Tappets

| Tappets |

| To remove |

|

||||||||||||||||||||||

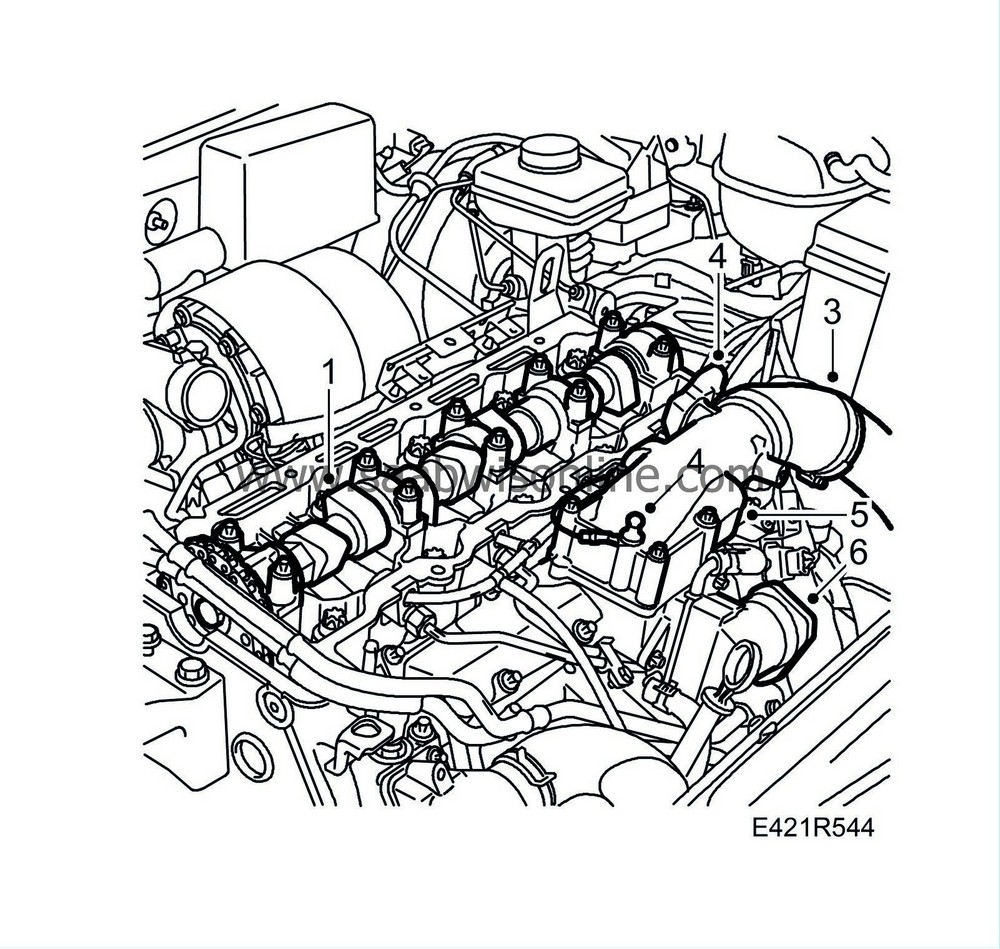

| 1. |

Remove the camshaft, see

Camshaft.

|

|

| 2. |

Remove any oil found on top of the cylinder head.

|

|

| 3. |

Remove the turbocharger delivery pipe with hose from the throttle body and move it out of the way.

|

|

| 4. |

Unplug the pressure/temperature sensor and disconnect the ground cable.

|

|

| 5. |

Remove the throttle body.

|

|

| 6. |

Unplug the EGR valve connector and remove the EGR valve from the intake manifold.

|

|

| 7. |

Place a receptacle under the car to collect any spilled fuel. Remove the fuel return hoses.

|

|

| 8. |

Make a note of the position of the fuel distribution pipes and their clips, mark the pipes.

|

|

| 9. |

Remove the fuel rail (remove the rail clips if necessary).

|

|

| 10. |

Remove the upper part of the intake manifold and plug the passageways.

|

|

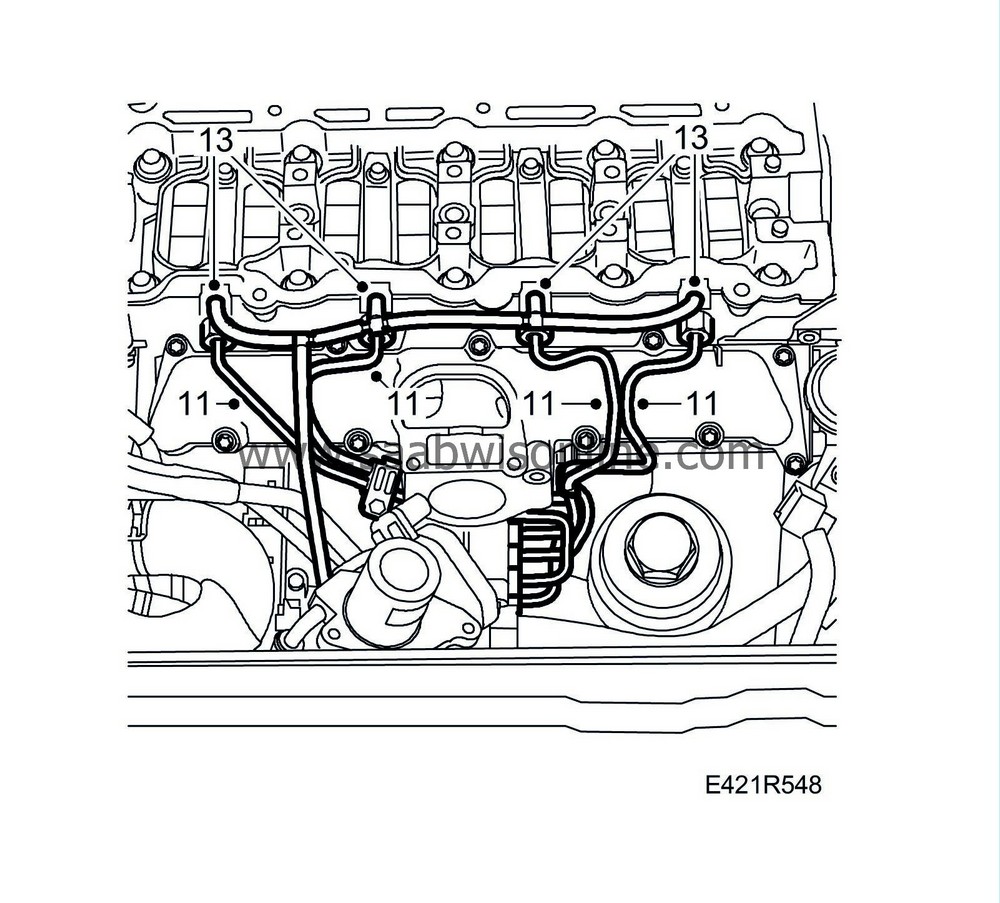

| 11. |

Remove the retaining bolts for the fuel bridges, lift and pull out the fuel bridges from the cylinder head.

|

|

| 12. |

Remove the valve bridges.

|

||||||||||

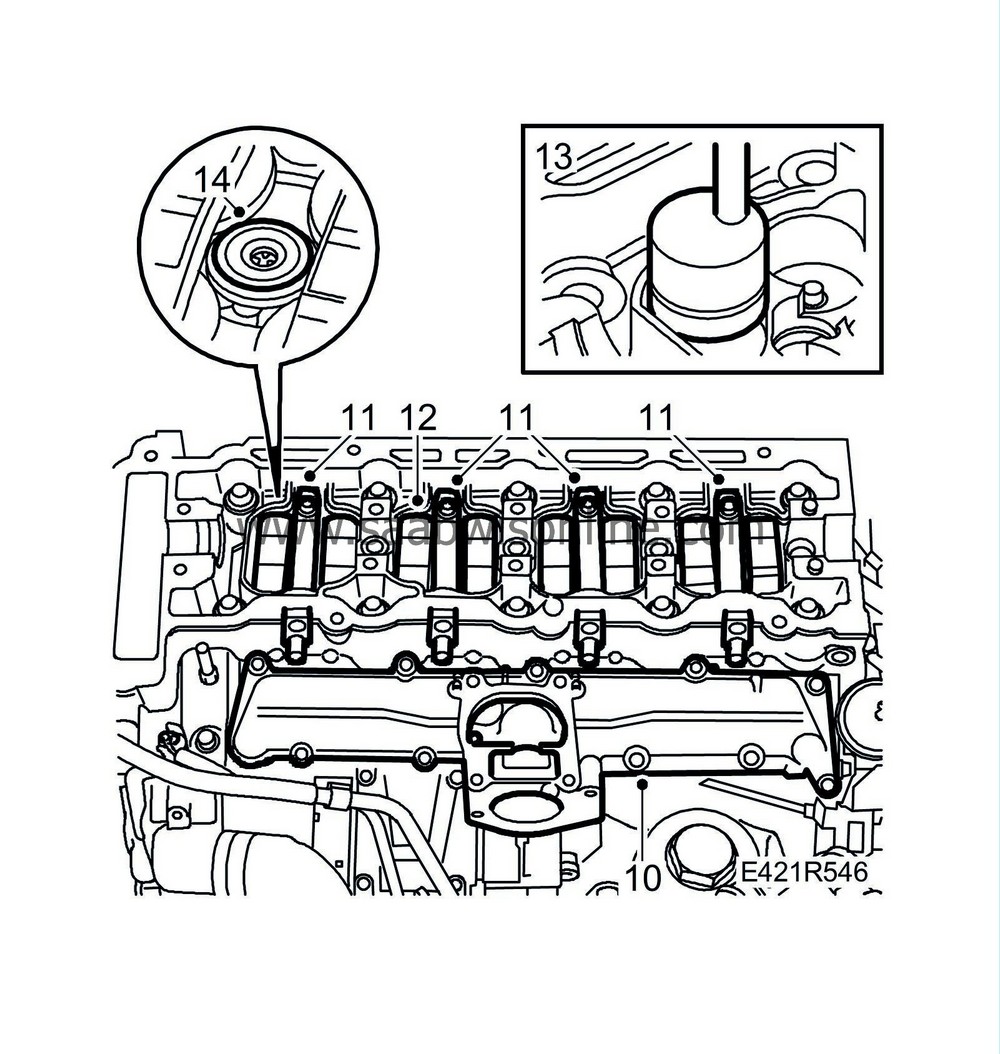

| 13. |

Lift up the tappets with

83 91 401 Magnetic tool

.

|

|

| 14. |

Remove the seals from the injector connections in the fuel bridges.

|

|

| To fit |

| 1. |

Clean all dismantled parts and inspect for wear. Change as necessary.

|

|

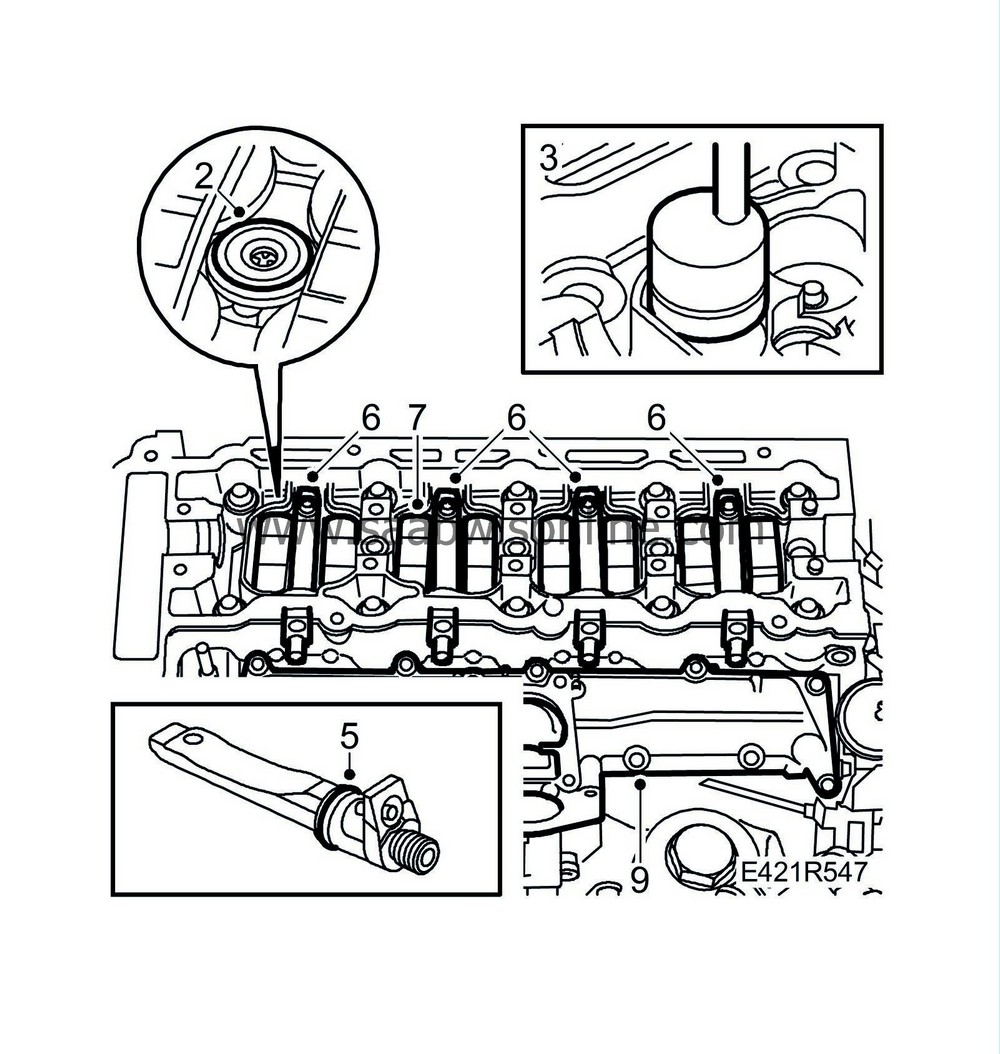

| 2. |

Fit the seals from the injector connections in the fuel bridges.

|

|

| 3. |

Lubricate the tappets with engine oil and position them in the cylinder head.

|

|

| 4. |

Blow clean the holes for the fuel bridge retaining bolts.

|

|

| 5. |

Fit the new O-rings onto the fuel bridges, lubricate the O-rings with non-acidic Vaseline and carefully push them into the cylinder head.

|

|

| 6. |

Tighten the fuel bridge bolts.

Tightening torque: 5 Nm + 360°(4 lbf ft + 360°) |

|

| 7. |

Fit the valve bridges.

|

||||||||||

| 8. |

Clean the sealing surfaces.

|

|

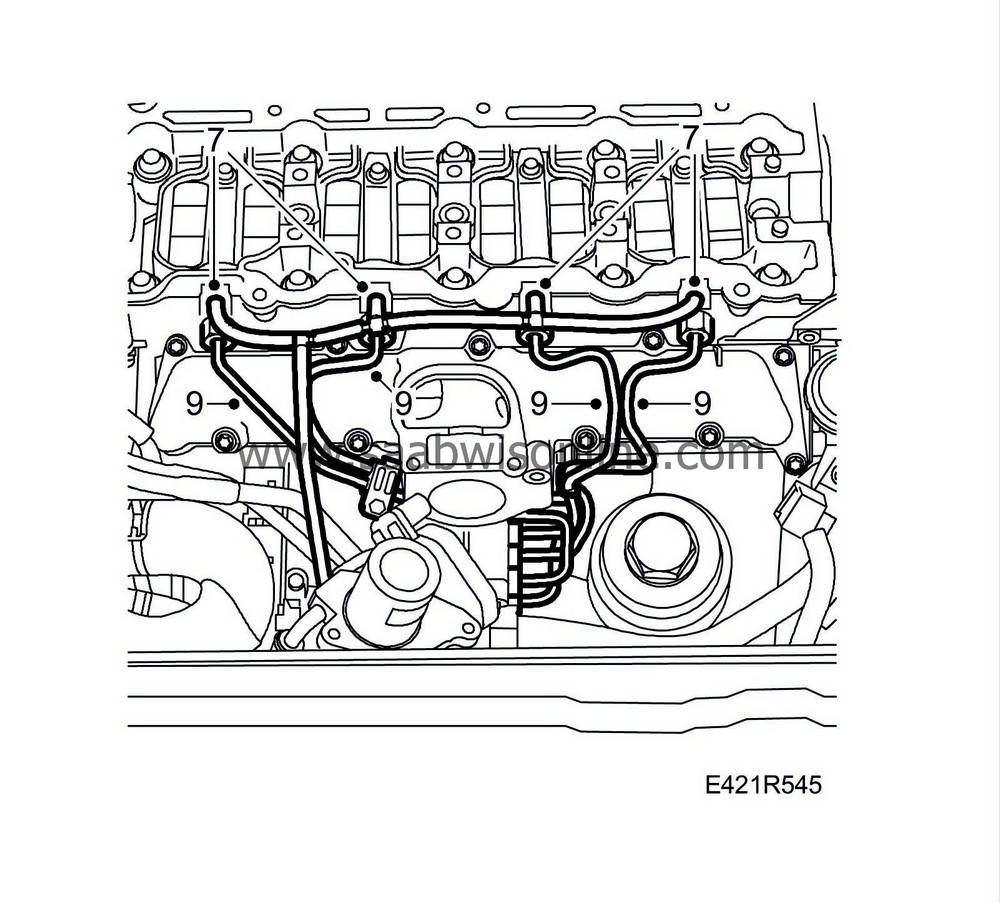

| 9. |

Place a new gasket on the lower part of the intake manifold and fit the upper part.

Tightening torque: 10 Nm (7 lbf ft). |

|

| 10. |

Inspect the tapered fuel rail connections and replace as necessary.

|

|

| 11. |

Connect the fuel rail with clips in their original positions.

Tightening torque: 25 Nm (19 lbf ft).

|

|

| 12. |

Check the condition of the fuel return hoses and joints and change as necessary.

|

|

| 13. |

Connect the fuel return hoses to the fuel bridges. Loosen the fuel return connection from the fuel pump and connect

30 14 883 Pressure/vacuum pump

. Pump up a vacuum of 750 mbar and wait for 1 minute. Check that the indicator on the tool has not moved.

If there is a leak, the fuel bridges must be inspected individually. Connect a pressure/vacuum pump to each fuel bridge return fuel line, do not use the existing return hose. If the fuel bridges are free from faults, inspect the return fuel hoses with T-pieces. The hoses must be supple and not be cracked or damaged in any other way. If there are signs of leaks, change all the fuel return hoses with T-pieces. If the fuel bridge is leaking, remove it, change the seal and fit the fuel bridge. Check for leaks again. |

|

| 14. |

Fit the EGR valve with a new O-ring.

Tightening torque: 10 Nm (7 lbf ft)

|

|

| 15. |

Plug in the EGR valve connector.

|

|

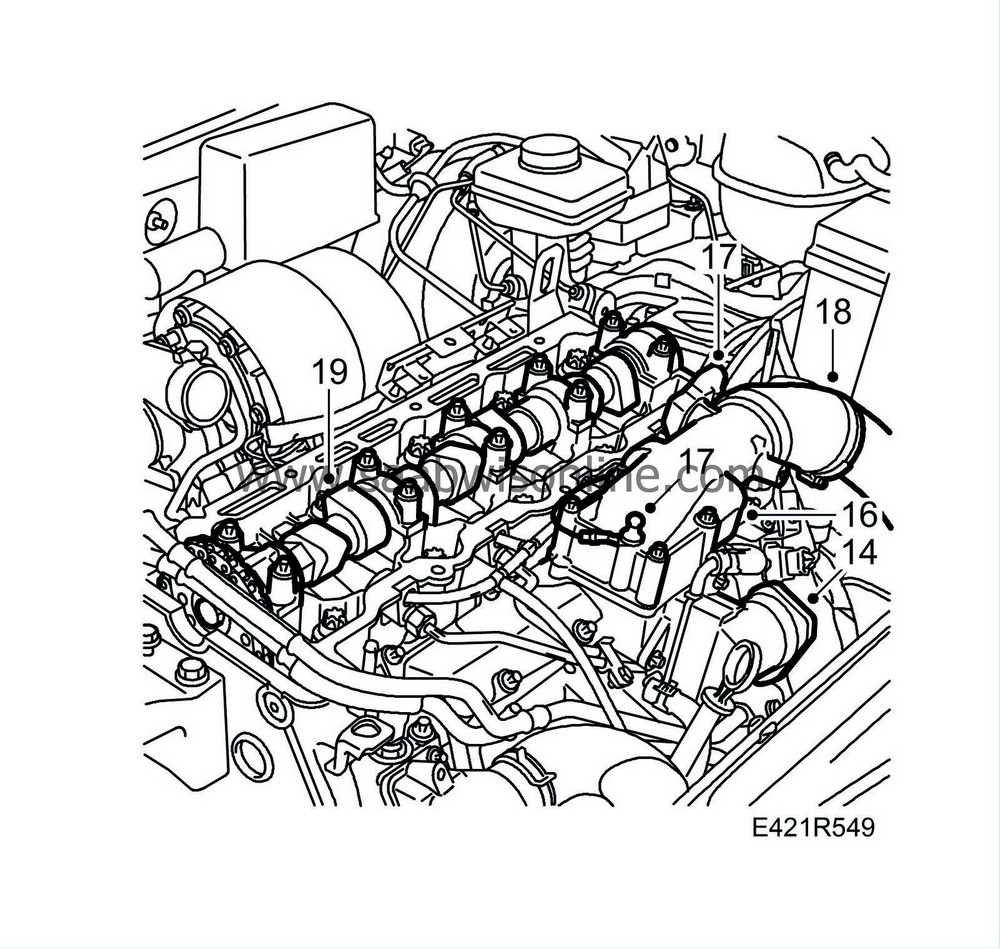

| 16. |

Fit the throttle body with a new gasket.

Tightening torque: 10 Nm (7 lbf ft) |

|

| 17. |

Fit the ground cable and the pressure/temperature sensor connector on the throttle body.

|

|

| 18. |

Connect the turbocharger delivery pipe with hose to the throttle body.

|

|

| 19. |

Fit the

Camshaft.

|

|

Warning

Warning