tighten the power steering pipe front fixings (2 x) before the subframe is fully raised.

|

|

| 30. |

Guide the radiator core guide pins into the subframe.

|

|

| 31. |

Guide the A/C pipe into its holder on the subframe.

|

|

| 32. |

Adjust the subframe so that the screw hole lines up with the body. On the trolley lift are 2 guide pins, front left and rear right, which guide the subframe into position.

|

|

| 33. |

Mount the screws and rear supporting plate which holds the subframe.

|

|

| 34. |

Remove the trolley lift.

|

|

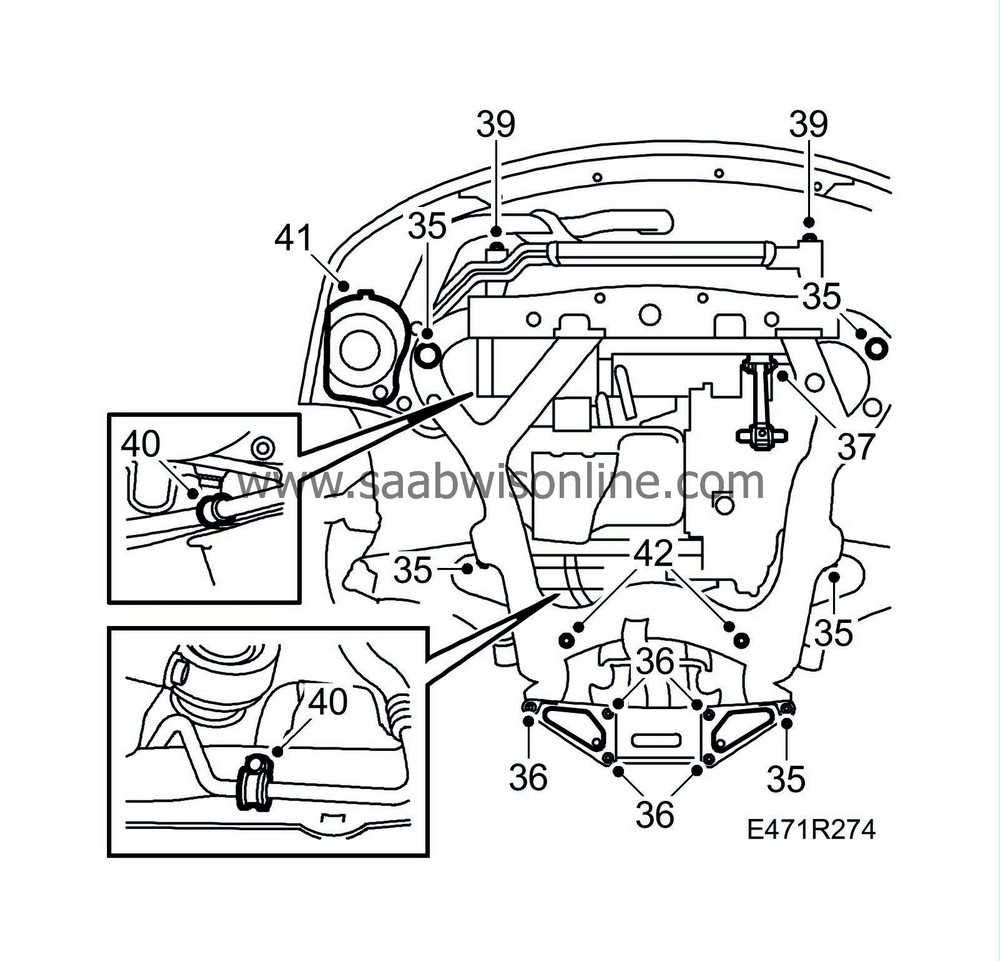

| 35. |

Tighten the bolts to the subframe.

Tightening torque 100 Nm + 45° (74 lbf ft + 45°) |

|

| 36. |

Tighten the supporting plate bolts.

Tightening torque 60 Nm (44 lbf ft) |

|

| 37. |

Fit and tighten the bolts which hold the torque rod to the subframe.

Tightening torque 90 Nm + 90° (66 lbf ft + 90°) |

|

| 38. |

Remove the cable tie supporting the radiator core.

|

|

| 39. |

Refit the oil cooler.

|

|

| 40. |

Tighten the 2 rear fixing clamps connecting the power steering pipe to the subframe, tighten the nuts which fasten the oil cooling coil.

|

|

| 41. |

Tighten the air filter housing.

|

|

| 42. |

Tighten the steering gear.

Tightening torque 90 Nm (66 lbf ft) |

|

| 43. |

Tighten the outer ball joints on the steering swivel member.

Tightening torque: 50 Nm (37 lbf ft)

|

|||||||||

| 44. |

Fit the anti-roll bar stay. Hold in place with a thin, open-ended 17 mm wrench or a hold the hex plug with a socket.

Tightening torque: 84 Nm (62 lbf ft) Tightening torque, nut with steel lock 95 Nm (66 lbf ft)

|

|||||||

| 45. |

Fit the protective plate between the engine and gearbox (not B235R).

|

|

| 46. |

Fit the rear engine cushion with bolts to the subframe, and insert the front two bolts.

|

|

| 47. |

Fit the rear engine mounting, the linkage to the gear change follows.

Tightening torque: 70 Nm (50 lbf ft) |

|

| 48. |

Fit and tighten the stay between the engine mount and engine.

Tightening torque: 22 Nm (16 lbf ft) |

|

| 49. |

Fit the front exhaust pipe, by:

|

|

| • |

Tightening the flange to the turbo.

Tightening torque: 25 Nm (18 lbf ft) |

| • |

Fit and tighten the stay to the engine.

Tightening torque: 22 Nm (16 lbf ft) |

| • |

Fit the circlip for the rubber mounting.

|

| • |

See also

Front exhaust system with catalytic converter, 4-cyl. B205E

or

Front exhaust system with catalytic converter, B235E/R

.

|

| 50. |

Fit the headlamp position sensor (option). Fit the shields and brake circuit splash guard.

|

|

| 51. |

Lower the car and remove the lifting beam.

|

|

| 53. |

Tighten the nut to the rear engine cushion.

Tightening torque: 45 Nm (33 lbf ft) |

|

| 54. |

Lift the car.

|

|

| 55. |

Tighten the bolt to the front torque rod at the gearbox, centre the rubber cushion in the stay and tighten.

Tightening torque: 47 Nm (34 lbf ft) |

|

| 56. |

Lower the car to the floor.

|

|

| 57. |

Remove the brake clamp from the clutch pedal. Connect a hose to the breather nipple, loosen this and allow some brake fluid to escape. Tighten the nipple and check the clutch; if it does not work, bleed as described in

Bleeding the brake system

.

Check the system for leaks. |

|

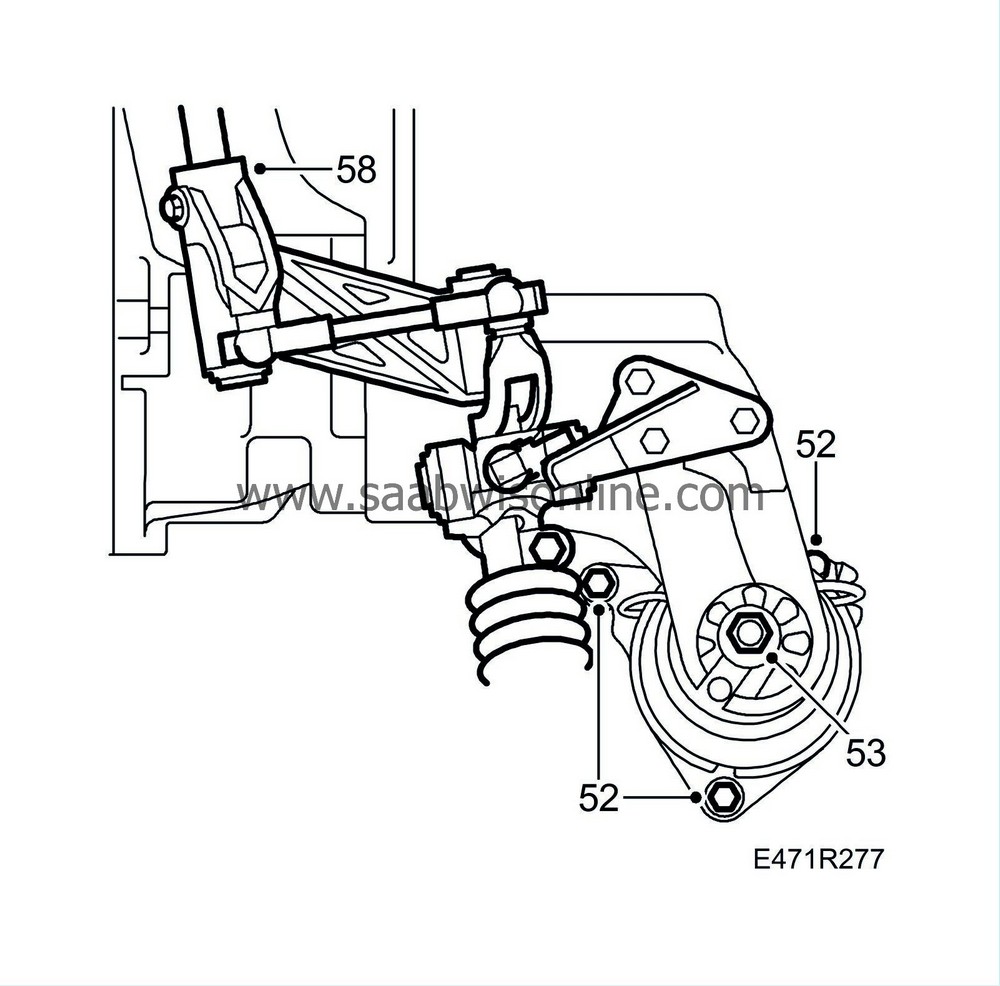

| 58. |

Fit the shim and gearbox linkage to the gearbox and tighten. Use

74 96 268 Thread locking adhesive

on the bolt.

Tightening torque: 20 Nm (15 lbf ft) |

|

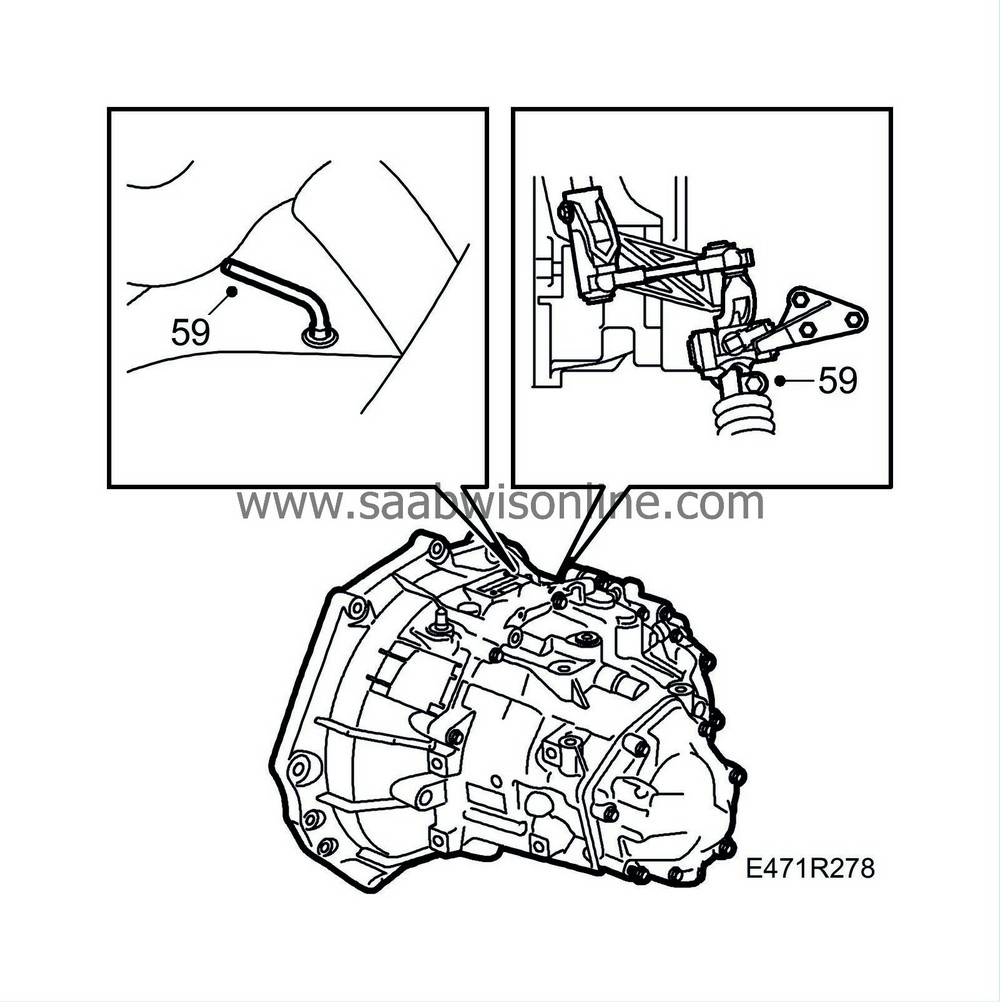

| 59. |

Remove the lock pin

87 92 335 Lock pin

from the selector rod housing, and connect the gear linkage to the selector rod.

|

|

| 60. |

Select 4th gear and insert

87 92 632 Lock pin

. Tighten the clamp on the gear linkage.

Tightening torque: 22 Nm (16 lbf ft) |

|

| 61. |

Remove the lock pins, check the gear positions and that the ignition key can be removed. Insert the plastic plug in the gearbox. Fit the gaiter.

|

|

| 62. |

Connect the oxygen sensors.

|

|

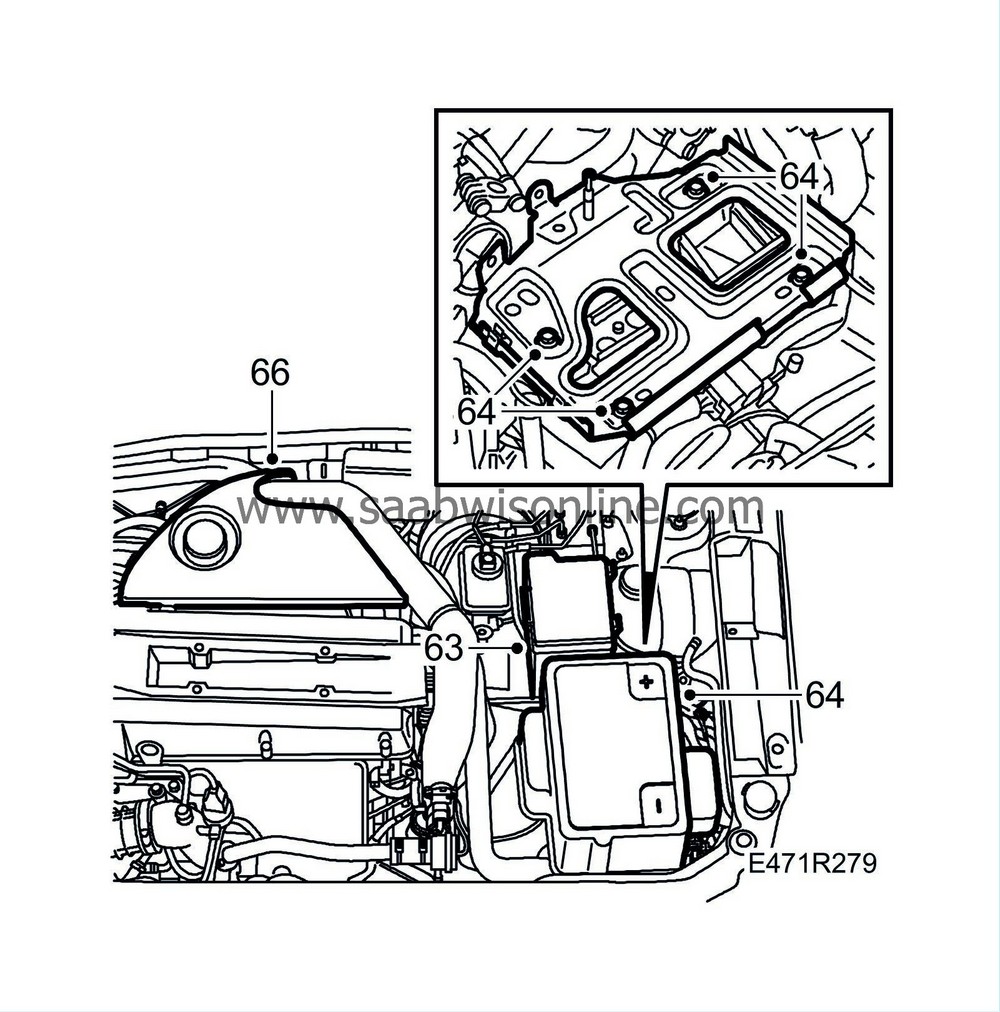

| 63. |

Fit the electrical unit.

|

|

| 64. |

Fit the battery tray and connect the battery, attach the plastic cover.

|

|

| 65. |

Fit the front wheels which must be freely suspended. See

Wheels

Tightening torque: 110 Nm (80 lbf ft) |

|

| 66. |

Fit the cap over the throttle body.

|

|

| 67. |

Test drive the car. Check the steering wheel position during driving on straight roads. Adjust if necessary.

|

|

| 68. |

Set the clock and radio code.

|

|

Warning

Warning