Brief description

| Brief description |

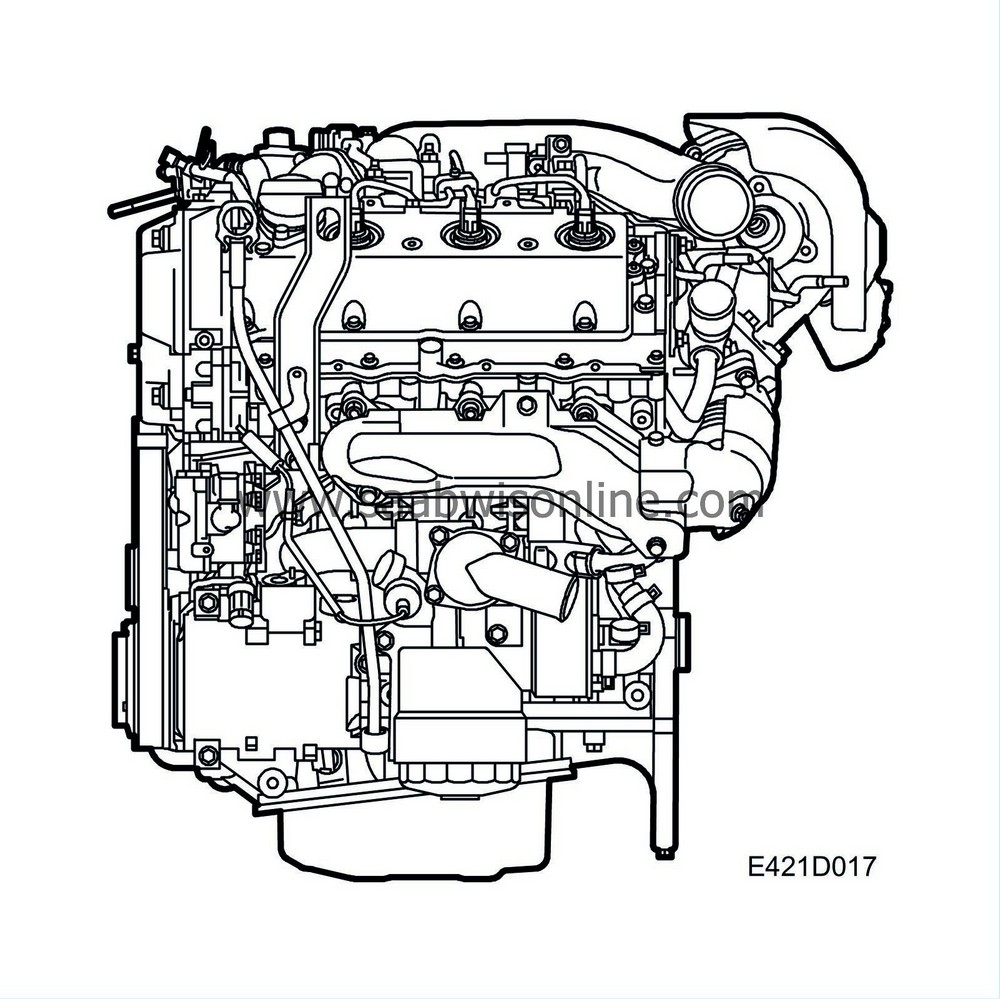

The engine has direct injection, which means that the fuel is injected directly into the combustion chamber, and a turbocharger to provide high engine torque within normal engine speed ranges.

The engine is cross-flow type, i.e. with inlet ports on one side of the combustion chamber and the exhaust ports on the other side.

The total cubic capacity of 2.958 litres and the turbocharger provide a high torque at low speed, improving performance in normal traffic conditions.

The new V6 TiD diesel is one of the lightest and most compact engine of its class (2.5 - 3 litres) in the world. It has been designed principally for front-wheel-drive cars. This engine is top of its class regarding power and has excellent driver response with high engine torque. Good fuel economy coupled with quiet running and a minimum of vibration thanks to the design of certain timing gears, crankshaft rotation and piston construction characterise this engine.

The V6 TiD is one of the first diesel engines in its class (2.5 - 3 litre) that has been constructed completely in aluminium.

| Working principle |

A diesel engine works with four strokes, induction, compression, power and exhaust, but does not have spark plugs to initiate the combustion of the air/fuel mixture. Instead, the engine is designed with high compression and especially shaped combustion chambers on top of the pistons. The principle is that pure air is drawn into the cylinders and is compressed there. In the compression stroke, the air will become so hot that the fuel being injected will self-ignite and expand rapidly, causing the power stroke.

The next step is the exhaust stroke as normal. The engine works by mixing air and fuel only when the fuel is injected into the compressed air. There is no throttle body either and the air can flow freely the whole time. A high-pressure pump supplies the cylinders with fuel via a common fuel rail. This design means that electrically controlled injectors can be used for injecting each cylinder individually under high pressure and with great precision. The correct amount of fuel at just the right moment is obtained to deliver the engine torque requested by the driver. The injectors are controlled by the engine control module, which is informed of the accelerator pedal position and other parameters by various sensors and then makes a fuel calculation. After this calculation, the control module sends a request for a certain amount of fuel to the injectors. This design helps to reduce diesel knocking.

The amount of fuel then determines the torque delivered by the engine. A diesel engine is normally 30% more efficient than a petrol engine. This means that fuel consumption will be lower than for a corresponding petrol engine.

Mechanically, a diesel engine is constructed in much the same way as a petrol engine, with crankshaft, connecting rods, pistons, camshaft and valves, but without an ignition system and throttle body. Since the engine does not have throttle body, there will not be any vacuum and thus no possibility of connecting hoses for a vacuum servo, etc. This means that a separate vacuum pump is needed for the brake servo.

An electronically controlled VNT turbocharger enhances performance together with the electronically controlled EGR system. In combination with the high injection precision of the fuel system, this will minimise emissions.