Compressor low-pressure pipe (4-cyl)

|

|

Compressor low-pressure pipe (4-cyl)

|

The compressor's low-pressure pipe runs from the expansion valve via a joint to the compressor.

|

Important

|

|

Be careful not to contaminate the expansion valve.

|

|

|

|

1.

|

Place the car on a lift.

|

|

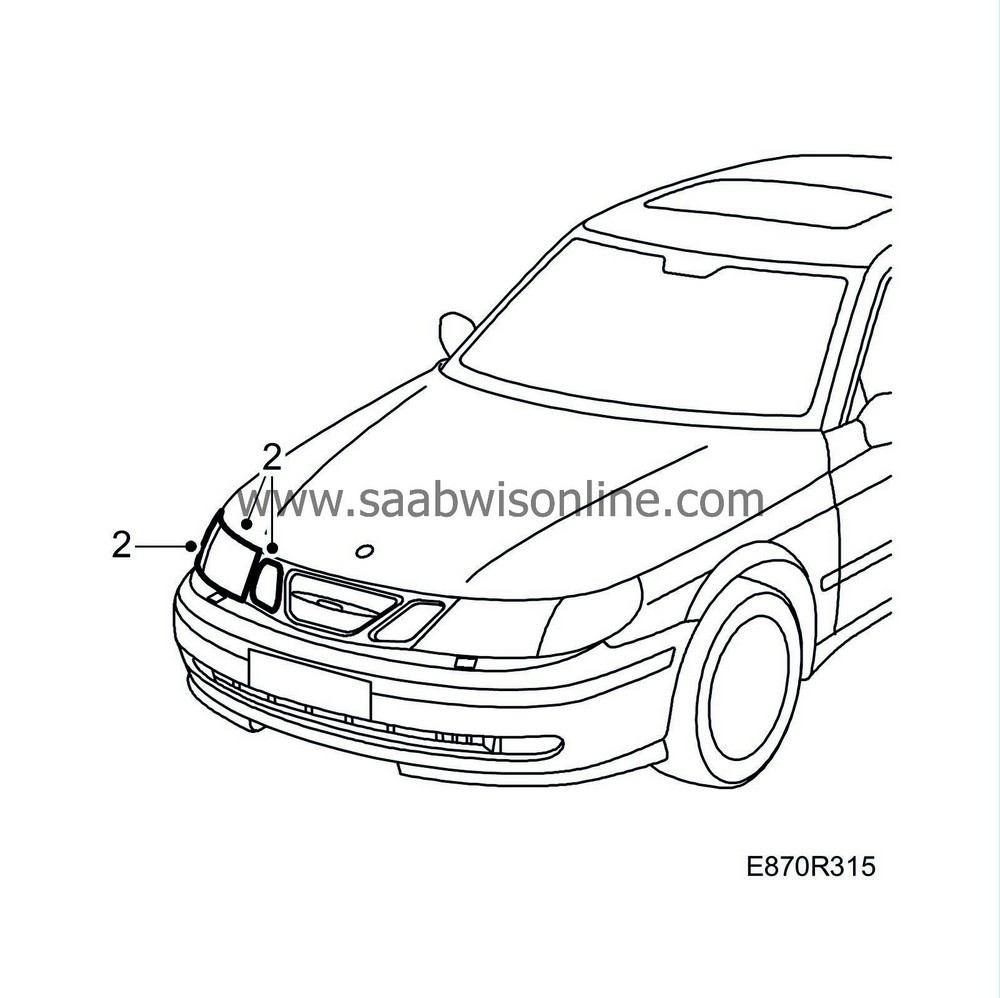

2.

|

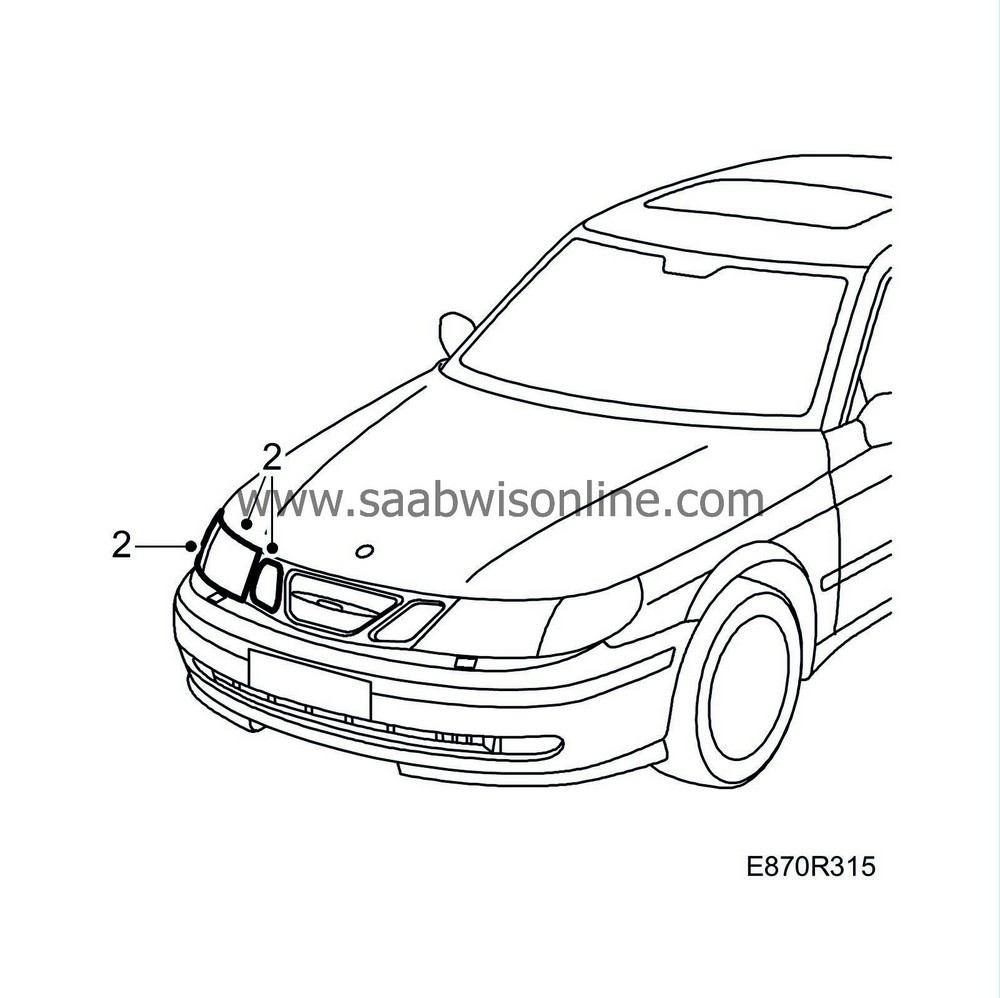

Remove the right headlamp, direction indicator and grille.

|

|

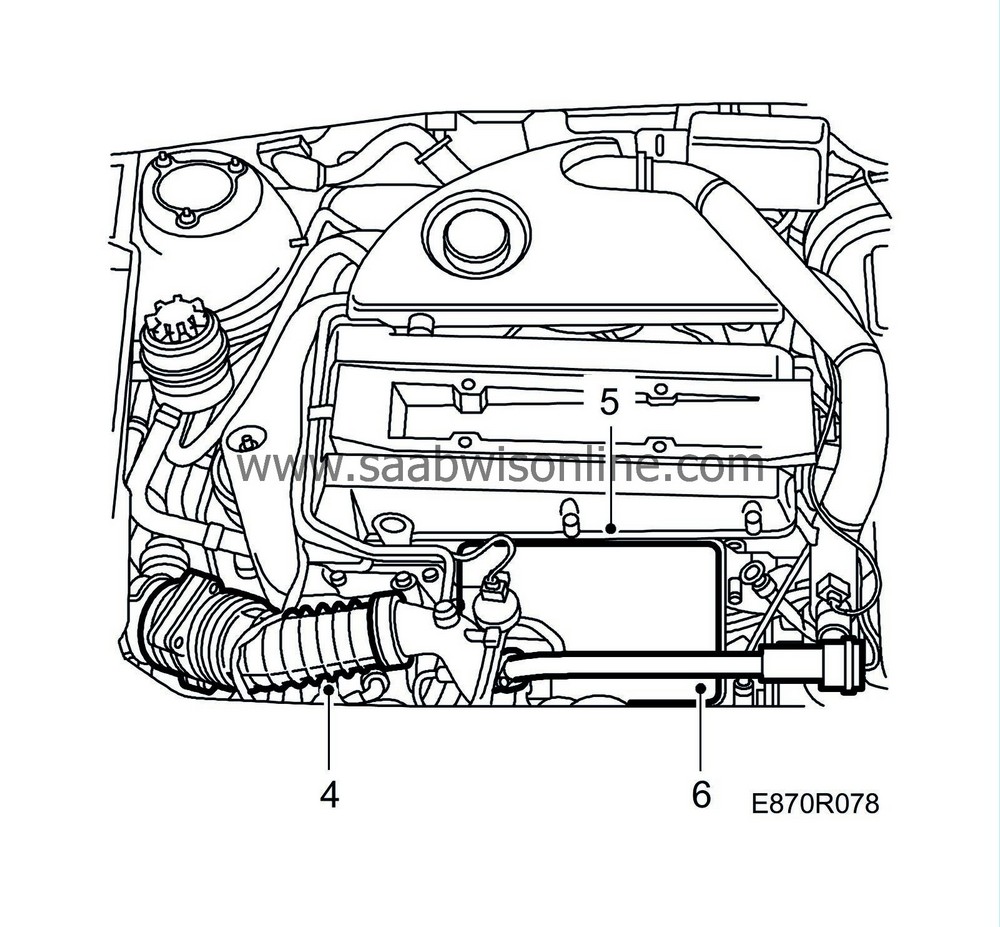

4.

|

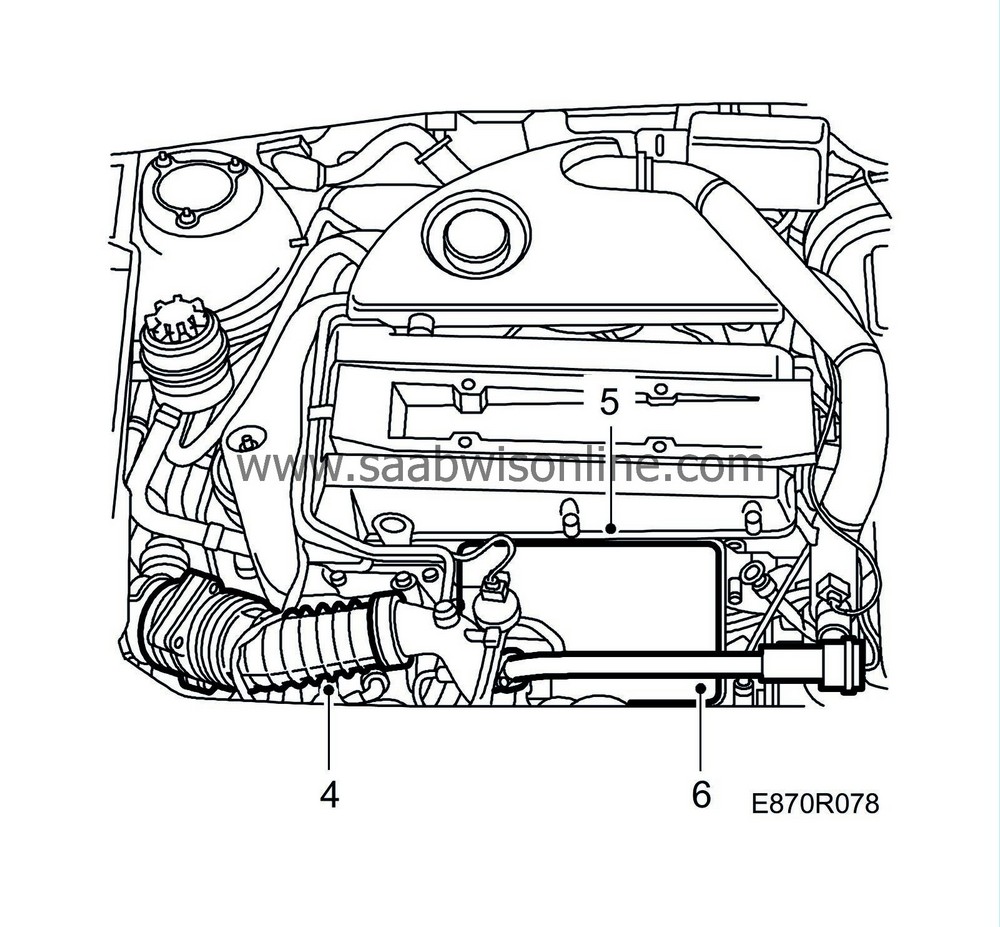

Detach the inlet hose with mass air flow sensor without unplugging the contact and place it to one side.

|

|

5.

|

Remove the heat shield from the exhaust manifold.

|

|

6.

|

Remove and move away the by-pass pipe including the valve.

|

|

7.

|

Unplug the radiator fan connectors on the fan cowling. Undo the hose clamps holding the hose to the coolant expansion tank.

Cars with automatic transmission:

Disconnect the oil cooler hose from the bottom of the fan cowling.

|

|

8.

|

Remove the fan cowling.

|

|

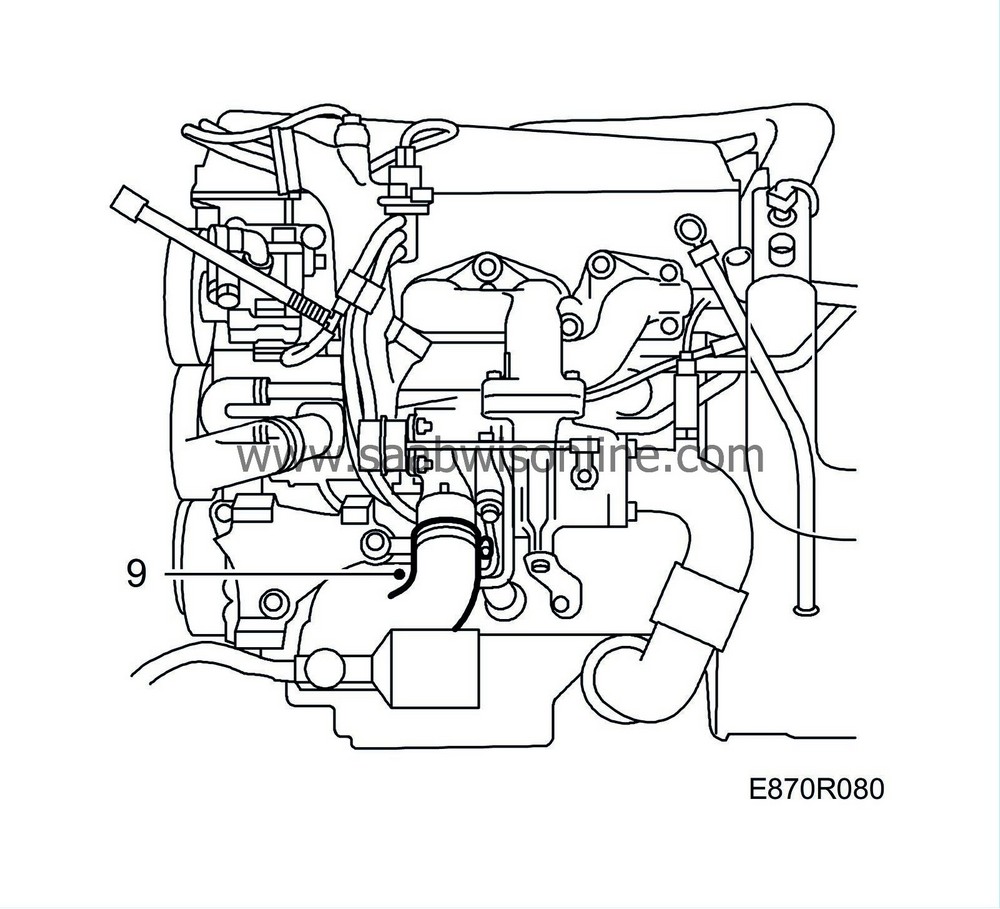

9.

|

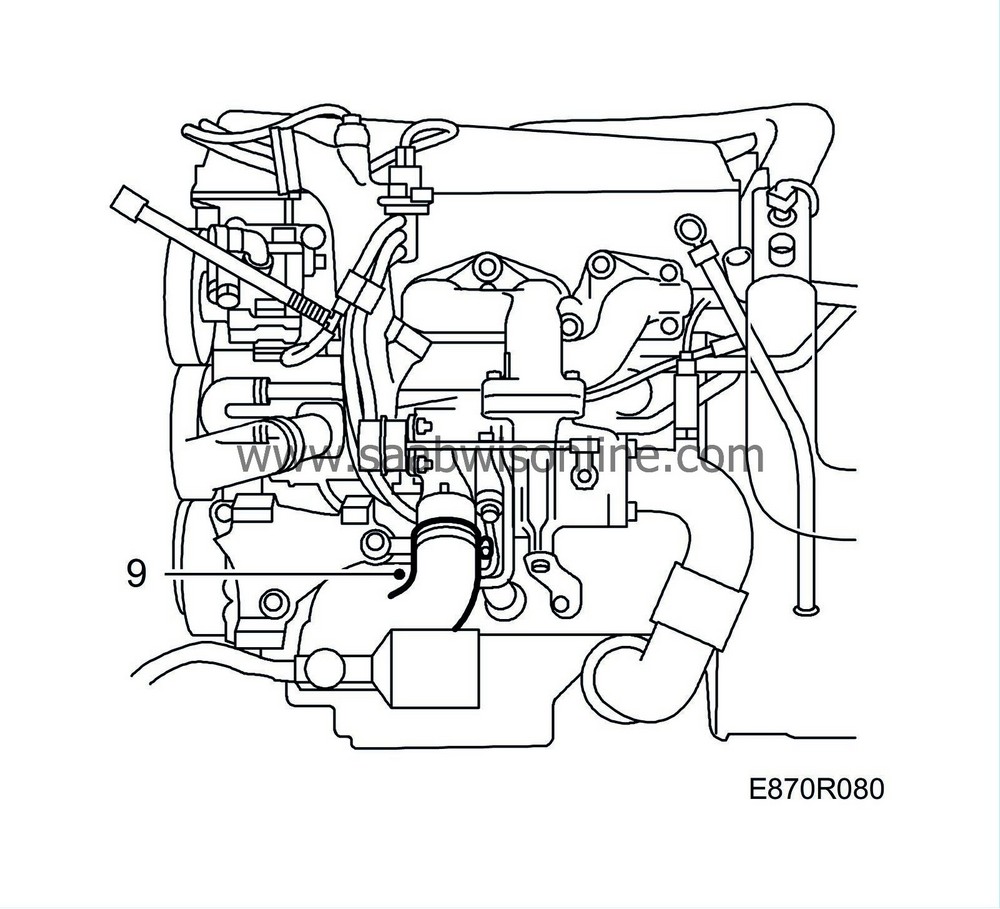

Disconnect and fold away the pressure hose from the turbo.

|

|

10.

|

Detach the high-pressure pipe from the compressor and place it to one side.

Plug the openings.

|

|

11.

|

Detach the front end of the low-pressure pipe from the compressor.

Plug the openings.

|

|

12.

|

Detach the low-pressure pipe from the joint block on the right-hand structure by the service nipple.

|

|

13.

|

Remove the low-pressure pipe.

First, pull it down from the compressor under the car and then up.

|

Note

|

|

Make a note of how the pipe is positioned before removing it.

|

|

|

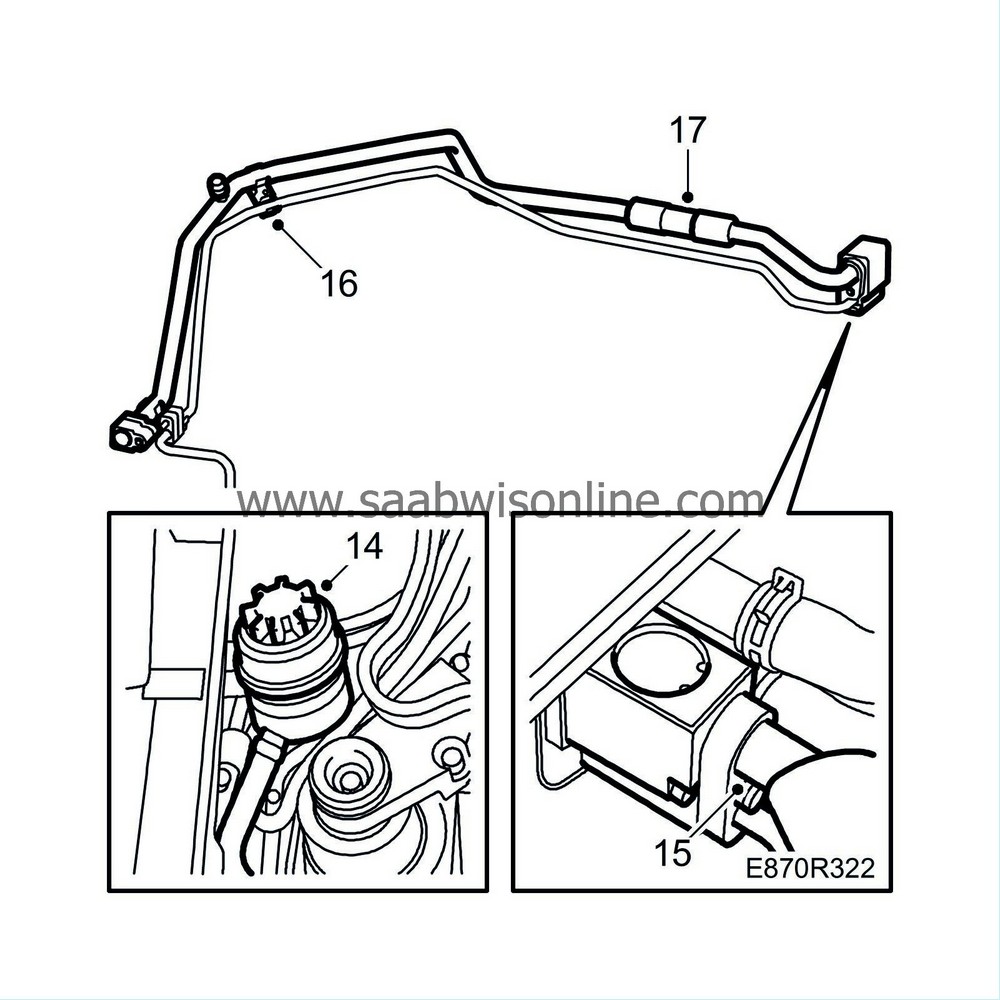

14.

|

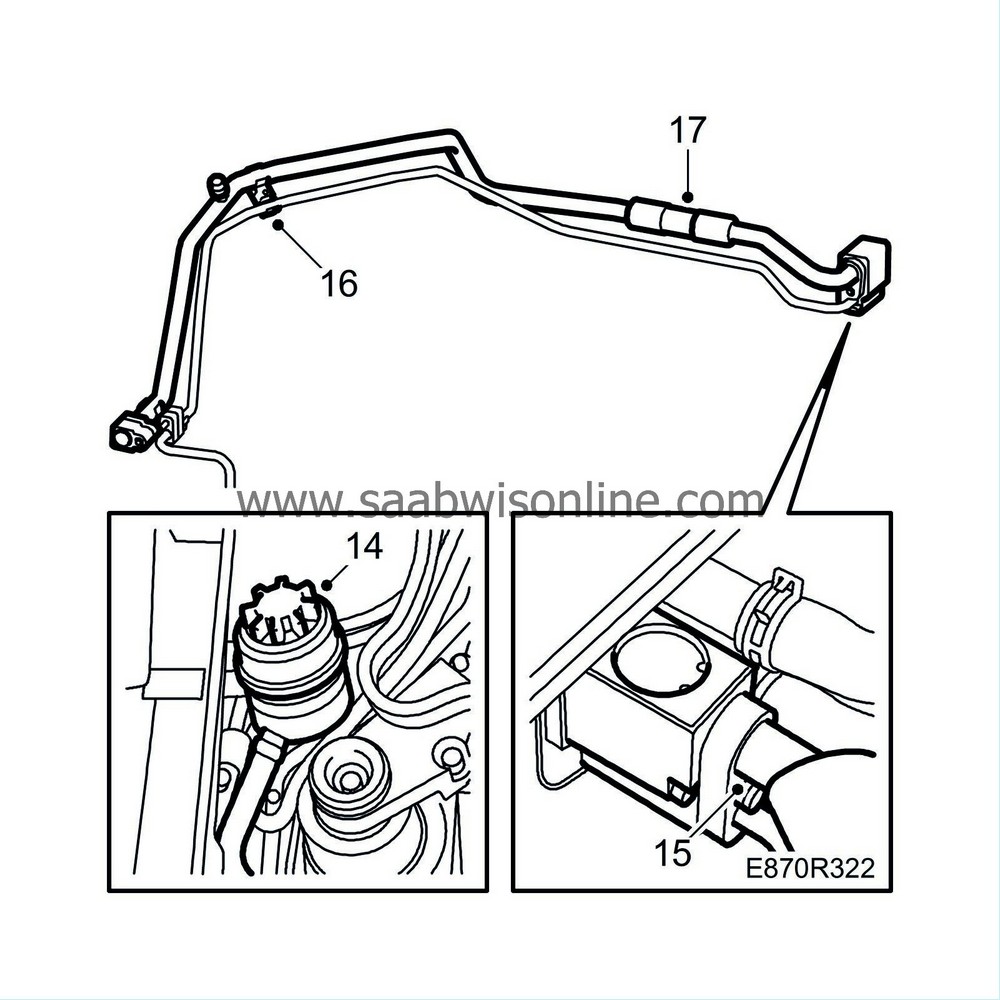

Loosen and push aside the power-steering oil container.

|

|

15.

|

Detach the rear end of the low-pressure pipe from the expansion valve.

Plug the openings.

|

|

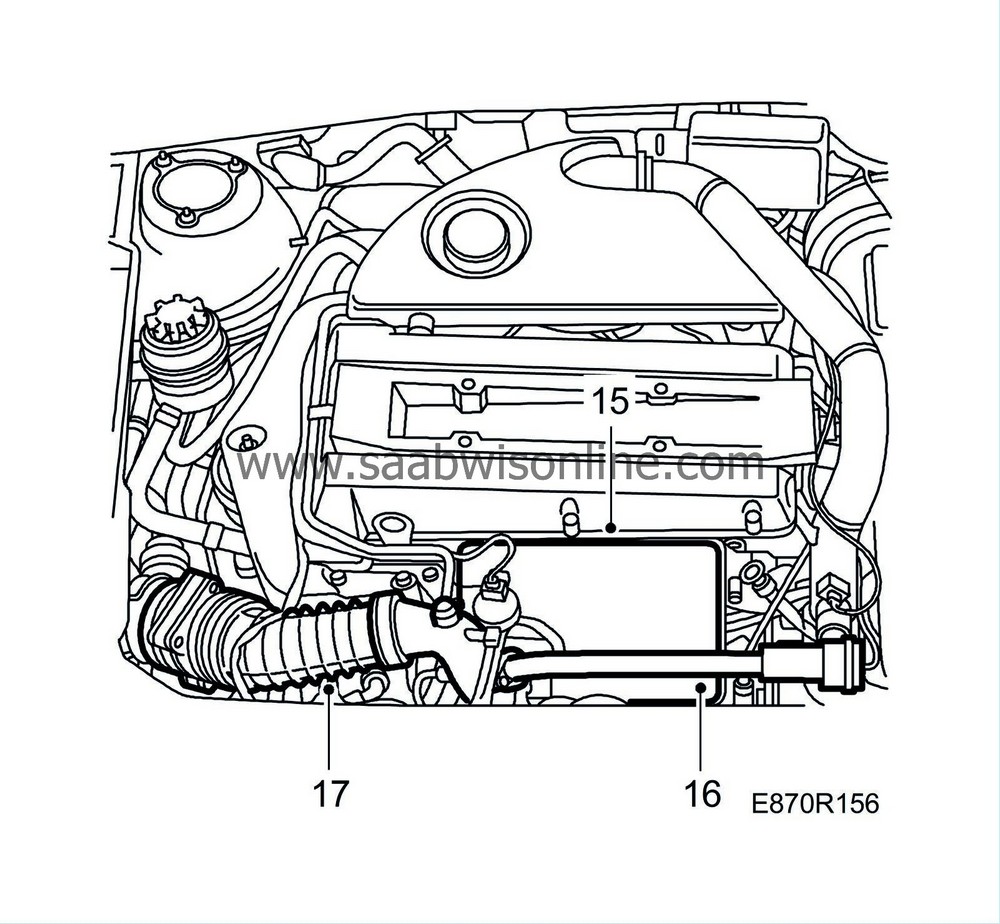

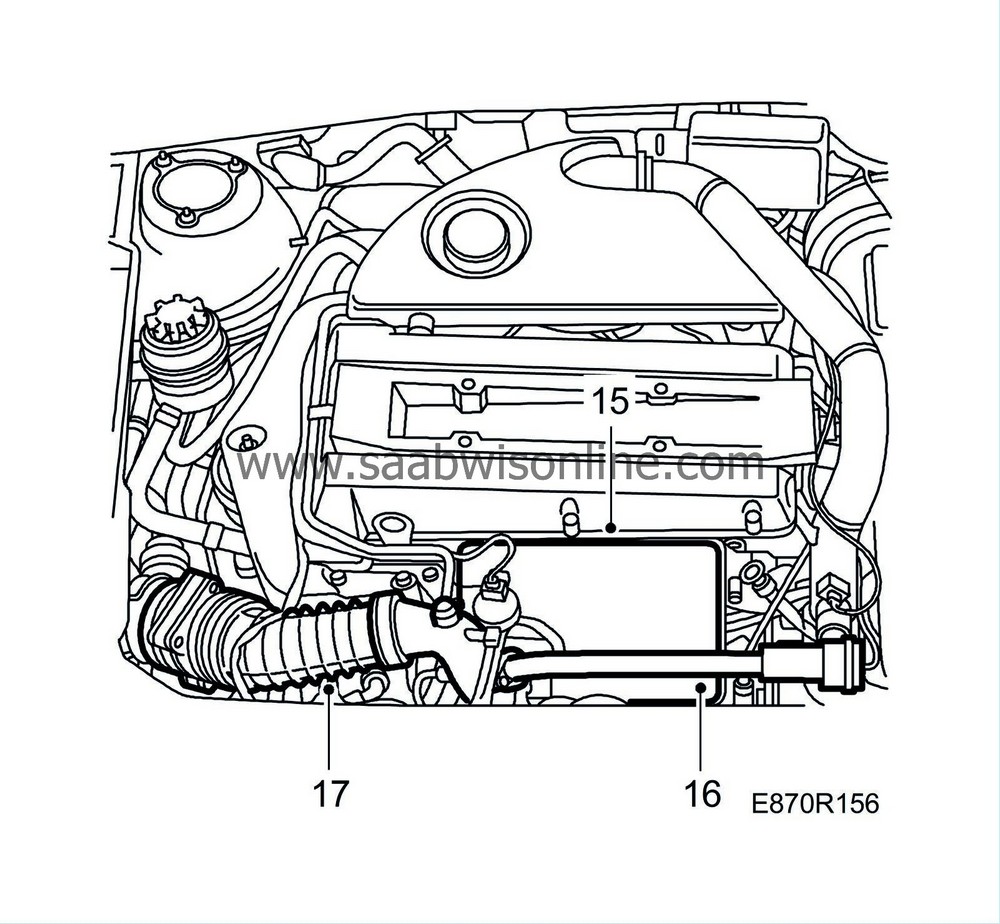

16.

|

Loosen the pipe from the holders on the structure.

|

|

17.

|

Carefully lift out the low-pressure pipe.

|

|

2.

|

Remove the plugs and lubricate the O-rings on the low-pressure pipe.

|

|

3.

|

Connect the low-pressure pipe to the expansion valve.

Tightening torque: 7 Nm (5 lbf ft)

|

|

4.

|

Fit the power-steering oil container.

|

|

5.

|

Fasten the pipe with the holders on the structure.

|

|

6.

|

Position the front end of the low-pressure pipe.

|

Note

|

|

Begin by inserting the pipe from the structure out in the right wing in front of the air filter, into the engine bay and up to the compressor above and behind the existing pipes to the inlet for power steering.

|

|

|

7.

|

Remove the plugs. Replace and lubricate the O-rings on the compressor pipes.

|

|

8.

|

Mount the O-ring on the connection towards the joint block, lubricate with synthetic vaseline.

|

|

9.

|

Press together the joint block and tighten.

Tightening torque: 8 Nm (6 lbf ft)

|

|

10.

|

Remove the plugs. Replace and lubricate the O-rings on the low-pressure pipe.

|

Note

|

|

Check that the low-pressure pipe is positioned correctly.

|

|

|

11.

|

Press the low-pressure pipe onto the compressor and tighten.

Tightening torque: 20 Nm (14.8 lbf ft)

|

|

12.

|

Fit a new O-ring on the high-pressure pipe, lubricating with synthetic vaseline. Screw the high-pressure pipe in place.

Tightening torque: 20 Nm (14.8 lbf ft)

|

|

13.

|

Connect the pressure hose to the turbo.

|

|

14.

|

Fit the fan cowling.

Replace the hose clamp and connect the connectors to the radiator fans on the fan cowling.

Cars with automatic transmission:

Connect the oil cooler hose on the bottom of the fan cowling.

|

|

15.

|

Fit the heat shield to the manifold.

|

|

16.

|

Fit the by-pass pipe and valve.

|

|

17.

|

Fit the inlet hose and mass air flow sensor.

|

|

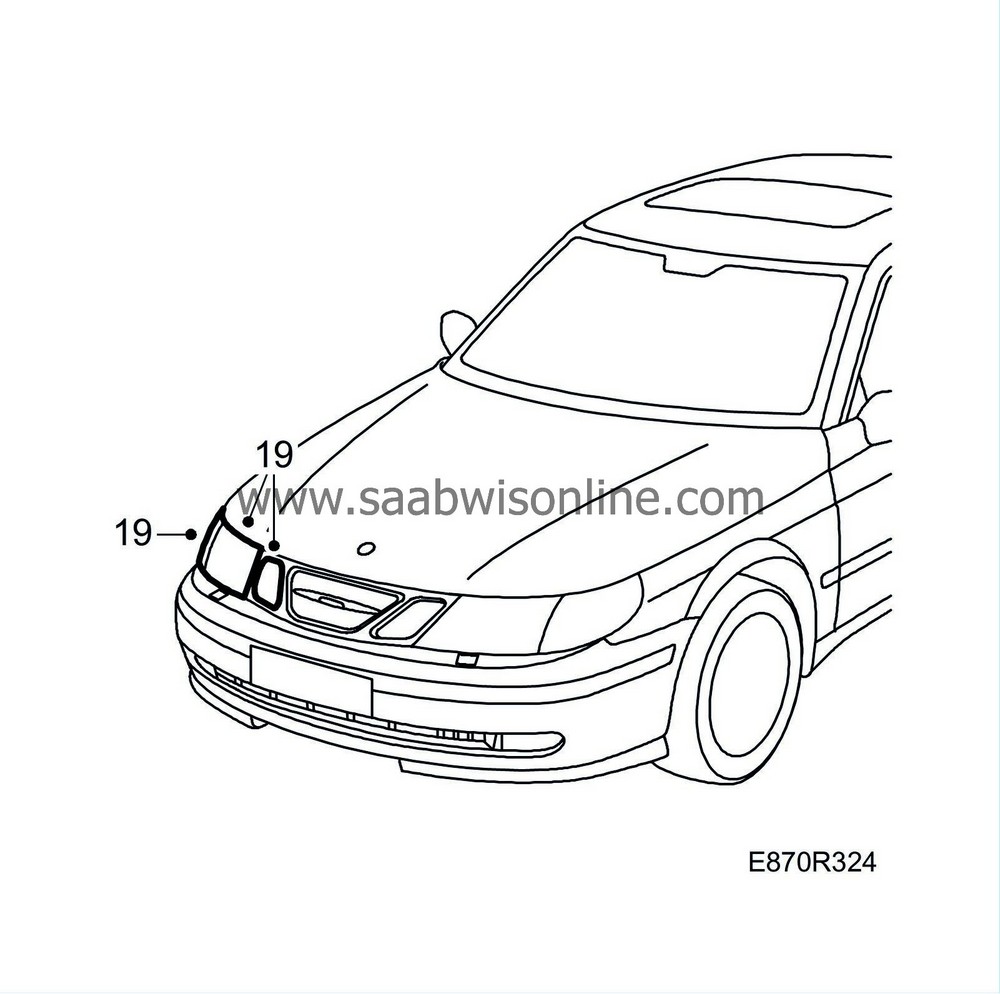

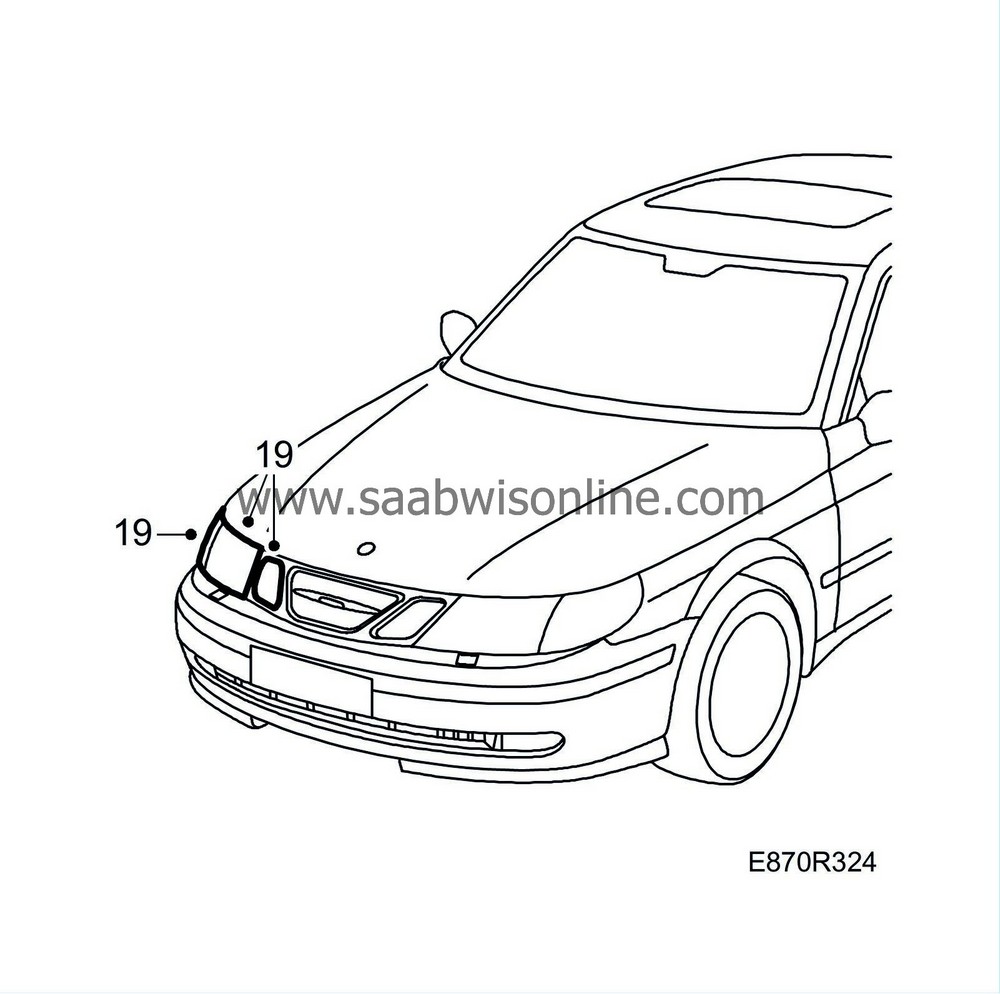

19.

|

Fit the right-hand headlamp and grille.

|