Oil sump (in situ)

| Oil sump (in situ) |

| To remove |

| 1. |

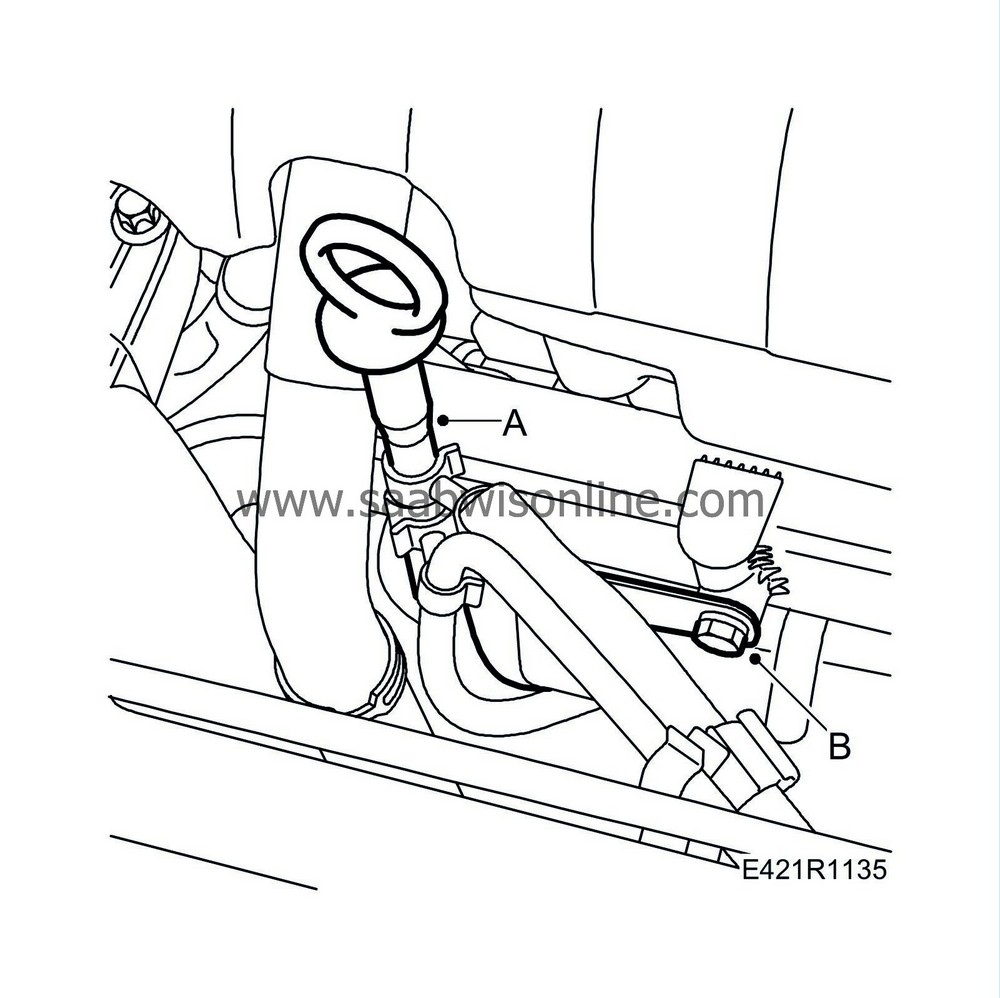

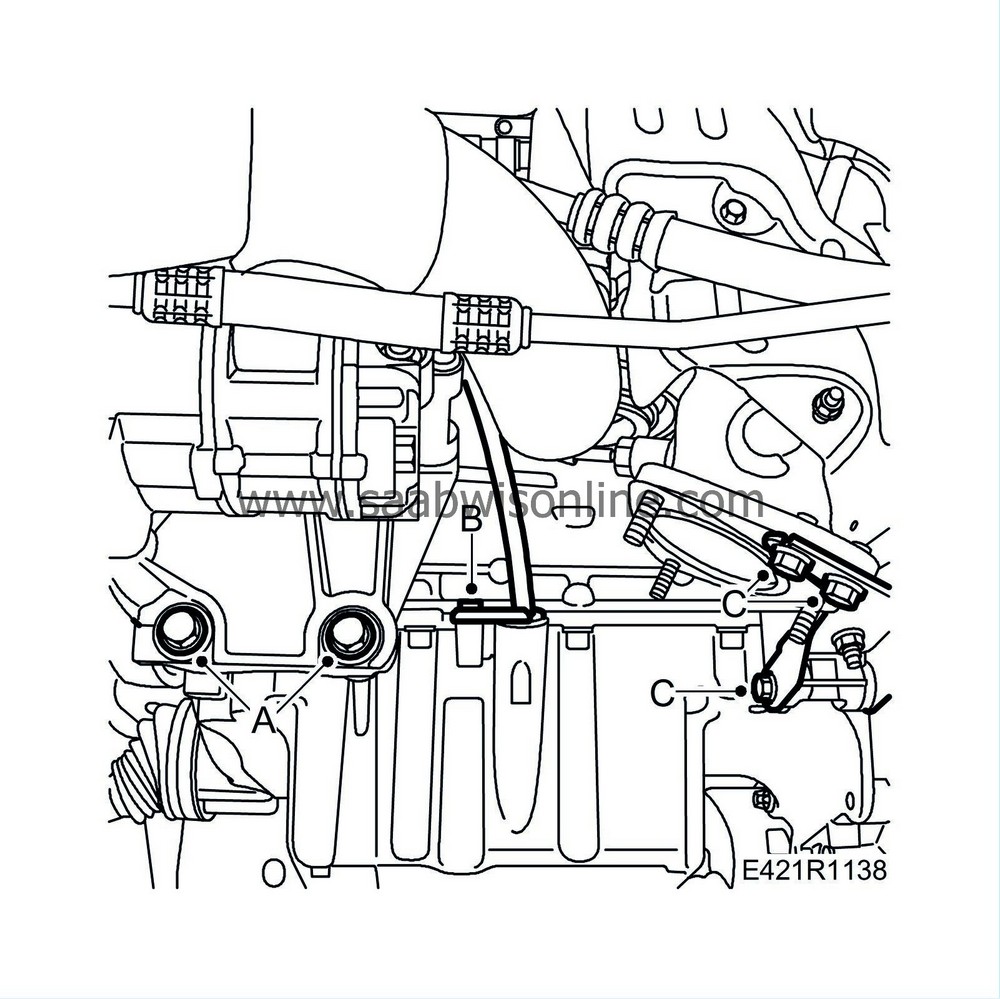

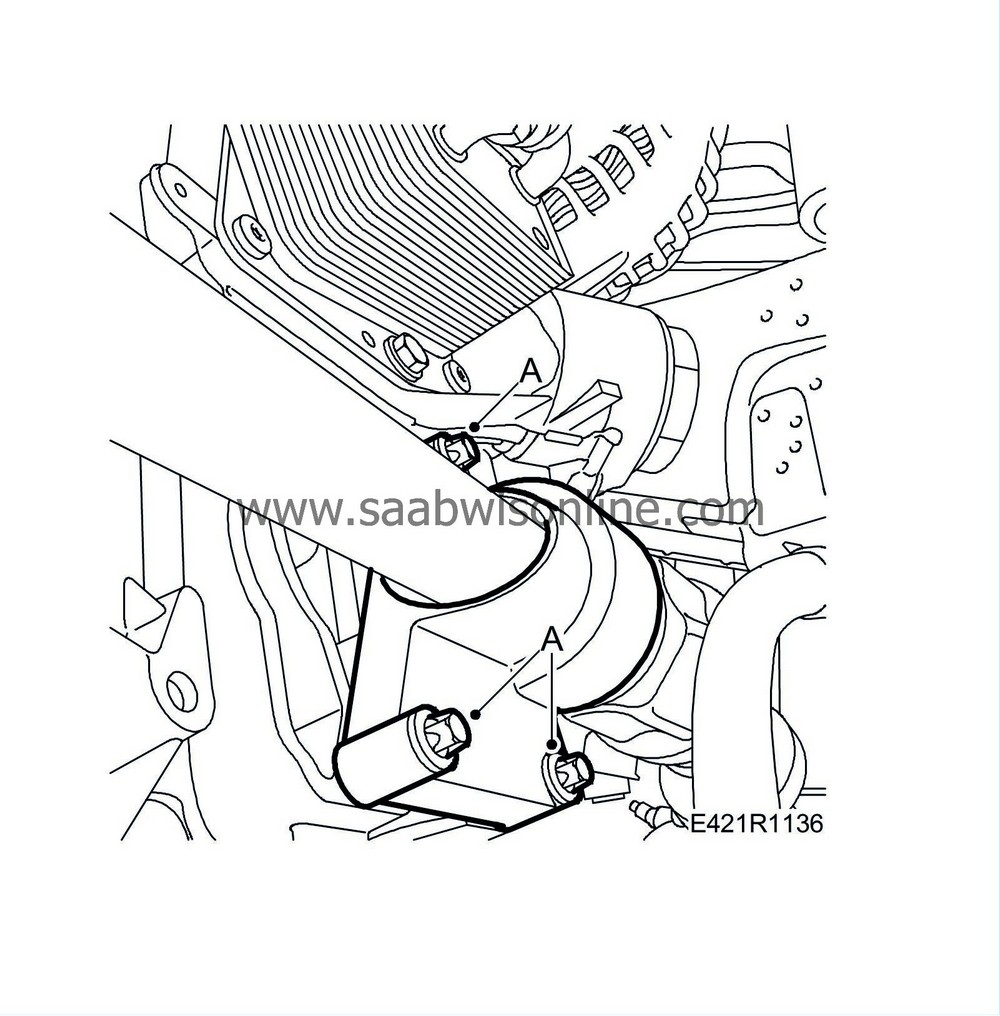

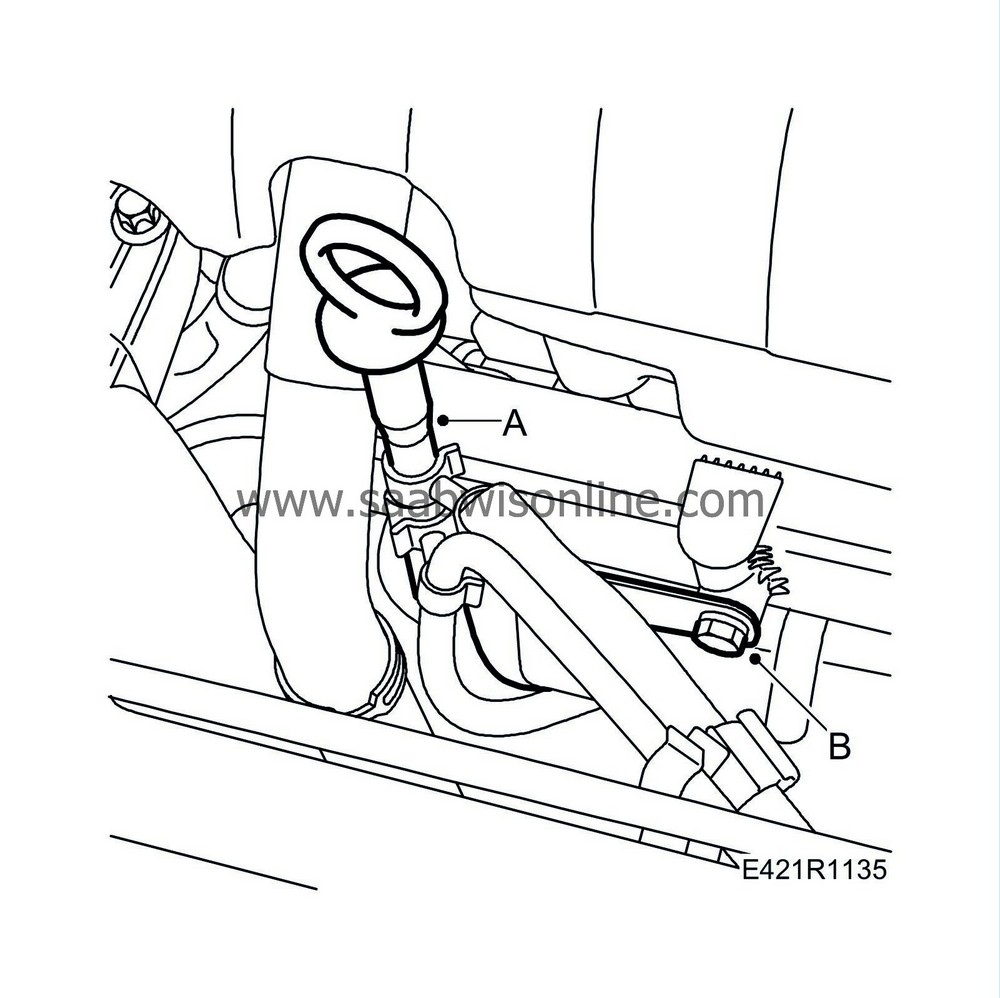

Remove the dipstick (A) and the upper retaining bolt (B) for the dipstick's tube.

|

|

| 2. |

Remove the upper engine cover with the insulation.

|

|

| 3. |

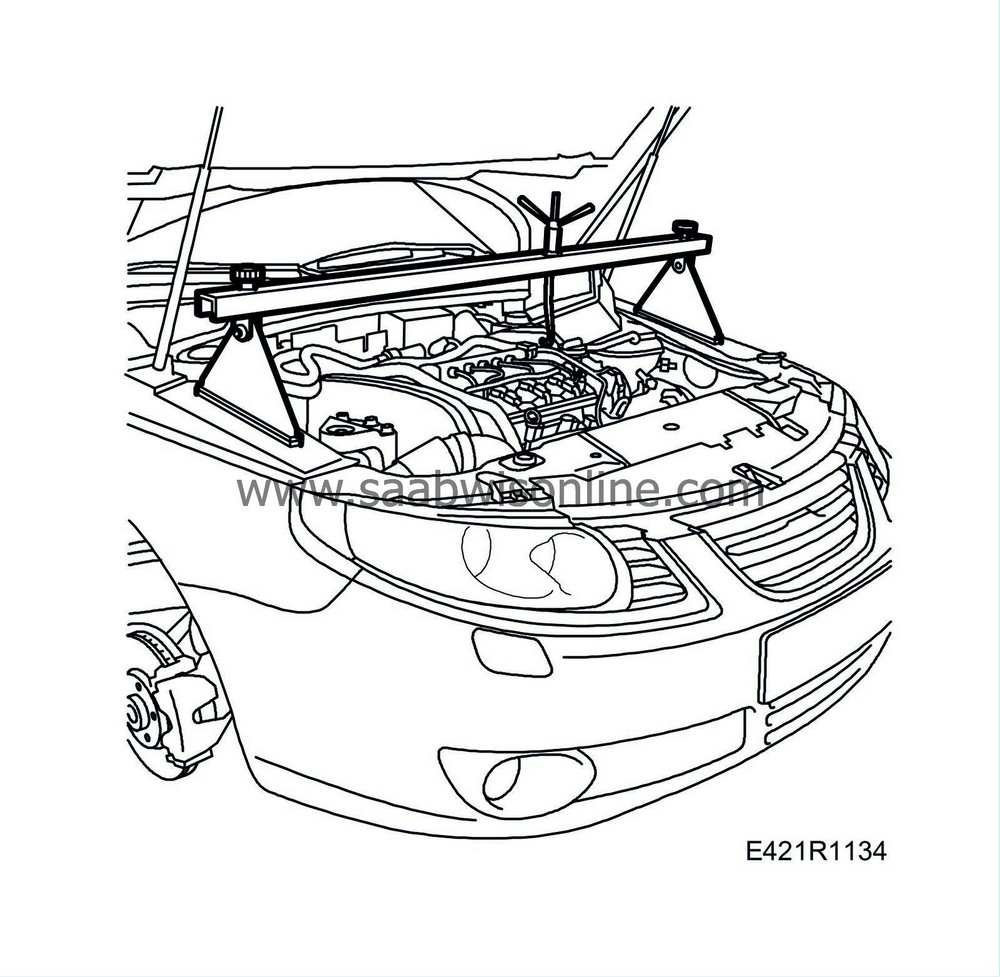

Relieve the load on the engine and gearbox with

83 94 850 Lifting beam

. Position the yoke on the wheel housings so that it is in contact with the wing edges, near the wing retaining bolts.

|

|

| 4. |

Remove

Subframe, diesel engine

.

|

|

| 5. |

Place a receptacle under the car.

|

|

| 6. |

Drain the engine oil.

|

|

| 7. |

Fit the oil plug with a new seal.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 8. |

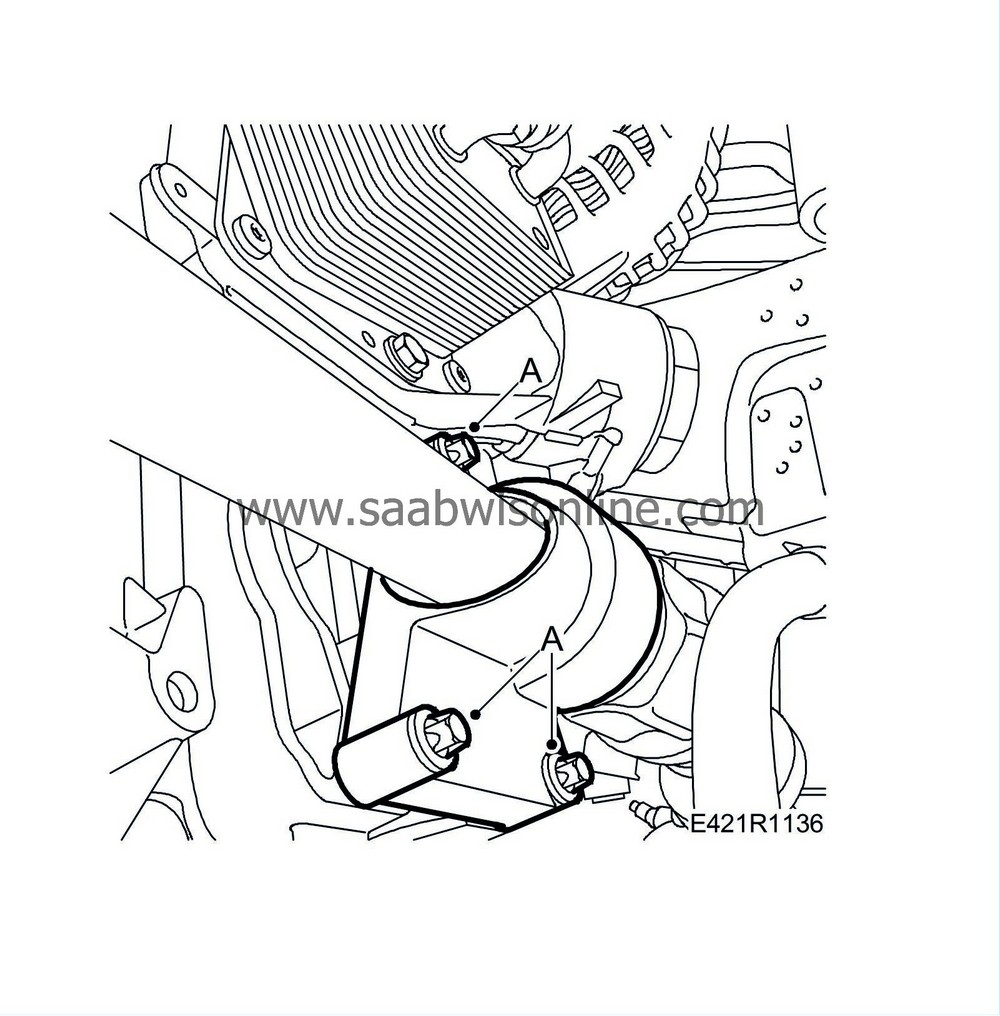

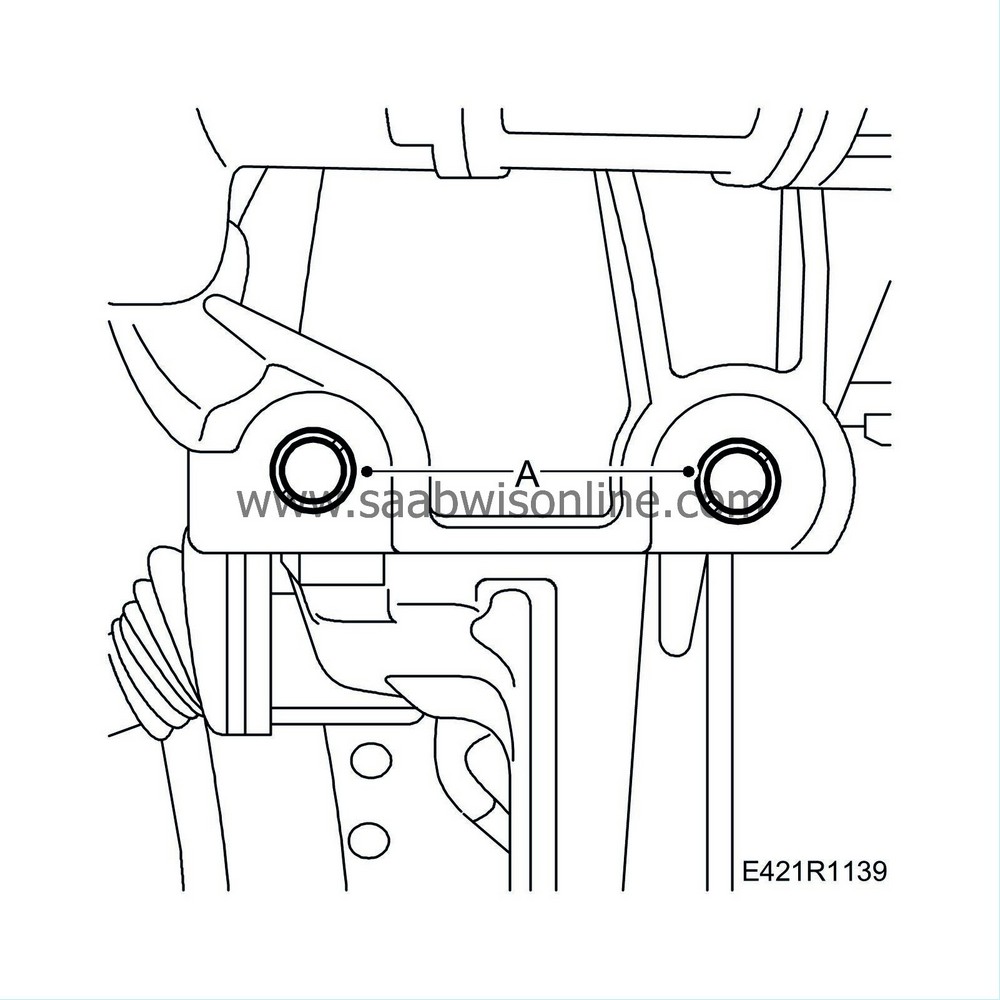

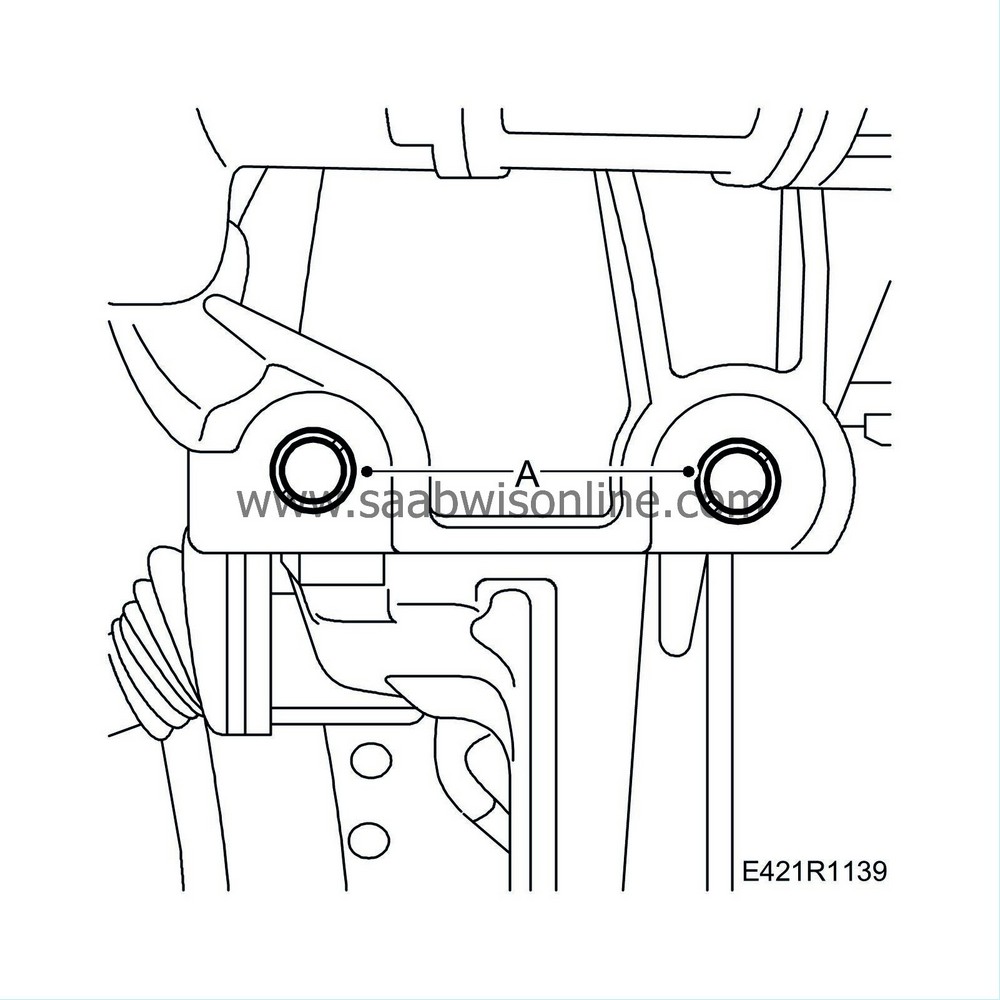

Remove the bearing pedestal bolts (A).

|

|

| 9. |

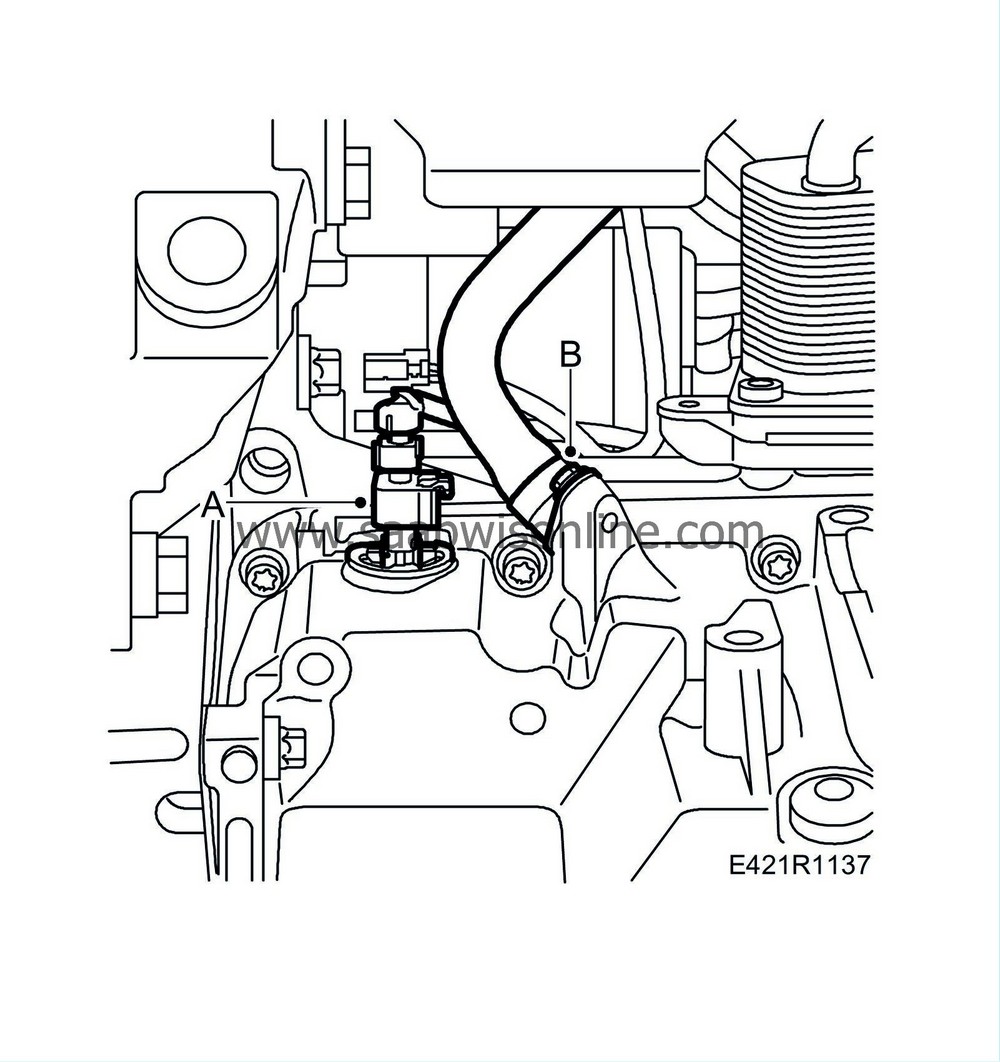

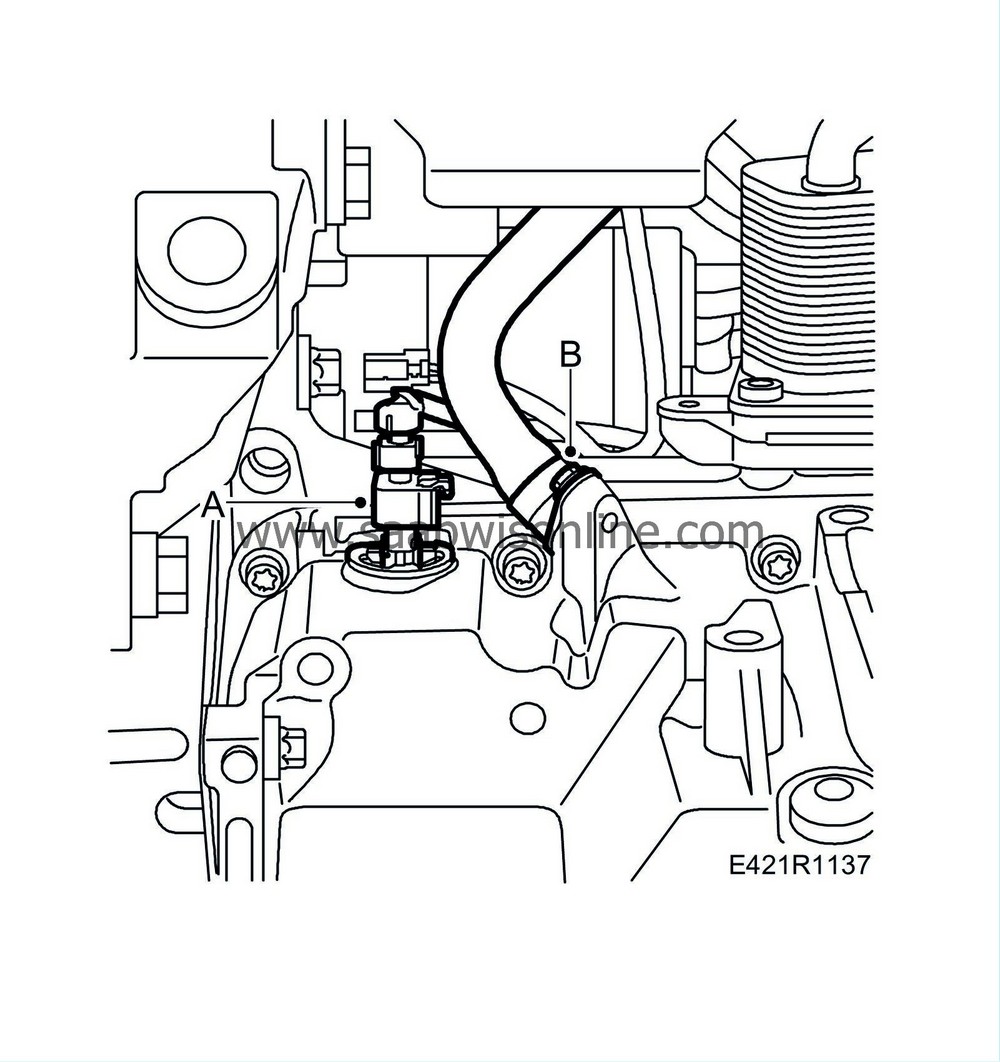

Unplug the oil level sensor connector (A).

|

|

| 10. |

Detach the crankcase ventilation hose (B) from the oil sump.

|

|

| 11. |

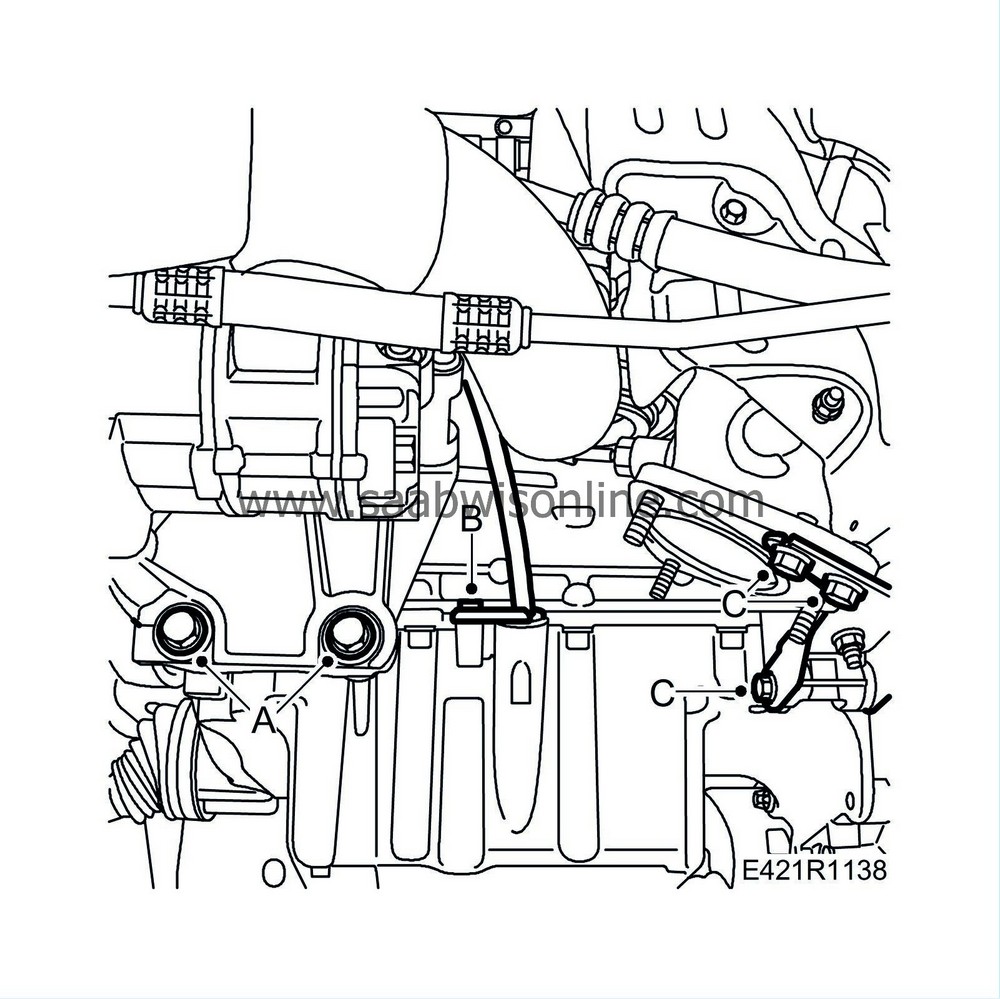

Remove the lower bolts (A) from the A/C compressor bracket.

|

|

| 12. |

Remove the bolt (B) and lift up the dipstick's tube slightly out from the oil sump.

|

|

| 13. |

Remove the lower mounting (C) for the front catalytic converter.

|

|

| 14. |

Screw back the spacer sleeves (A) in the A/C compressor bracket.

|

|

| 15. |

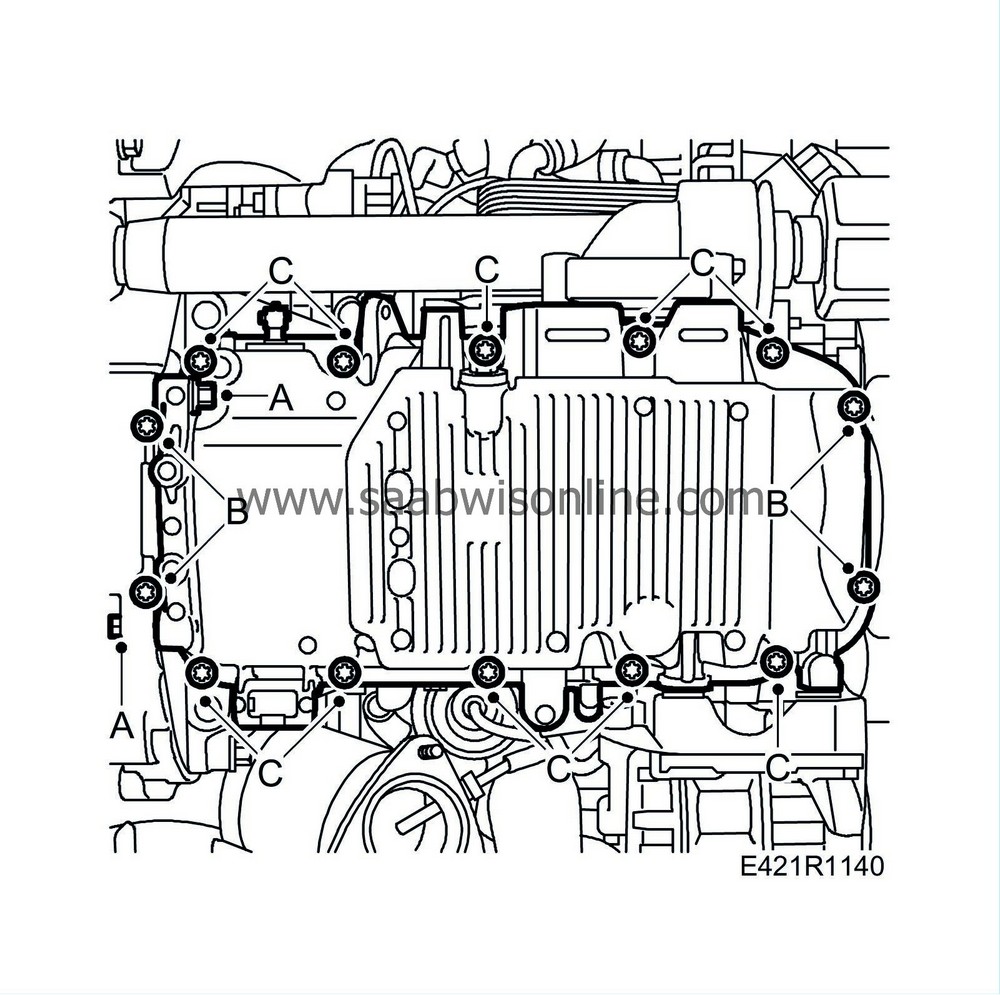

Remove the oil sump's bolts (A) to the gearbox.

|

|

| • |

Move the bolts (B) towards the sump, use

32 025 015 Extension ribe M7

.

|

| • |

Move the bolts (C) towards the sump, use

32 025 016 Extension ribe M8

.

|

| 16. |

Man:

The engine must be turned so that the recess in the flywheel aligns with the bolts.

|

|

| 17. |

Position a screwdriver between the sump and the timing cover at the A/C compressor bracket and carefully prize away the oil sump.

|

|

| To fit |

| 1. |

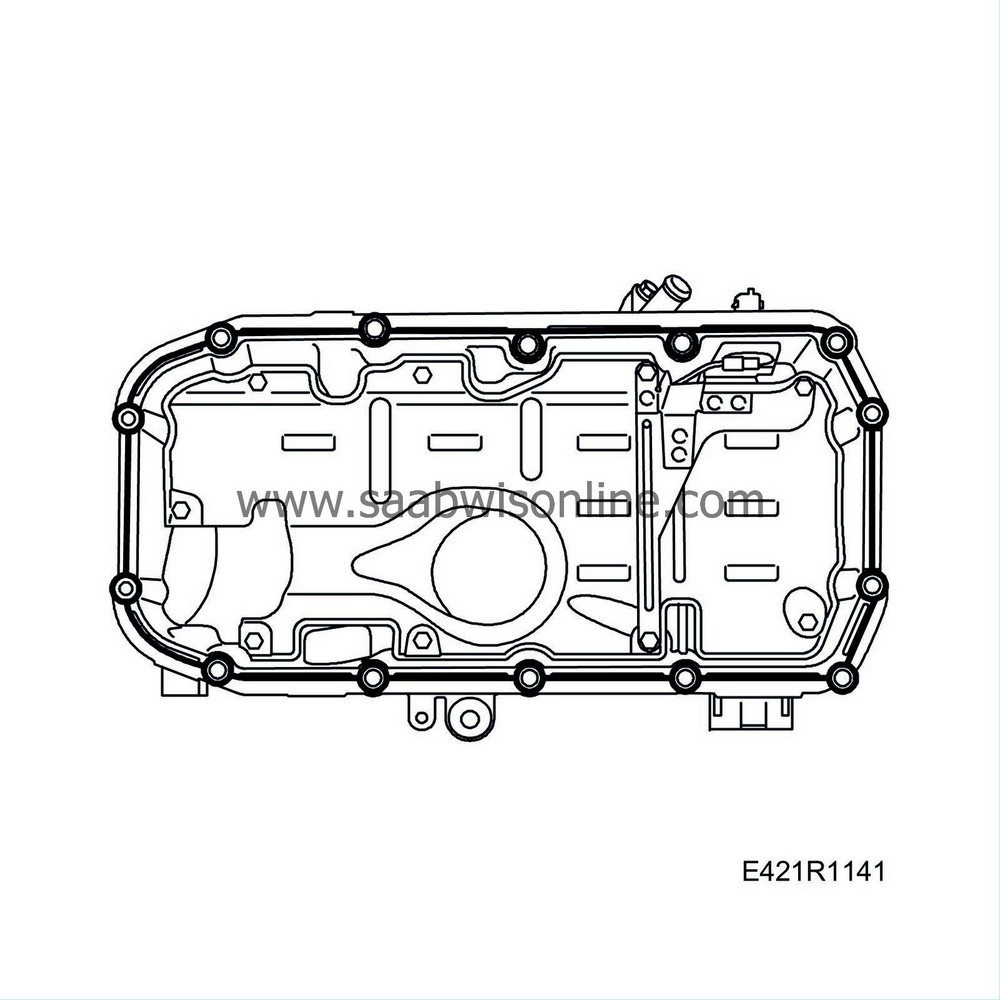

Clean the sealing surfaces of the cylinder block and sump. Clean away any contaminants in the oil sump.

|

|

| 2. |

Apply a bead of

90 543 772 Silicone flange sealant

on the oil sump sealing surface.

|

|

| 4. |

Screw in the spacer sleeves (A) in the A/C compressor bracket until they are in contact with the oil sump.

|

|

| 5. |

Fit the lower bolts for the A/C bracket (A).

Tightening torque: 47 Nm (35 lbf ft)

|

|

| 6. |

Fit the bolt for the (B) dipstick tube.

|

|

| 7. |

Fit the lower mounting (C) for the pre-catalytic converter.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 8. |

Attach the crankcase ventilation hose (B) to the oil sump.

|

|

| 9. |

Plug in the oil level sensor connector (A).

|

|

| 10. |

Fit the bearing pedestal bolts (A).

Tightening torque: 50 Nm (37 lbf ft)

|

|

| 11. |

Fit

Subframe, diesel engine

.

|

|

| 12. |

Lower the car and remove the lifting beam.

|

|

| 13. |

Fit the upper retaining bolts (B) to the dipstick tube. Fit the dipstick.

|

|

| 14. |

Fill with engine oil. See

Lubricating system

.

|

|