Turbo, 4-cyl.

| Turbo, 4-cyl. |

| To remove |

|

|||||||

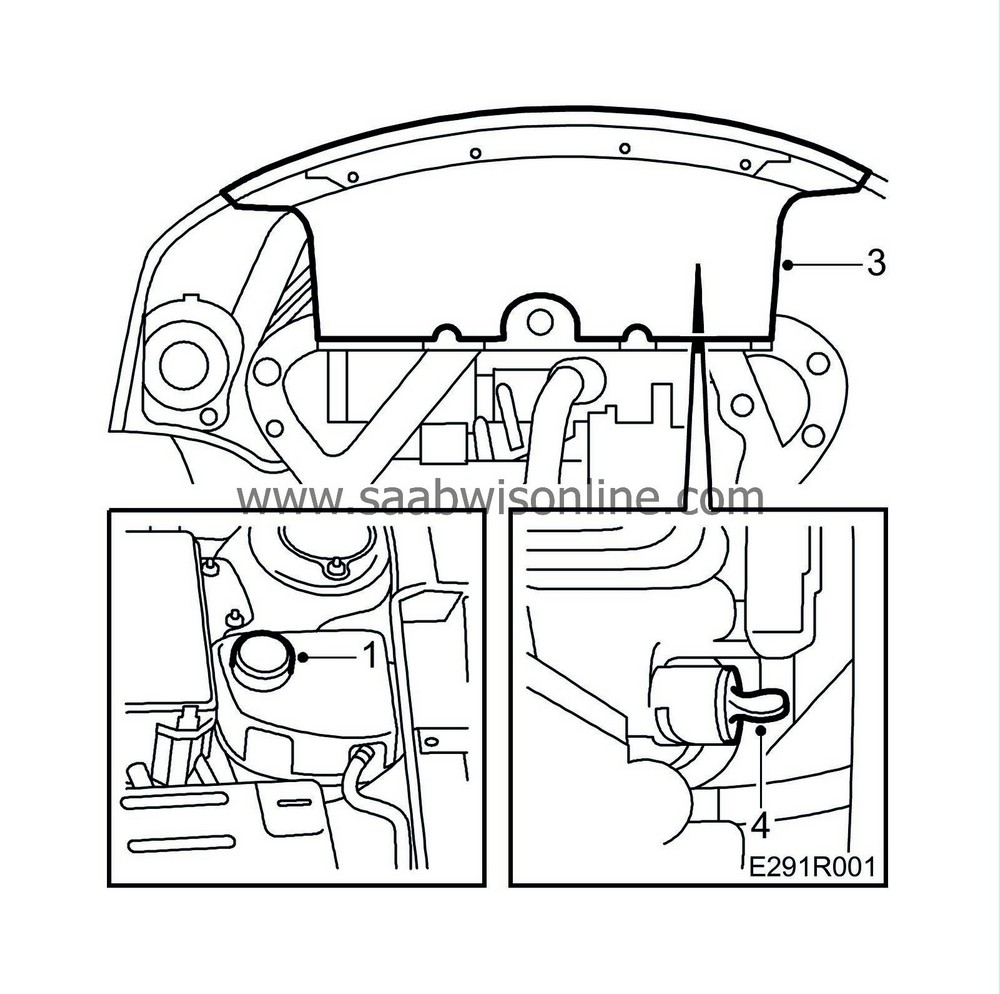

| 1. |

Open the expansion tank cap to release the system pressure.

|

|

| 2. |

Raise the car.

|

|

| 3. |

Remove the lower front cover.

|

|

| 4. |

Drain off the coolant.

|

|

| 5. |

Remove the turbo stays.

|

|

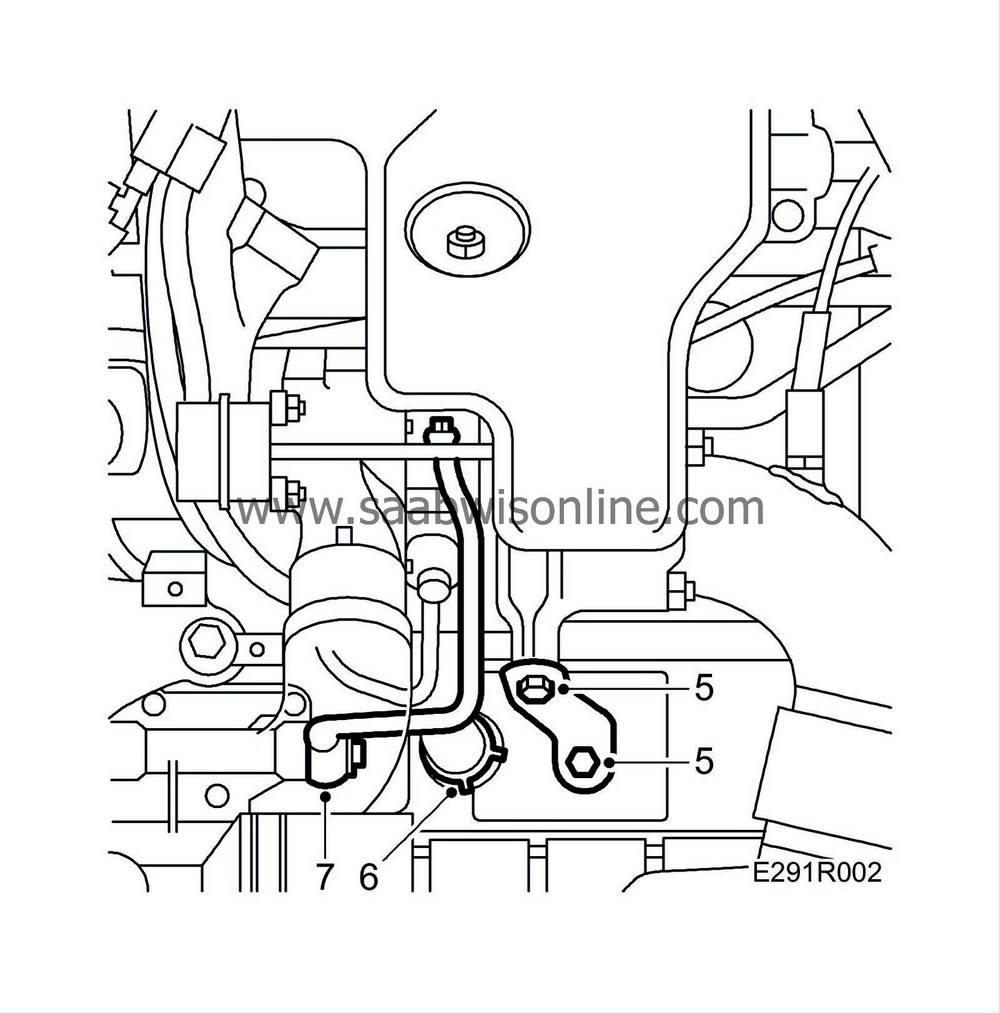

| 6. |

Loosen the return oil nipple and the pipe from the turbo to the cylinder block. Plus the hole in the block.

|

|

| 7. |

Loosen the oil pipe between the oil filter adapter and the turbo (at the turbo).

|

|

| 8. |

Lower the car to the floor.

|

|

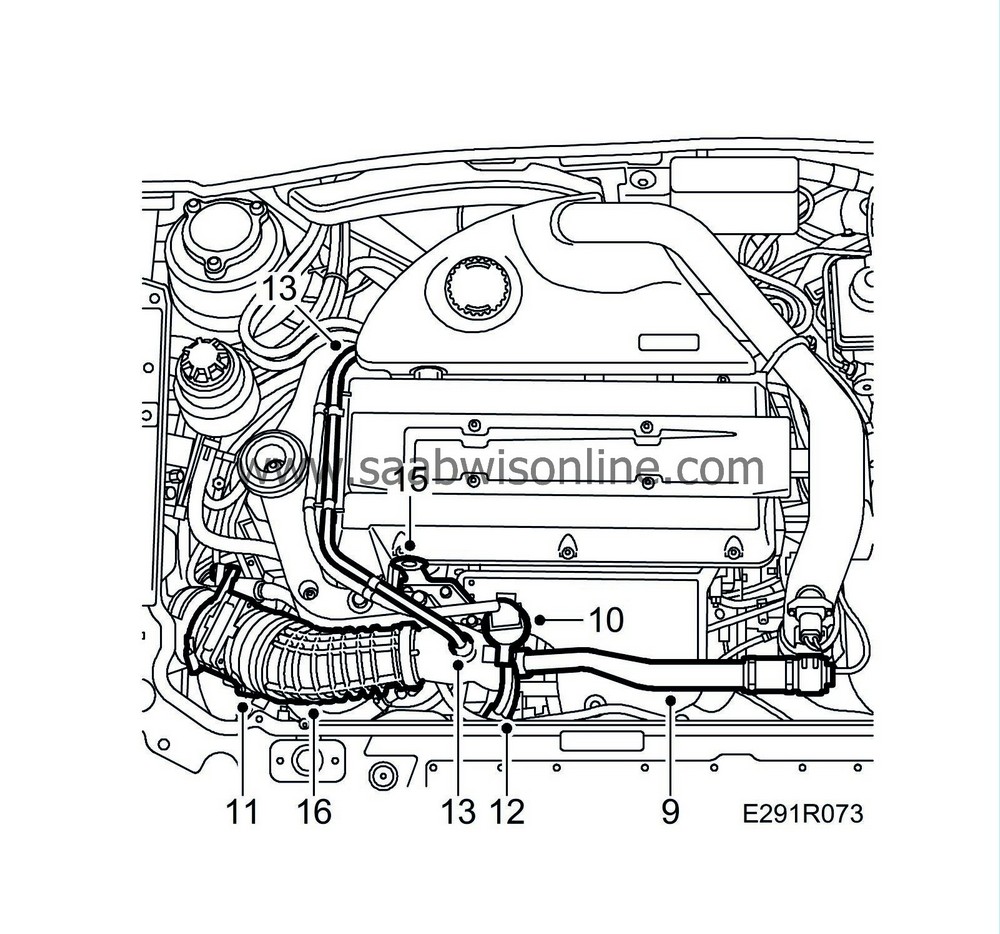

| 9. |

Remove the bypass pipe and valve.

|

|||||||

| 10. |

Unplug the connector from the control valve.

|

|

| 11. |

Unplug the mass air flow sensor connector.

|

|

| 12. |

Loosen the hoses to the turbo and diaphragm housing.

|

|

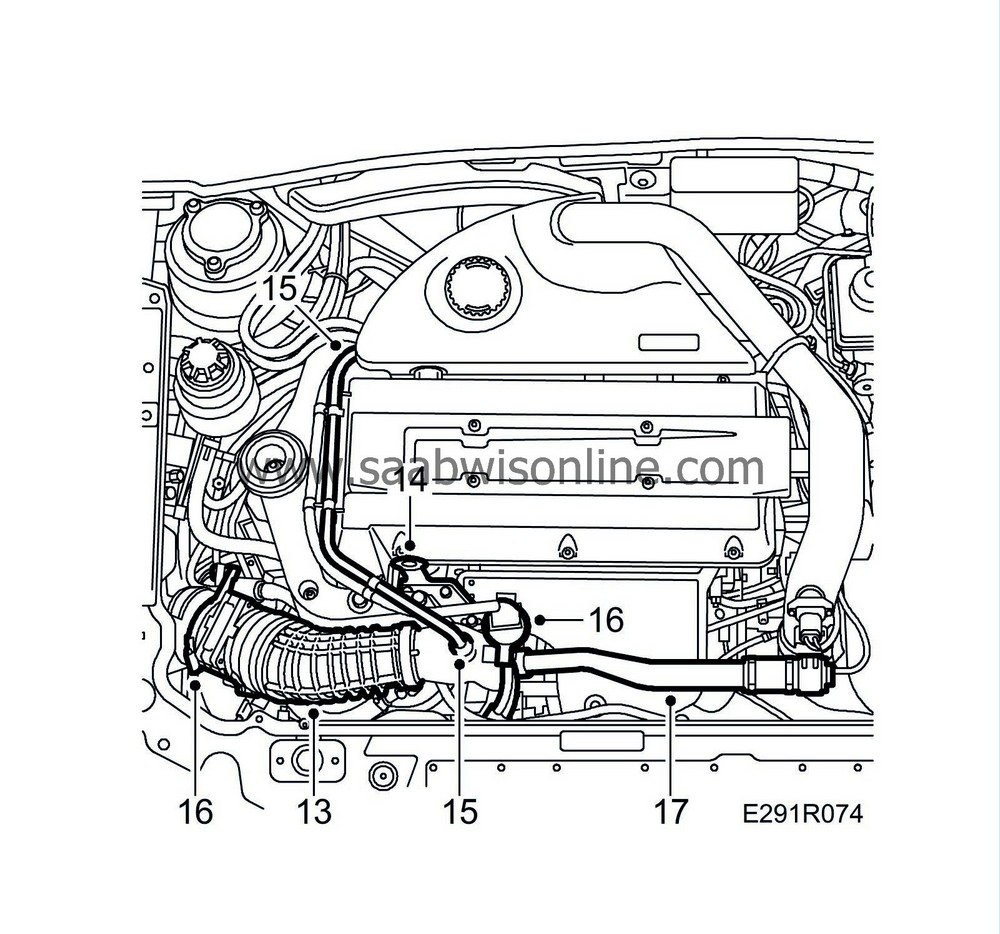

| 13. |

Unscrew the crankcase breather pipe's banjo bolt from the intake manifold and unscrew the bolt from the camshaft cover.

|

|

| 14. |

Bend the pipe and wiring aside.

|

|

| 15. |

Remove the engine lifting eye.

|

|

| 16. |

Remove the mass air flow sensor and air hose.

|

|

| 17. |

Remove the exhaust manifold heat shield. The heat shield is attached with a nut and two clips on the underside.

|

|

| 18. |

Undo the quick coupling on the bleeder hose using

83 95 261 Tool, fuel line

.

|

|

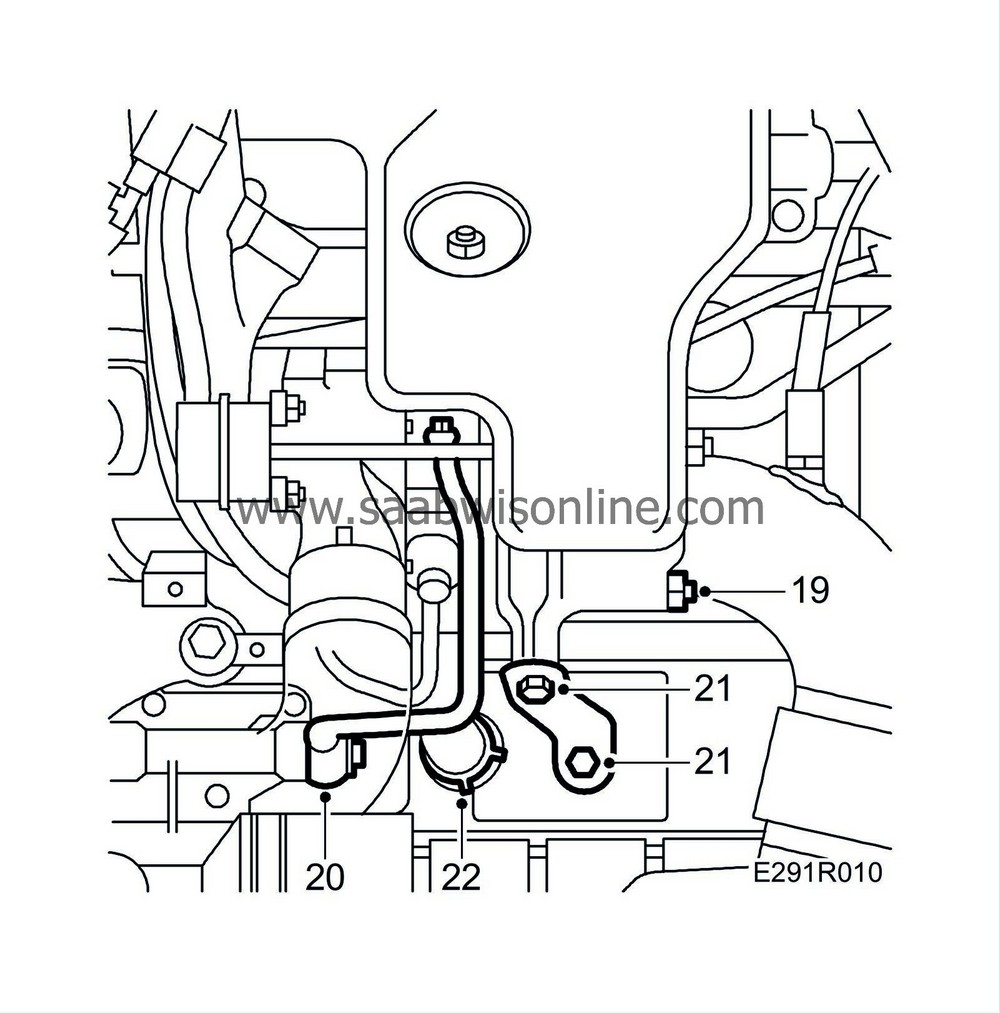

| 19. |

Undo the V-clamp of the intake manifold at the turbocharger.

260 hp:

Remove the upper bolt of the wastegate-box and slightly loosen the lower bolt.

|

|

| 20. |

Lift out the intake manifold.

|

|

| 21. |

Undo the hose clip on the hose between the charge air cooler and the turbo (at the turbo). Plug the hose to prevent dirt entering the hose, use plug

83 94 595 Plug, turbo hose

or similar.

|

|

| 22. |

Loosen the front exhaust system from the turbo.

|

|

| 23. |

Carefully lower the front exhaust system away from the turbo.

|

|||||||||||||

| 24. |

Remove the oil pipe from the oil filter adapter. Collect the copper washers.

|

|

| 25. |

Undo the coolant pipe by the turbo. Keep the copper washers safe.

|

|

| 26. |

Slacken the coolant pipe bolt by the coolant pump.

|

|

| 27. |

Detach the coolant return pipe from the cylinder head and also from the pressure sensor bracket. Collect the copper washers.

|

|

| 28. |

Undo the coolant return pipe bolt by the turbo.

|

|

| 29. |

Undo the nuts securing the turbo to the exhaust manifold.

|

|||||||

| 30. |

Remove the turbo.

|

|

| To fit |

| Important | ||

|

It is essential that there is oil in the turbo bearing housing when the engine is started. An extra check should be made when fitting a new turbo. |

||

|

Fill the turbo oil inlet with oil from an oilcan. Rotate the compressor wheel by hand many times to ensure that oil enters the bearings. |

||

| Note | ||

|

Coat the studs thinly with Molycote 1000, part No. 30 20 971, or similar. |

| Note | ||

|

Spray the connector with Anti-corrosion agent, Contact Protect before connecting. |

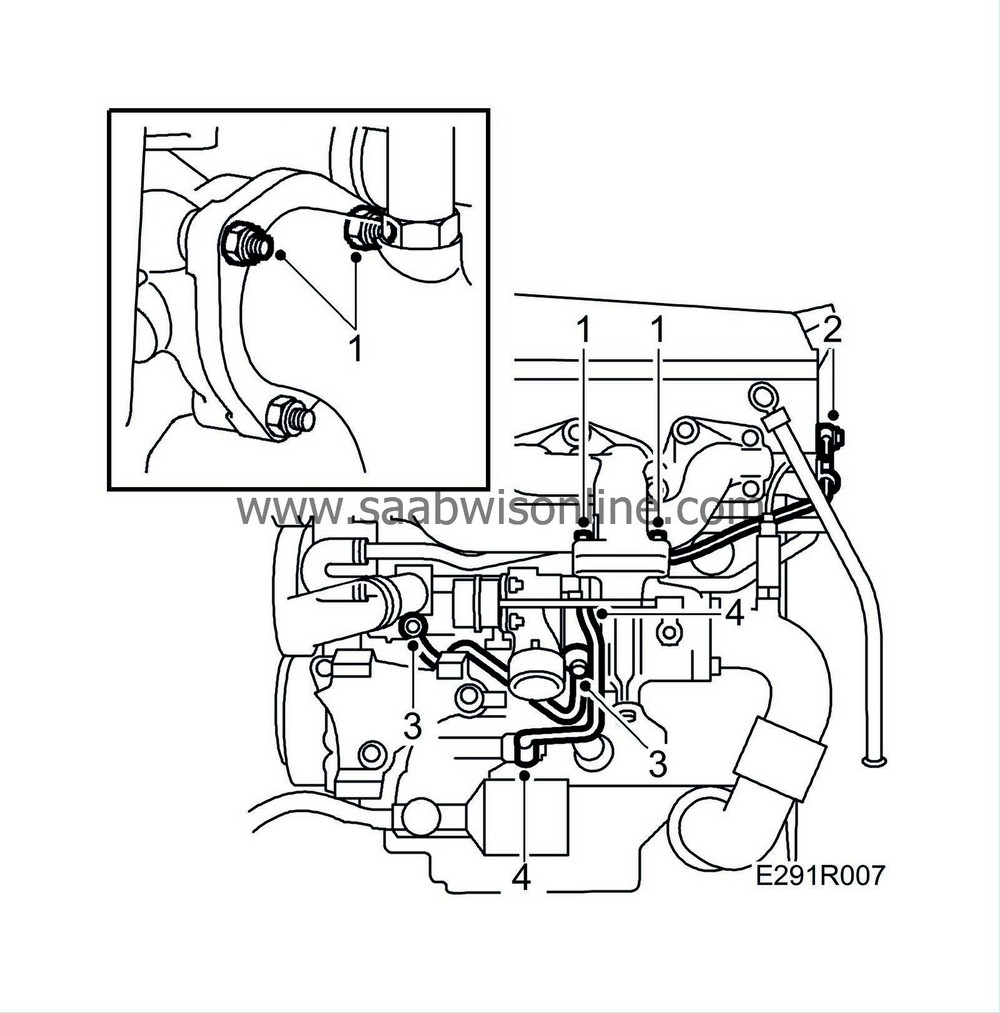

| 1. |

Fit the turbo. Tighten only the two upper lock nuts at the connection between the turbo and the front exhaust system.

Tightening torque: 24 Nm (18 lbf ft)

|

||||||||||

| 2. |

Fit the turbo coolant return pipe. Fit new copper washers.

Tightening torques Nipple in cylinder head: 35 Nm (26 lbf ft) Banjo screw, cylinder head: 25 Nm (18 lbf ft) coolant return pipe/turbo 25 Nm (18 lbf ft) Clamp, coolant return pipe 9 Nm (7 lbf ft) |

|

| 3. |

Fit the coolant return pipe to the turbo. Also, tighten the pipe by the coolant pump. Fit new copper washers.

Tightening torques Banjo screw, turbo: 25 Nm (18 lbf ft) Banjo screw, coolant pump: 20 Nm (15 lbf ft) |

|

| 4. |

Fit the turbo oil pipe (connection to the turbo). Use new copper washers.

Tightening torques Banjo screw, turbo: 20 Nm (14 lbf ft) |

|

| 6. |

Slacken the adjusting screw on the intake manifold to adjust the pipe.

|

|

| 7. |

Tighten the V-clamp between the turbo and the turbo intake pipe.

Tightening torque 3 Nm (2 lbf ft) |

|

| 8. |

Tighten the intake manifold bolt in the power steering pump mounting. Also tighten the adjusting screw.

Tightening torque: 24 Nm (18 lbf ft)

|

||||||||||

| 9. |

260 hp:

Fit the wastegate-box.

All:

Connect all the hoses to the turbocharger and the diaphragm box.

|

|

| 10. |

Remove the plug from the charge air cooler inlet pipe.

|

|

| 11. |

Connect the charge air cooler's inlet hose to the turbo.

Tightening torque: 8 Nm (6 lbf ft) |

|

| 12. |

Fit the heat shield. Press on the left-hand holder first. Apply Molycote 1000, part no. 30 20 971, to the stud.

Tightening torque, nut, heat shield 20 Nm (15 lbf ft) (up to and including engine no. 7011078) Tightening torque, nut, heat shield 21 Nm (16 lbf ft) (from and including engine no. 7011079) |

|

| 13. |

Fit the mass air flow sensor and air hose.

|

|

| 14. |

Fit the engine lifting eye.

|

|

| 15. |

Screw the crankcase breather pipe's bolt in the camshaft cover and the banjo bolt in the turbo intake pipe.

Tightening torque: 24 Nm (18 lbf ft)

|

||||||||||

| 16. |

Plug in the mass air flow sensor and boost pressure control valve connectors.

|

|

| 17. |

Connect the charge air bypass valve and pipe. Fit a new O-ring greased with non-acidic vaseline.

|

|

| 18. |

Tighten the bolts and fit the hose clip.

Tightening torque: 8 Nm (6 lbf ft) |

|

| 19. |

Raise the car and fit the third nut at the connection between the turbo and the front exhaust system.

Tightening torques: Stud: 22 Nm (16 lbf ft) Lock nut 24 Nm (18 lbf ft) |

|

| 20. |

Fit the turbo oil pipe (connection to oil filter adapter). Fit new copper washers.

Tightening torque: 25 Nm (18 lbf ft) |

|

| 21. |

Fit the turbo stays.

Tightening torque: 24 Nm (18 lbf ft) |

|

| 22. |

Fit the return oil connection and pipe from the turbo to the cylinder block. Lower the car.

Tightening torques M6 bolts 2x, turbo: 14 Nm (10 lbf ft) |

|

| 23. |

Fill up with coolant to MAX. Do not forget to close the drain cock on the radiator first. For the correct mixture, see

coolant

. Close the cap.

|

|

| 24. |

Start the engine and warm it up without load, preferably at varying speeds until the radiator fan cuts in.

|

|

| 25. |

Turn off the engine and top up with engine oil/coolant as necessary.

|

|

| 26. |

Raise the car.

|

|

| 27. |

Inspect the system for possible leaks.

|

|

| 28. |

Fit the lower front cover.

|

|

| 29. |

Lower the car to the floor.

|

|

Warning

Warning