Cylinder head (in situ)

| Cylinder head (in situ) |

|

||||||||||||||||||||||

| To remove |

|

|||||||

| Important | ||

|

Always use wing covers when working in the engine bay. |

||

| 1. |

Remove

Timing belt (in situ)

.

|

|

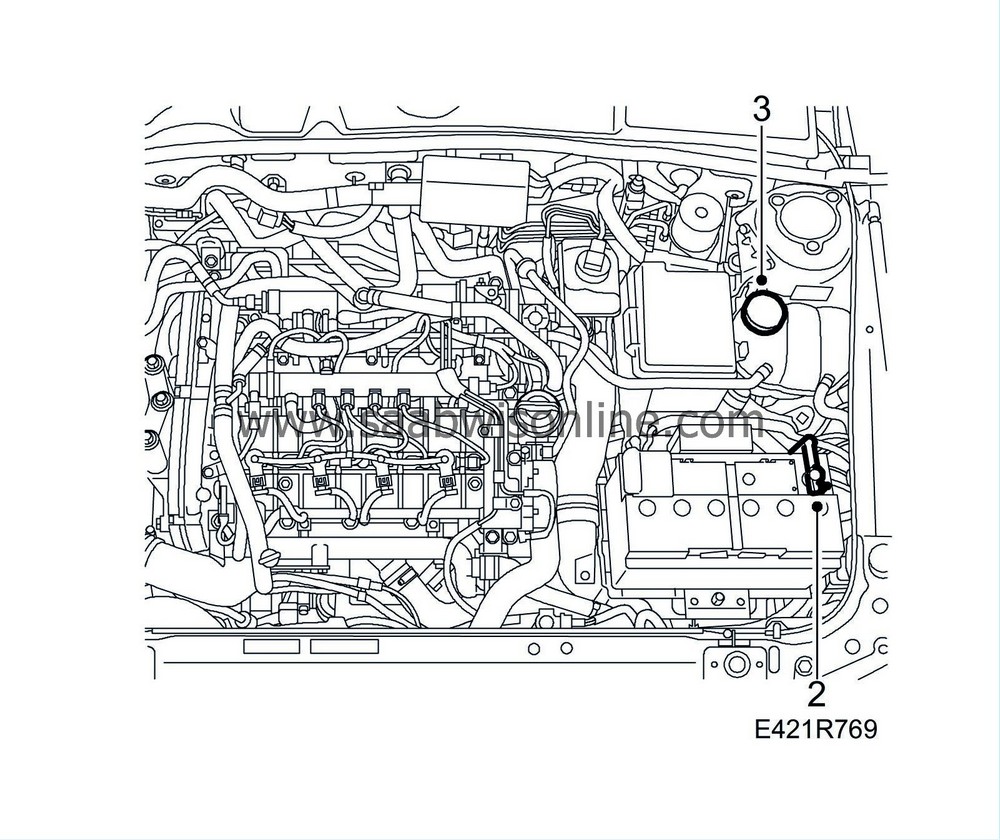

| 3. |

Loosen the coolant expansion tank cap to release any pressure.

|

|

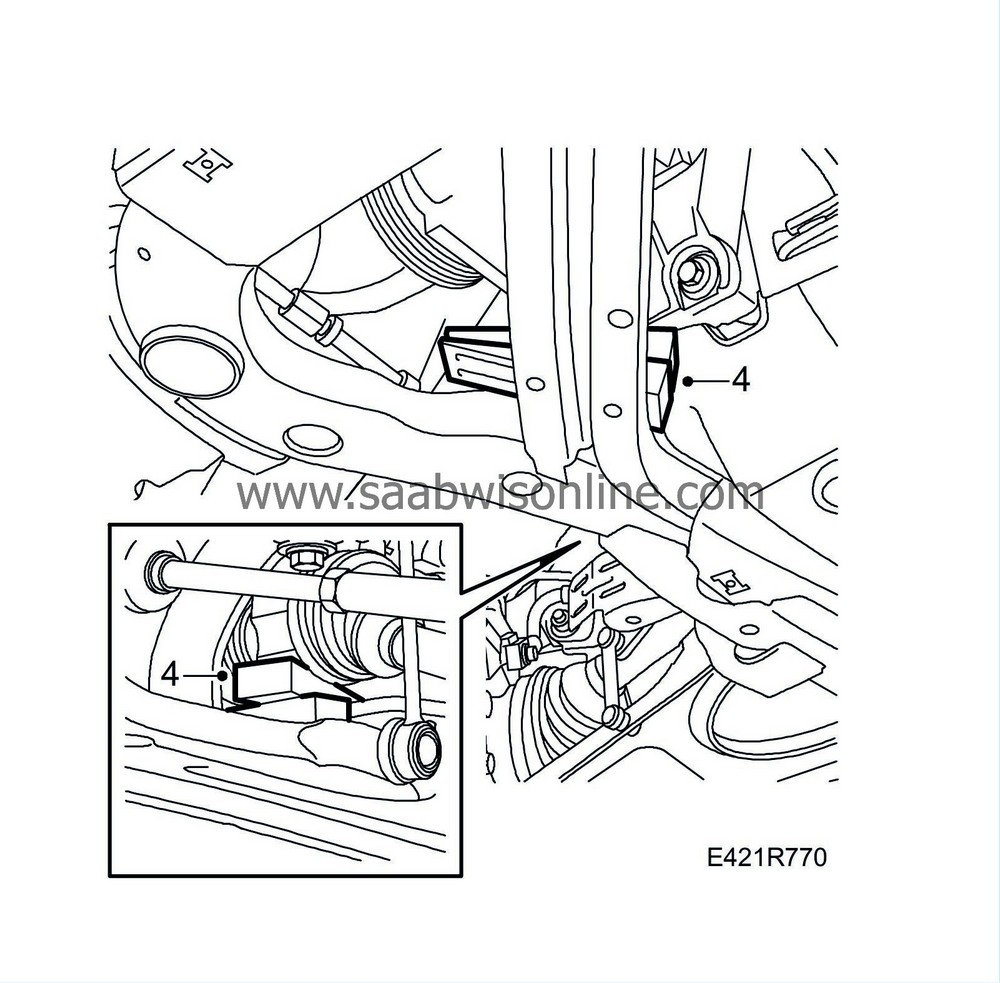

| 4. |

Raise the car and position plastic wedges or the like between the drive shaft and subframe as well as between the A/C compressor bracket and subframe.

|

|

| 5. |

Place a suitable receptacle under the radiator, attach a hose to the radiator and drain the coolant. Close the cock and fit the cover.

|

|

| 6. |

Remove the front exhaust pipe.

|

|

| 7. |

Detach the turbocharger oil return pipe from the engine block.

|

|

| 8. |

Remove the lower nuts and bolts from the turbocharger heat shield.

|

|

| 9. |

Slightly loosen the lower mounting of the front catalytic converter.

|

|

| 10. |

Lower the car and remove the lifting beam.

|

|

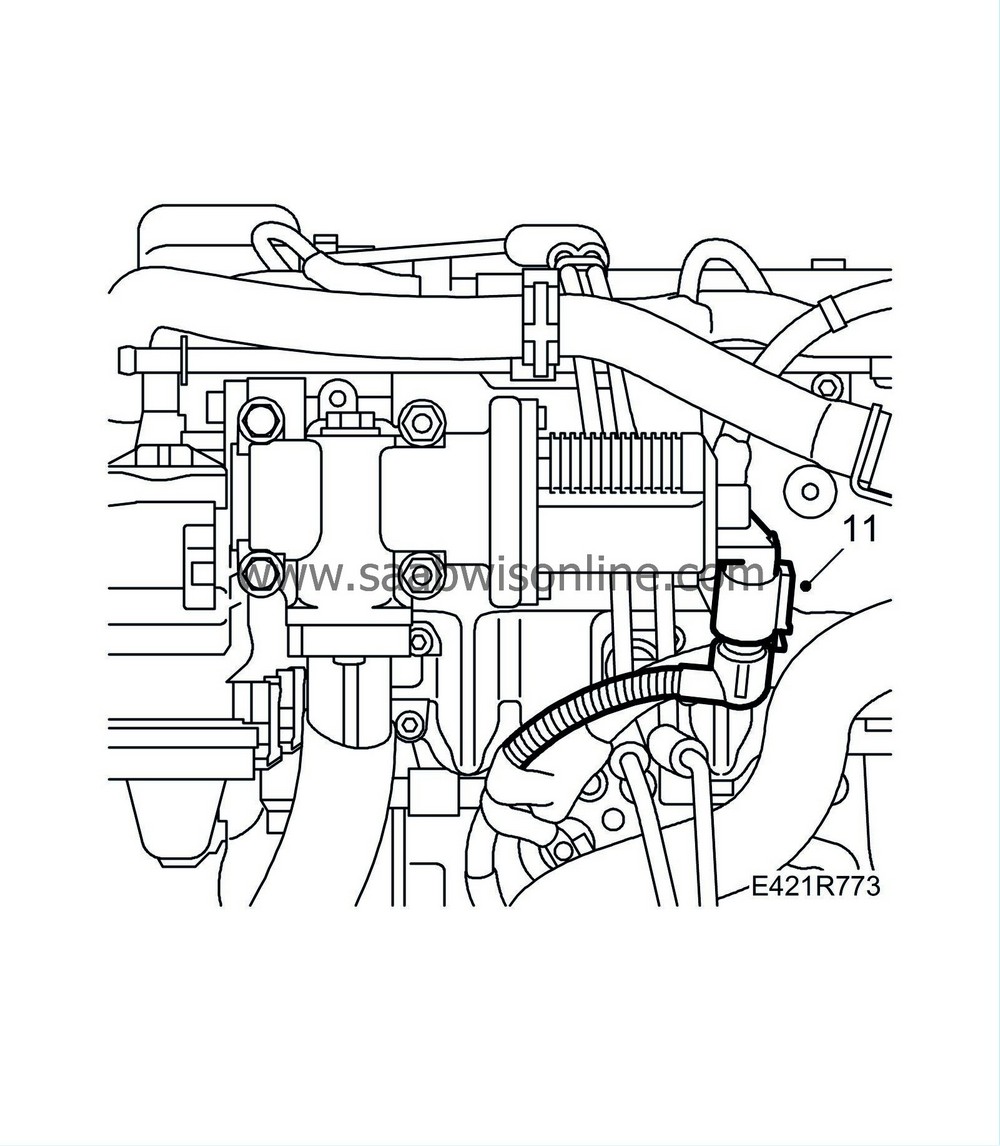

| 11. |

Detach the EGR valve connector.

|

|

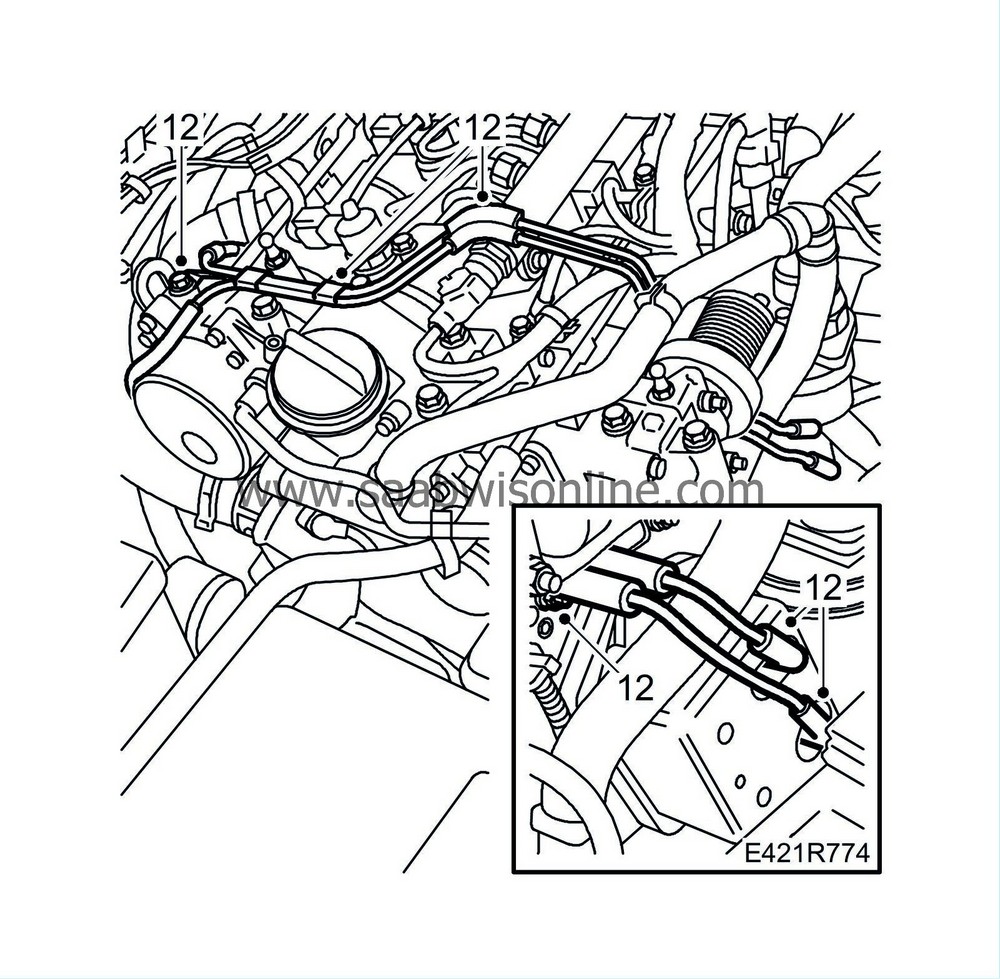

| 12. |

Detach the vacuum pipes from the camshaft housing and vacuum tank.

|

|

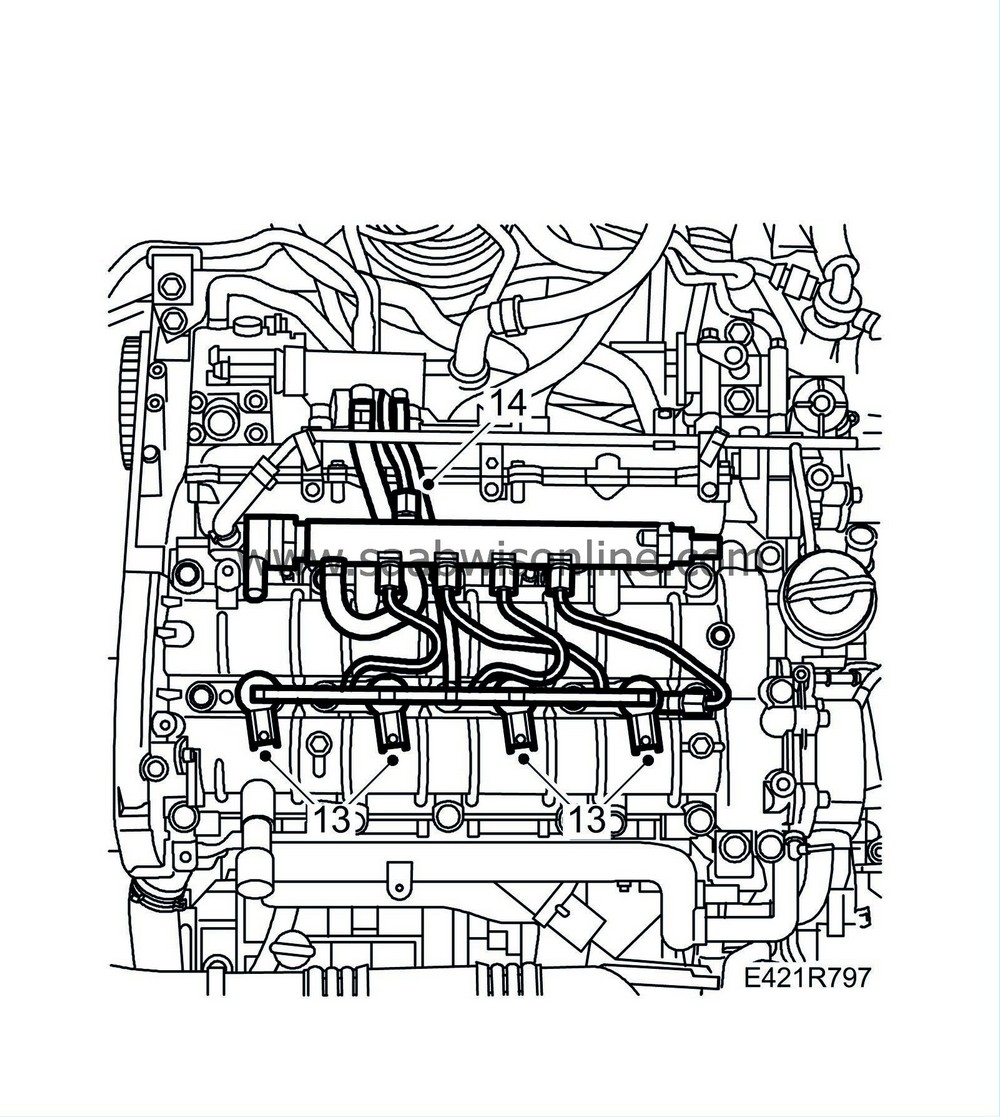

| 13. |

Remove the nuts from the radiator pipe holder on the starter motor bracket.

|

|

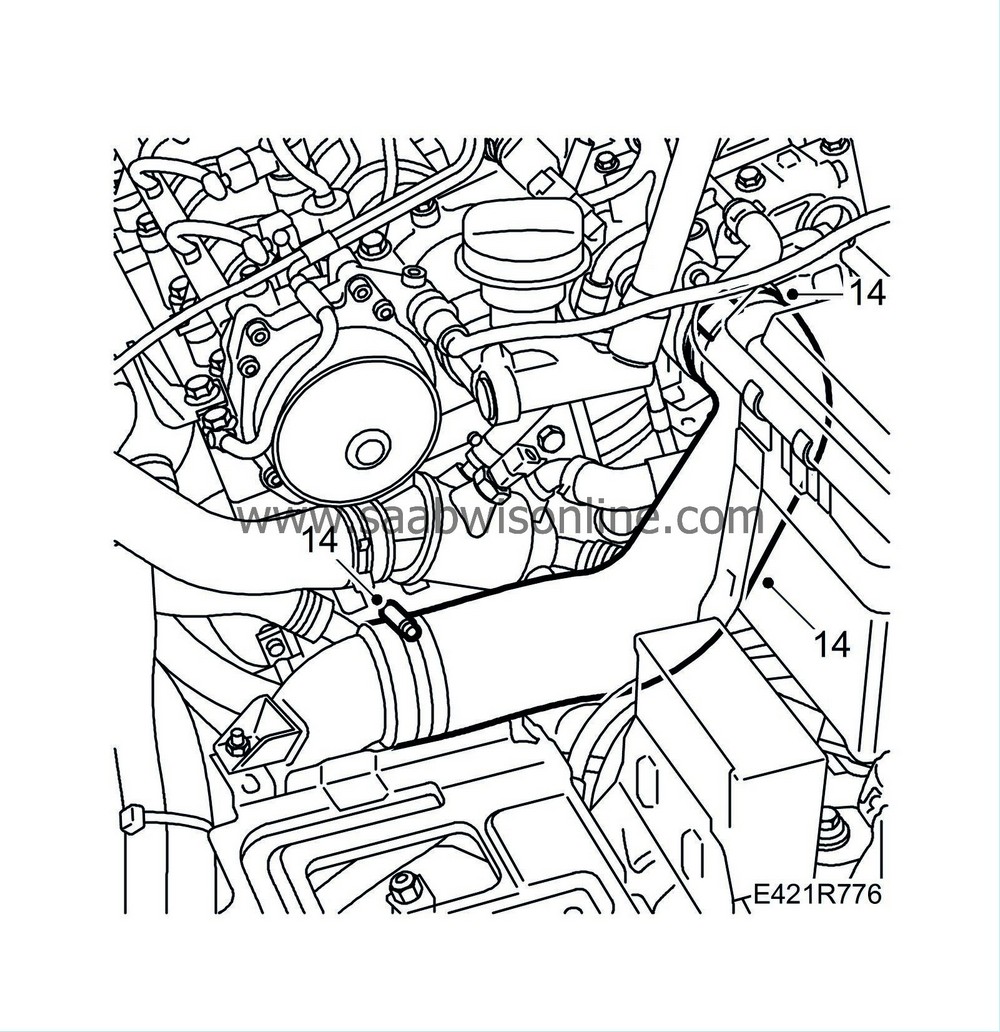

| 14. |

Detach the turbocharger delivery hose from the pipe and throttle body.

|

|

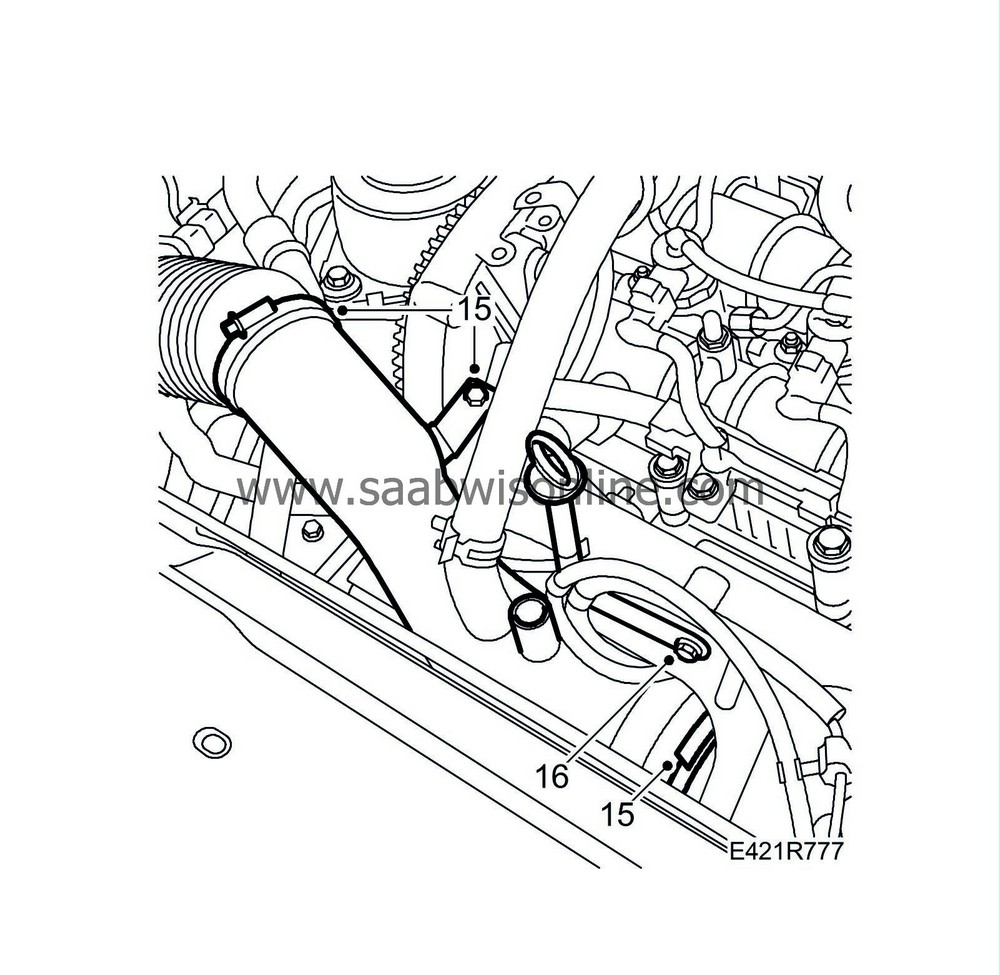

| 15. |

Remove the turbocharger intake manifold. Plug the connections.

|

|

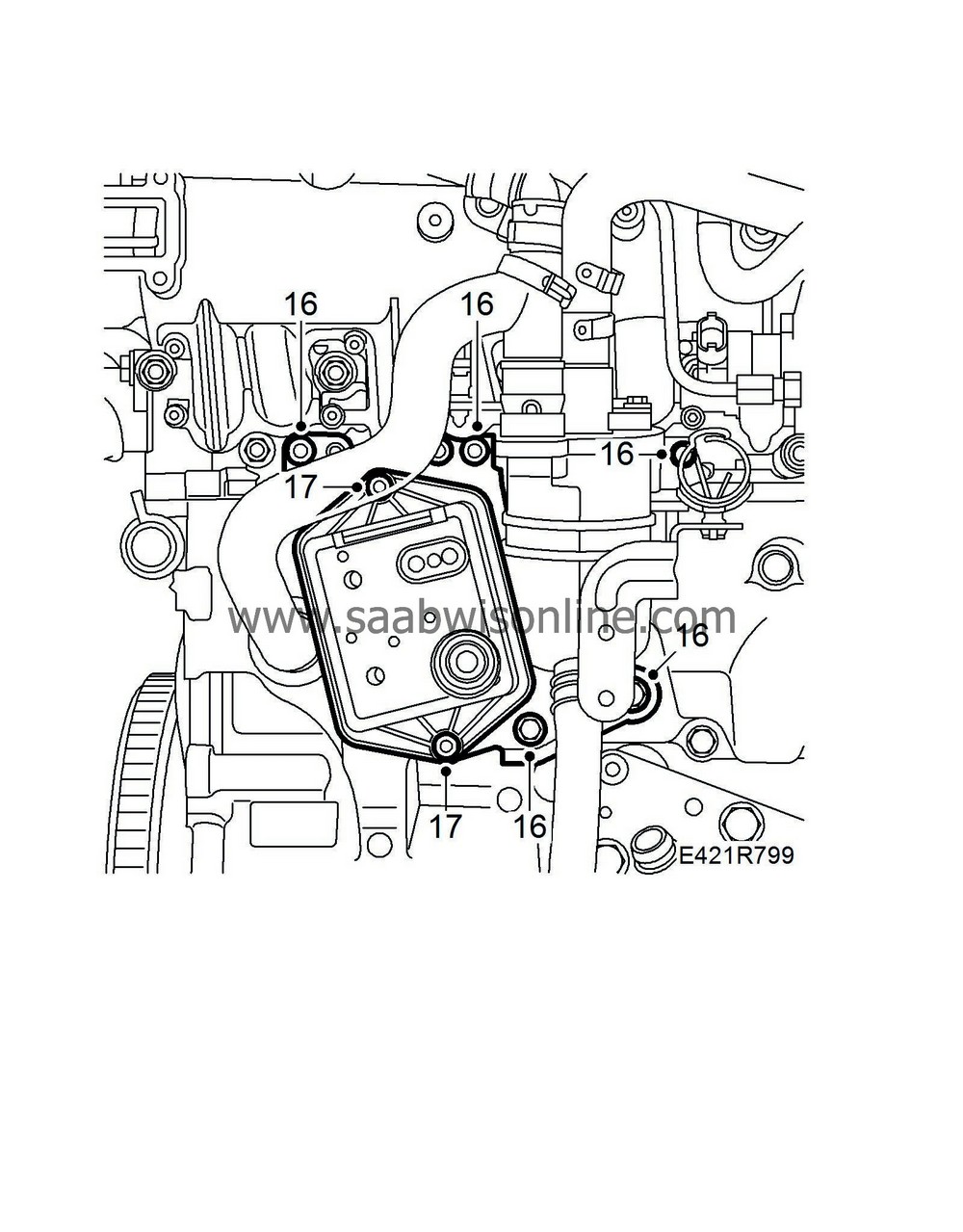

| 16. |

Remove the bolt securing the dipstick guide tube.

|

|

| 17. |

Remove the brake vacuum hose.

|

|

| 18. |

Unplug the connector of the coolant temp. sensor.

|

|

| 19. |

Detach the expansion tank bleeder hose.

|

|

| 20. |

Remove the crankcase ventilation hose from the clip. Move the hose aside.

|

|

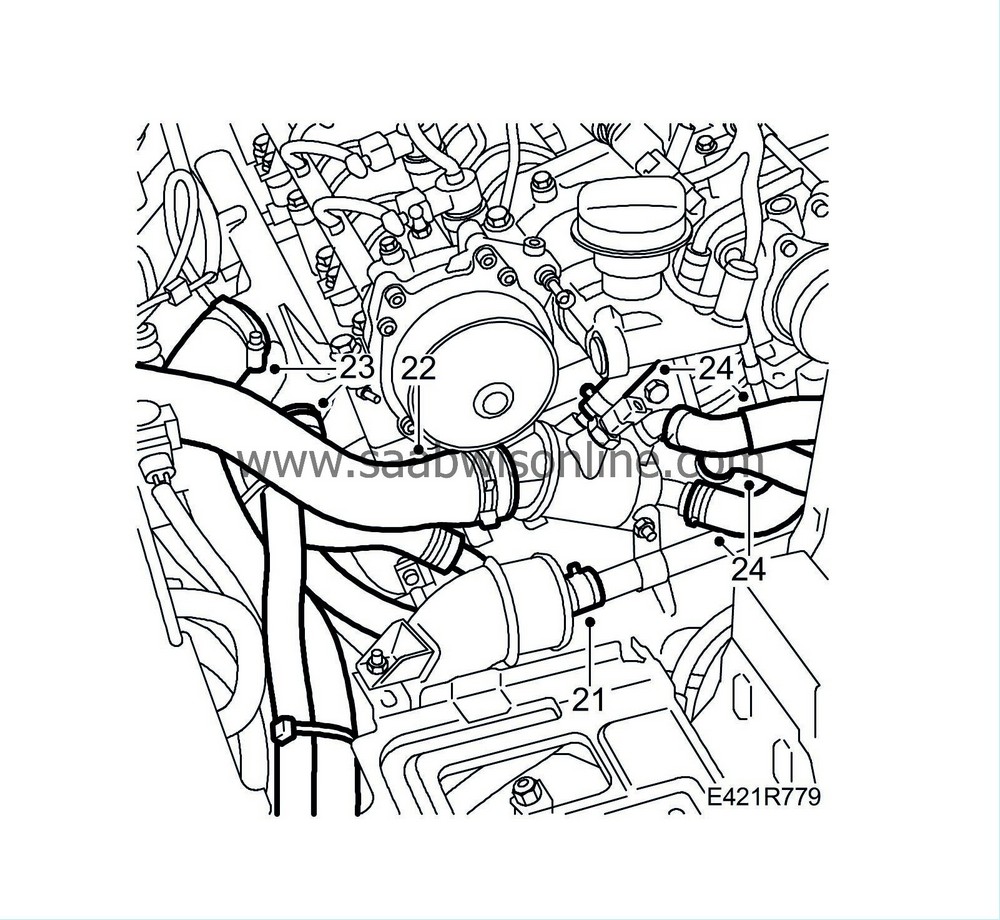

| 21. |

Detach the lower radiator hose from the coolant pipe.

|

|

| 22. |

Detach the upper radiator hose from the thermostat housing.

|

|

| 23. |

Detach the coolant hoses from the coolant pipe.

|

|

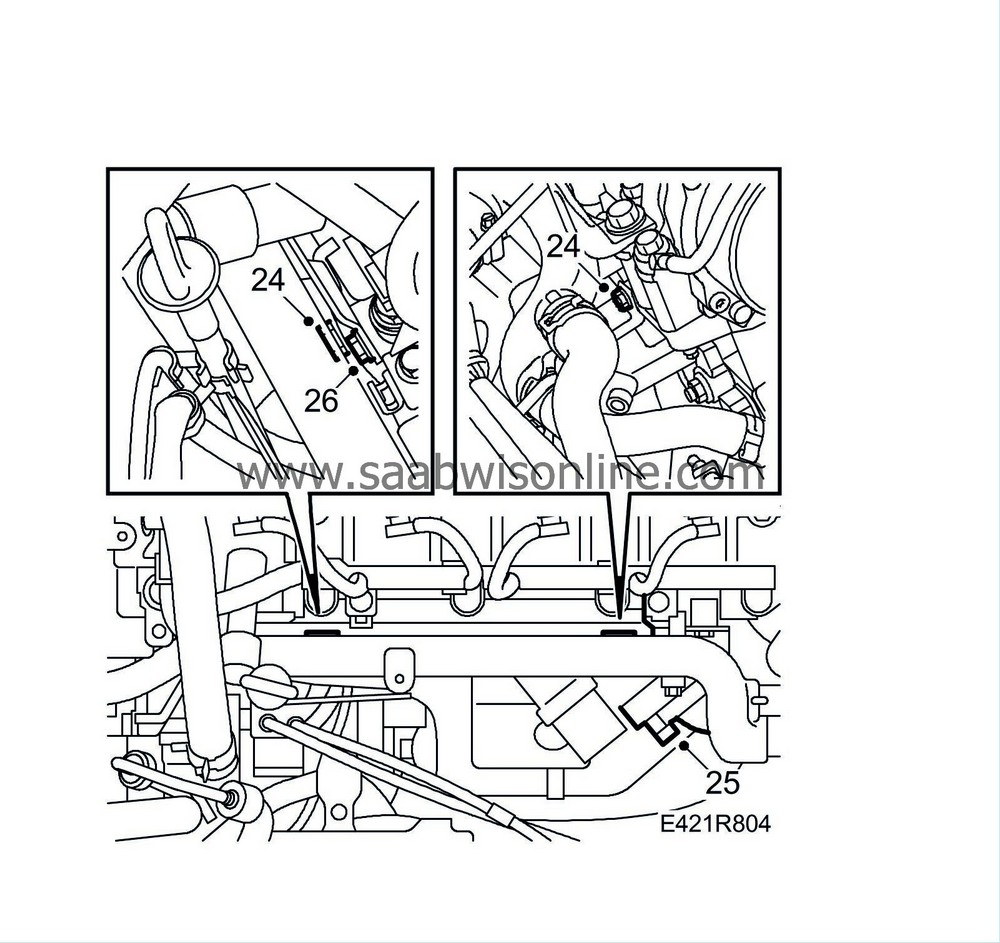

| 24. |

Detach the hoses from the thermostat housing.

|

|

| 25. |

Slightly slacken the bolt securing the turbo inlet pipe's upper retaining bracket.

|

|

| 26. |

Detach the EGR pipe between the exhaust manifold and heat exchanger.

|

|

| 27. |

Remove the heat shield.

|

|

| 28. |

Remove the exhaust manifold nuts and move it forward so that the studs are accessible.

|

|

| 29. |

Detach the return fuel pipe from the return fuel tank.

|

|

| 30. |

Detach the fuel hose from the high pressure pump.

|

|

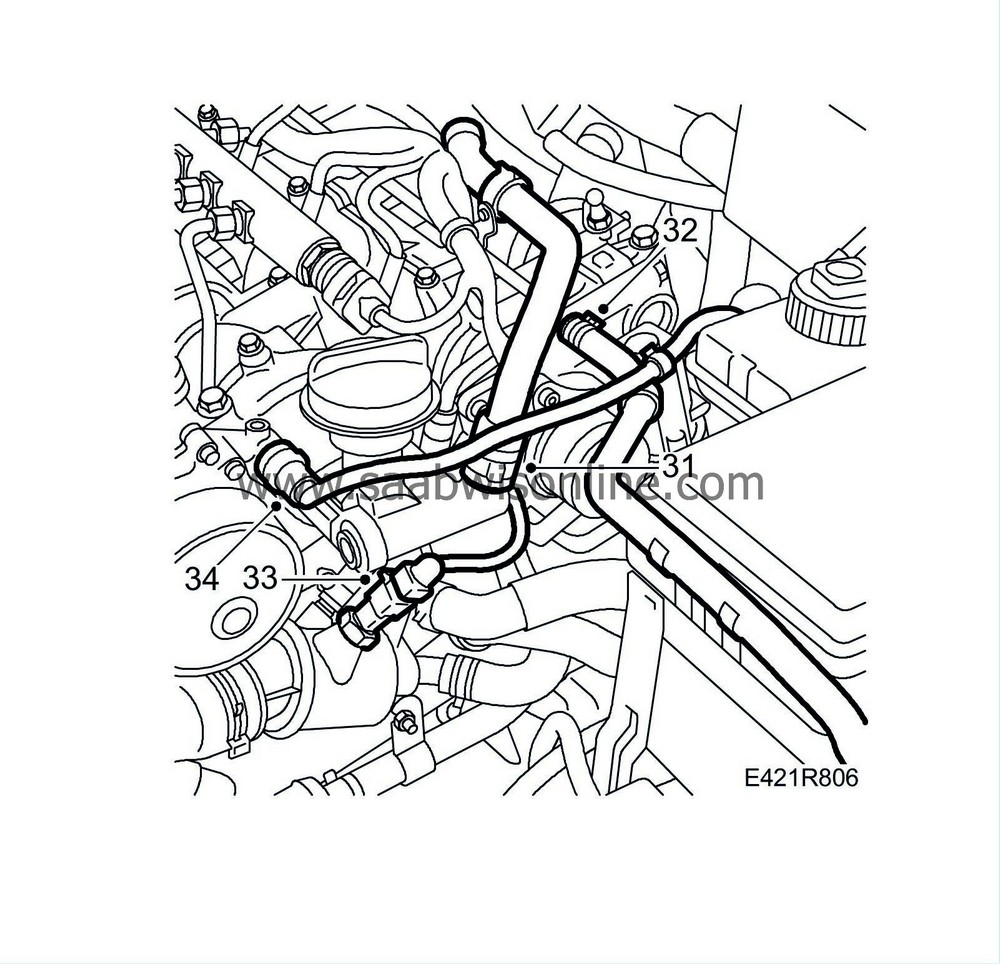

| 31. |

Detach the wiring harness from the crankcase ventilation pipe. Remove the bolts holding the pipe in place and move it aside.

Cars with preheated crankcase ventilation:

Cut the cable tie and remove the brackets.

|

|

| 32. |

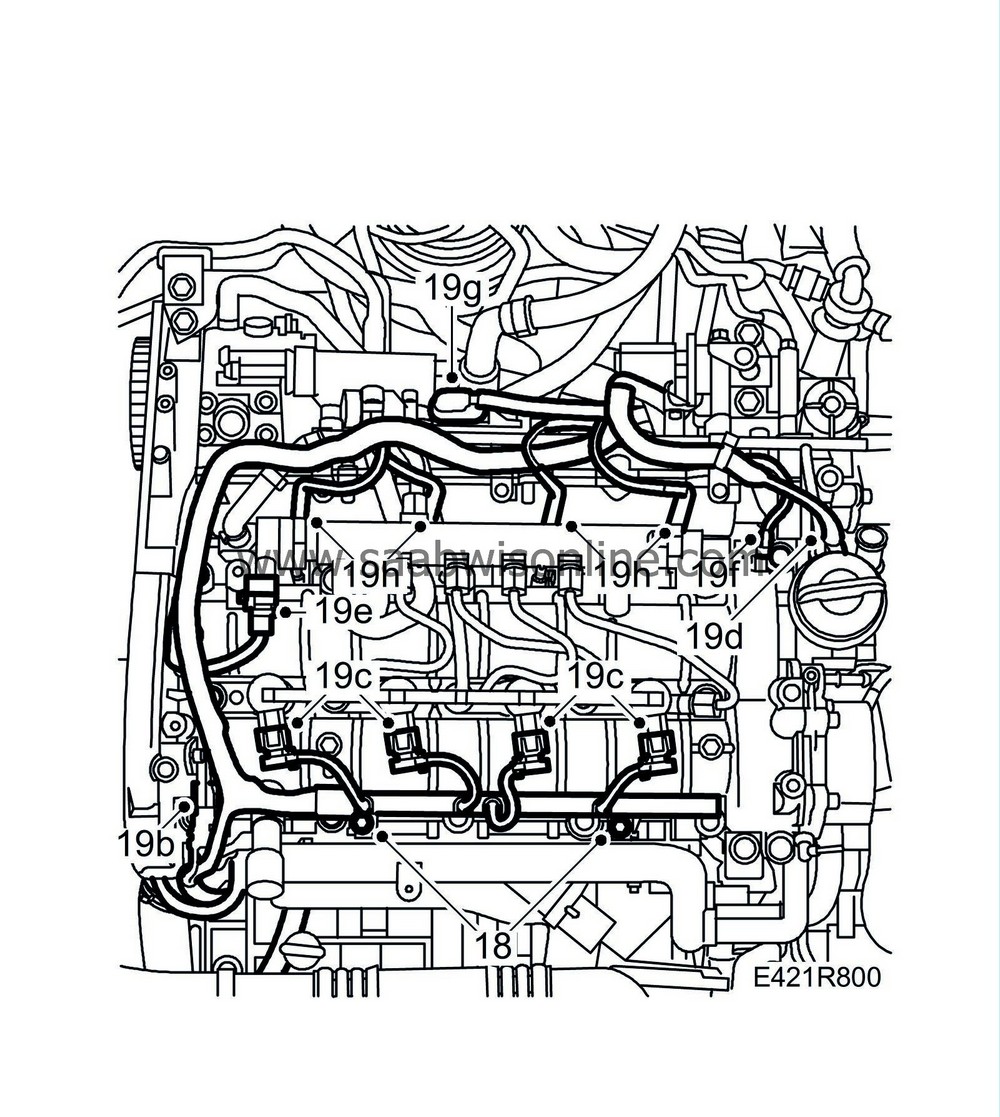

Unplug the following connectors:

|

|

| 32.a. |

Mass air flow sensor connector. (686)

|

| 32.b. |

Wiring harness connector. Fit bracket and cable tie.

|

| 32.c. |

A/C compressor connector (170).

|

| 32.d. |

Front temperature sensor (602).

|

| 32.e. |

Camshaft position sensor (555).

|

| 32.f. |

Injectors (206).

|

| 32.g. |

Fuel pressure sensor (653).

|

| 32.h. |

Fuel pressure solenoid valve (652a).

|

| 32.i. |

Electronic throttle actuator (604).

|

| 32.j. |

Intake air sensor (688).

|

| 32.k. |

Glow plug connector (398).

|

| 33. |

Remove the retaining bolts of the cable duct and move the wiring harness aside.

|

|

| 34. |

Remove the vacuum reservoir.

|

|

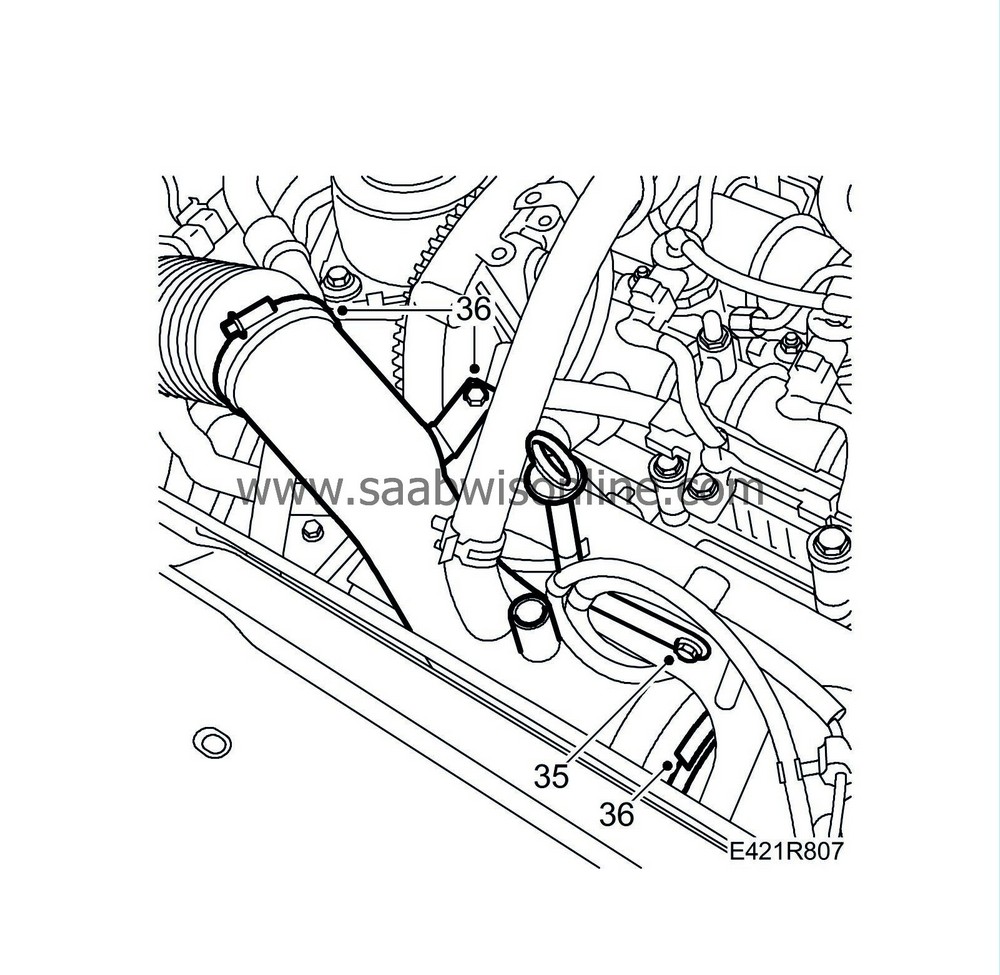

| 35. |

Remove the nuts and bolts holding the oil trap bracket in place and move it aside.

|

|

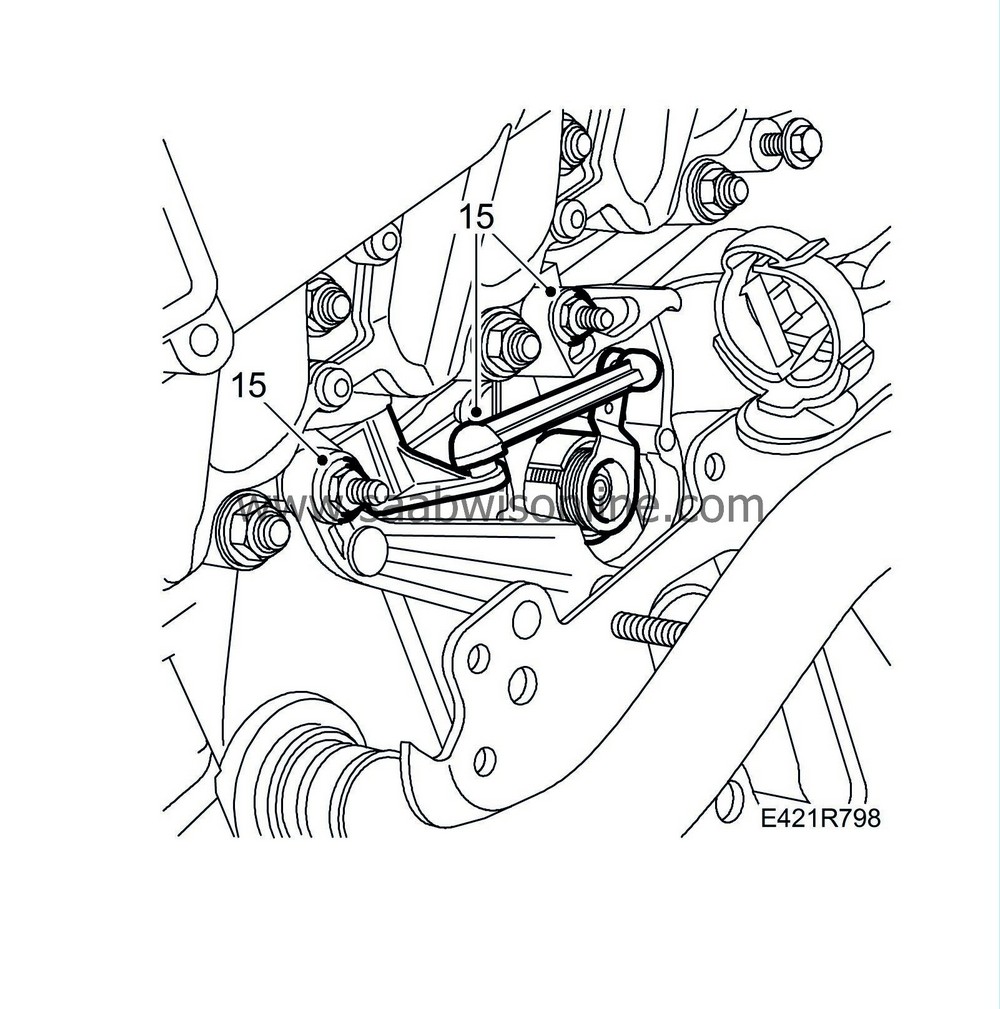

| 36. |

Remove the combustion circulation actuator. Carefully bend the control arm from the ball coupling.

|

|

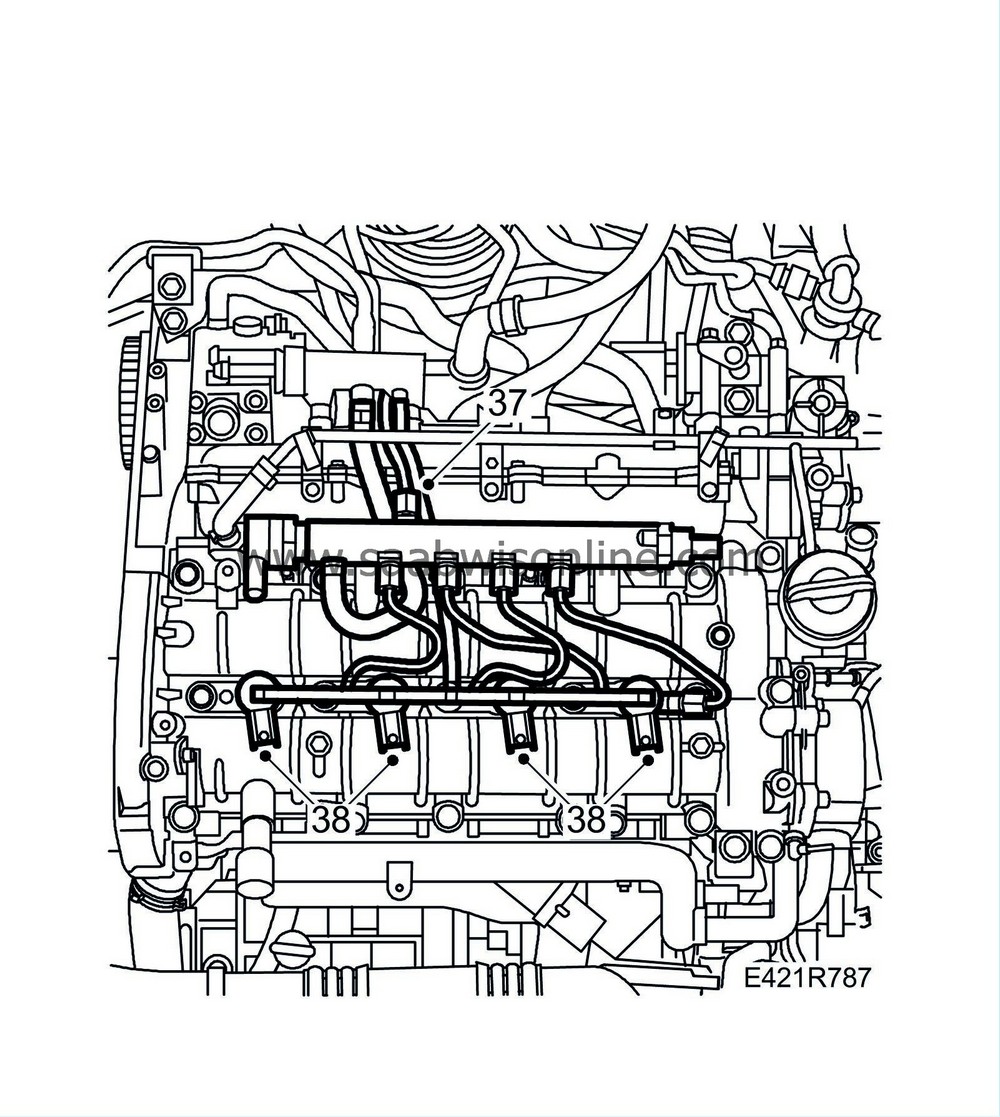

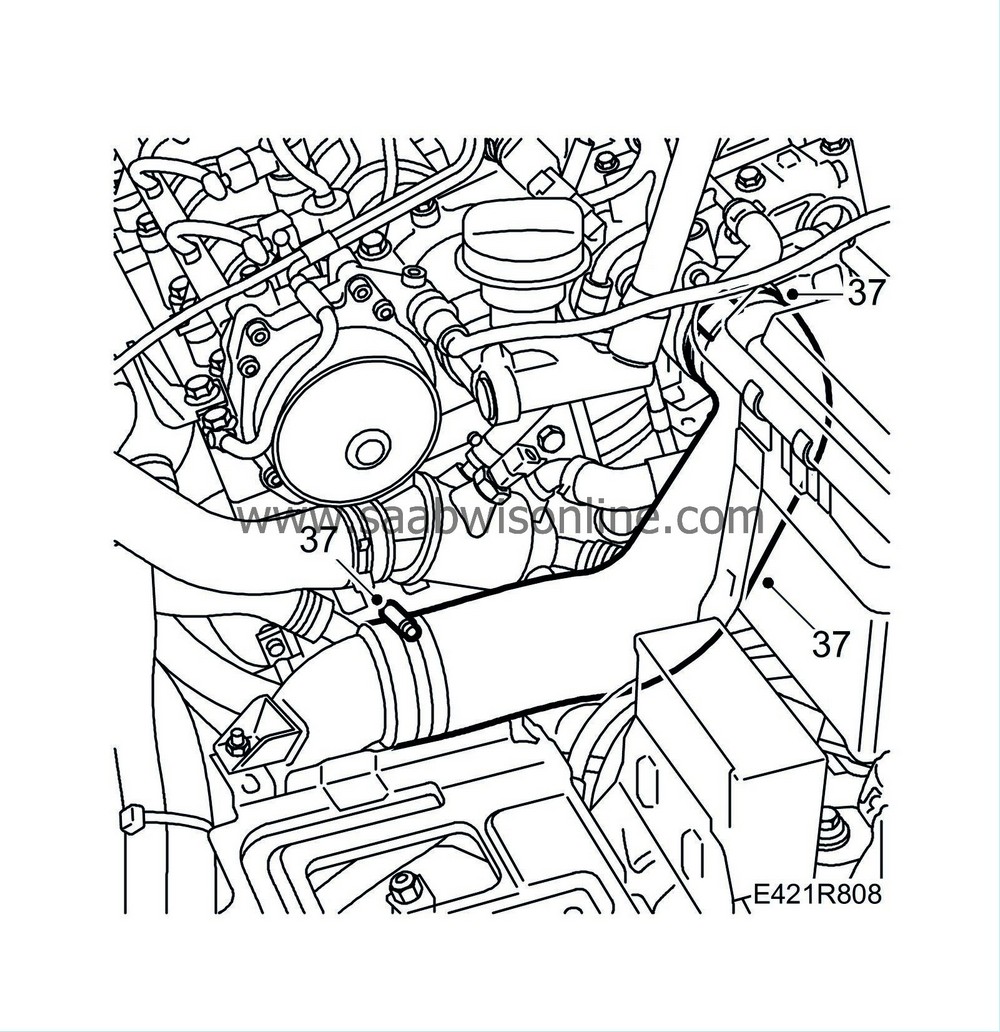

| 37. |

Detach the fuel delivery pipe between the pump and fuel rail.

|

||||||||||

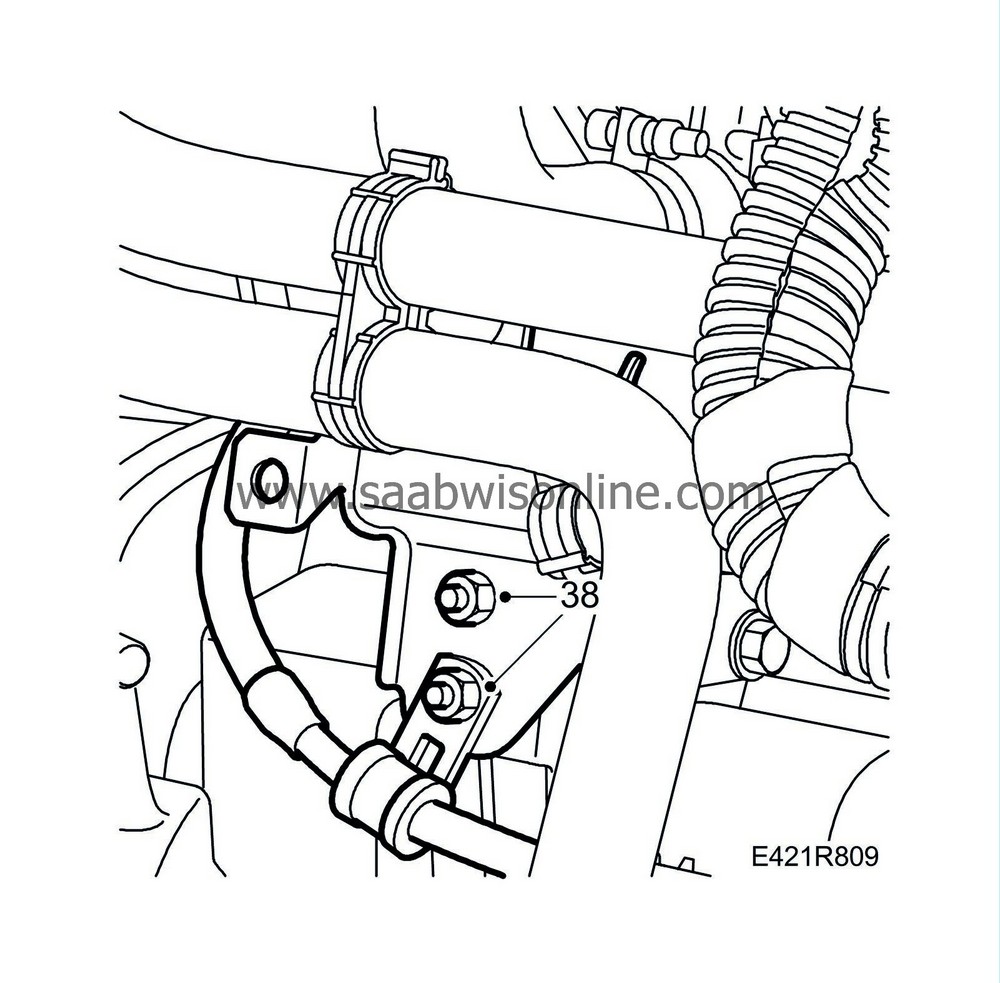

| 38. |

Remove the injector (206)

|

|

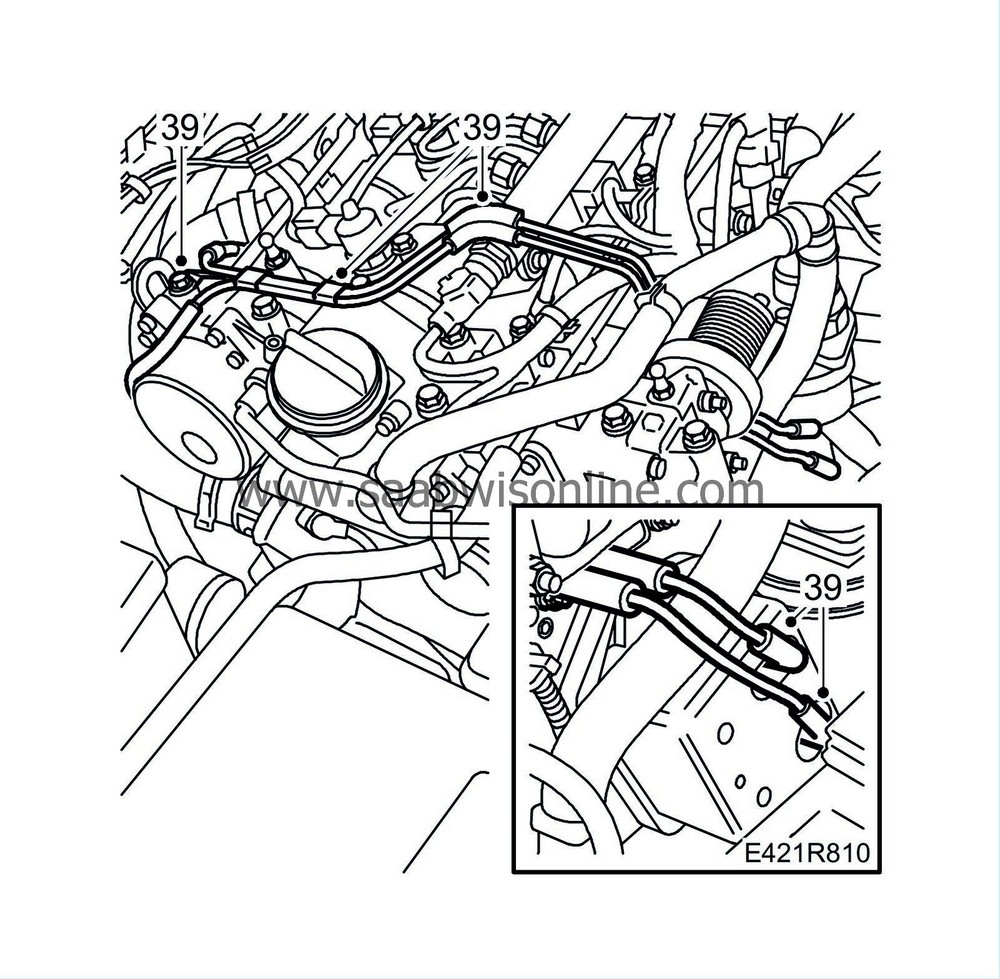

| 39. |

Remove the fuel rail and hose.

|

|

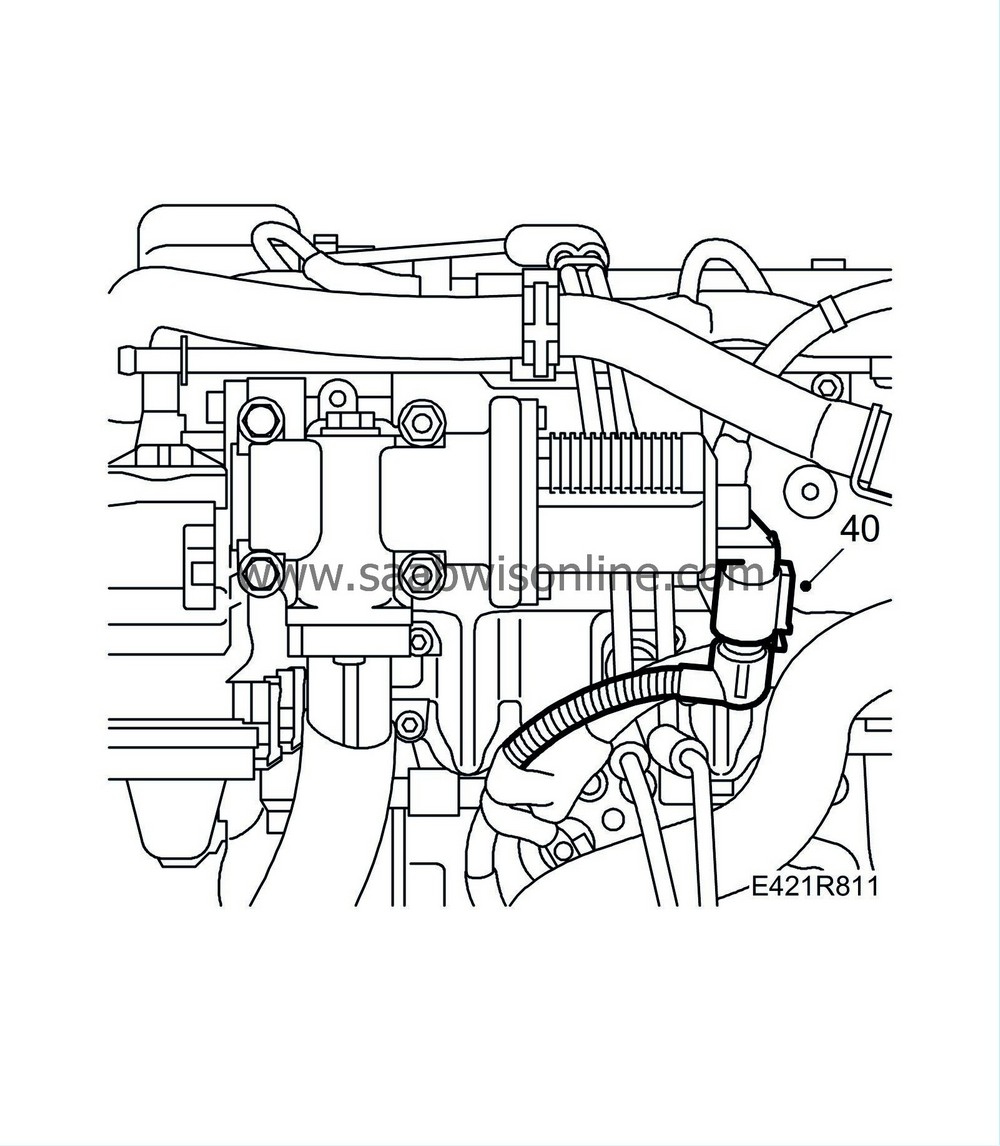

| 40. |

Remove the bolt between the fuel pump bracket and cylinder head. Slacken the spacer bolt a few turns.

|

|

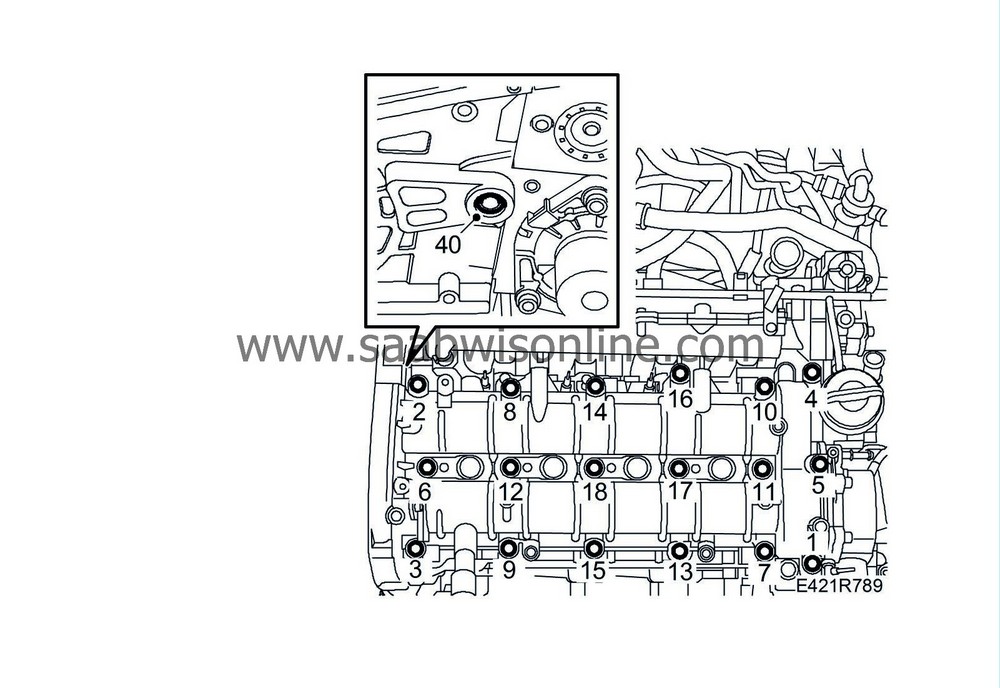

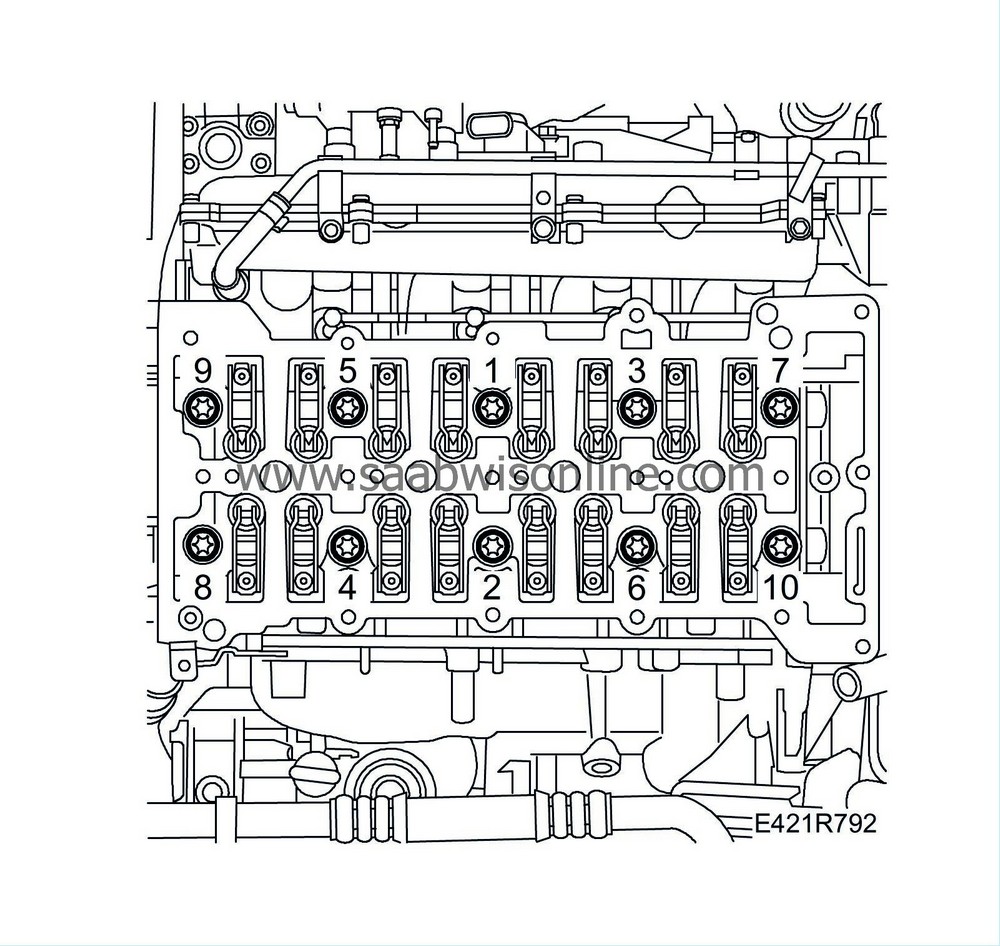

| 41. |

Loosen and remove the camshaft shaft housing and the guide sleeves. Remove in alternating order as illustrated.

|

|

| 42. |

Remove the cylinder head by undoing the bolts in the order illustrated.

|

|

| 43. |

Carefully lift off the cylinder head.

|

||||||||||

| 44. |

Remove the engine block guide sleeves.

|

|

| To fit |

| 1. |

Clean the bolt holes in the cylinder block.

|

|

| 2. |

Clean away any gasket residue from the sealing surfaces of the cylinder head and cylinder block.

|

|

| 3. |

Use a steel rule to check that the cylinder head and cylinder block are flat and the sealing surfaces are not damaged.

|

||||||||||

| 4. |

Position the guide sleeves on the cylinder block.

|

|

| 5. |

Position a new gasket with the same thickness as the old one.

|

|

| 6. |

Fit the cylinder head to the cylinder block.

|

|

| 7. |

Tighten the cylinder head bolts in the order illustrated.

Tightening torques Step I: 65 Nm (48 lbf ft) Step II: +90° Step III: +90° Step IV: +90°

|

|

| 8. |

Clean away any gasket residue from the sealing surfaces of the cylinder head and camshaft housing.

|

|

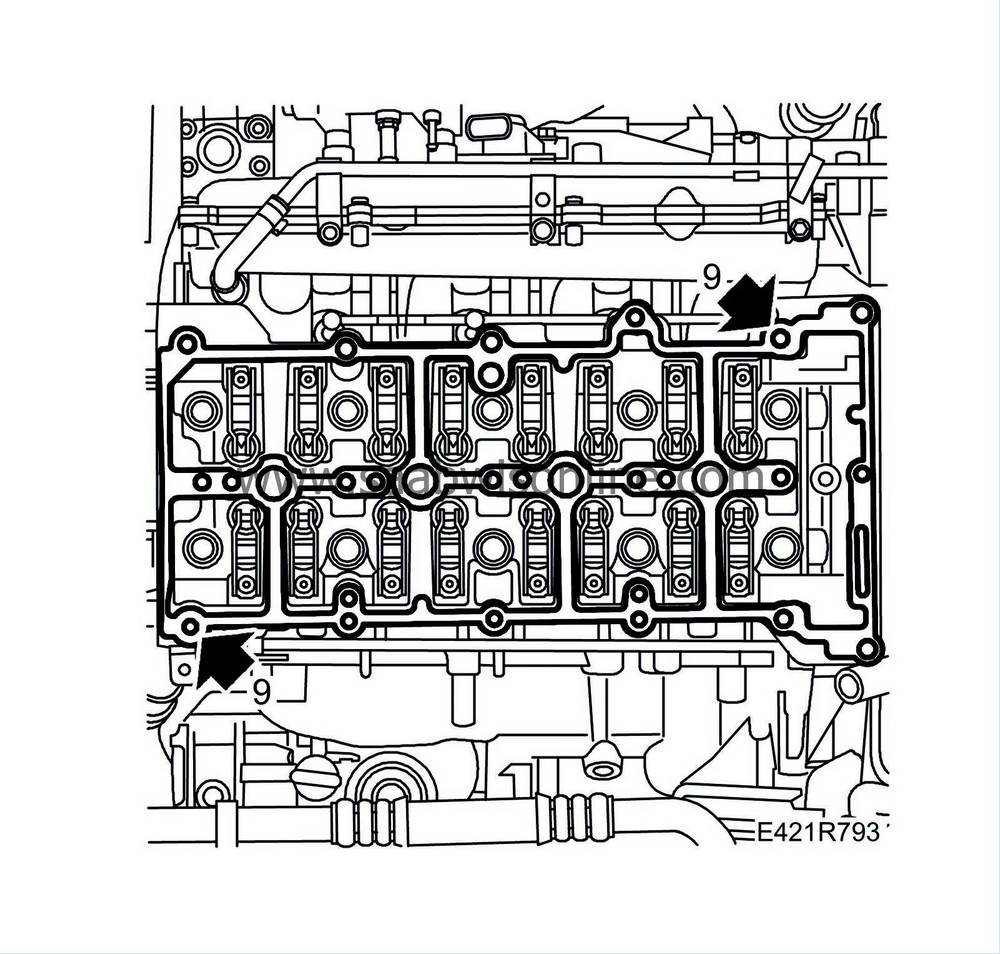

| 9. |

Fit the guide sleeves and position a new gasket on the cylinder head.

|

|||||||

| 10. |

Fit the camshaft housing, tightening the bolts alternatingly. Check that the guide sleeves are properly positioned in the camshaft housing.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 11. |

Screw in the spacer sleeve to the cylinder head and fit the bolt.

|

|

| 12. |

Fit the fuel rail and hose.

|

|

| 13. |

Fit the injector (206)

|

|

| 14. |

Fit the fuel delivery pipe between the pump and fuel rail.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 15. |

Fit the combustion circulation actuator and attach the control arm to the ball coupling.

|

|

| 16. |

Fit the nuts and bolts holding the oil trap bracket in place.

|

|

| 17. |

Fit the vacuum reservoir.

|

|

| 18. |

Fit the wiring harness and cable duct retaining bolts.

|

|

| 19. |

Reposition the engine harness and plug in the following connectors:

|

|

| 19.a. |

Front temperature sensor (602).

|

| 19.b. |

Camshaft position sensor (555)

|

| 19.c. |

Injectors (206).

|

| 19.d. |

Fuel pressure sensor (653).

|

| 19.e. |

Fuel pressure solenoid valve (652a).

|

| 19.f. |

Throttle body actuator (604)

|

| 19.g. |

Sensor, intake air (688)

|

| 19.h. |

Glow plug connector (398).

|

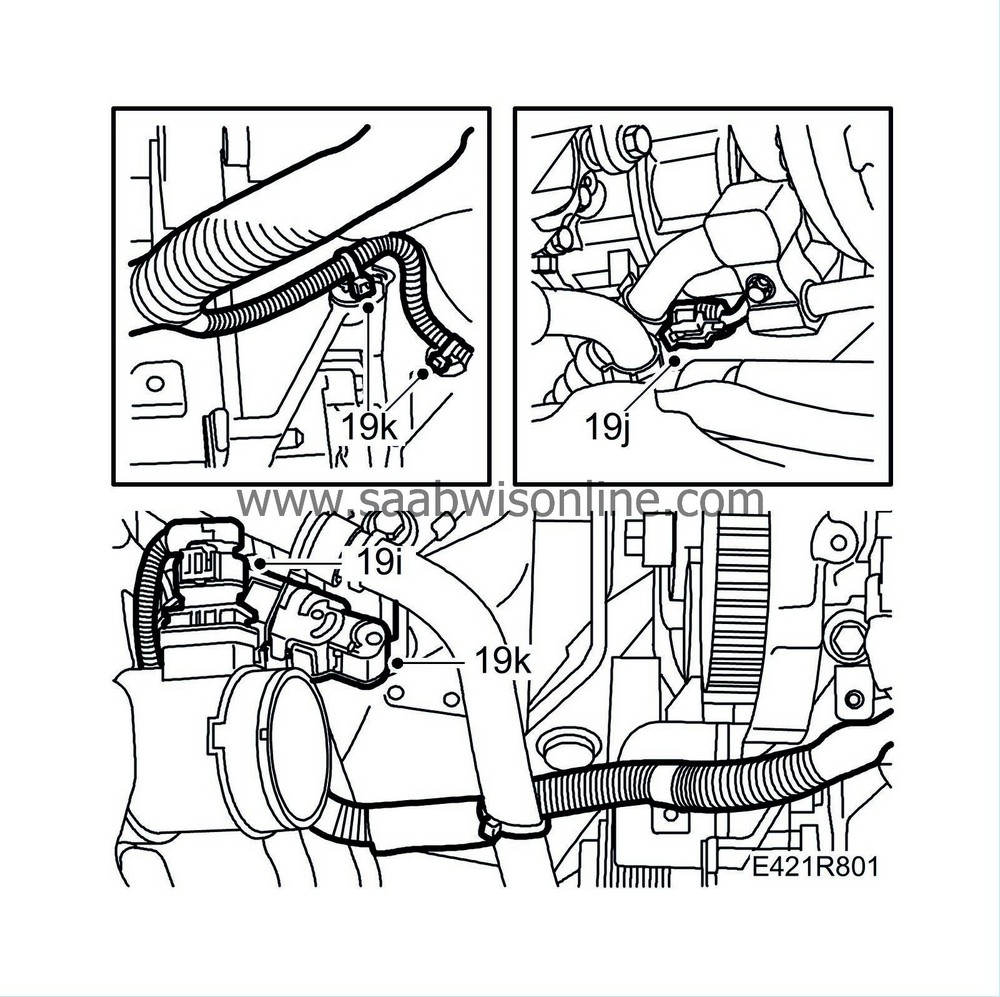

| 19.i. |

Mass air flow sensor connector. (686)

|

| 19.j. |

A/C compressor connector (170).

|

| 19.k. |

Wiring harness connector. Fit bracket and cable tie.

|

| 20. |

Cars with preheated crankcase ventilation:

Fit the brackets.

All:

Fit the bolts of the crankcase ventilation pipe. Fit the wiring harness.

|

|

| 21. |

Attach the fuel hose to the high pressure pump.

|

|

| 22. |

Attach the return fuel pipe to the return fuel tank.

|

|

| 23. |

Fit the exhaust manifold nuts and move it forward so that the studs are accessible. Use a new gasket.

Tightening torque: 20 Nm (15 lbf ft)

|

|

| 24. |

Fit the upper bolts of the heat shield.

|

|

| 25. |

Attach the EGR pipe between the exhaust manifold and the heat exchanger. Use new gaskets.

|

|

| 26. |

Tighten the bolt securing the turbo inlet pipe's upper retaining bracket.

|

|

| 27. |

Attach the hoses to the thermostat housing.

|

|

| 28. |

Attach the coolant hoses to the coolant pipe.

|

|

| 29. |

Attach the upper radiator hose to the thermostat housing.

|

|

| 30. |

Attach the lower radiator hose to the coolant pipe.

|

|

| 31. |

Fit the crankcase ventilation hose to the clip.

|

|

| 32. |

Fit the expansion tank bleeder hose.

|

|

| 33. |

Plug in the connector of the coolant temp. sensor.

|

|

| 34. |

Attach the brake vacuum hose.

|

|

| 35. |

Fit the bolt securing the dipstick guide tube.

|

|

| 36. |

Remove the plugs and attach the turbocharger intake manifold.

|

|

| 37. |

Attach the turbocharger delivery hose to the pipe and throttle body.

|

|

| 38. |

Fit the nuts from the radiator pipe holder on the starter motor bracket.

Tightening torque: 10 Nm (7 lbf ft)

|

|

| 39. |

Attach the vacuum pipes to the camshaft housing and vacuum tank.

|

|

| 40. |

Attach the EGR valve connector.

|

|

| 41. |

Raise the car.

|

|

| 42. |

Tighten the lower mounting of the front catalytic converter.

Tightening torque: 25 Nm (18 lbf ft)

|

|

| 43. |

Fit the lower nuts and bolts of the turbocharger heat shield.

|

|

| 44. |

Attach the turbocharger oil return pipe to the cylinder block.

Tightening torque: 20 Nm (15 lbf ft) |

|

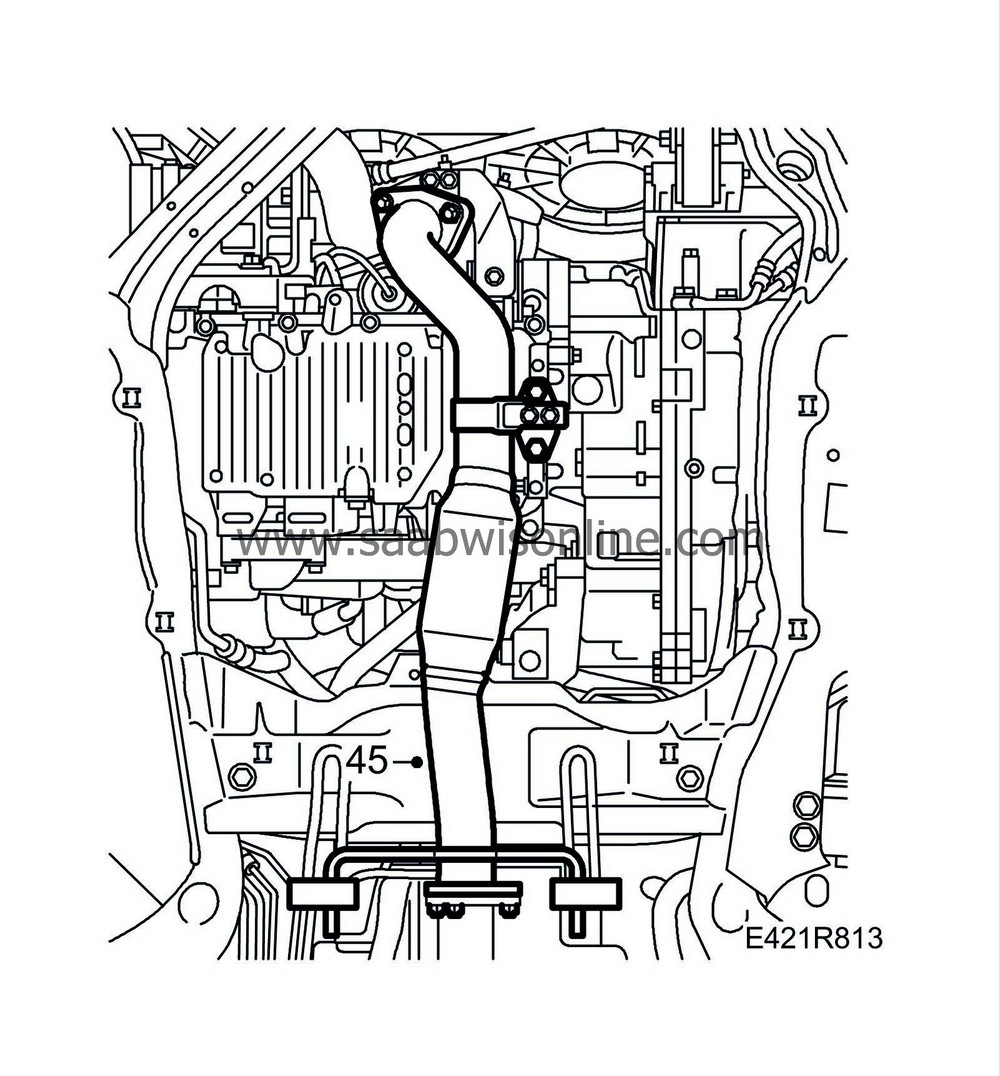

| 45. |

Attach the front exhaust pipe using new gaskets.

Tightening torque: 25 Nm (18 lbf ft)

|

|

| 46. |

Connect the negative battery cable.

|

|

| 47. |

Fit

Timing belt (in situ)

.

|

|

| 48. |

Pressure test - see Cooling system, pressure testing - and fill coolant - see Filling and bleeding cooling system.

|

|

| 49. |

Carry out

Procedure after battery disconnection

.

|

|

| 50. |

Check and clear any diagnostic trouble codes using the diagnostic tool.

|

|

Warning

Warning