Oil sump (in situ)

| Oil sump (in situ) |

| To remove |

| 1. |

Remove the upper engine cover and insulation.

|

|

| 2. |

Remove the nut of the right engine pad.

|

|

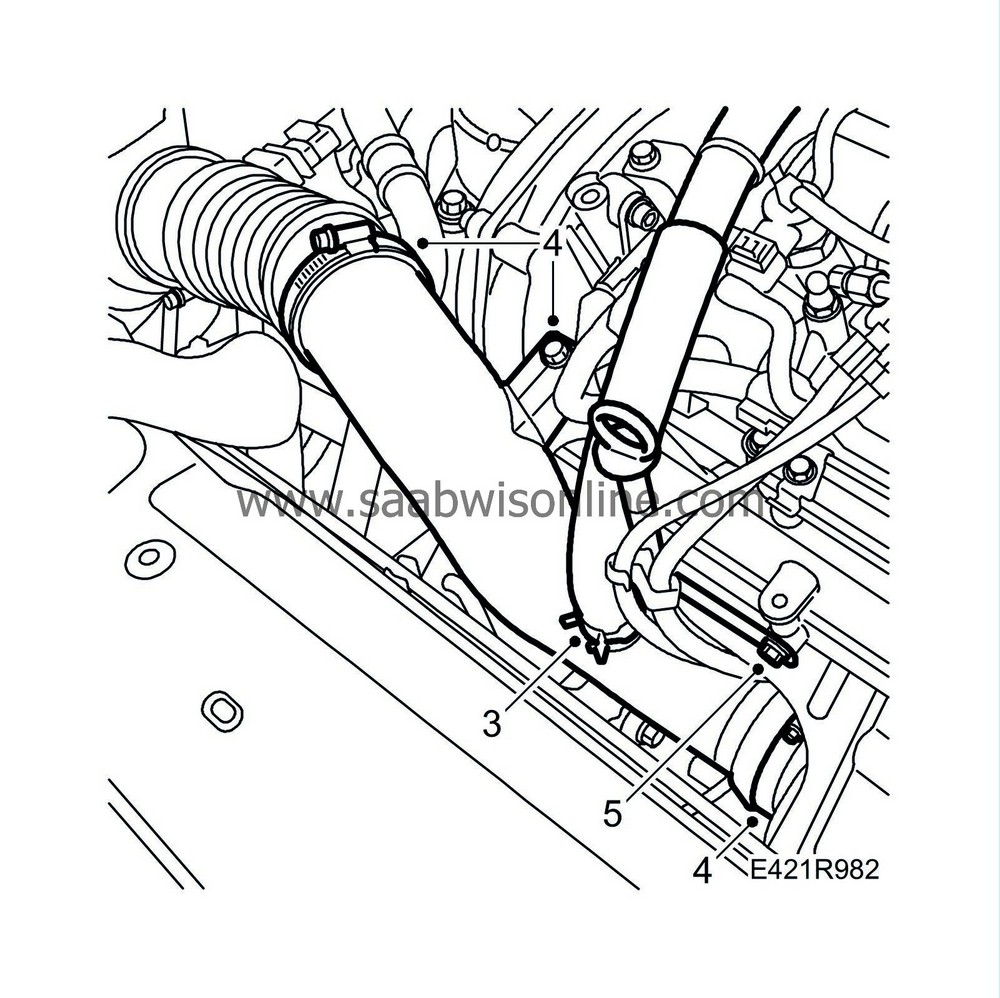

| 3. |

Detach the crankcase ventilation hose from the turbo intake manifold.

|

|

| 4. |

Remove the turbo intake pipe.

|

|

| 5. |

Remove the upper retaining bolt of the dipstick guide tube.

|

|

| 6. |

Raise the car and remove the front right wheel.

|

|

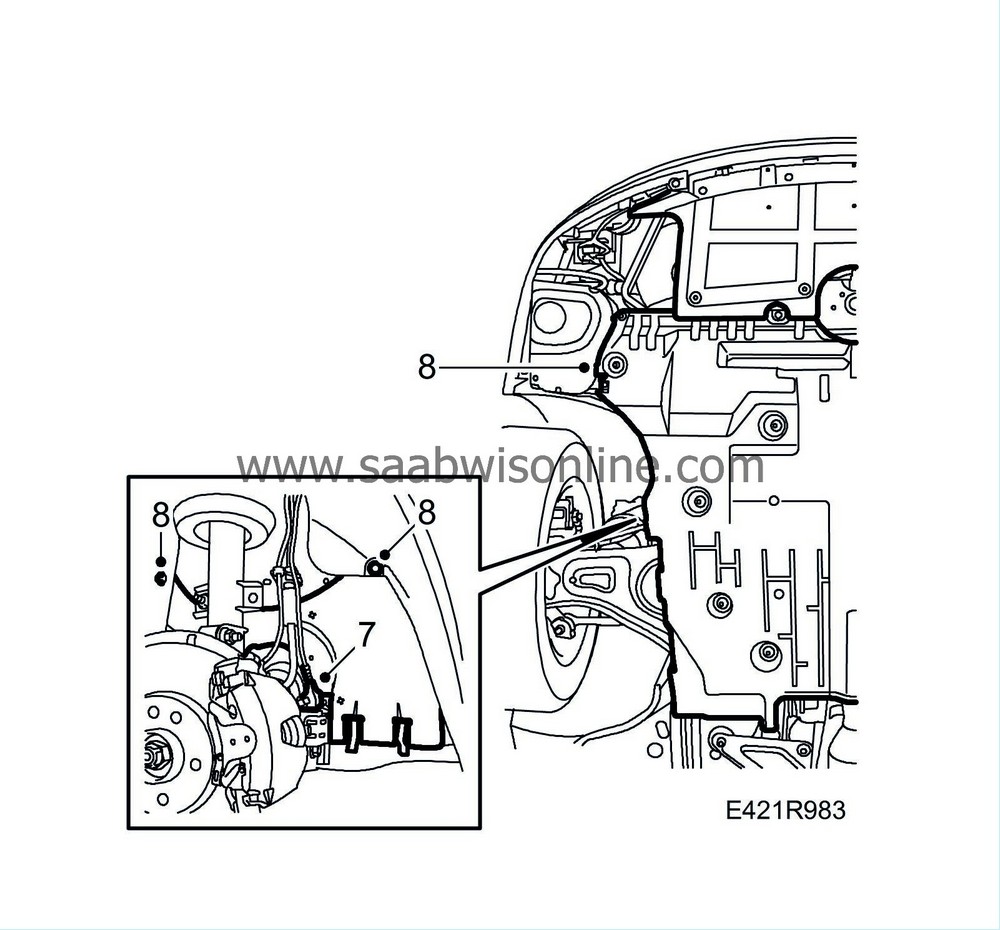

| 7. |

Remove the headlamp position sensor (option).

|

|

| 8. |

Remove the right side cover.

|

|

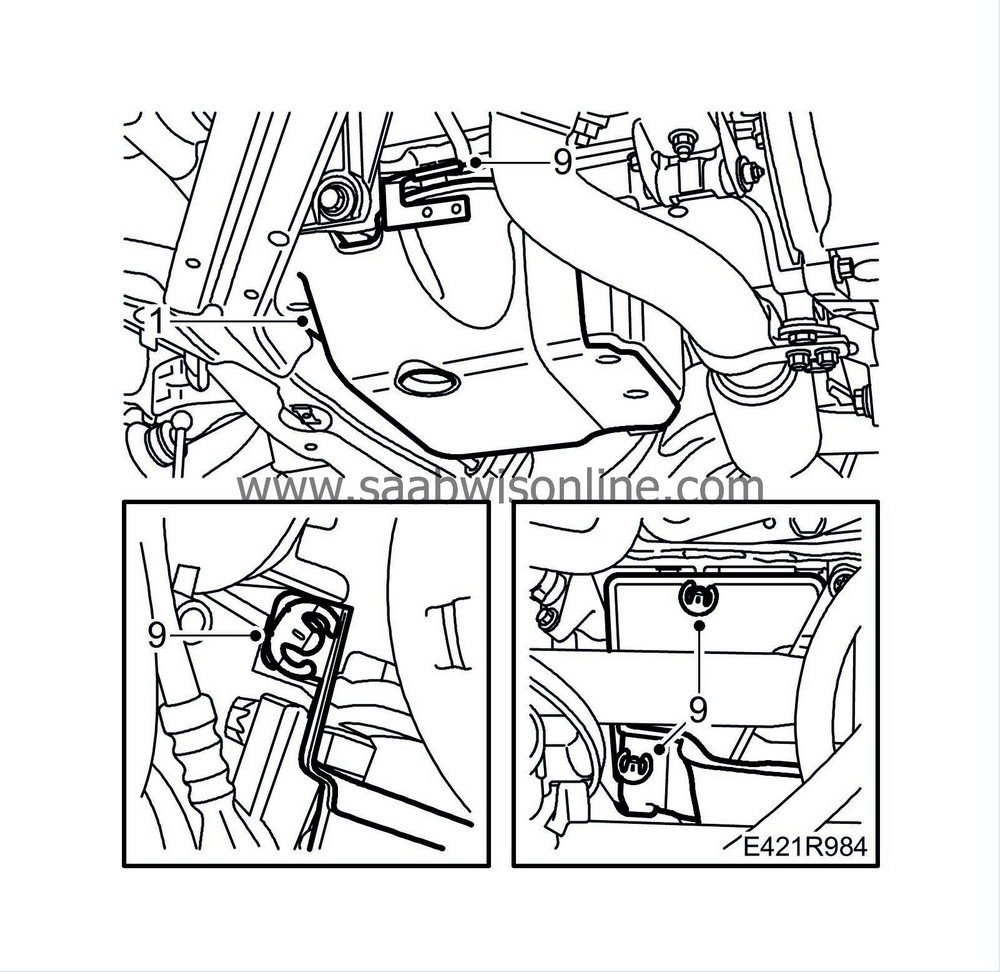

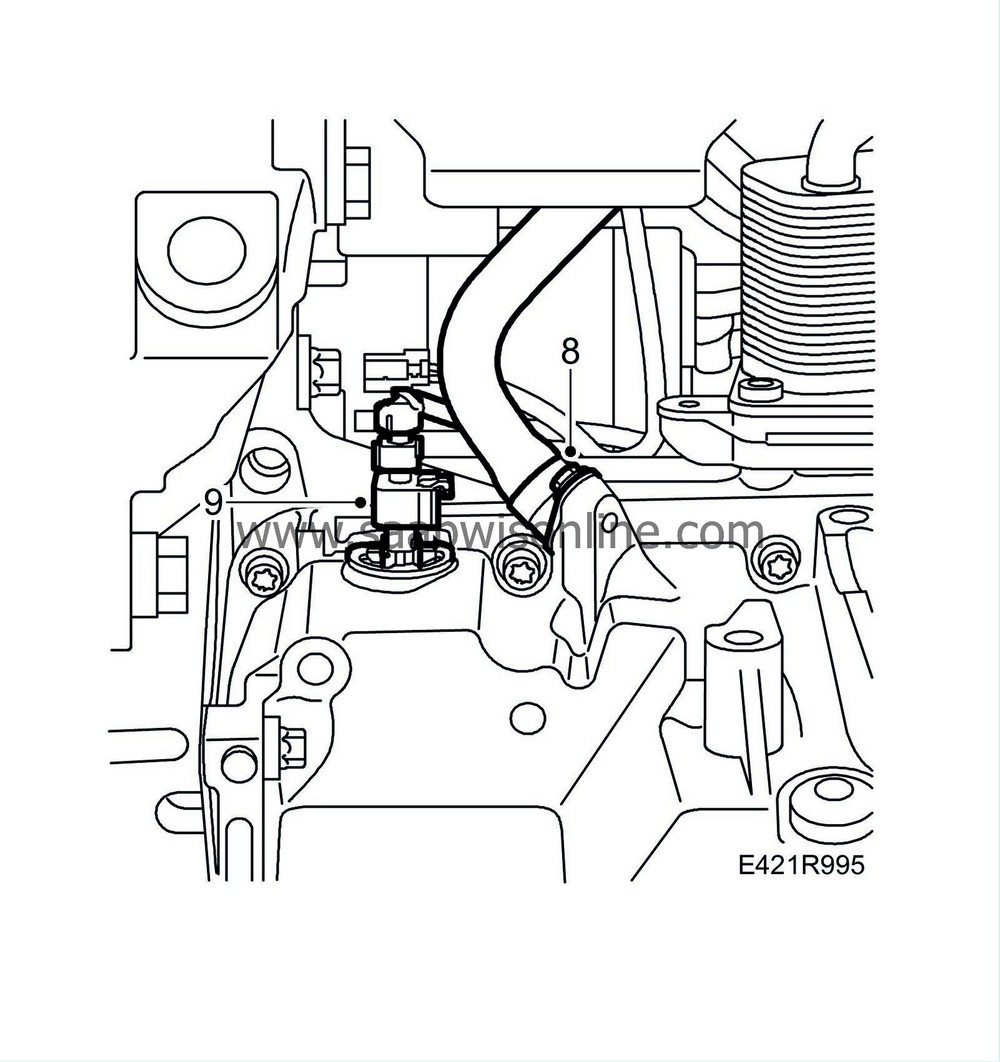

| 9. |

Remove the oil sump insulation. Unscrew the clips holding the insulation in place.

|

|

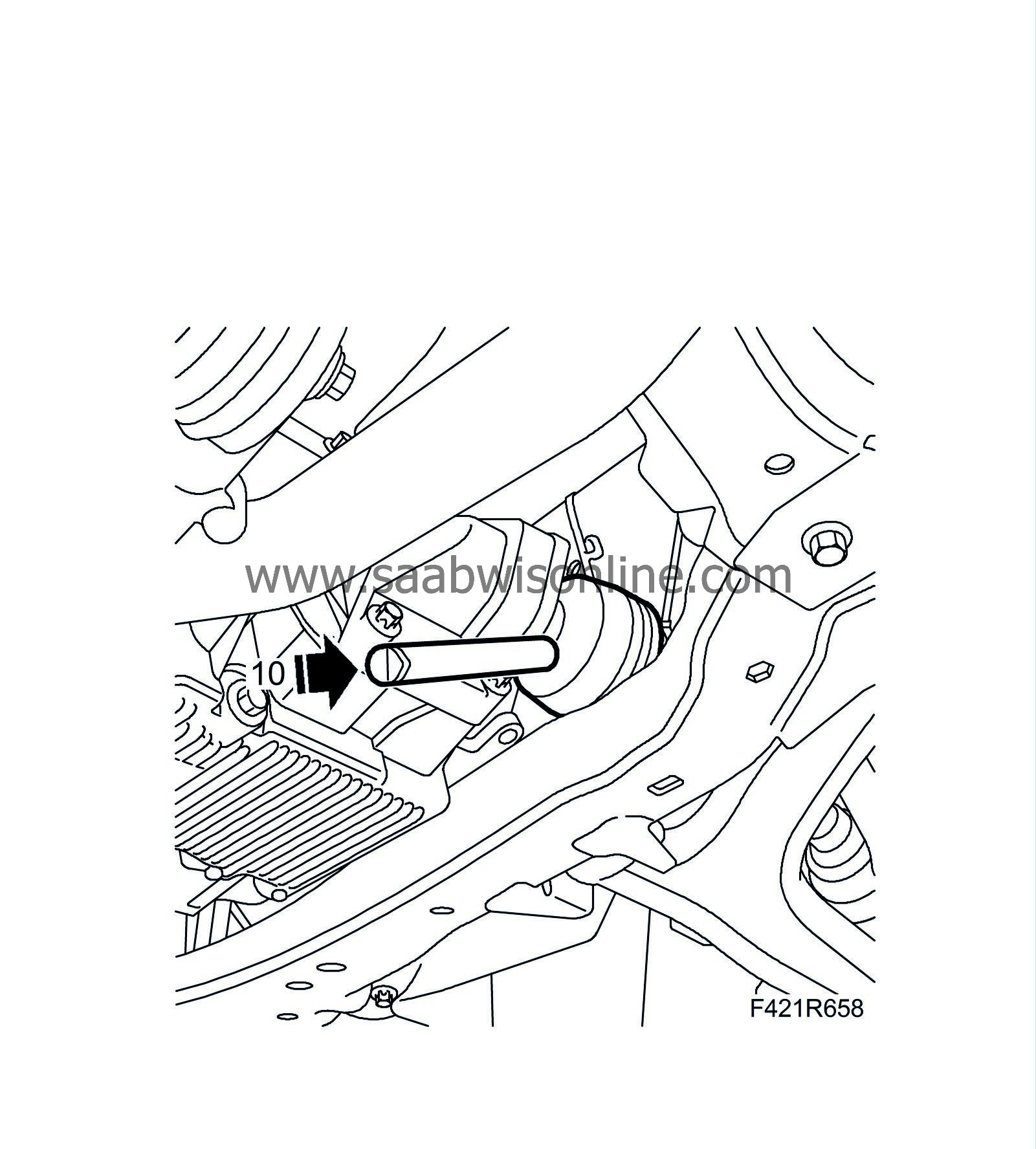

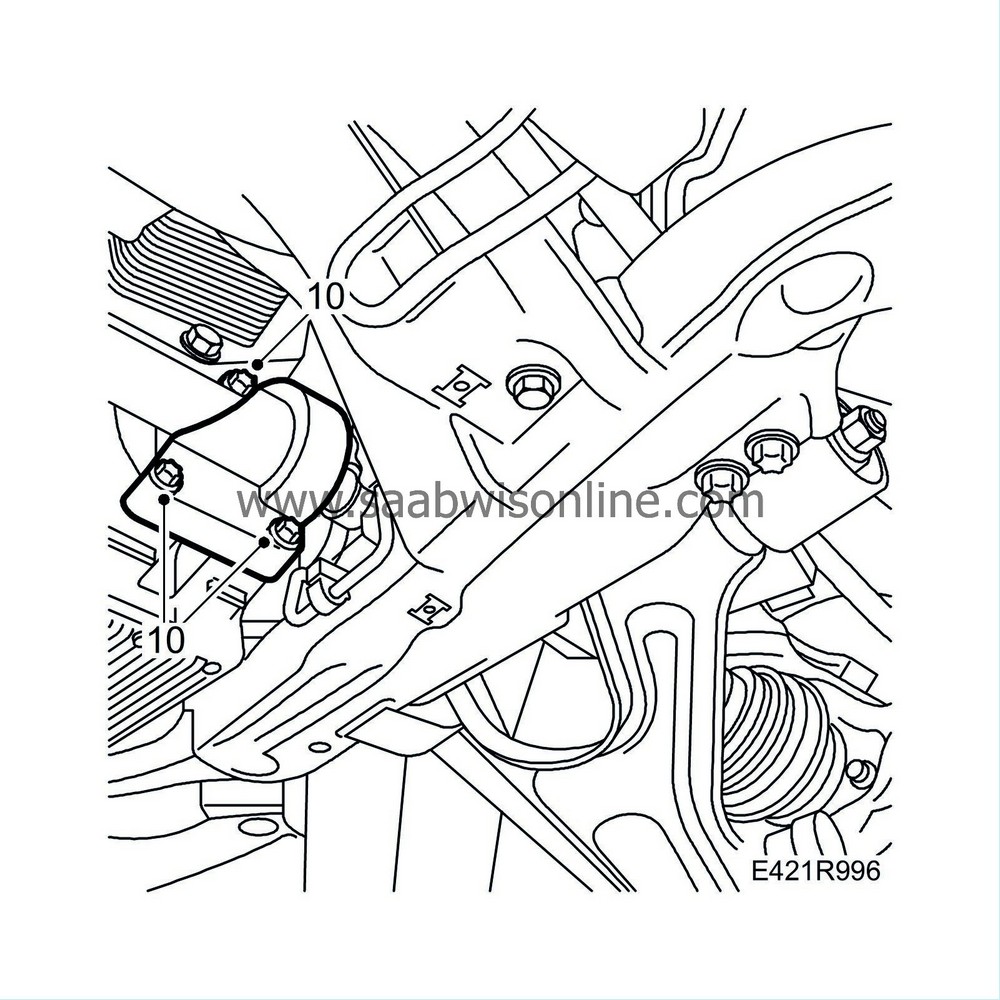

| 10. |

Remove the front exhaust pipe.

|

|

| 11. |

Remove the lower mounting of the front catalytic converter.

|

|

| 12. |

Position a receptacle under the car and drain the engine oil.

|

|

| 13. |

Fit the oil plug with a new seal.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 14. |

Drain the transmission fluid.

|

|

| 15. |

Fit the gearbox oil plug using a new seal.

Tightening torque: 25 Nm (18 lbf ft) |

|

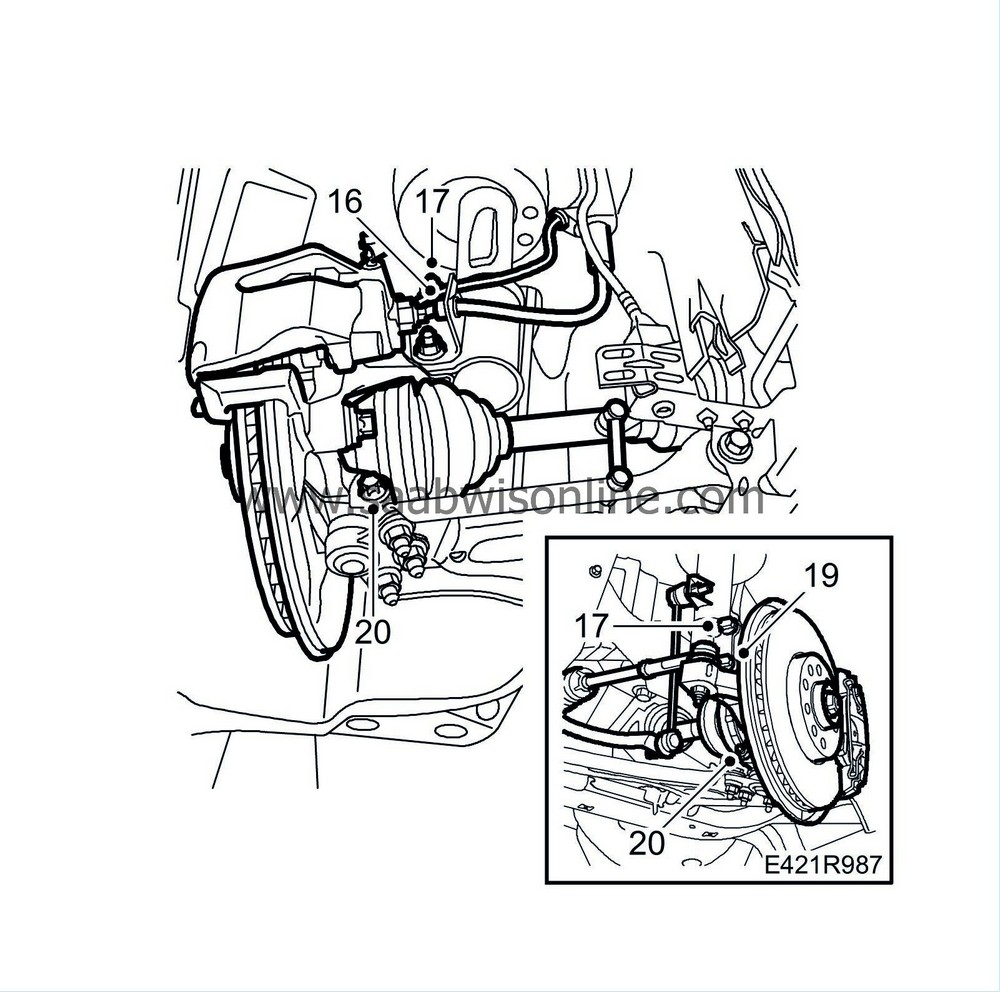

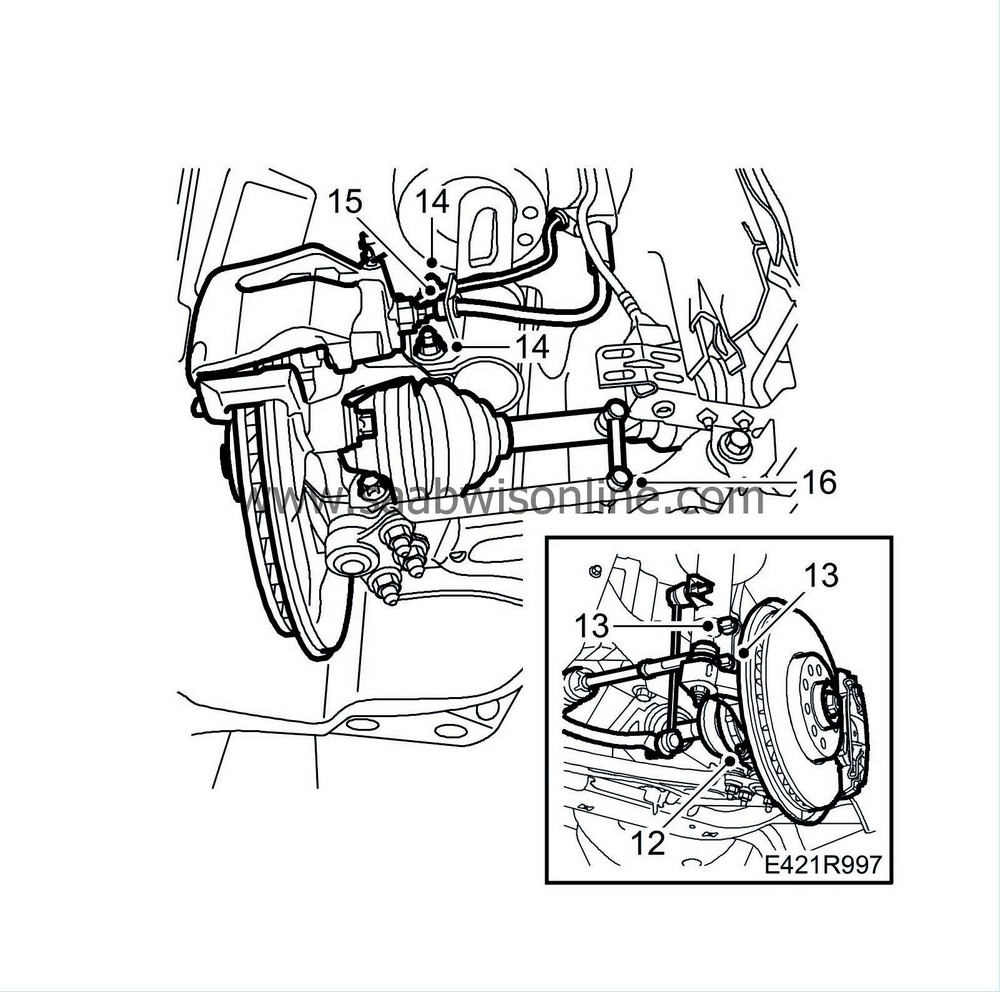

| 16. |

Undo the clips of the brake hose and move it aside. Undo the clips of the ABS cable.

|

|

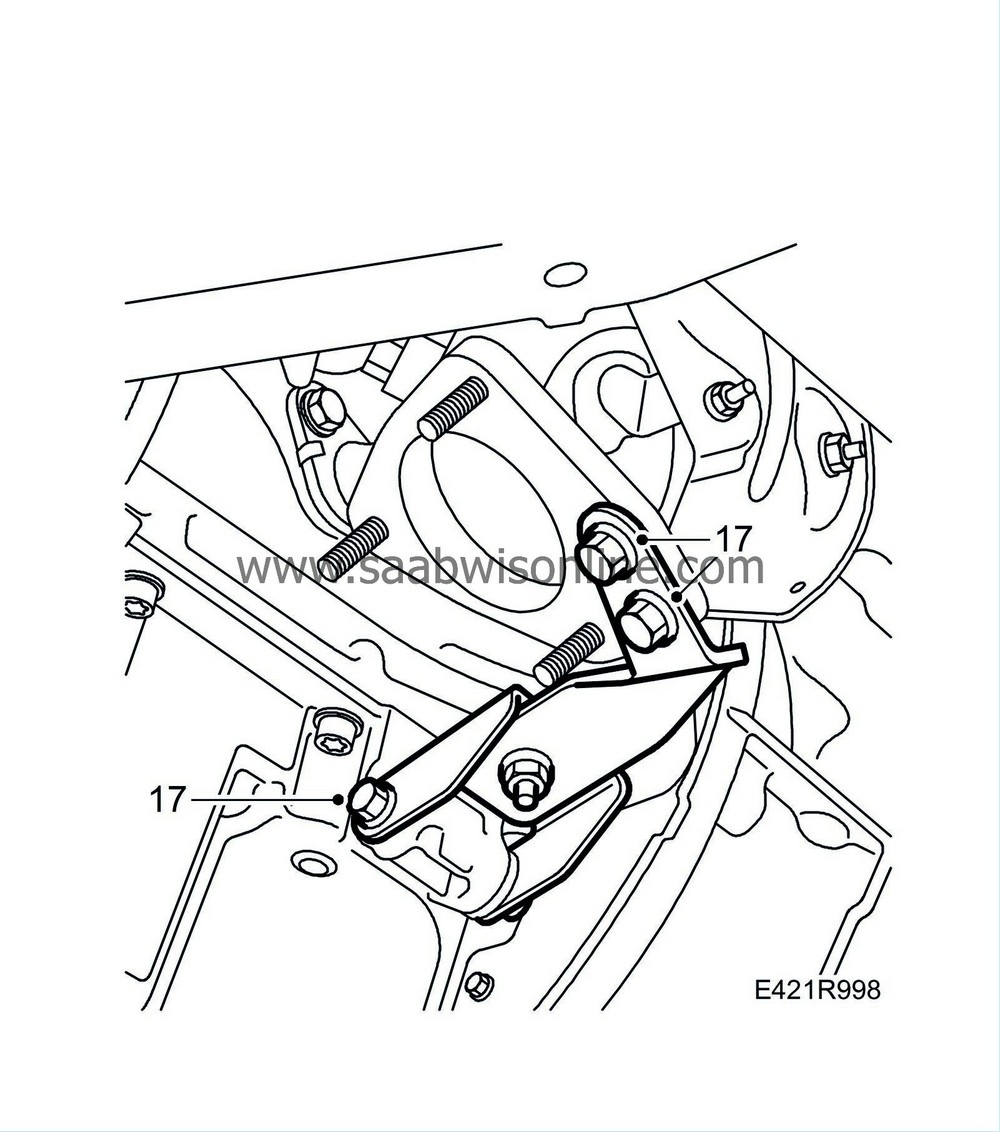

| 17. |

Remove the upper bolt of the steering swivel member. Hold the bolt and remove the nut.

|

|

| 18. |

Tap out the bolt. A new bolt will be used for installation.

|

|||||||

| 19. |

Undo the lower nut slightly and move the steering swivel member out slightly.

|

|

| 20. |

Remove the suspension arm's outer lead-through bolt from the steering swivel member. Prise loose the suspension arm, move it down and secure it in that position using two

83 95 238 Wedge

that are placed between the suspension arm and the anti-roll bar.

|

|

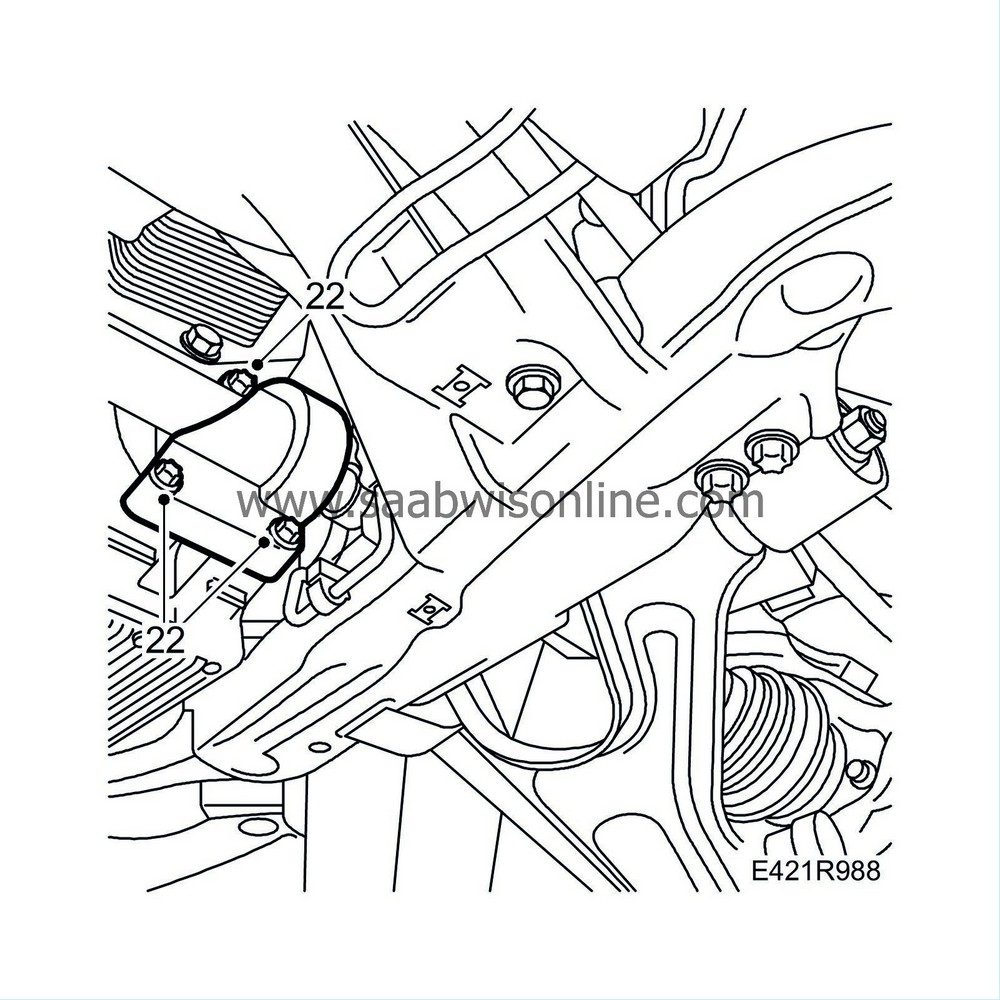

| 22. |

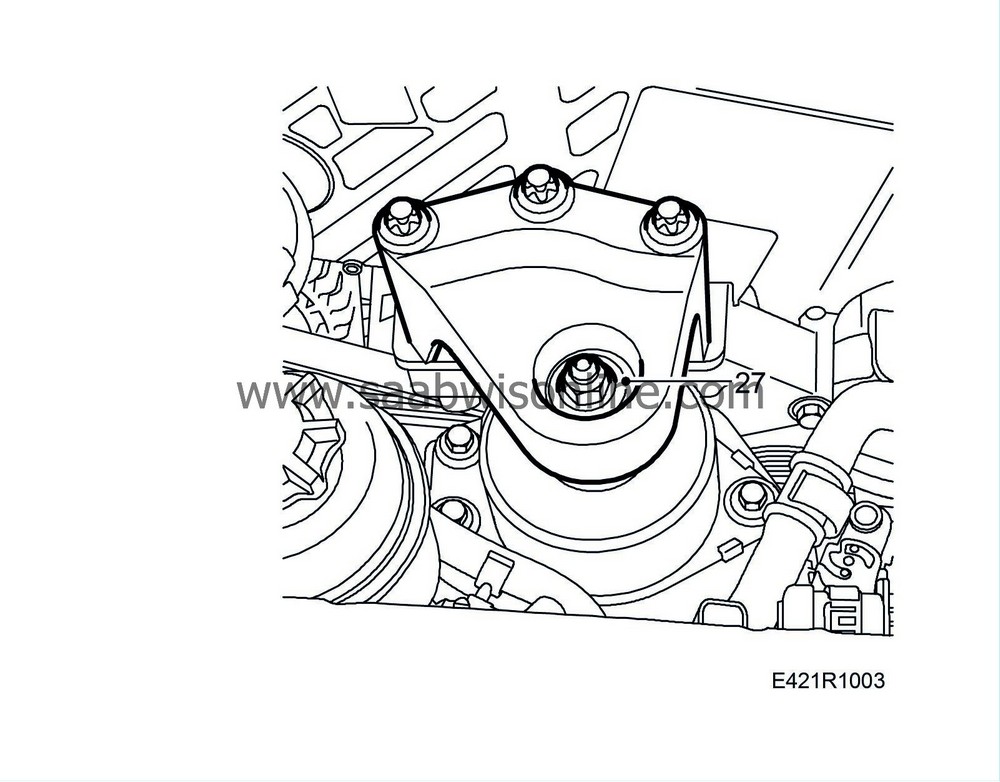

Remove the bearing pedestal bolts. Pull the intermediate shaft out of the gearbox. Plug the gearbox with

87 92 665 Protective plug, drive shaft hole

.

|

|

| 23. |

Unplug the oil level sensor connector.

|

|

| 24. |

Detach the crankcase ventilation hose from the oil sump.

|

|

| 25. |

Remove the lower bolts of the A/C compressor bracket.

|

|

| 26. |

Screw back the spacer sleeves in the A/C compressor bracket.

|

|

| 27. |

Raise the dipstick guide tube out of the oil sump.

|

|

| 28. |

Aut:

Remove the cover.

|

|

| 29. |

Remove the oil sump bolts. Use

32 025 015 Extension rib M7

and

32 025 016 Extension rib M8

. Use the first behind the flywheel.

|

|

| 30. |

Use EN-47631 on the bolts behind the pulley.

|

|

| 31. |

Man:

The engine must be turned so that the recess in the flywheel aligns with the bolts.

|

|

| 32. |

Position a screwdriver between the oil sump and the timing cover at the A/C compressor bracket and carefully prise away the oil sump.

|

|

| 33. |

Position a gearbox lift under the A/C compressor bracket and raise the engine approx. 40 mm. Turn the sump one quarter turn and lower it.

|

|

| To fit |

| 1. |

Clean the sealing surfaces of the cylinder block and sump. Clean away any contaminants in the oil sump.

|

|

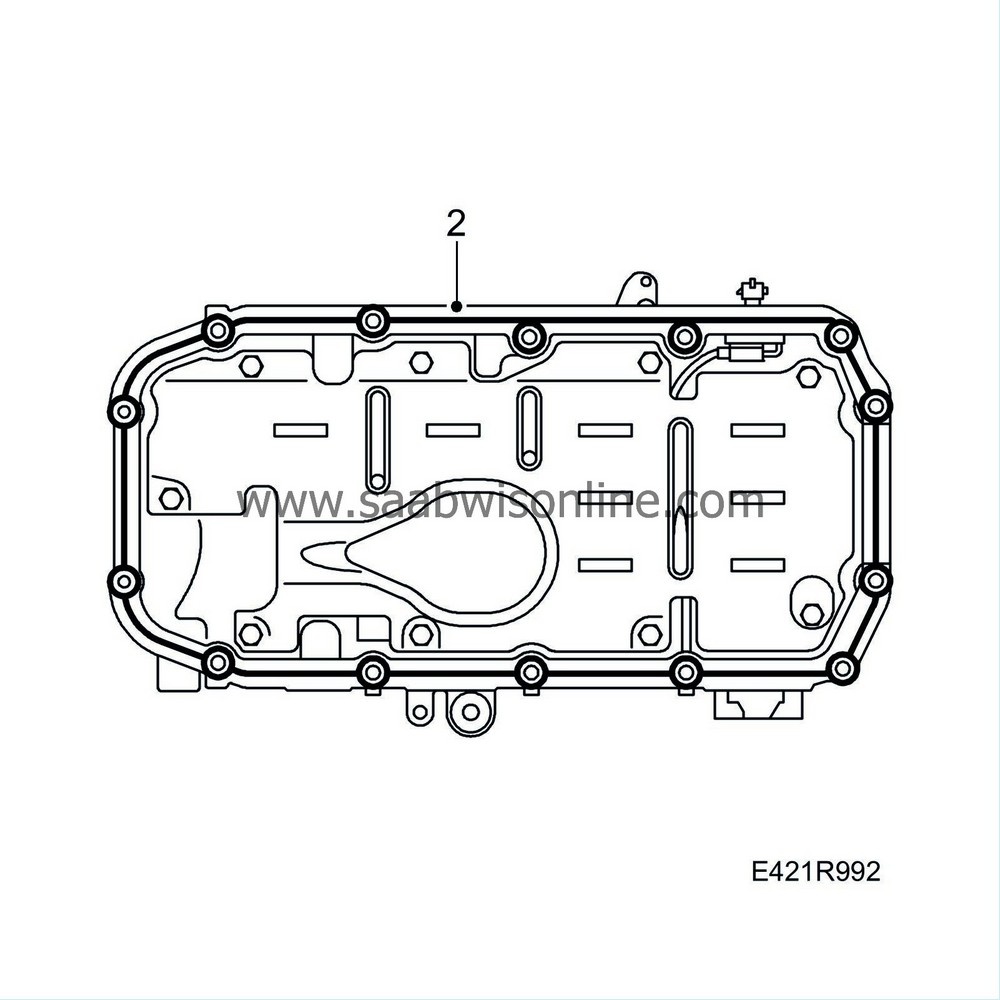

| 2. |

Apply a bead of

90 543 772 Silicone flange sealant

on the oil sump sealing surface.

|

|

| 3. |

Use a gearbox lift to raise the engine approx. 40 mm and fit the oil sump, being careful not to scrape away the sealing compound.

Tightening torque, M6 bolts: 9 Nm (7 lbf ft) Tightening torque, M8 bolts: 25 Nm (18 lbf ft) Tightening torque, gearbox bolts: 40 Nm (30 lbf ft)

|

|

| 4. |

Aut:

Fit the cover.

|

|

| 5. |

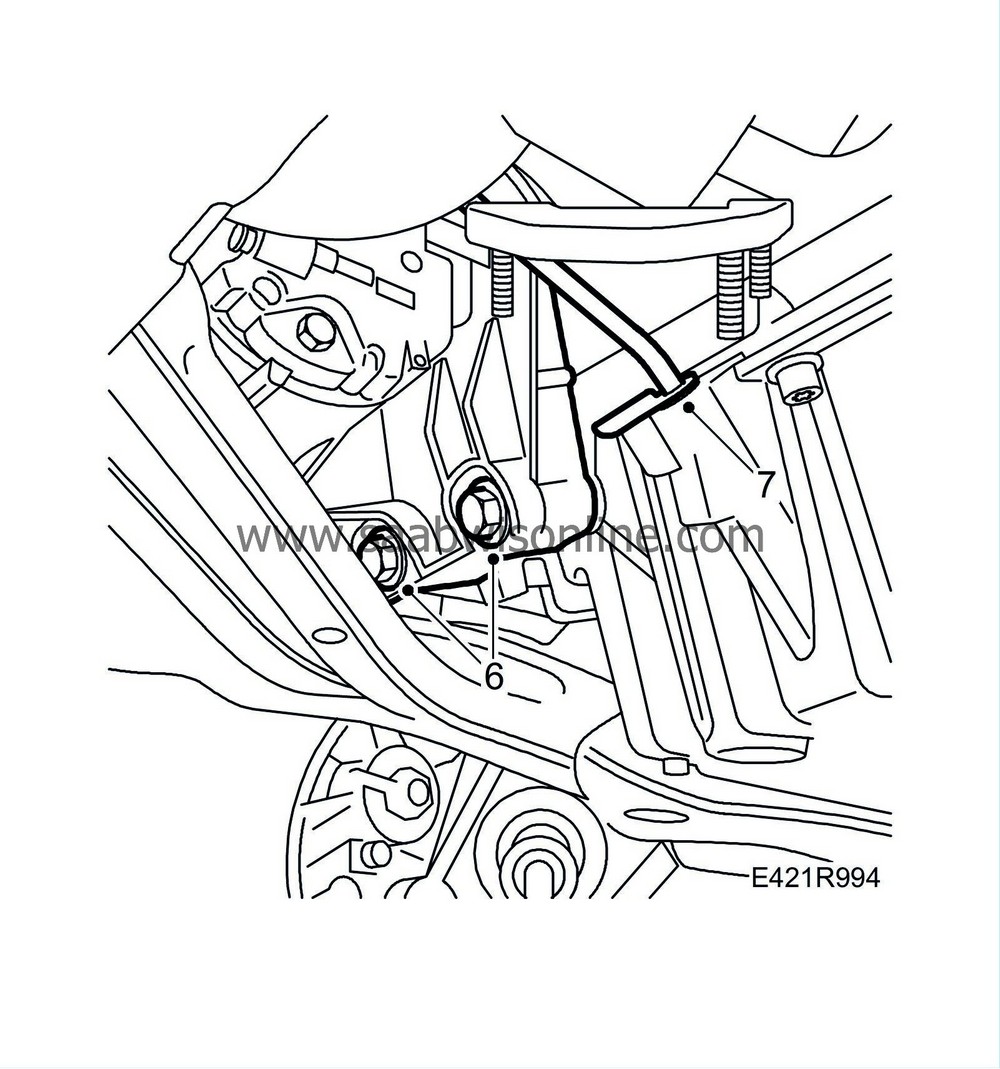

Screw in the spacer sleeves in the A/C compressor bracket until they lie against the oil sump.

|

|

| 6. |

Fit the lower bolts of the A/C bracket.

Tightening torque: 47 Nm (35 lbf ft)

|

|

| 7. |

Insert the dipstick guide tube in the oil sump.

|

|

| 8. |

Attach the crankcase ventilation hose to the oil sump.

|

|

| 9. |

Plug in the oil level sensor connector.

|

|

| 10. |

Remove the plug and insert

83 95 162 Protective collar, drive shafts

in the shaft seal. Insert the intermediate shaft in the gearbox until about 20 mm remains. Pull away the collar and insert the rest of the intermediate shaft. Fit the bearing pedestal bolts.

Tightening torque: 50 Nm (37 lbf ft)

|

|

| 11. |

Move out the McPherson strut and connect the drive shaft to the intermediate shaft until the circlip engages. Lubricate with

90 513 210 Universal paste

.

|

|

| 12. |

Remove the wedges, reposition the suspension arm and connect it to the steering swivel member. Fit and tighten the nut to torque.

Tightening torque: 50 Nm (37 lbf ft) |

|

| 13. |

Attach the steering swivel member to the MacPerson strut using a new bolt. Hold the bolt in place and fit the nut.

|

|||||||

| 14. |

Tighten both nuts.

Tightening torque: 100 Nm +90° (74 lbf ft +90°) |

|

| 15. |

Fit the brake hose in the mounting on the steering swivel member and fit the lock clips. Connect the ABS cable.

|

|

| 16. |

Fit the headlamp position sensor (option)

|

|

| 17. |

Fit the lower mounting of the pre-catalytic converter.

Tightening torque: 25 Nm (18 lbf ft)

|

|

| 18. |

Fit the front exhaust pipe using new gaskets.

Tightening torque: 25 Nm (18 lbf ft)

|

|

| 19. |

Fit the oil sump insulation with the bolt and clips.

|

|

| 20. |

Lower the car slightly and fit the right side cover.

|

|

| 21. |

Plug in the connector of the headlamp position sensor (option).

|

|

| 22. |

Fit the right front wheel. See

Wheels

.

|

|

| 23. |

Lower the car to the floor.

|

|

| 24. |

Fit the upper retaining bolt of the dipstick guide tube.

|

|

| 25. |

Fit the turbo's intake pipe.

|

|

| 26. |

Fit the crankcase ventilation hose.

|

|

| 27. |

Fit the nut of the right engine pad.

Tightening torque, up to and including Vehicle Identification Number 73514907: 84 Nm (62 lbf ft) Tightening torque, from and including Vehicle Identification Number 73514908: 74 Nm (55 lbf ft)

|

|

| 28. |

Fill with engine oil. See

Lubricating system

.

|

|

| 29. |

Fit the insulation and upper engine cover.

|

|

| 30. |

Fill with transmission fluid. See

List of lubricants and sealing compounds

.

|

|

Warning

Warning