General thermoforming

| General thermoforming |

As already mentioned, thermoplastics can be affected by heat. However, thermosetting plastics have once and for all attained their final shape and cannot be changed.

Thermoplastic parts that for some reason have become deformed, can be trued using a hot-air gun or in a paint oven. Thermoforming is suitable if the part has become skew or if it has a large “dent” but is not cracked. On dark plastic “cracks” are visible as white areas around the edge of the dent. Follow the following procedure:

| 1. |

Clean the part.

|

|

| 2. |

Heat the oven to 65°C and insert the part to be trued. Make sure that it lies flat.

|

|

| 3. |

Leave it in the oven for about one hour.

|

|

| 4. |

Check the result. Rectify any damage to the finish through grinding - filling - painting.

|

|

| Small dents can be repaired as follows: |

| 1. |

Clean the part.

|

|

| 2. |

Warm the reverse of the plastic part with a hot-air gun. Warm an area that is at least double the size of the dent.

|

|

| 3. |

Warm the part until you can only just hold your hand on the front of the part, approx. 70°C.

|

|

| 4. |

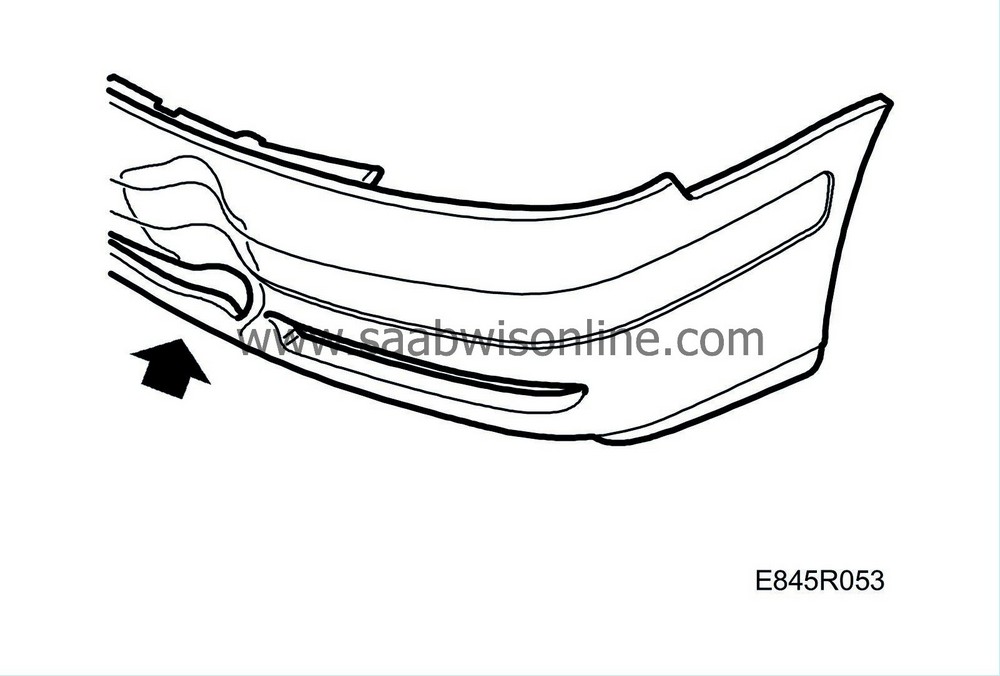

True the plastic using a wooden block or flat metal instrument. "Over true" about 10 % and hold the block in place while you cool the plastic with a sponge and cold water.

|

|

| 5. |

Check the result. Rectify any damage to the finish through grinding - filling - painting.

|

|