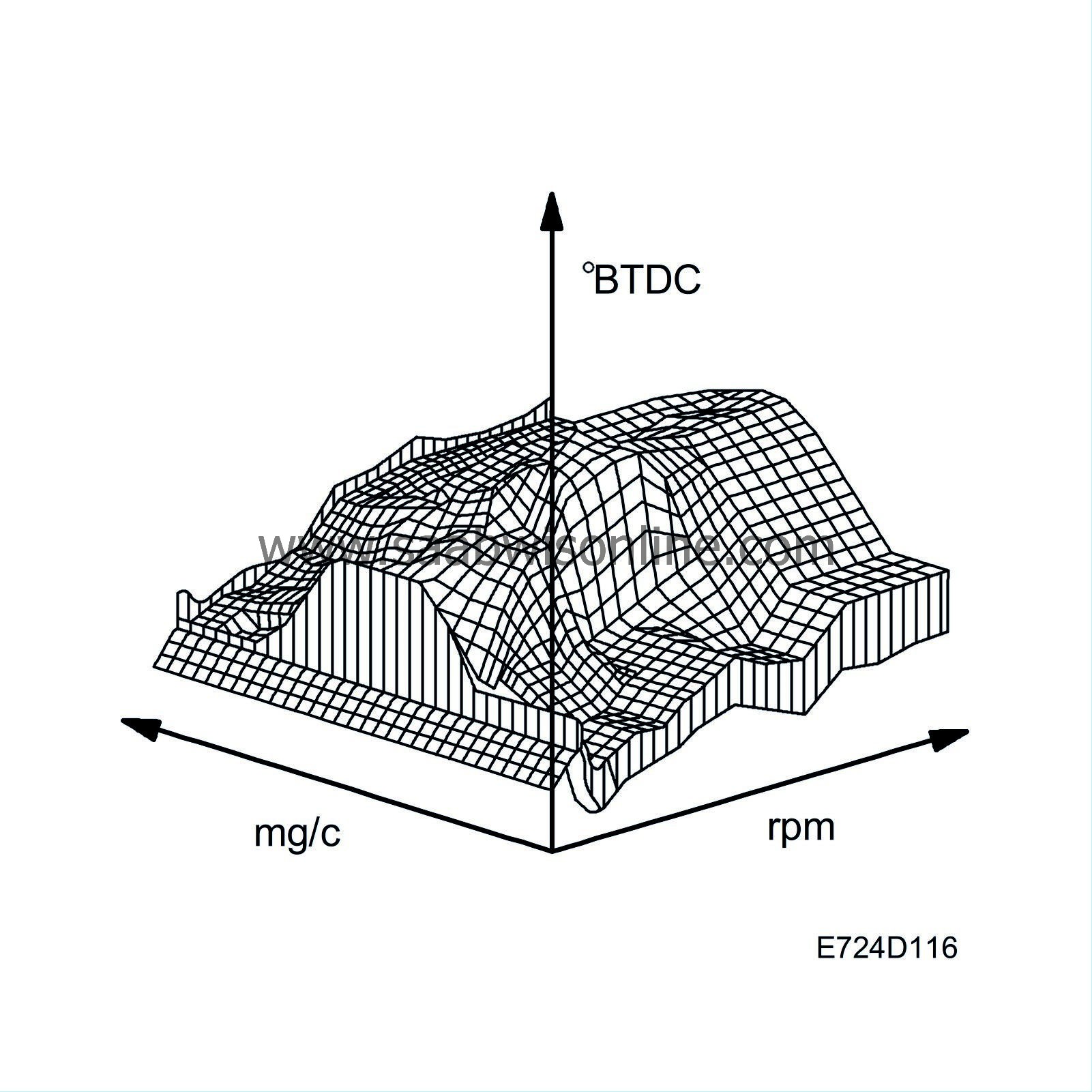

Normal ignition timing

| Normal ignition timing |

The ignition must be advanced as engine speed increases because the combustion pressure would otherwise act on the pistons too late and hence reduce the efficiency of the engine.

A load increase means that a larger quantity of air is drawn into the cylinder during each induction stroke (mg air/combustion). This gives rise to a higher gas pressure with the result that the speed of combustion increases. For this reason, the ignition must be retarded when the load increases.

The ignition timing for each load and engine speed is written into a matrix in the control module memory. The ignition timing is optimised for the maximum engine torque at any one point, which coincides with the best efficiency and thereby the lowest fuel consumption.

The following text explains why normal ignition timing must occasionally be advanced or retarded slightly, as factors other than load and engine speed can affect it.

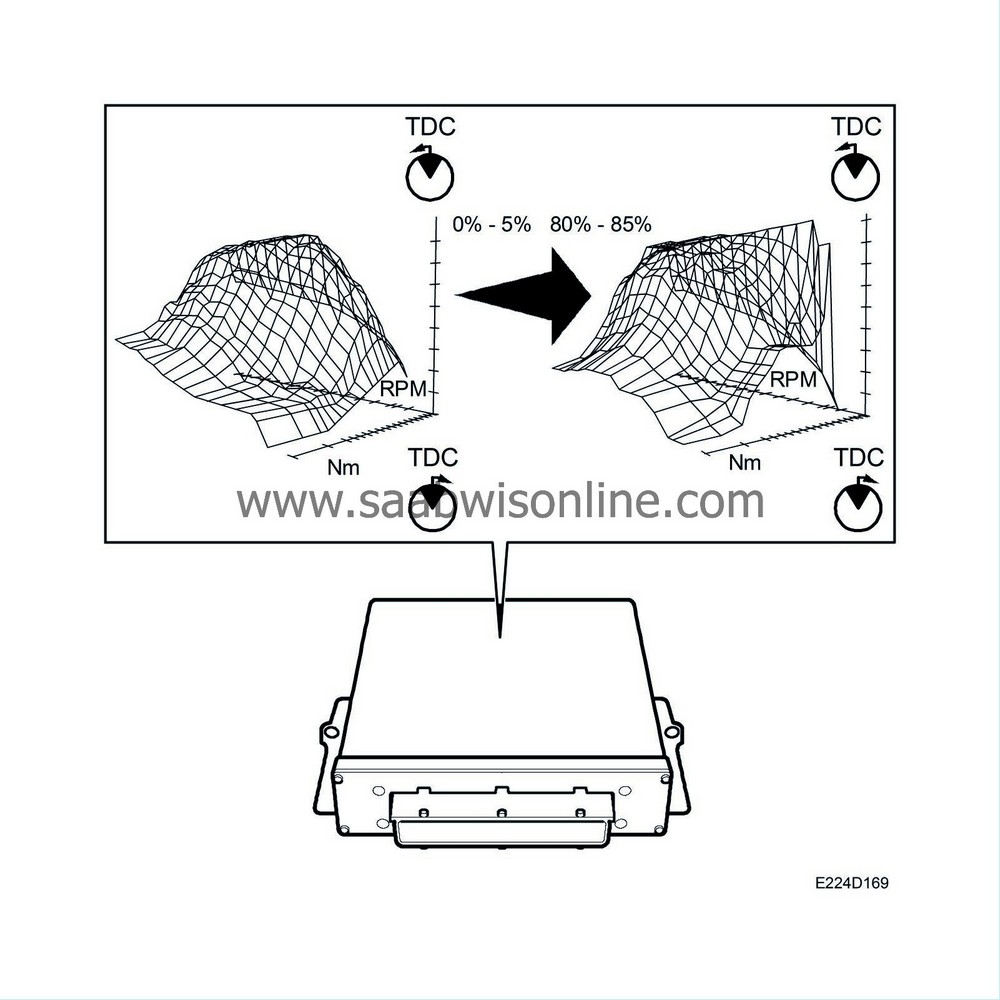

| Ignition, BioPower |

Other ignition timings are required with ethanol mixture due to other properties of ethanol as fuel. For this reason, a further matrix has been added for ignition timing with E85 operation.

With adapted ethanol contents of 0-5% the table for petrol operation is used, while at 80-85% the new table for E85 is used. With ethanol contents between 5-80% the torque varies steplessly between the two tables.

The high octane rating in ethanol enables the additional use of slightly advanced ignition in many operational cases. This results in an improved combustion efficiency and lower exhaust temperature. The increased combustion efficiency means that fuel consumption can be reduced slightly with high ethanol content. The lower exhaust temperature means that fuel enrichment is not required below 4500-5000 rpm (depending on engine variant).