Balancer shafts

| Balancer shafts |

| To remove |

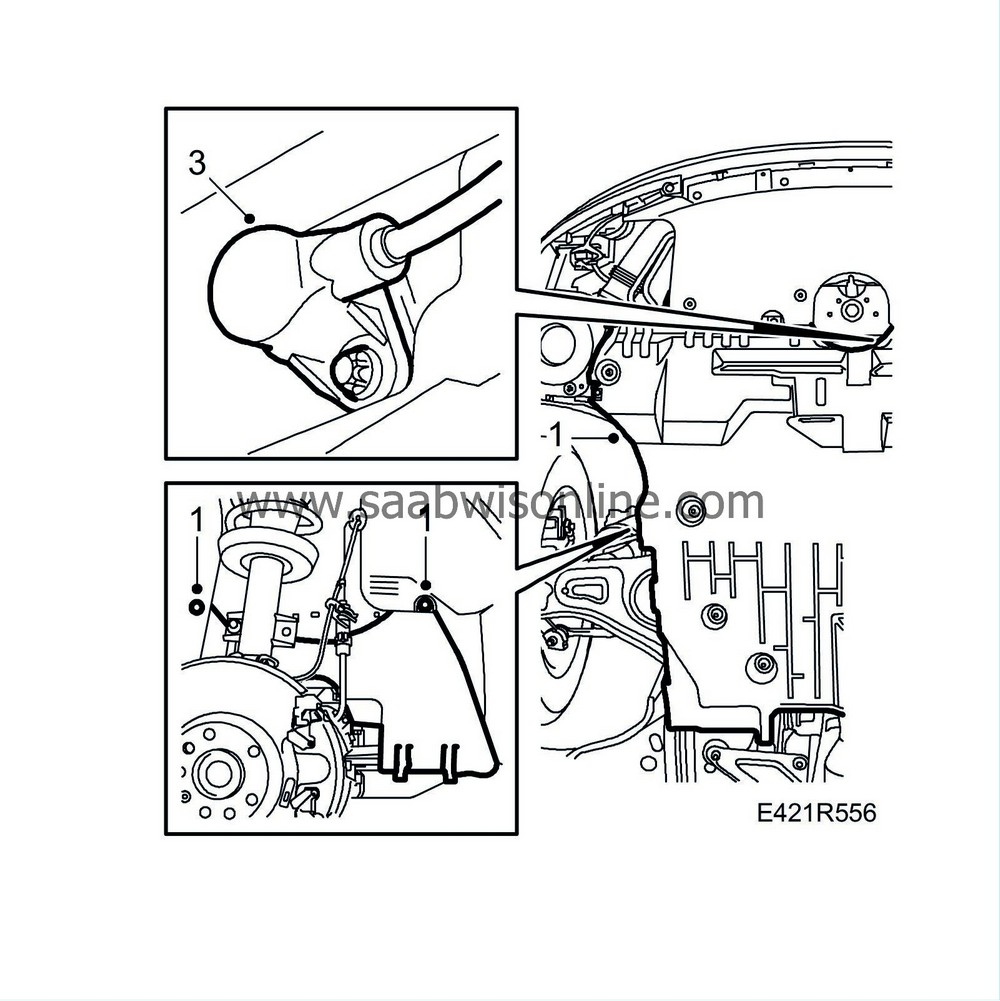

| 1. |

Raise the car and remove the lower engine cover and the drive belt cover.

|

|

| 2. |

Place a receptacle under the engine, undo the oil plug and drain the engine oil.

|

|

| 3. |

Remove the crankshaft position sensor and the O-ring.

|

|

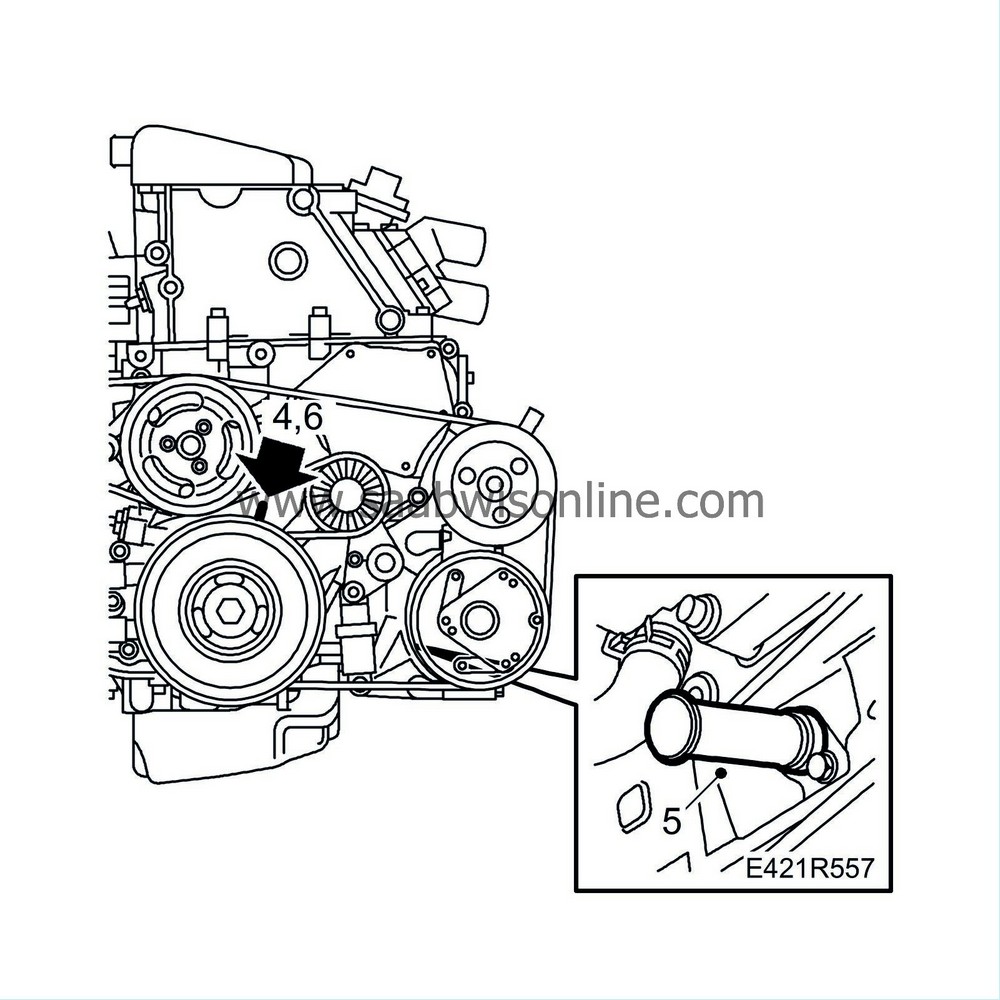

| 4. |

Turn the crankshaft with the help of the belt pulley's central screw to just before the mark for top dead centre in cylinder 1.

|

|

| 5. |

Insert

83 95 352 Setting tool, crankshaft

in the hole for the crankshaft position sensor. Push the tool somewhat inward at the same time as the crankshaft is turned to the zero point. The tool will then go into a recess in the crankshaft and lock it.

|

|

| 6. |

Make sure the markings on the crankshaft pulley and the timing cover are in line.

|

|

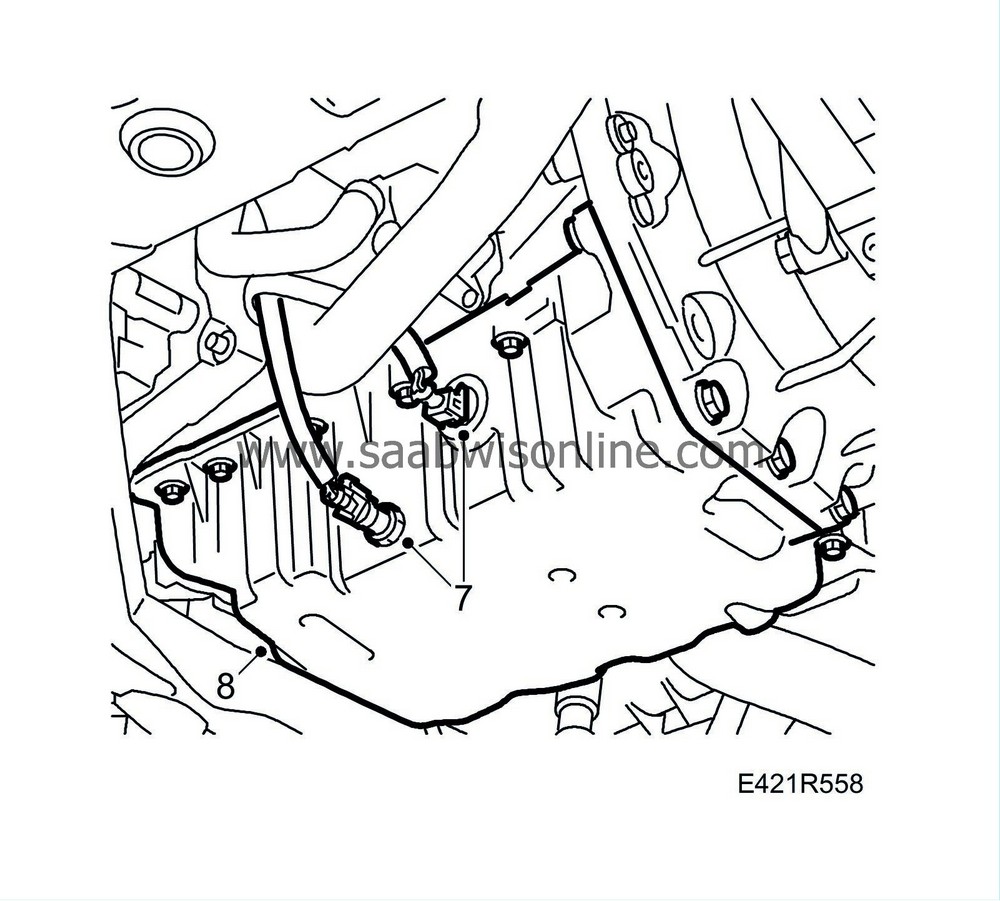

| 7. |

Unplug the oil temperature sensor and oil level sensor.

|

|

| 8. |

Remove the oil sump and take away the gasket. Wipe clean any dropping oil.

|

||||||||||

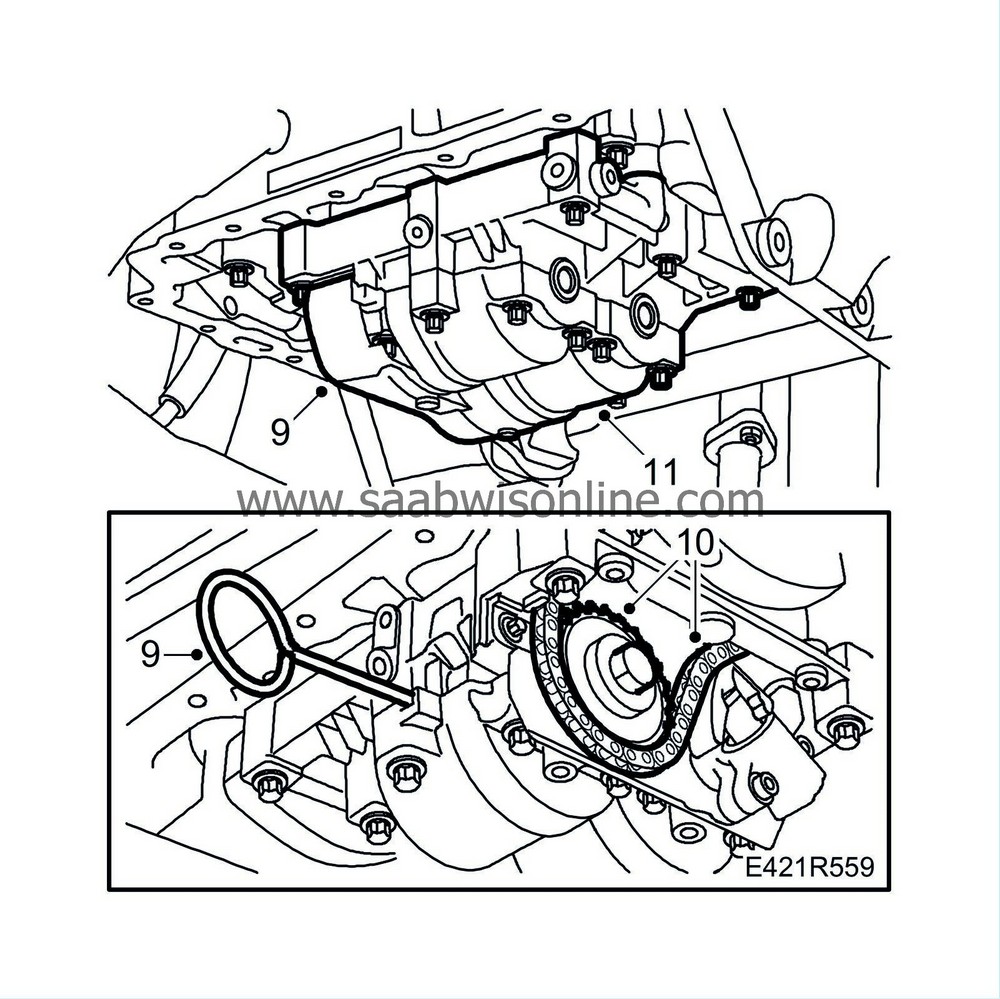

| 9. |

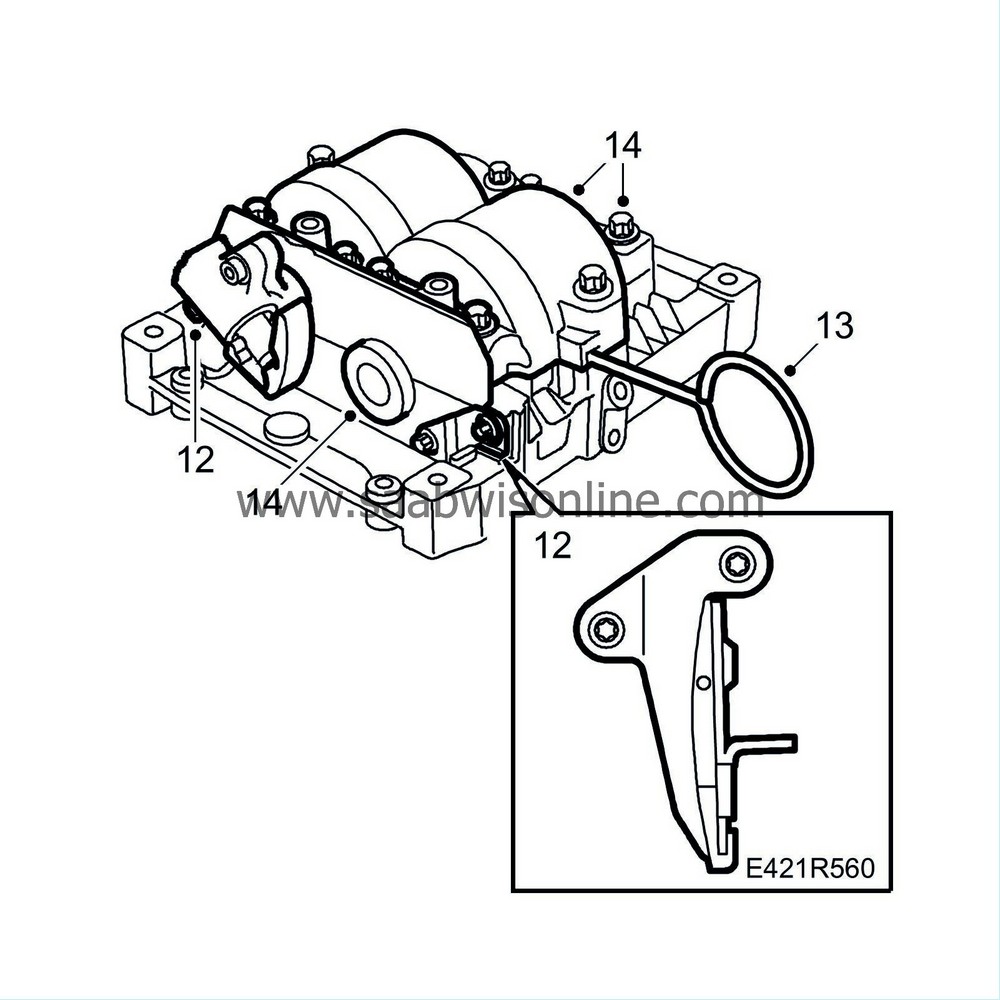

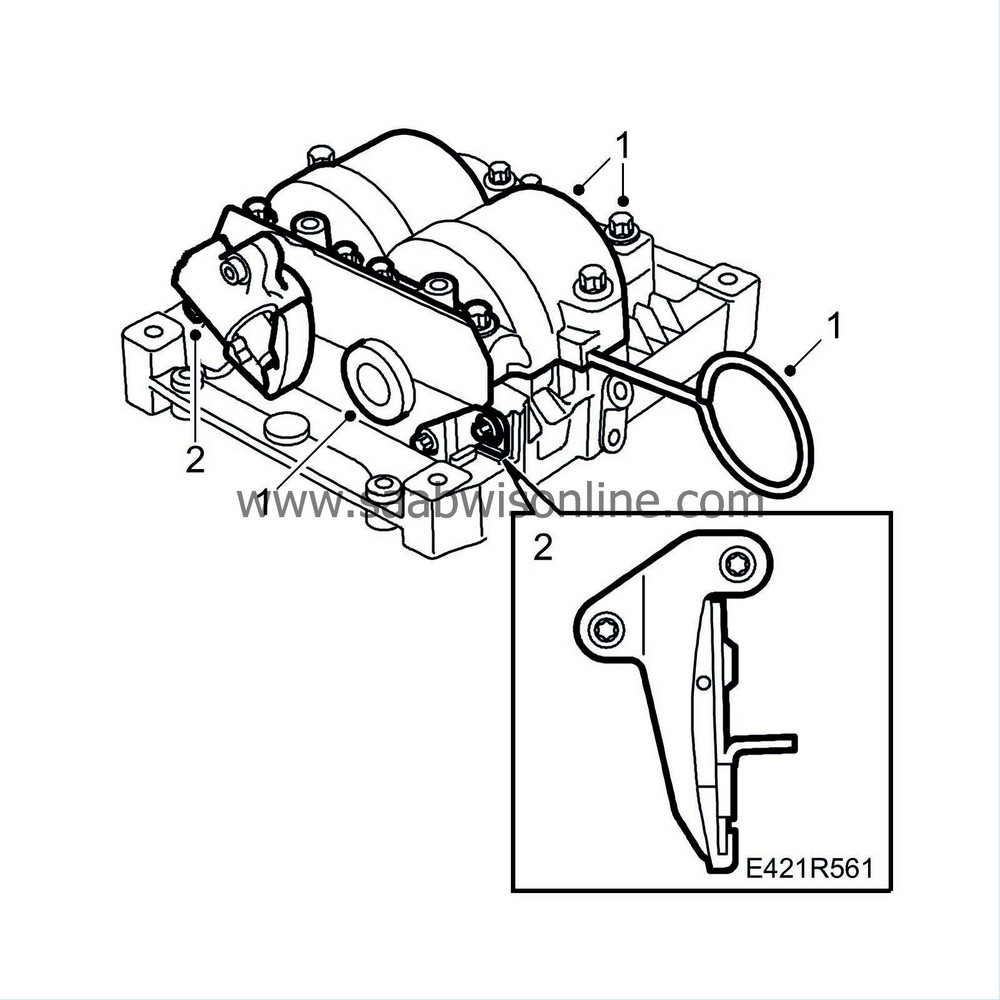

Lock the balancer shafts with

83 95 469 Setting tool, balancer shafts

and remove the cover over the balancer shaft timing chain.

|

|

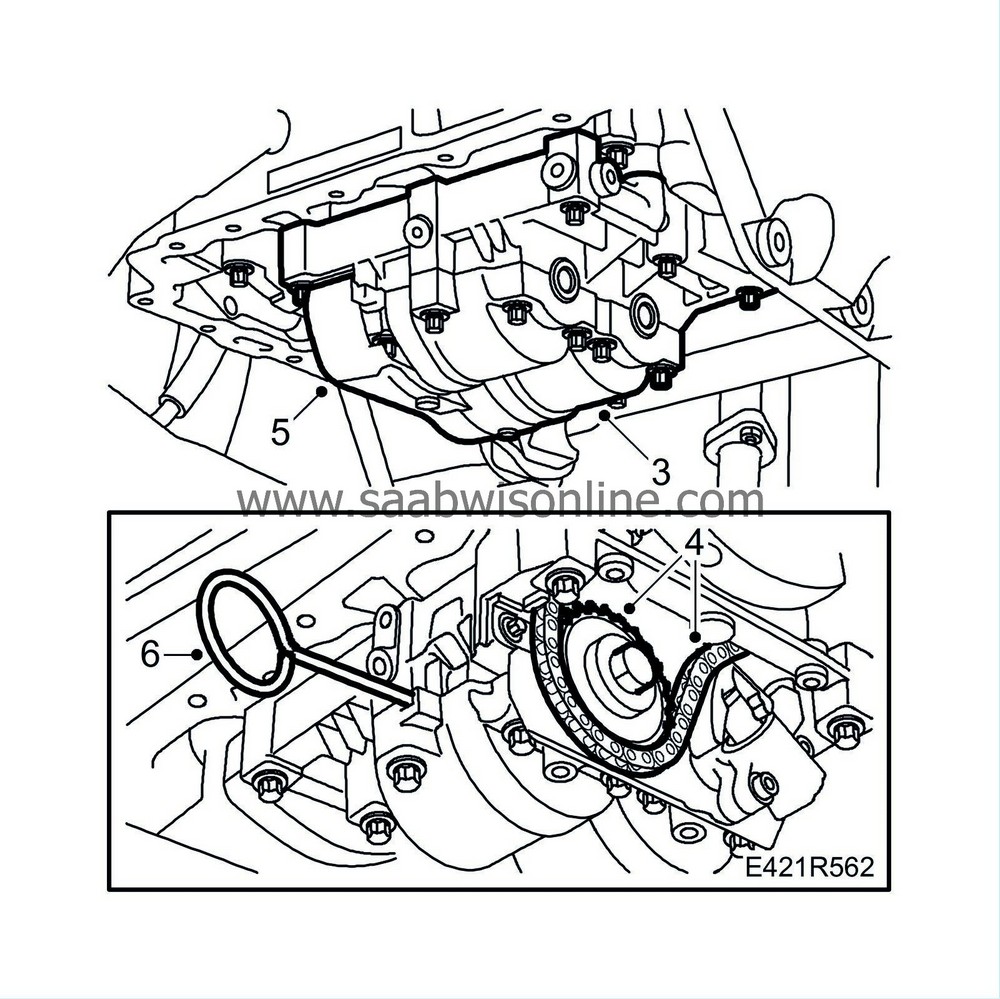

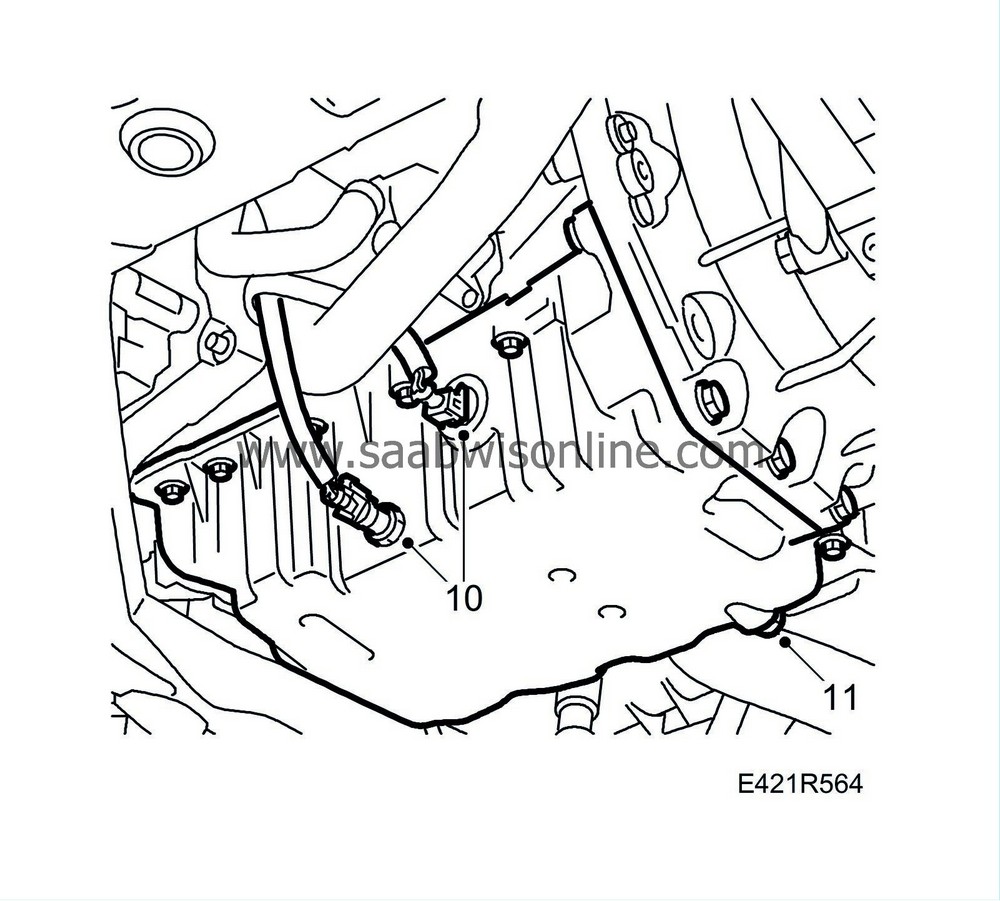

| 10. |

Move back and lock the balancer shaft chain tensioner and remove the pulley from the balancer shaft.

|

|

| 11. |

Undo the 7 outer bolts and remove the balancer shafts as one unit.

|

|

| 12. |

Lay the balancer shaft unit on a well cleaned work bench and remove the chain tensioner and chain guide.

|

|

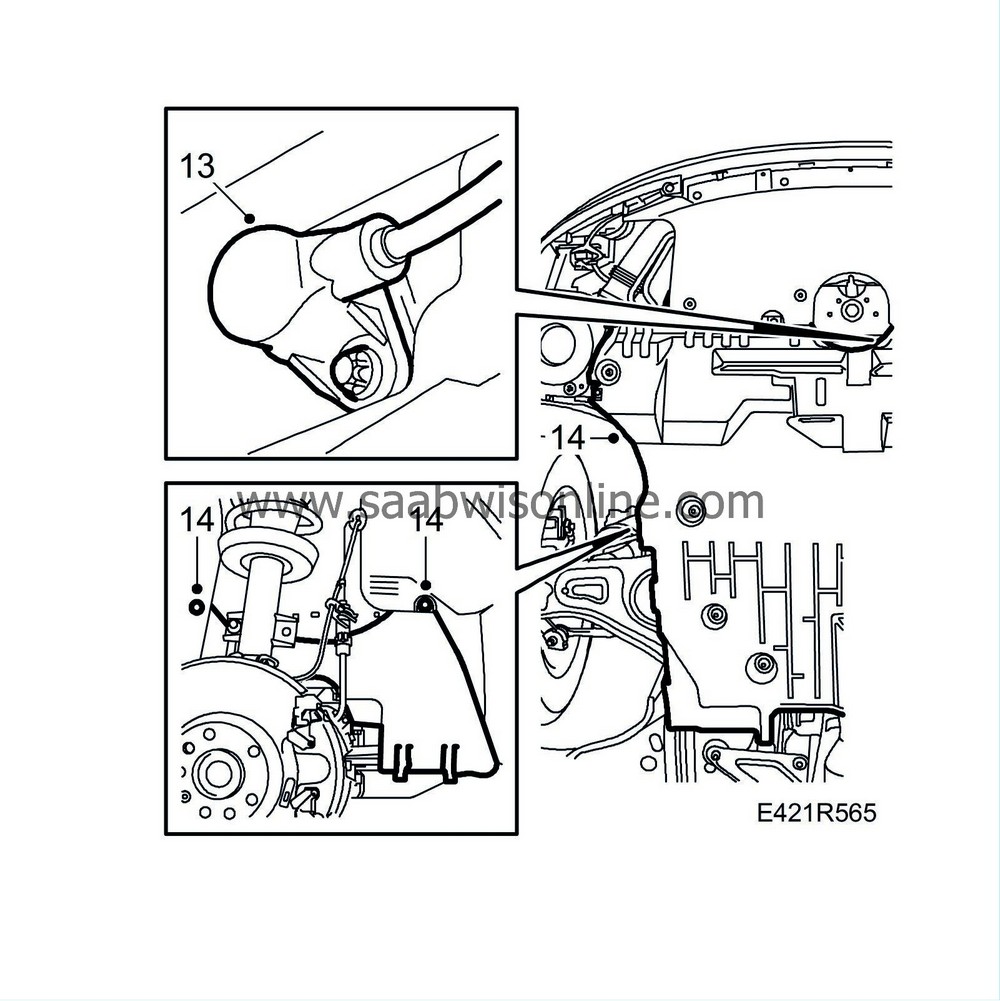

| 13. |

Remove the locking tool from the balancer shafts.

|

|

| 14. |

Undo the remaining bolts, remove the cover plate, note how the balancer shafts are fitted and lift them out.

|

|

| To fit |

| 1. |

Lay the balancer shafts as they were previously, turn them with the weights up, lock them with

83 95 469 Setting tool, balancer shafts

and fit the cover plate.

|

|

| 2. |

Fit the chain tensioner and chain guide.

|

|

| 3. |

Fit the balancer shaft unit.

Tightening torque: 110 Nm + 30° (81 lbf ft + 30°)

|

|

| 4. |

Position the pulley on the balancer shaft and tighten the bolt.

Tightening torque: 90 Nm + 30° (66 lbf ft + 30°) |

|

| 5. |

Release the chain tensioner and fit the cover plate.

|

|

| 6. |

Remove the locking tool from the balancer shafts.

|

|

| 7. |

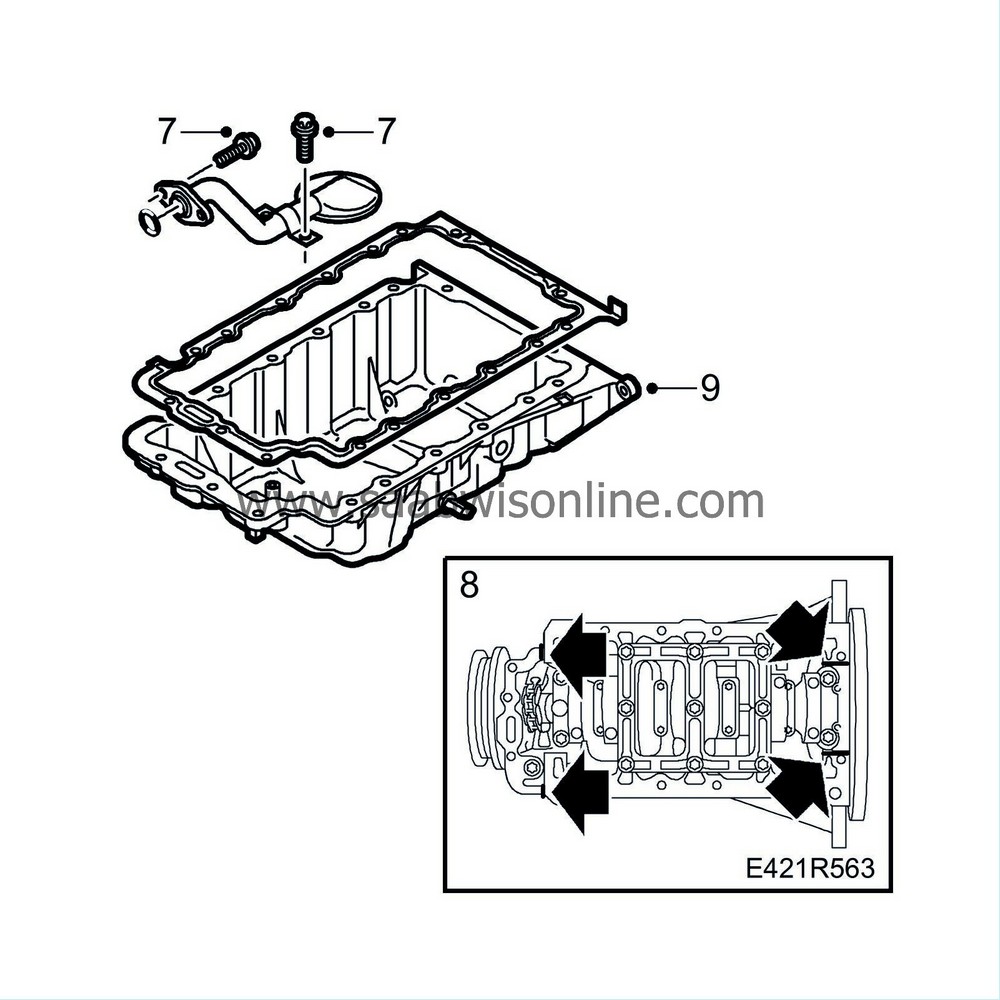

Check that there are no impurities or other foreign matter in the sump and clean the sealing surfaces with benzine. Fit the oil suction pipe if it has been changed.

|

|

| 8. |

Apply

87 81 841 Silicon flange sealant

on the partition joints, see illustration.

|

|

| 9. |

Position the oil sump on the gearbox and fit it with a new gasket. If the gearbox has been dismantled, a steel rule must be placed on the engine sealing surface on the gearbox to guide the position of the oil sump.

Tightening sequence: 1 Tighten all bolts by hand. 2 Tighten the bolts in the cylinder head and timing cover: 20 Nm (15 lbf ft). 3 Tighten the bolts in the gearbox. - 20 Nm (15 lbf ft) (M8) - 40 Nm (30 lbf ft) (M10) |

|

| 10. |

Connect the oil temperature sensor and oil level sensor.

|

|

| 11. |

Refit the oil plug with a new seal.

Tightening torque: 18 Nm (13 lbf ft). |

|

| 12. |

Remove the inspection gauge.

|

|

| 13. |

Fit the crankshaft position sensor with a new O-ring.

Tightening torque: 8 Nm (6 lbf ft)

|

|

| 14. |

Fit the drive belt cover and lower engine cover and lower the car.

|

|

| 15. |

Fill with engine oil as specified, see

Lubrication, lubricants

.

|

|