Pistons with connecting rods (in situ)

|

|

Pistons with connecting rods (in situ)

|

|

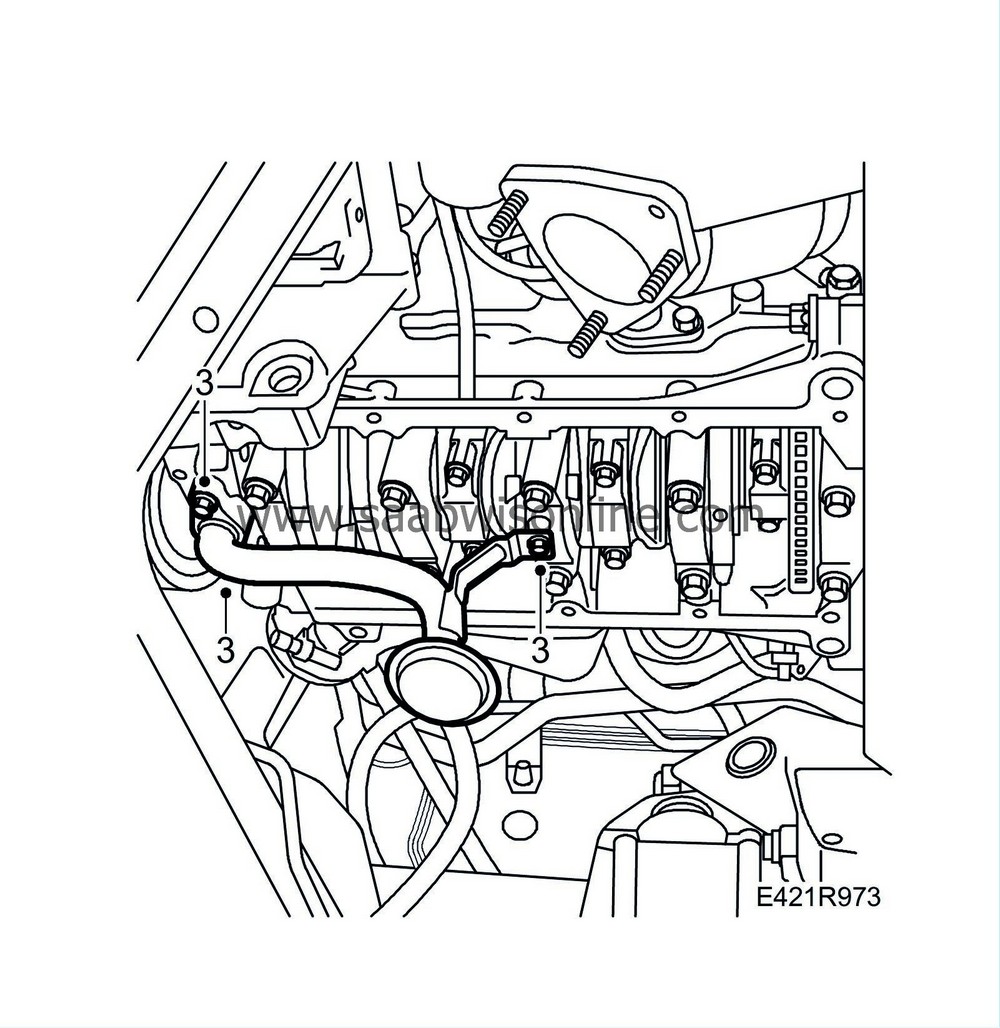

3.

|

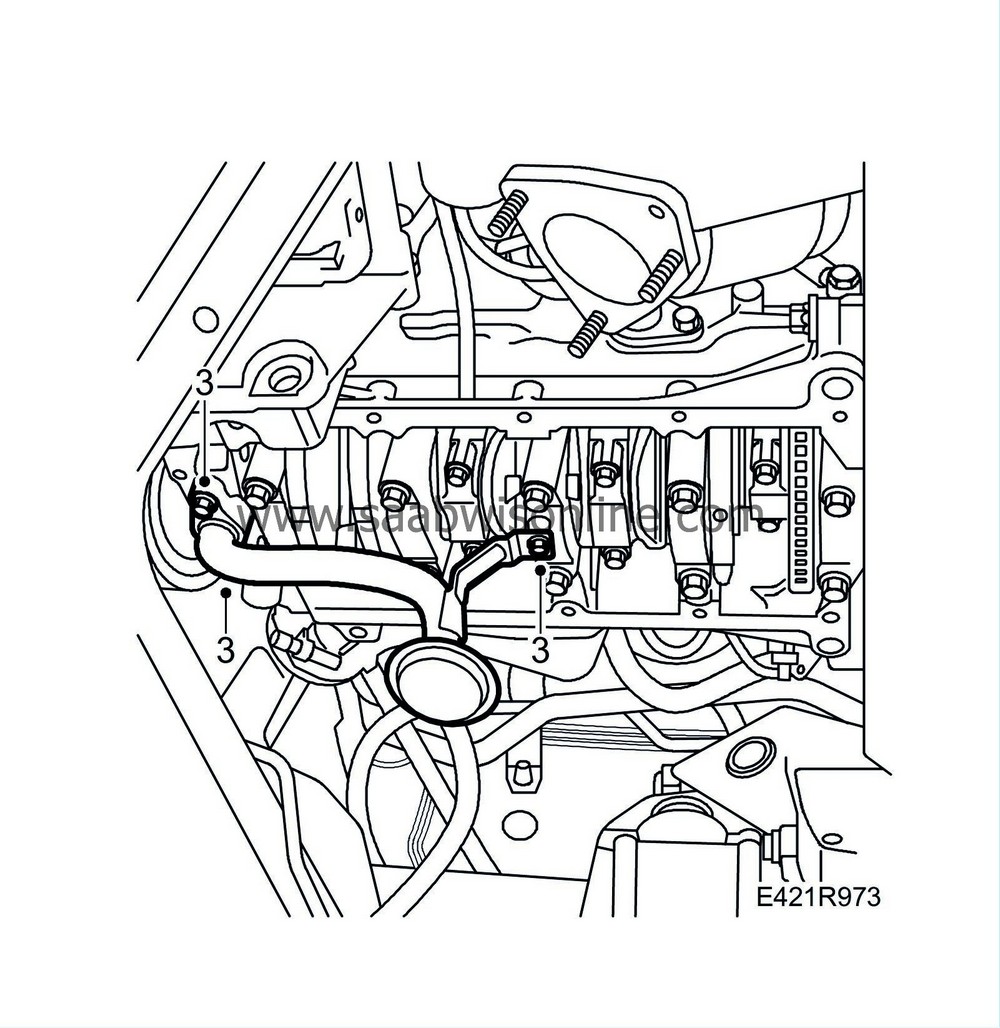

Remove the oil suction pipe.

|

|

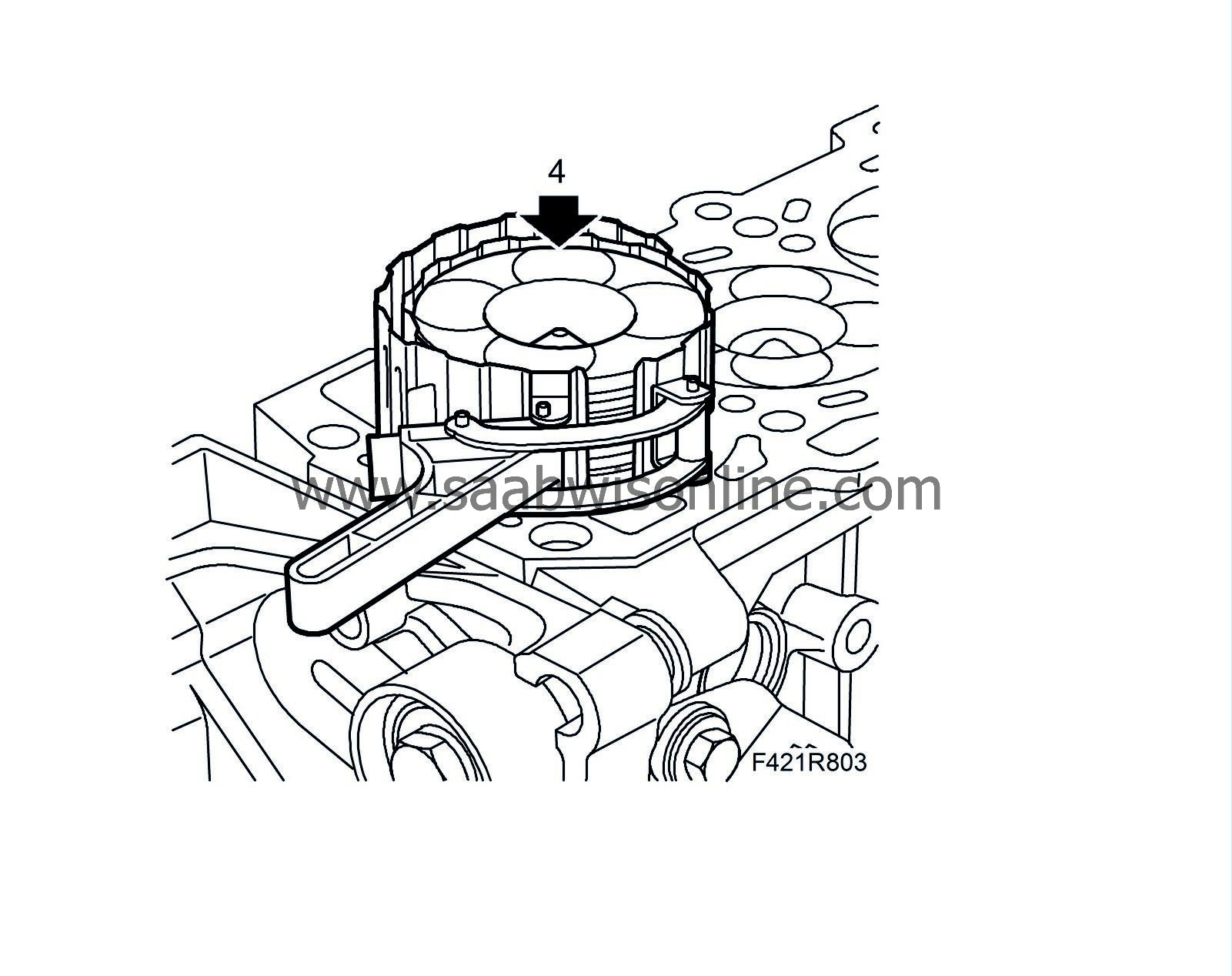

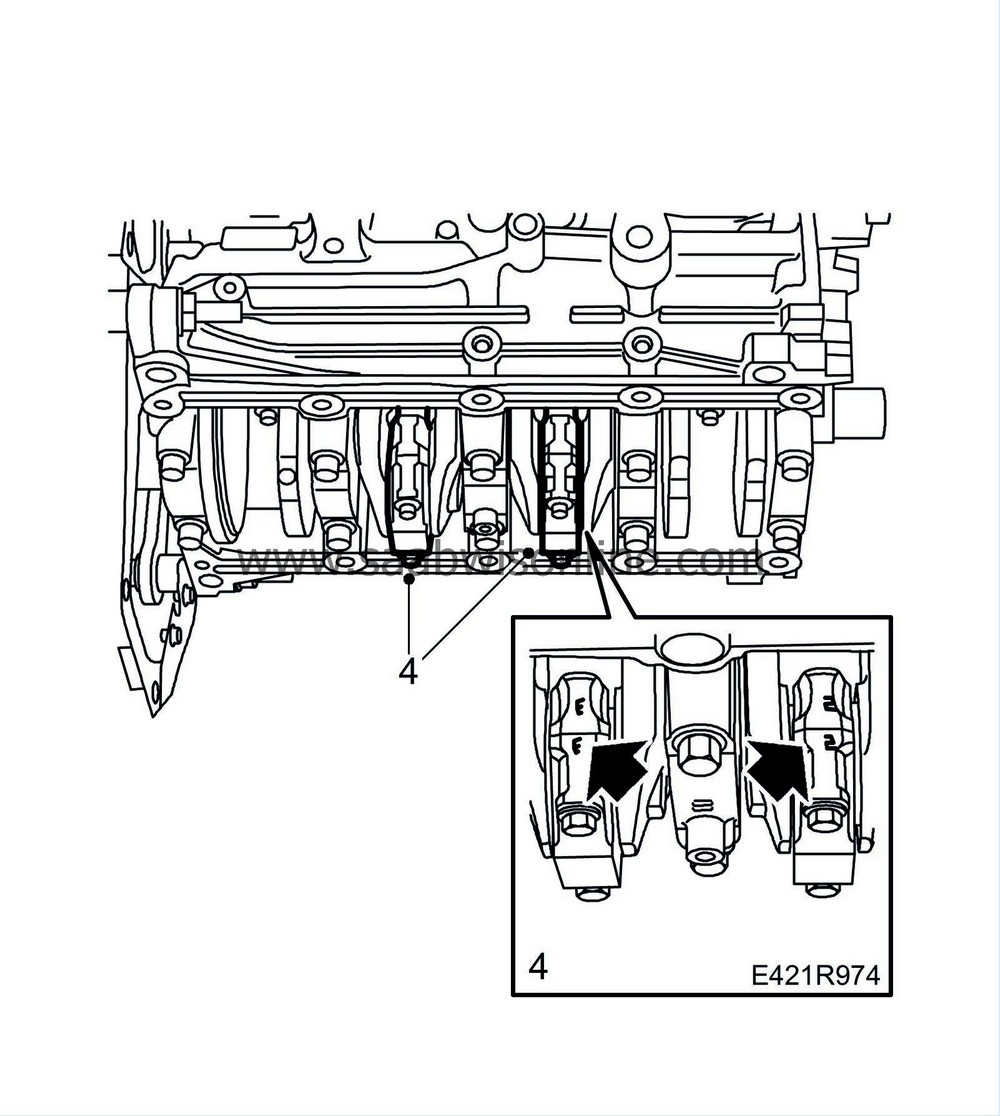

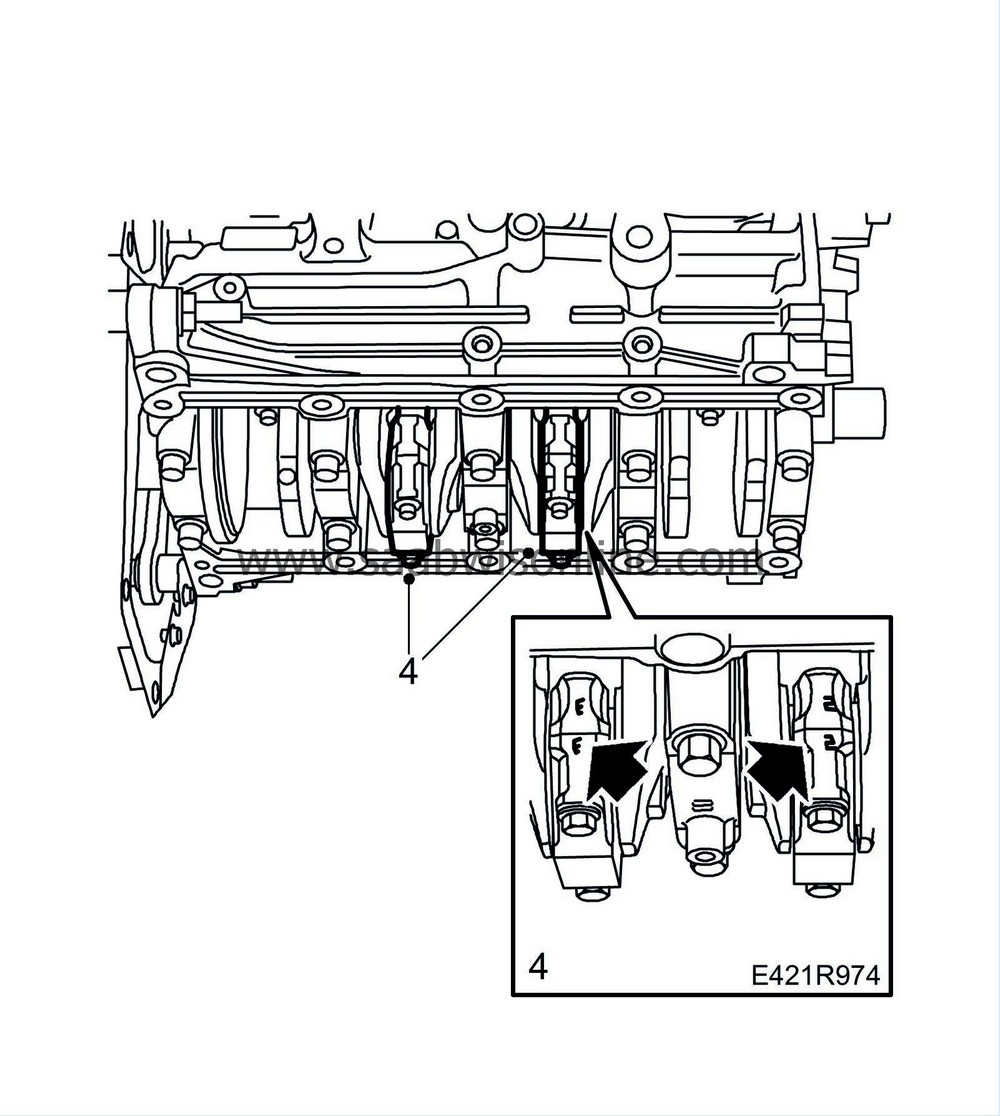

4.

|

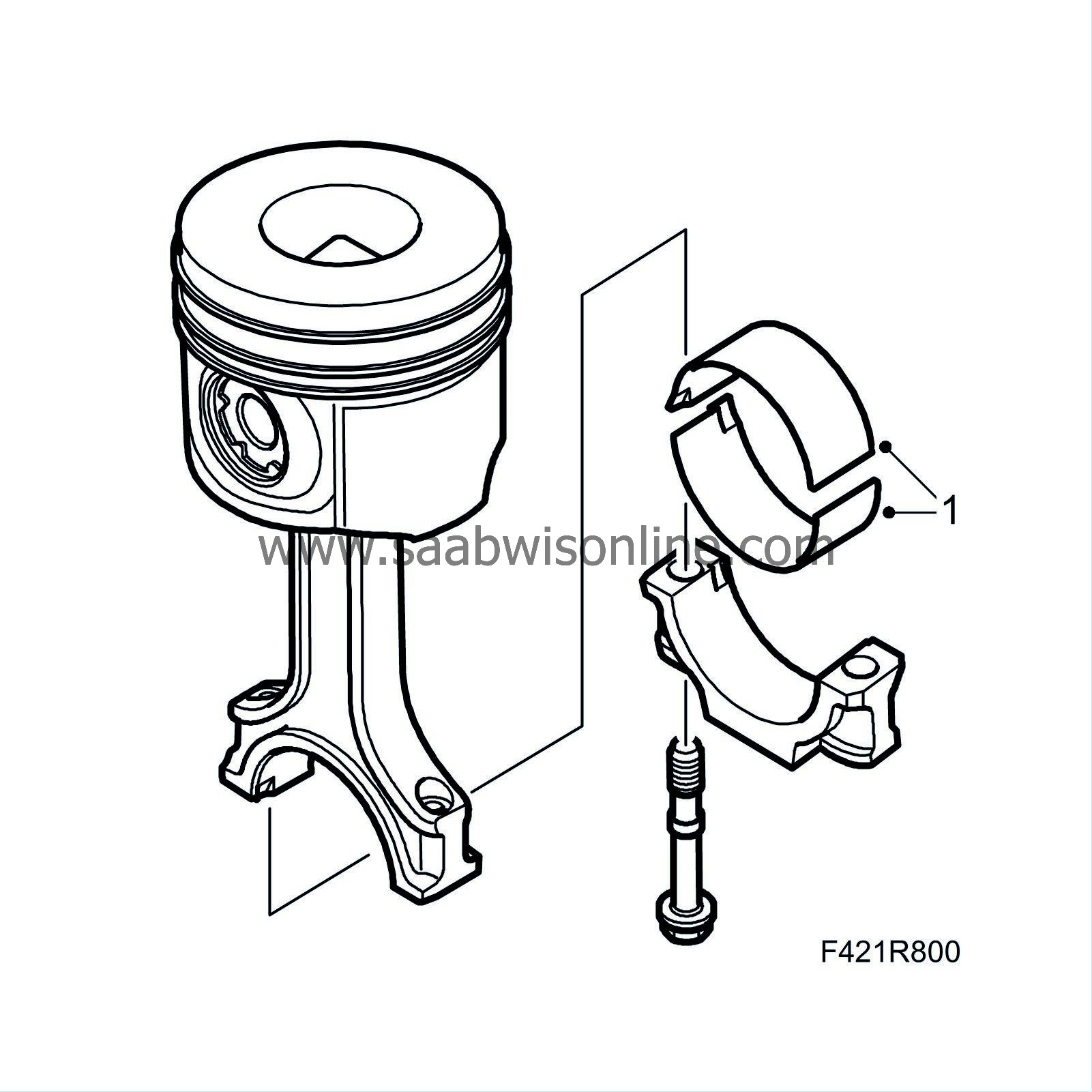

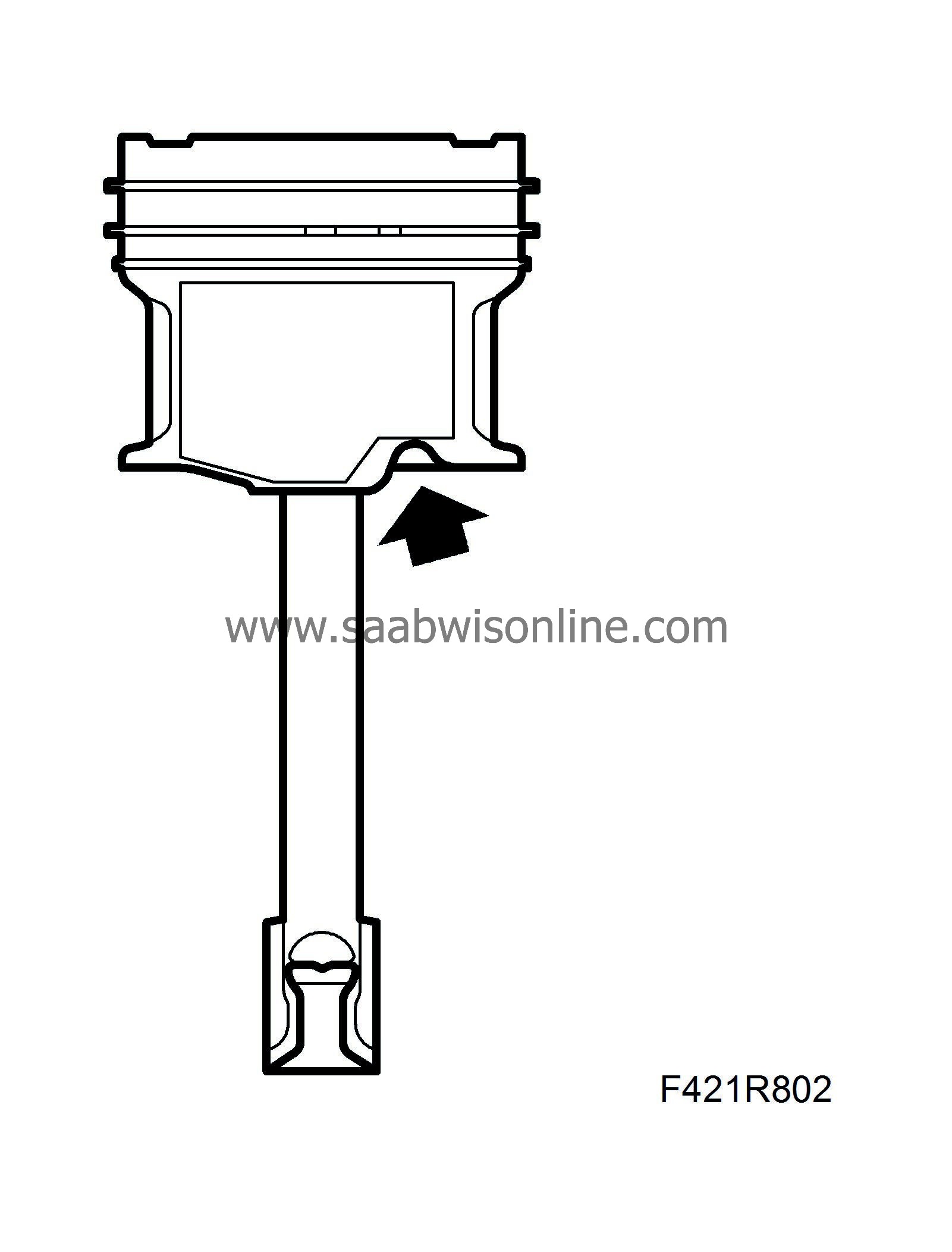

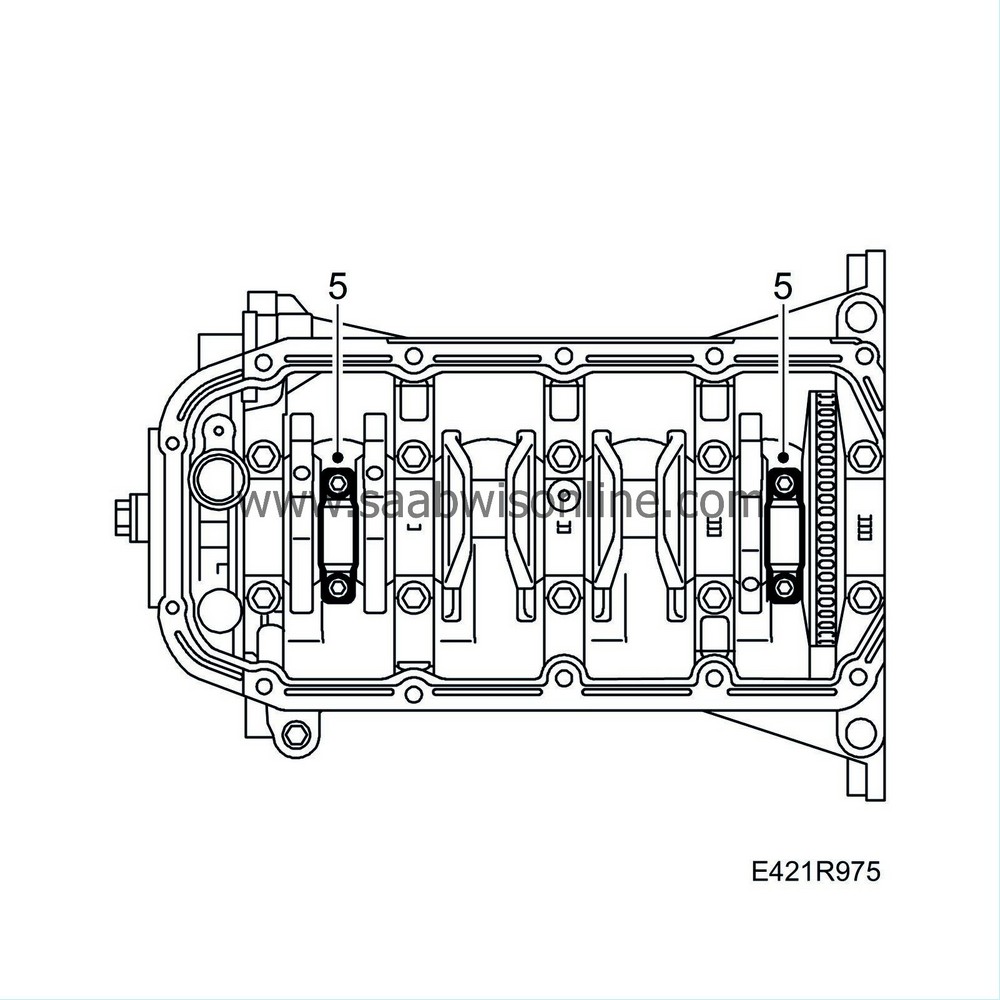

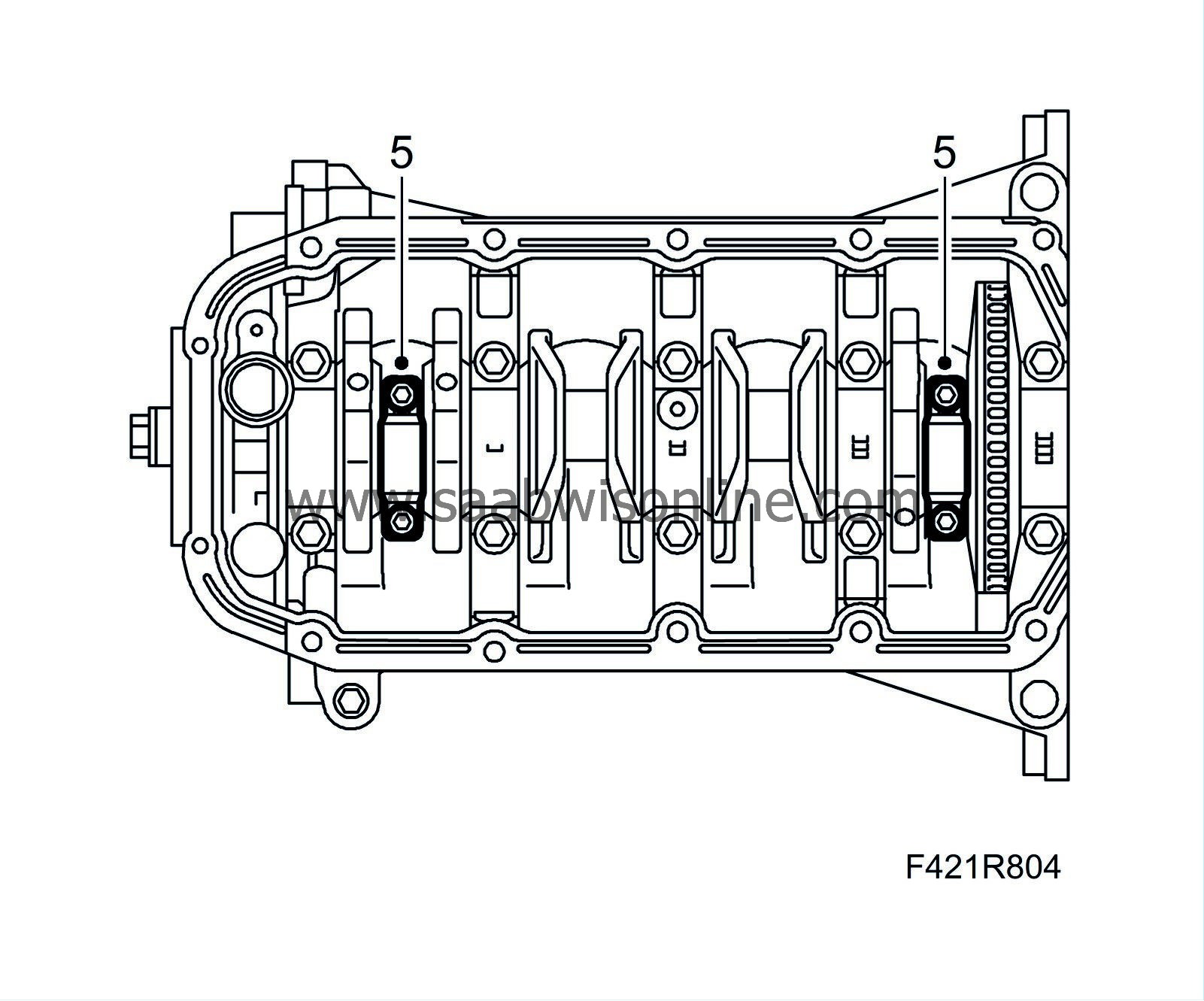

Note the marking on the connecting rods and bearing caps so that the can be refitted in their original spots. Remove the connecting rod bearing caps. Push the pistons and connecting rods up from the cylinder bore of cylinders 2 and 3.

|

|

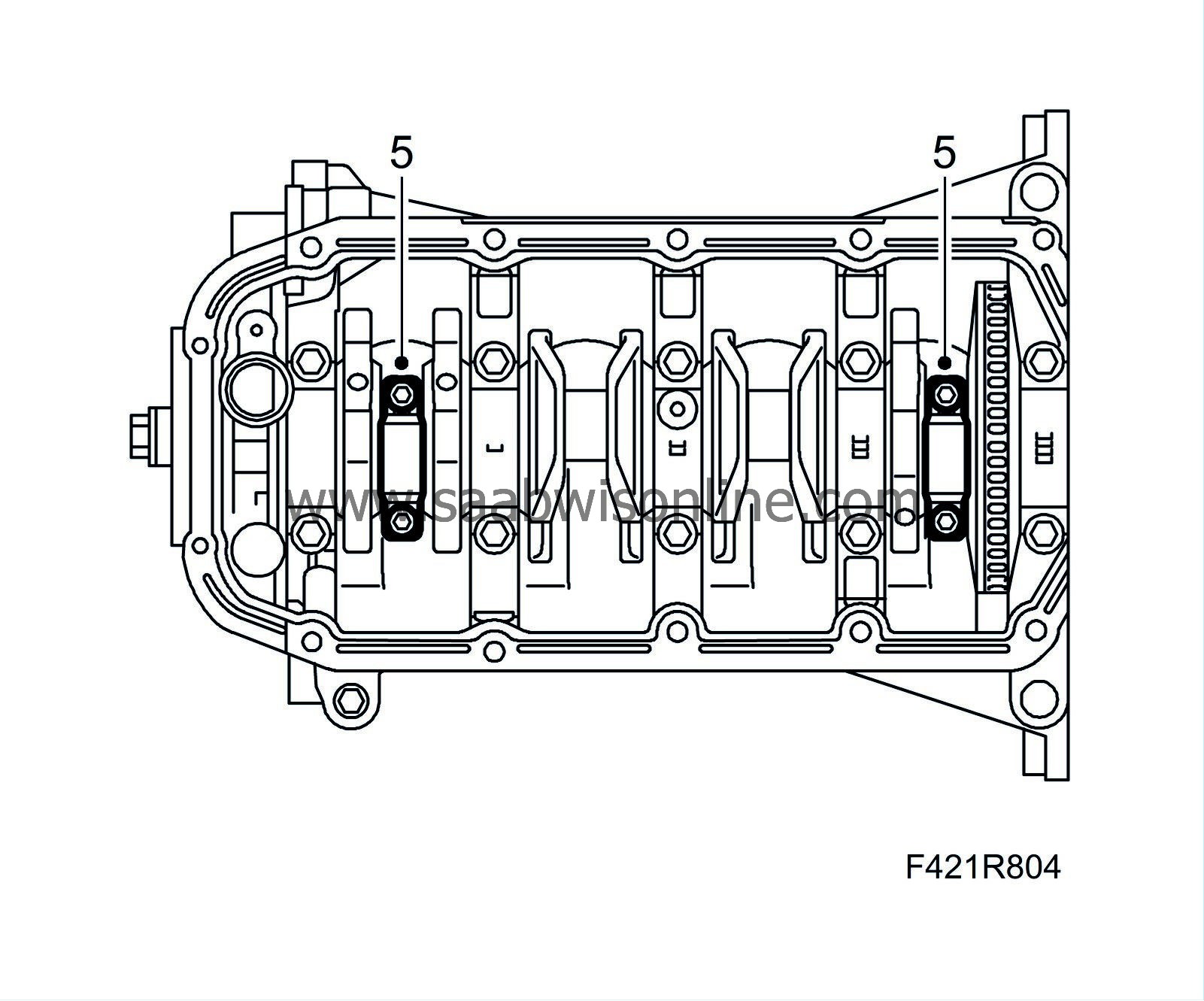

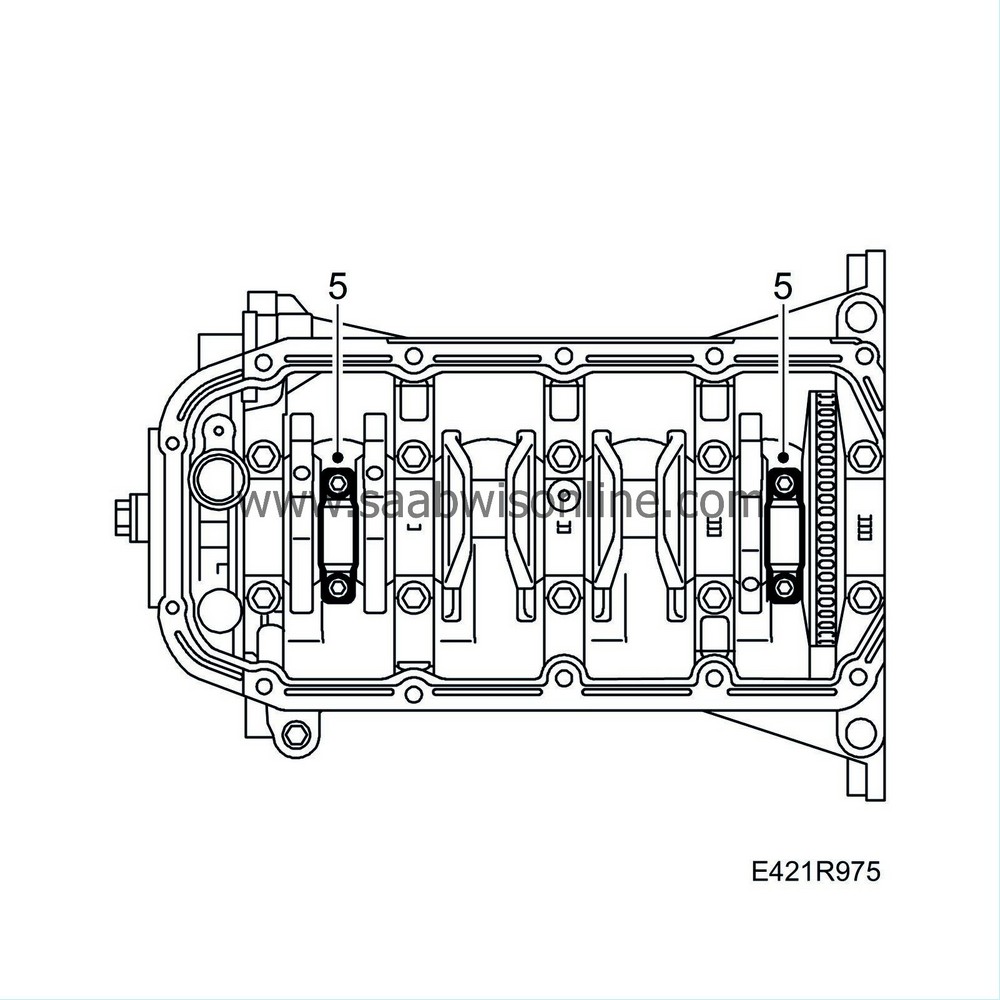

5.

|

Turn the crankshaft 1/2 turn. Note the marking on the connecting rods and bearing caps so that the can be refitted in their original spots. Remove the connecting rod bearing caps. Push the pistons and connecting rods up from the cylinder bore of cylinders 1 and 4.

|

|

1.

|

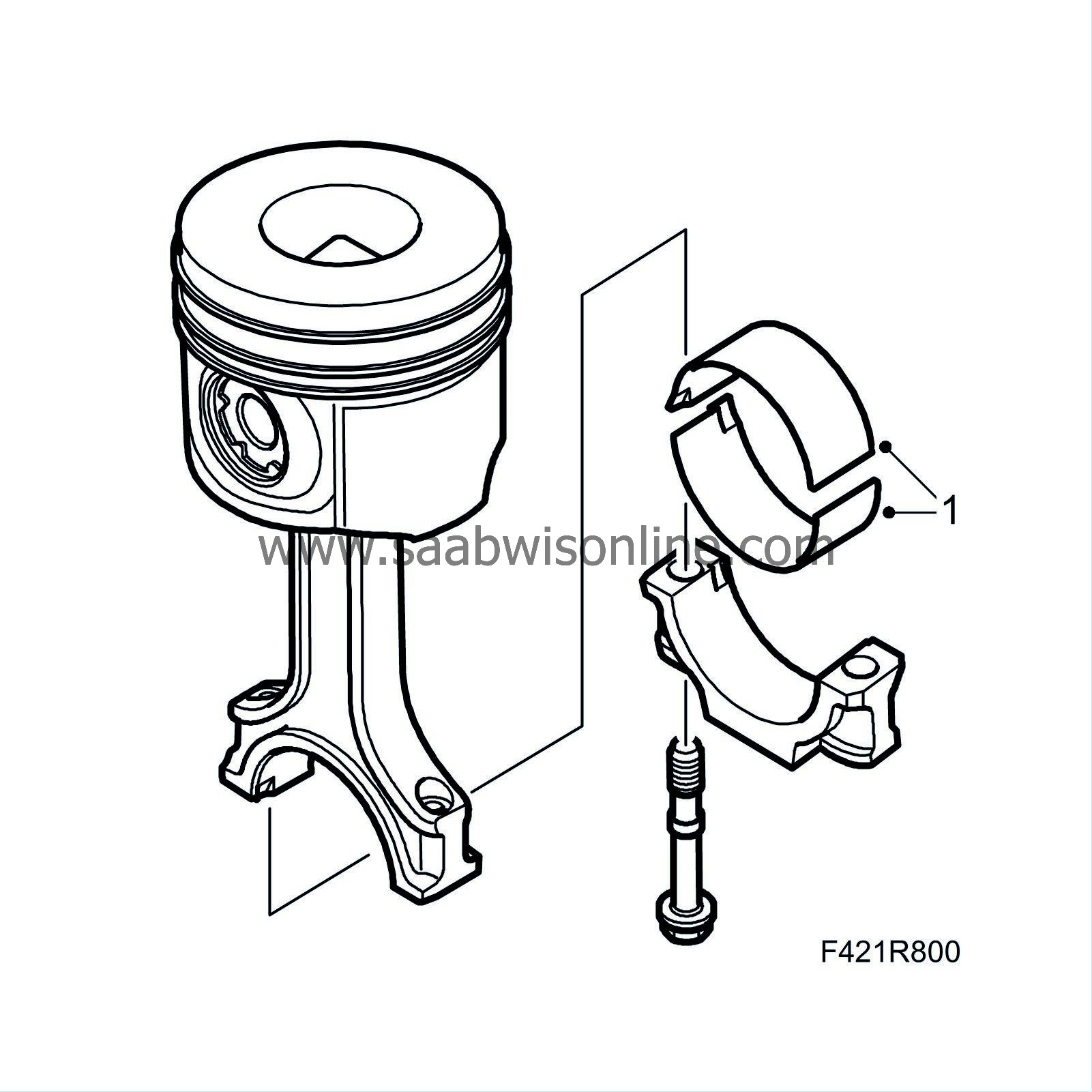

Fit the bearing shells in the connecting rod and bearing cap.

|

|

2.

|

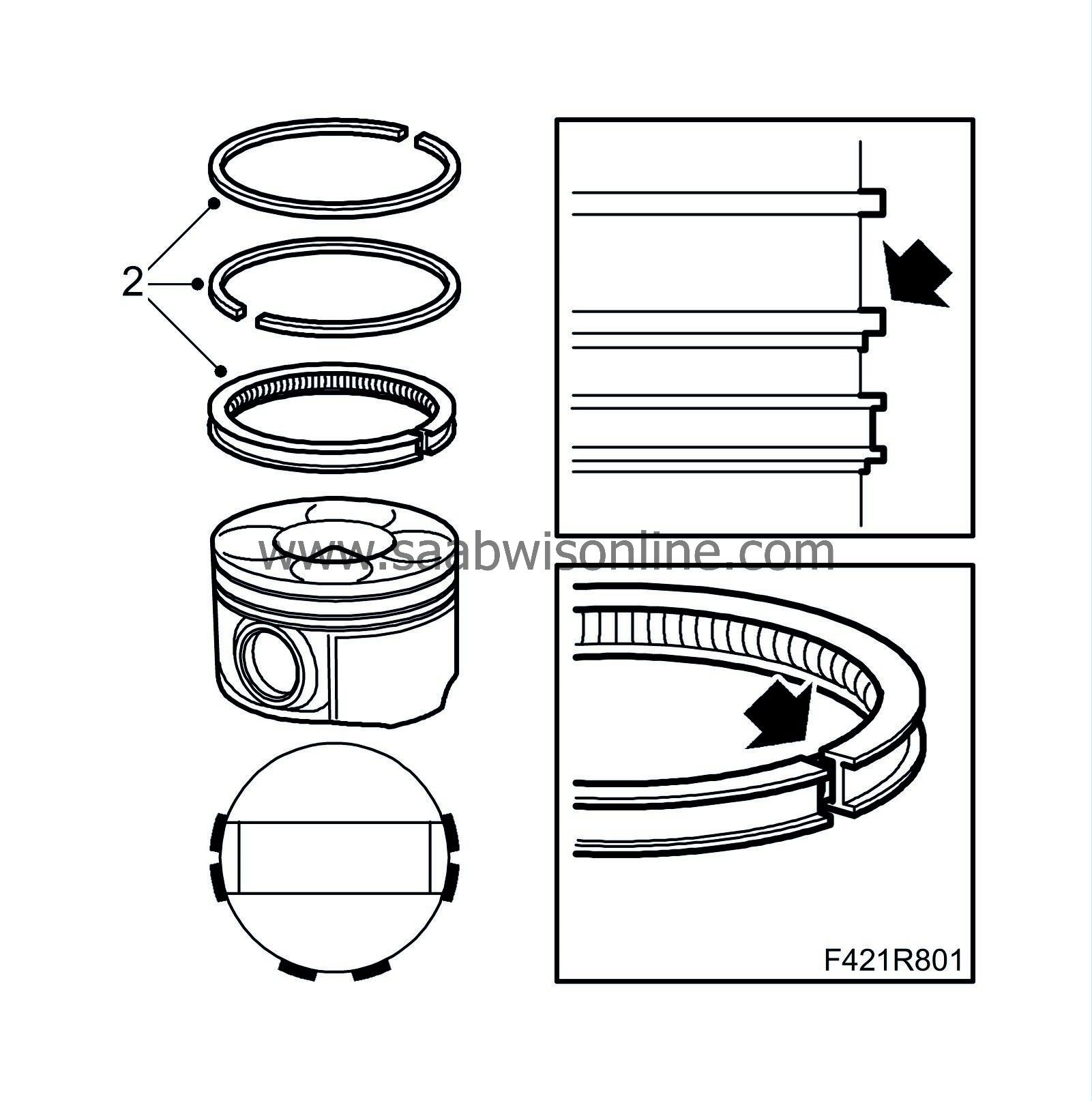

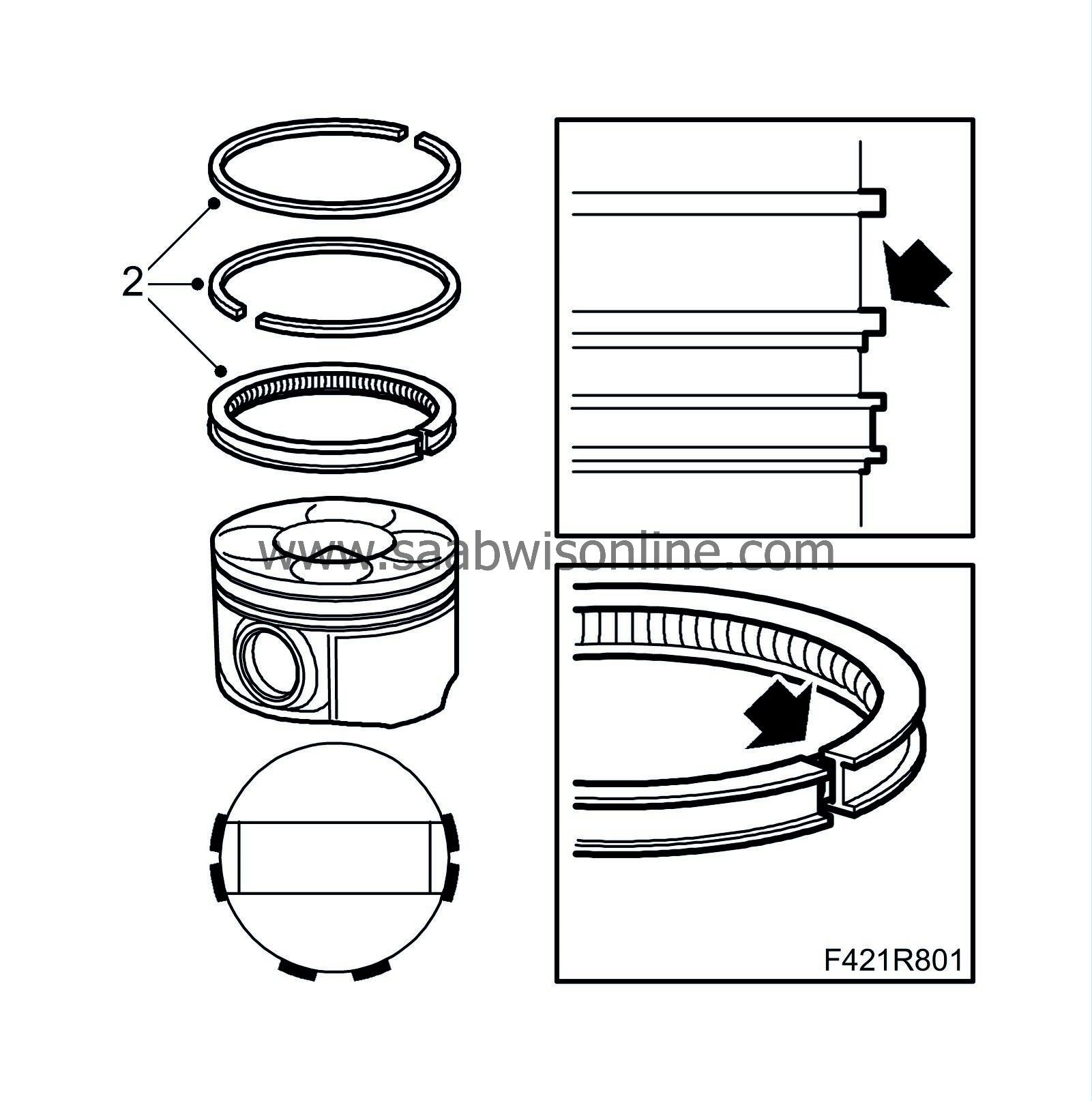

Position the piston rings as illustrated. The piston ring gaps should be spaced 120° from one another.

|

|

3.

|

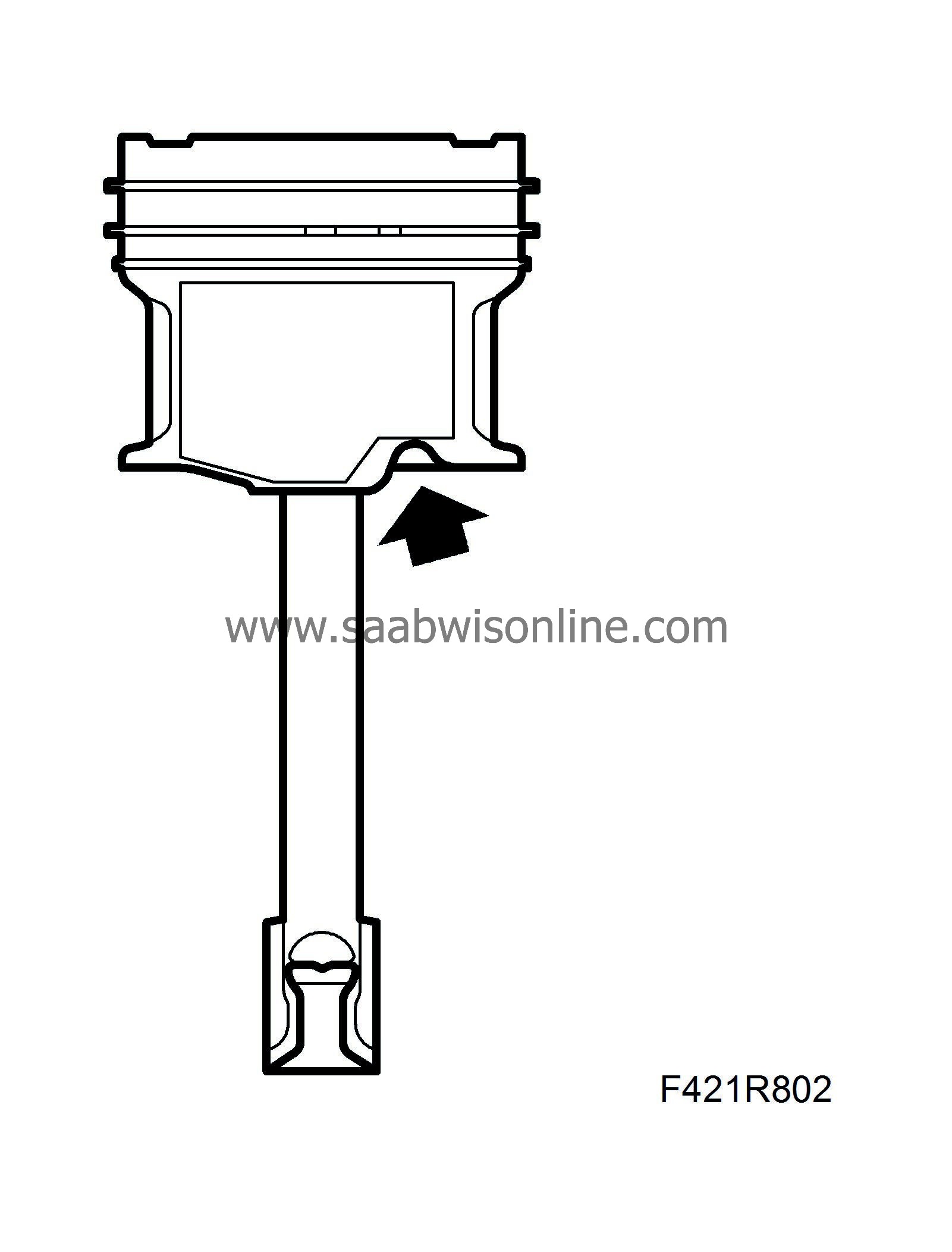

Lubricate the cylinder bore and piston with engine oil.

|

|

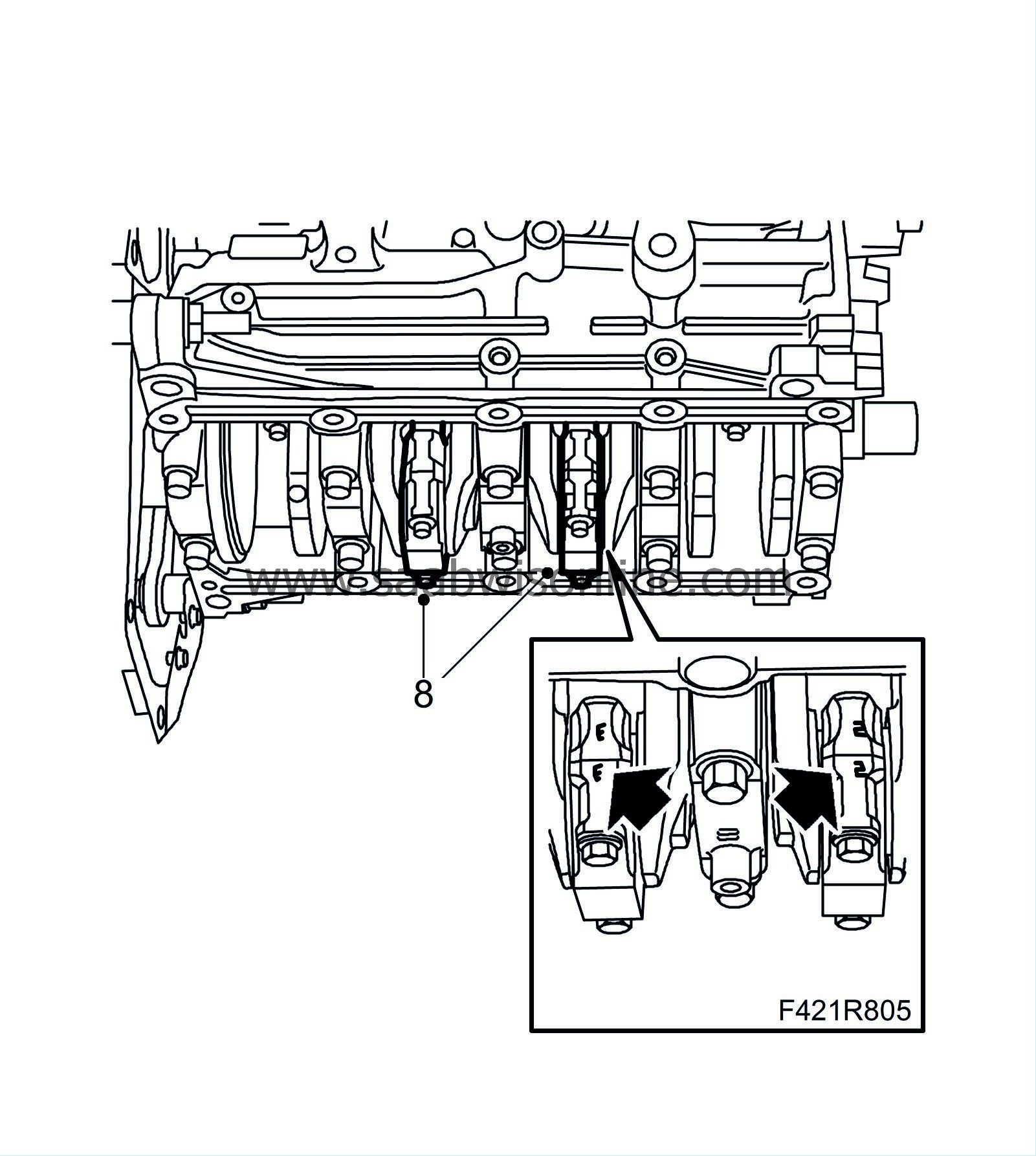

5.

|

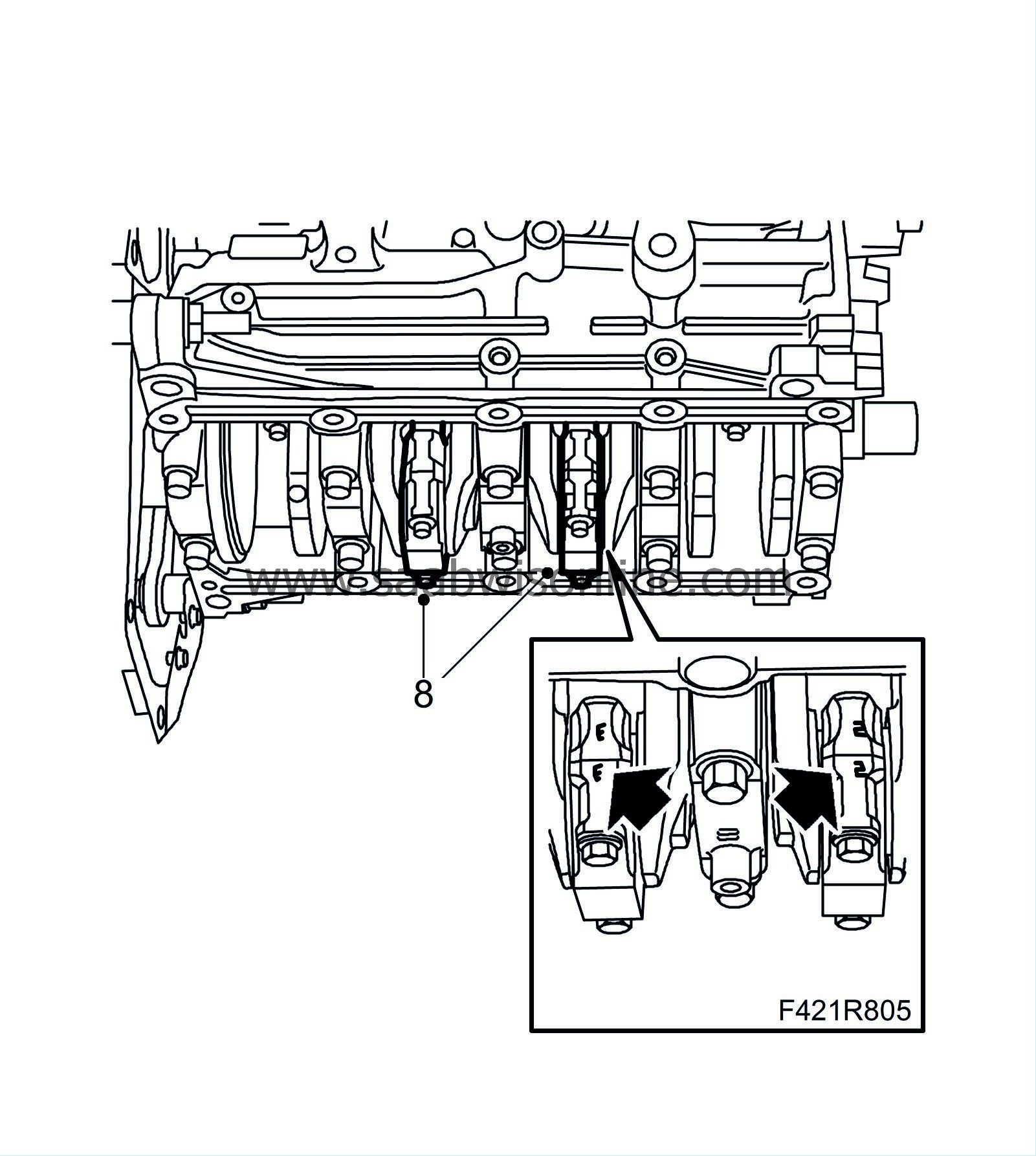

Fit the bearing caps. The marking on the bearing caps should face the marking on the connecting rod.

Tightening torque: 25 Nm +60° (18 lbf ft + 60 °)

|

|

6.

|

Turn the crankshaft 1/2 rotation.

|

|

8.

|

Fit the bearing caps. The marking on the bearing caps should face the marking on the connecting rod.

Tightening torque: 25 Nm +60° (18 lbf ft + 60 °)

|

|

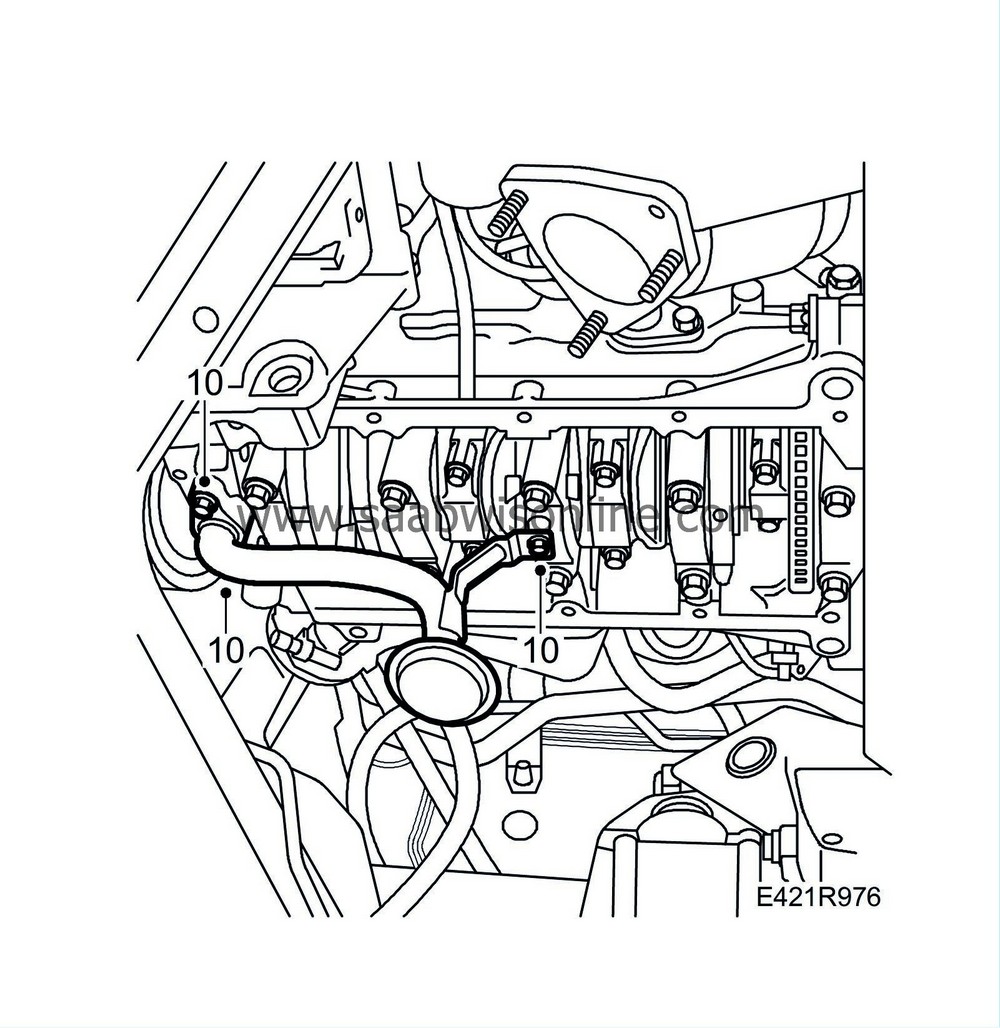

10.

|

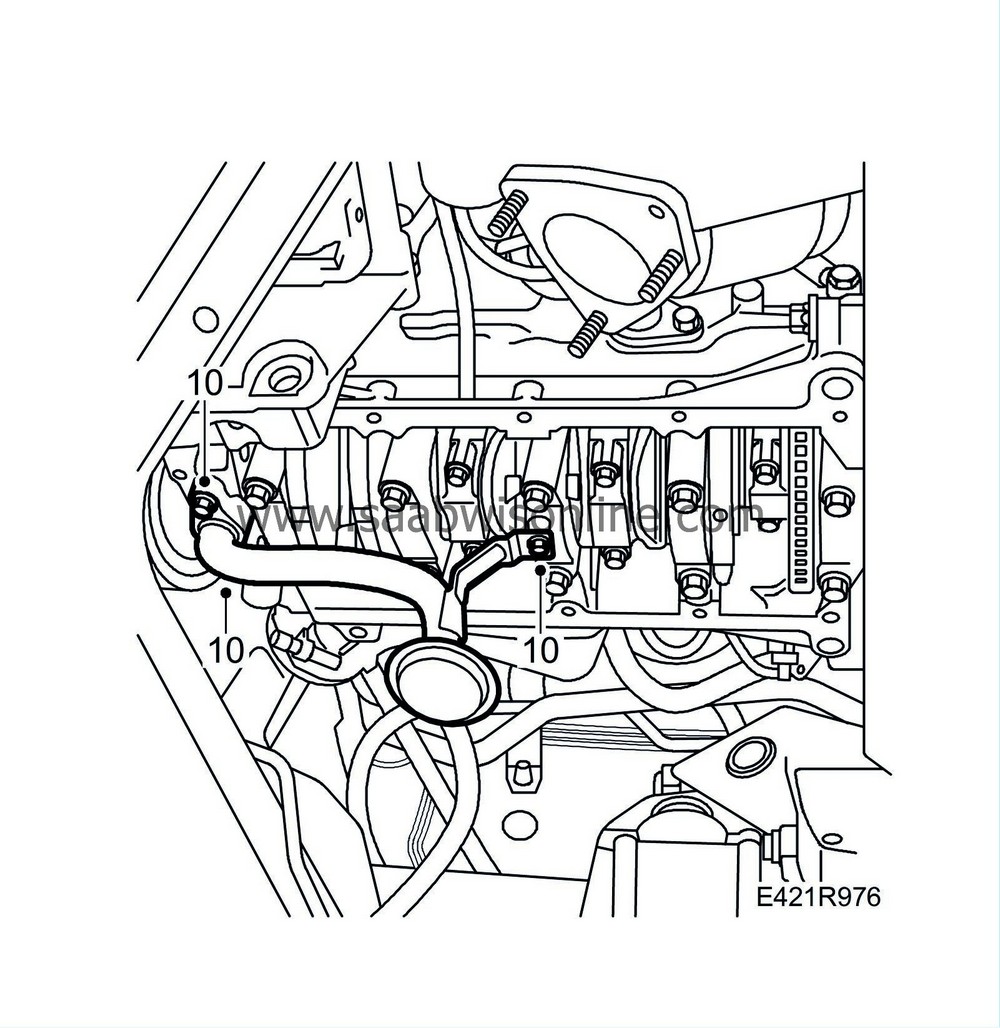

Fit the oil suction pipe.

|