Checking for leaks in the evaporative emission system

|

|

Checking for leaks in the evaporative emission system

|

|

1.

|

The shut-off valve should still be active.

|

|

2.

|

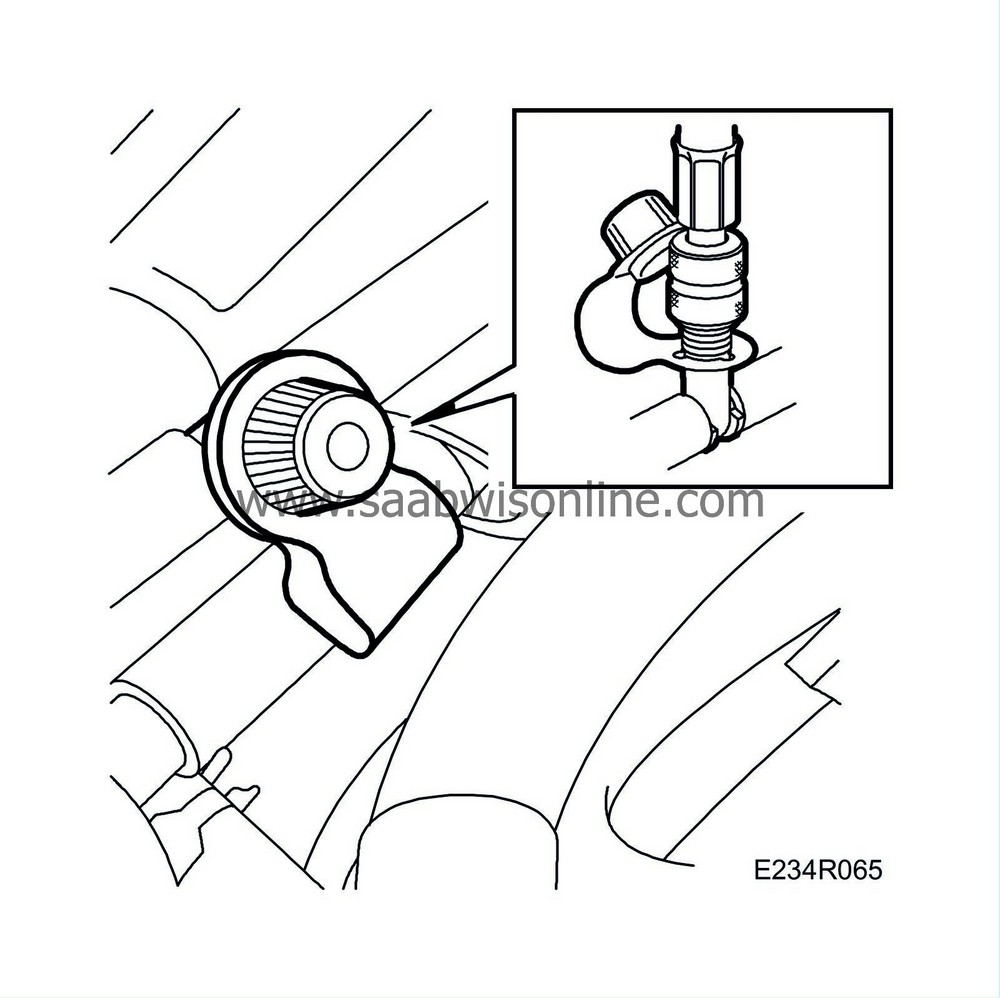

Disconnect the line from the EVAP canister purge valve at the intake manifold.

|

|

3.

|

Pressurize the system further as described in the Kent-Moore manual.

|

|

4.

|

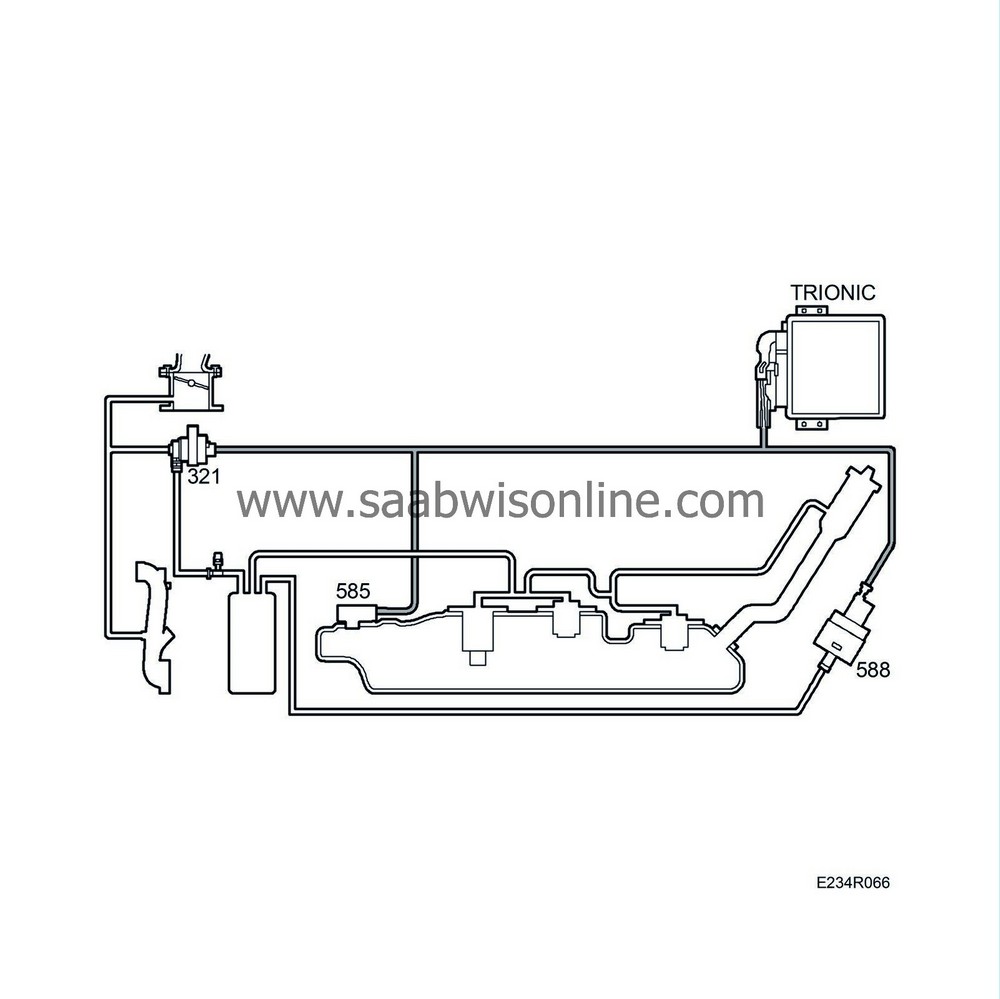

Locate leaks with the Ultrasonic Leak Detector J41416. Start at the line that has been disconnected from the intake manifold and then continue along the lines and components of the system. Perform a visual inspection of the system at the same time.

|

Note

|

|

It may be necessary to lower the tank slightly in order to detect leaks in components on top of the tank.

|

|

Note

|

|

The leak detector's ultrasonic equipment is sensitive to surrounding noise such as extractors, pneumatic machinery, air jets, leaking air hoses, etc.

|

|

The ventilation system in the workshop may also create air currents that can affect the equipment.

|

|

All of the above may cause a similar but misleading reading/detection as would a leak in the EVAP system.

|

|

|

5.

|

Regulate the sensitivity of the leak detector to filter out the surrounding and, in many cases, disturbing noise.

|

Note

|

|

A major leak, such as a defective shut-off valve or loose line, is difficult to detect as it will not emit the ”correct sound” for detection with the ultrasonic equipment.

|

|

Therefore, it is important to conduct a careful visual inspection and component check of the system in case of leaks with no noise.

|

|

|

6.

|

Once a leak has been detected, it must be rectified and a new test made of the system integrity.

|

|

7.

|

Restore the car to its original state.

|