Camshaft drive

| Camshaft drive |

The rotation is transferred to the exhaust camshafts from the intake camshafts using gears, of which one is two-piece and preloaded to give high valve opening precision and reduced noise. The camshafts are supported in 4 bearings that are pressed into the camshaft carrier and secured with camshaft holders at both ends. The camshaft position sensor is mounted by the intake camshaft on the front cylinder block. It comprises a sensor and a domed sprocket with 7 teeth. The inside of the timing belt also has teeth. The toothed surface is mesh with the cam gears and fuel pump while the smooth surface lies against the hydraulic belt tensioner and the guide pulleys.

The eccentric belt tensioner is self-adjusting to give an optimum belt tension in all operating conditions. The timing belt is made of a special rubber compound comprising various types of reinforced rubber. The belt is thin to retain its pliability irrespective of bending direction and for maximum mesh. On the rear of the belt is a mark that must correspond with a mark on the cam gear on the fuel pump and two marks that must correspond with the cam gears. After dismantling the belt tensioner, it should be kept in the same position as it was when fitted on the engine to avoid oil spill.

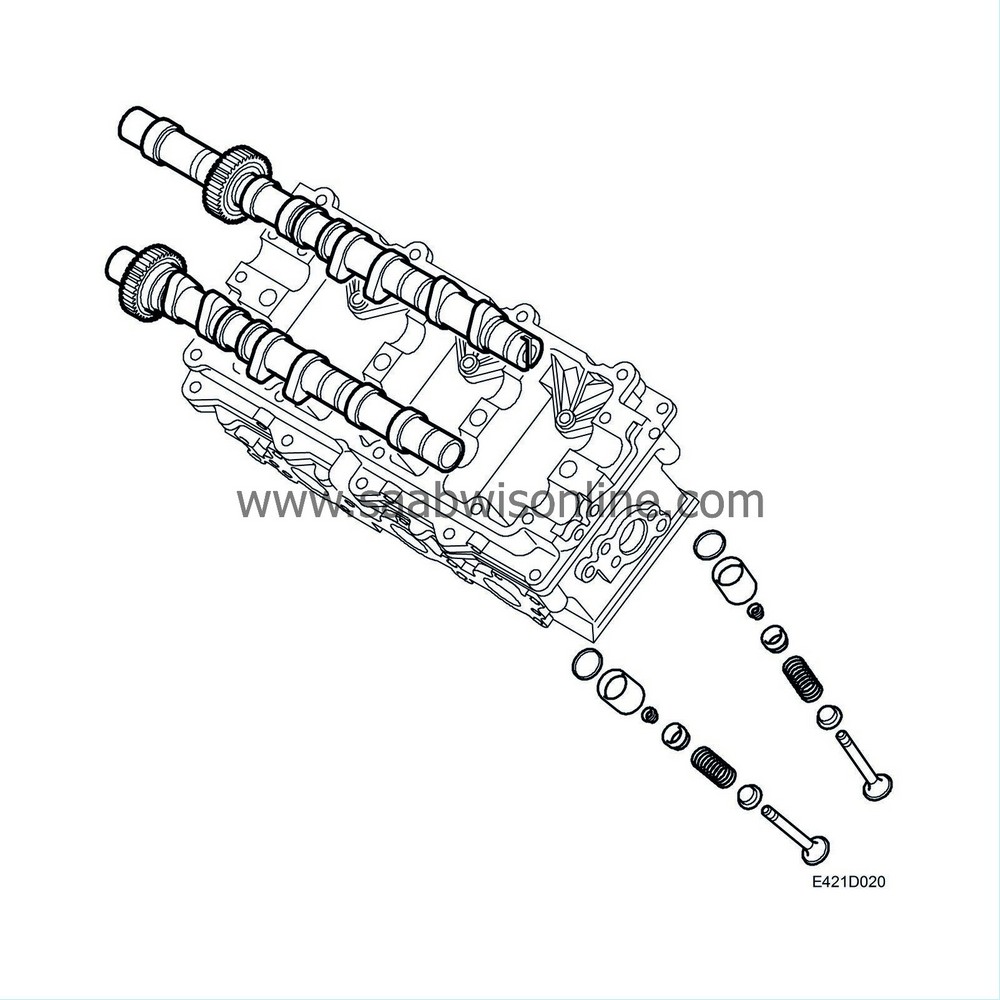

Valves and tappets

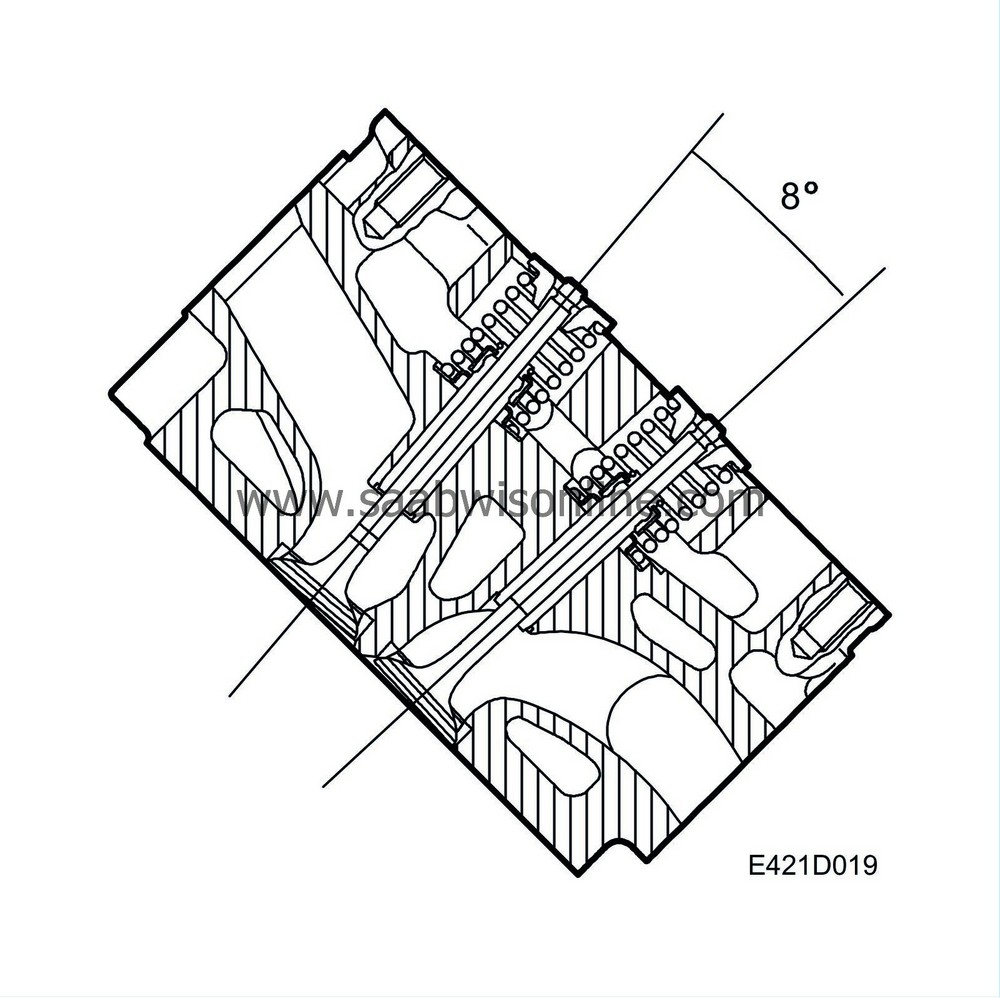

The valves are made of steel with chrome-plated stems. Each cylinder has two intake valves and two exhaust valves. The valves are opened directly by the cam lobes via tappets. Valve clearance should be 0.4 mm between cam lobe and tappet and is adjustable through the use of shims available in small thickness intervals. The angle between the inclined intake and exhaust valves is 8°, which allows for a more compact combustion chamber in the pistons and thereby more efficient combustion.

The valve seals are pressed around the valve stems for maximum tightness. The tappets have shims for adjusting the valve clearance. The valve springs are single. The upper part of each valve spring is weaker than the lower part. This design counteracts spring clatter and uneven valve return. The bottom of the spring is colour-coded for easy identification.

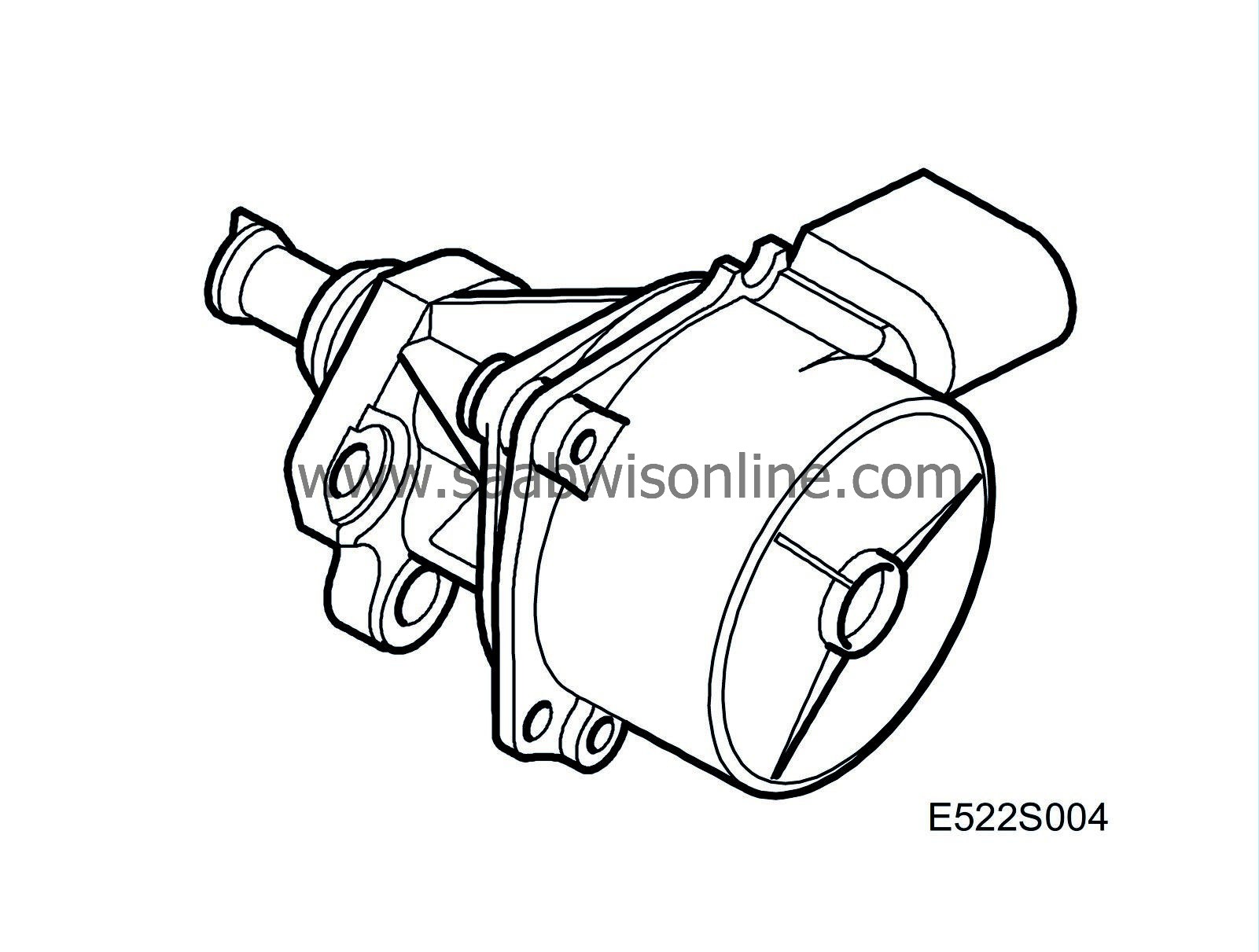

| Vacuum pump |

A mechanical vacuum pump is mounted on the rear cylinder head at the flywheel end. The vacuum pump is driven directly from the intake camshaft and is lubricated through the engine's normal lubricating system.