Leak check, fuel pressure, flow capacity and adaptation procedures

|

|

Leak check, fuel pressure, flow capacity and adaptation procedures

|

The car can exhibit certain fault symptoms without generating a diagnostic trouble code. This can be due to an air leak in the system or insufficient fuel pressure and flow capacity.

The fault diagnosis listed below includes checking air leaks, fuel pressure, flow capacity and adaptation procedures. If a trouble code is present the appropriate fault diagnosis procedure should be used. The method below is to be used if the problem cannot be traced with a diagnostic trouble code.

Warning

Warning

|

|

Removal of the fuel pressure regulator involves partial dismantling of the car's fuel system. The following points must therefore be observed in connection with this work:

|

|

•

|

Have a class BE fire extinguisher on hand! Be aware of the risk of sparks, i.e. in connection with electric circuits, short-circuiting, etc.

|

|

•

|

Absolutely No Smoking!

|

|

•

|

Ensure good ventilation! If there is approved ventilation for evacuating fuel fumes then this must be used.

|

|

•

|

Wear protective gloves! Prolonged exposure of the hands to fuel can cause irritation to the skin.

|

|

•

|

Wear protective goggles.

|

|

|

|

|

|

|

1.

|

Make 2 copies of the checklist at the end of this document. Fill out one of the copies of the checklist before undertaking the diagnostic procedure.

|

|

3.

|

Remove the upper engine cover.

|

|

6.

|

Coat the charge air pipe O-ring (the O-ring is fitted starting with VIN W3070001) with Vaseline and mount it on the throttle body. If needed, replace the O-ring.

Pressure test the system as follows:

|

|

7.

|

Detach the crankcase ventilation hoses at the camshaft cover and at the pipe to the banjo fitting.

|

|

8.

|

Plug the crankcase ventilation pipe at the cylinder head. Use the hose plug in

83 95 659 Plug kit

.

|

|

9.

|

Detach the hose from the check valve.

|

|

10.

|

Detach the hose from the mass air flow sensor. Mount

83 95 659 Plug kit

in the hose and connect the accompanying pressure regulator to an external air pressure outlet.

|

Important

|

|

Close the pressure regulator before connecting it to the air pressure outlet.

|

|

|

|

|

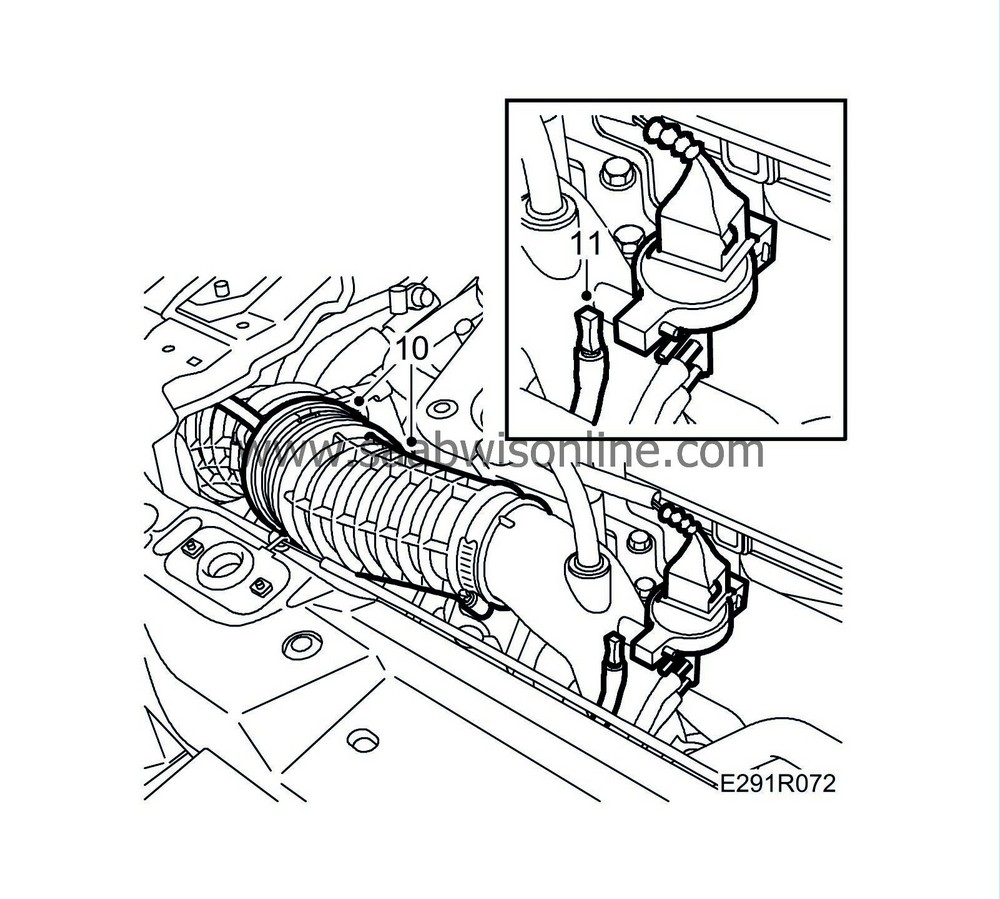

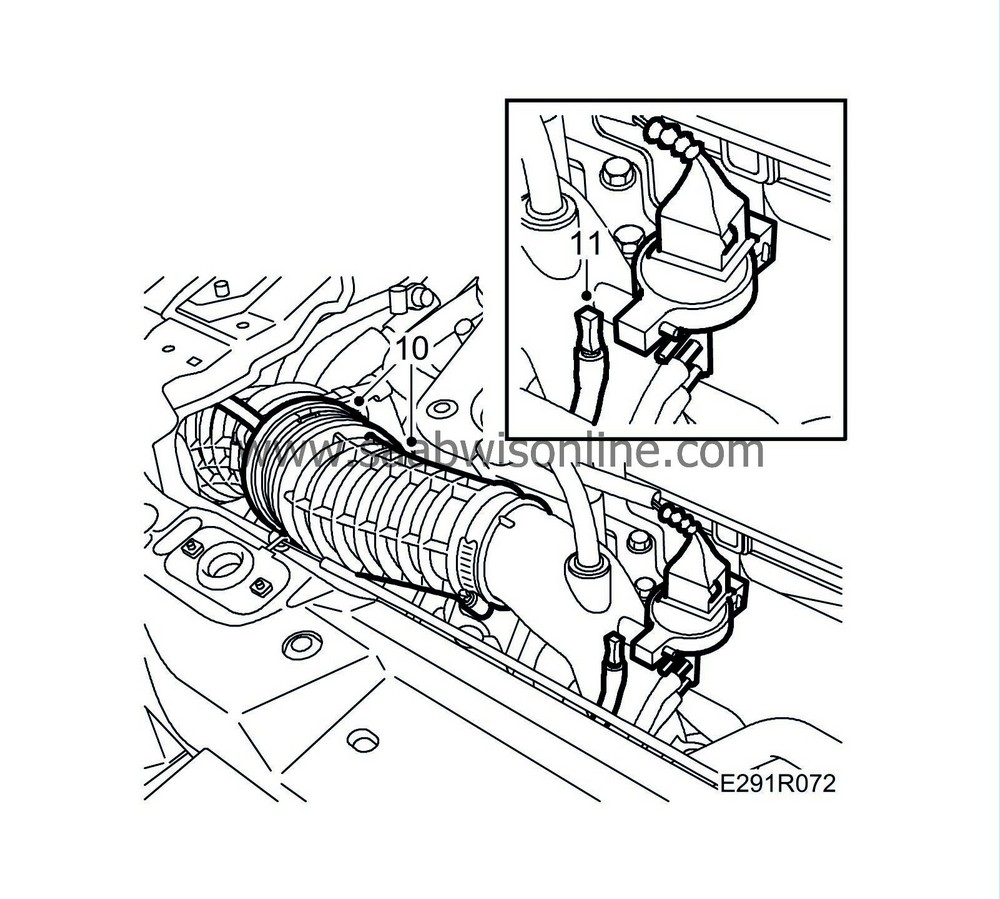

11.

|

Detach and plug the uppermost signal hose to the boost pressure control valve (connection R).

|

|

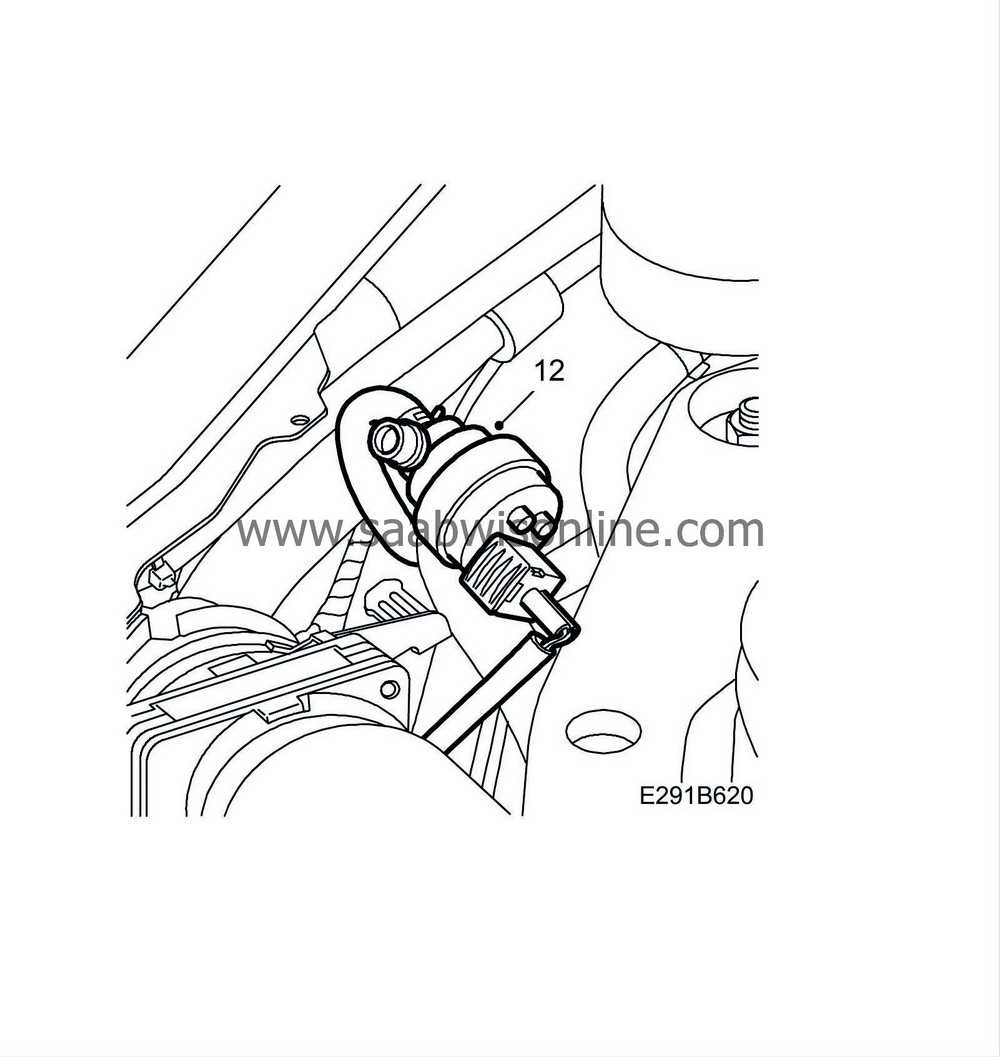

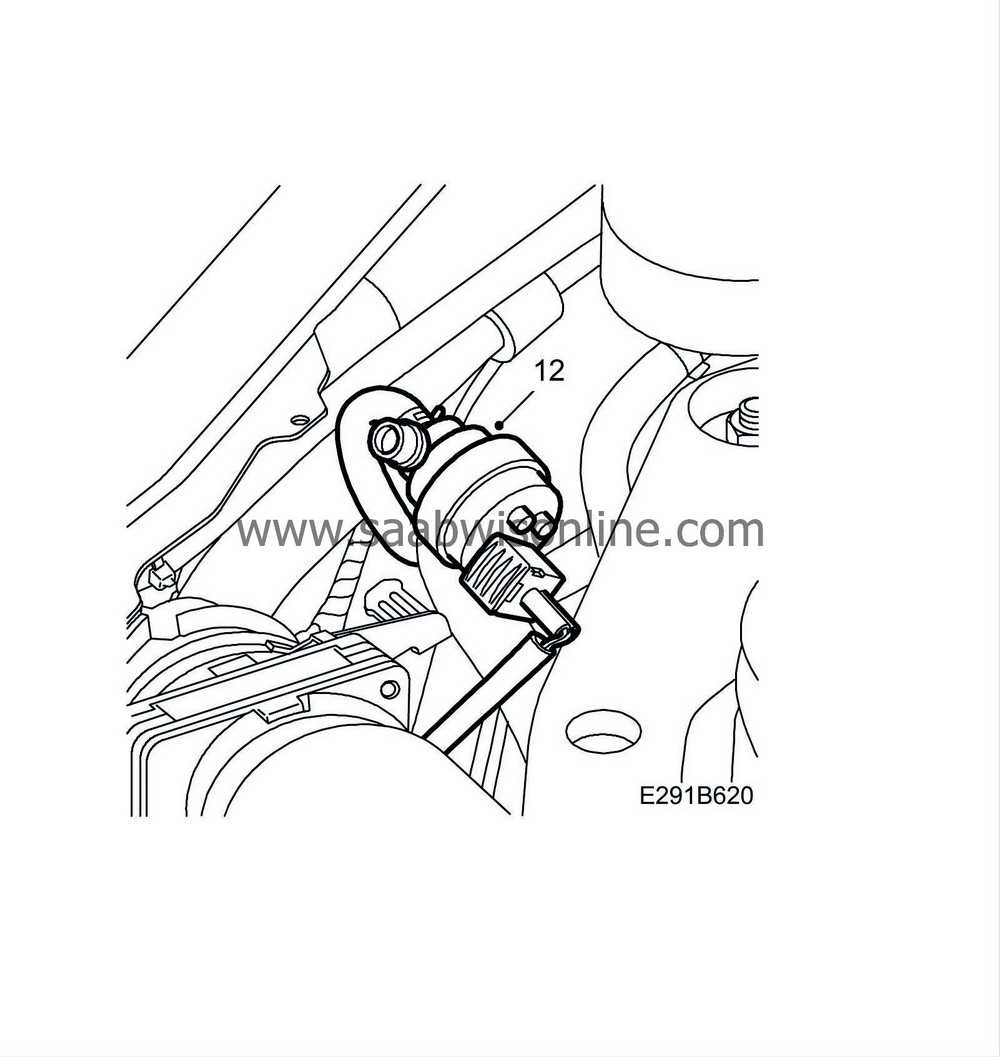

12.

|

Detach the lower quick-release coupling to the evap canister purge valve.

|

|

13.

|

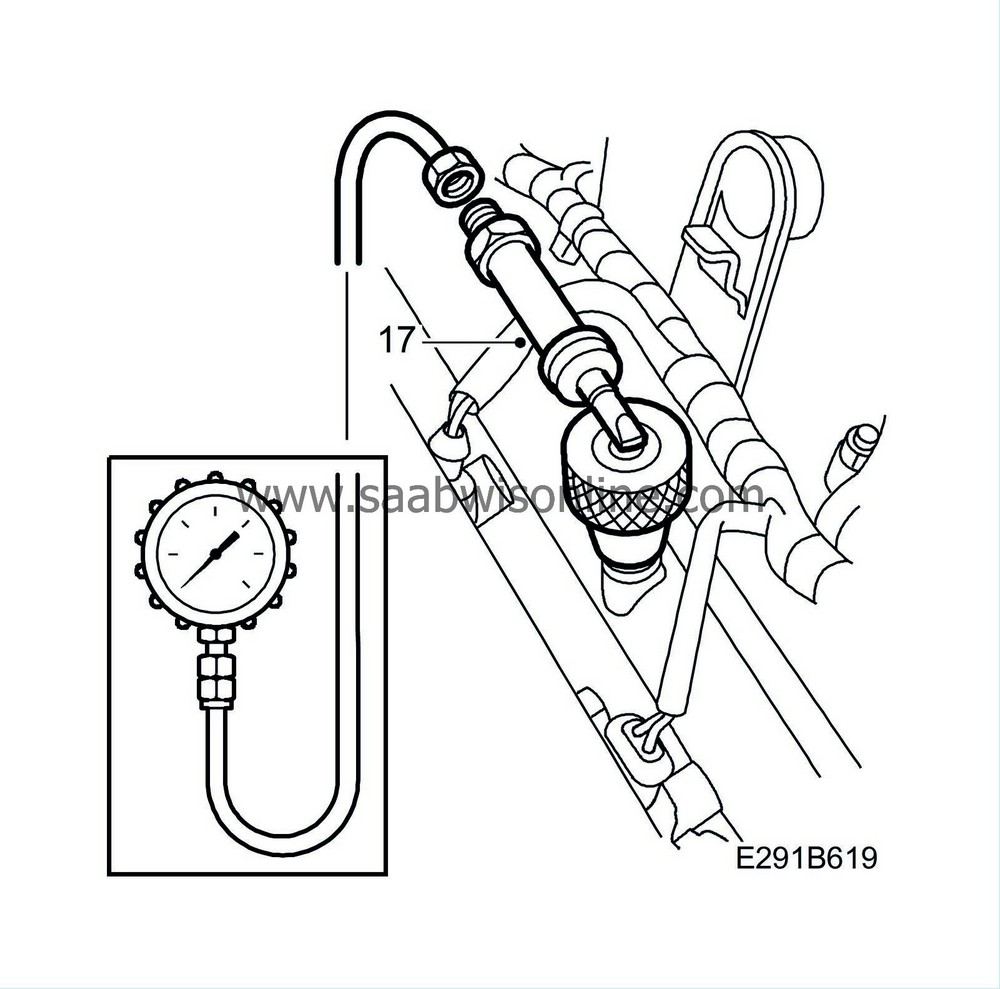

Pressurise the intake system by carefully turning the pressure regulator until max 0.6 bar is achieved. Read of the value using

83 93 514 Boost pressure gauge

.

|

|

14.

|

This will pressurise the entire intake system so that leaks can be detected using a leak detecting spray or soap solution. Check all the components, hoses and connections, and rectify any audible leaks.

|

Important

|

|

Only leaks that can be heard will affect the function of the engine management system. When leak-detecting spray or soapy water is used, even small leaks will be found. These do not need to be addressed.

|

|

|

|

|

15.

|

Remove the plugs and connect the hoses to the mass air flow sensor, the boost pressure control valve, the evap canister purge valve and the crankcase ventilation.

|

|

16.

|

Check the control module software version in Tech 2. If there is a more recent version in WIS it should be programmed into the control module.

Checking fuel pressure / flow capacity

|

Important

|

|

Use the assistance of a colleague when measuring on the move.

|

|

|

|

|

18.

|

Measure fuel pressure while driving with as high a load as possible. Read off the values on the pressure gauges. The pressure differential should always be 3 bar of fuel pressure according to the table below.

Then drive with varying loads and engine speeds. Check that the fuel pressure follows the pressure in the intake manifold. If the differential pressure is incorrect, check the fuel pressure regulator, fuel pump and fuel lines - inlet and return. Make sure the tank evaporation is working properly. See

Checking for leaks in the evaporative emission system

.

Pressure, intake manifold

|

Fuel pressure

|

-0.6 to -0.4 bar

|

2.4-2.6 bar

|

0 bar (barometric pressure)

|

3.0 bar

|

0.6 bar

|

3.6 bar

|

|

|

19.

|

Check the fuel adaptation with Tech 2. Carry out the adaptation as follows:

|

|

|

19.a.

|

Turn off the A/C or ACC.

|

|

|

19.b.

|

Engine temperature should be over 80°C and the engine should have been running for at least 3.5 minutes. The adaptation must be completed within 10 minutes of engine start-up.

|

|

|

19.c.

|

Drive on a flat road at between 1500 - 2750 rpm in 5th or 4th gear, attempting to keep the accelerator pedal completely still for approximately 2 minutes.

|

|

|

19.d.

|

Stop the car and let the engine idle.

|

|

|

19.e.

|

Read "multiplicative adaptation" on Tech 2.

|

|

|

19.f.

|

Read "additive adaptation" on Tech 2. If the value does not change within 10 minutes, turn off the engine and start it up again and repeat steps 19b - 19f. If the value still does not change, go to step 24.

|

|

20.

|

Carry out the adaptation of the throttle opening.

|

|

|

20.a.

|

Coolant temperature should be over 80°C. Turn off the A/C or ACC.

|

|

|

20.b.

|

Let the engine idle for 2 minutes. Turn off the engine.

|

|

|

20.c.

|

Repeat step 20b 3 times.

|

|

21.

|

Fill out the second copy of the checklist.

|

|

22.

|

Disconnect the pressure measuring equipment and Tech 2.

|

|

23.

|

Refit the upper engine cover.

|

|

24.

|

If the problems have not been solved, contact the importer's technical support. Have the completed checklists ready.

|

|

1.

|

Describe the fault symptom .......................................................................................................................................

...................................................................................................................................................

....................................................................................................................................................

|

|

3.

|

Turn off A/C or ACC and let the engine idle. Coolant temperature should be over 80°C.

|

Note

|

|

Diagnostic trouble codes must not be erased.

|

|

|

4.

|

Read and note any diagnostic trouble codes: .......................................................................................................................

|

|

5.

|

Select "Engine" - "Trionic" - "Read values / Activate" in Tech 2. Read and note the following values:

|

|

|

Unit

|

Turn Ignition On

|

Idle

|

Desired value

|

Engine speed

|

rpm

|

-------------

|

|

800-850

|

Airmass/Combustion

|

mg/c

|

-------------

|

|

|

Coolant temperature

|

°C

|

|

|

85-100

|

Deviation from calculated air mass

|

%

|

-------------

|

|

max. 10

|

Intake air temperature.

|

°C

|

|

|

40-60

|

Atmosphere Absolute Pressure

|

kPa

|

|

|

90-115

|

Charge Air Absolute Pressure

|

kPa

|

|

|

95-110

|

Manifold Absolute Pressure

|

kPa

|

|

|

25-60

|

Additive adaptation

|

mg/c

|

|

|

max. 0.6

|

Multiplicative adaptation

|

%

|

|

|

max. 6

|

Charge Air Adaptation

|

%

|

|

|

max. 10

|

|

|

Number of knocks

|

Number of misfires

|

Cylinder 1

|

|

|

Cylinder 2

|

|

|

Cylinder 3

|

|

|

Cylinder 4

|

|

|

Under “system information” you will find information on chassis and version numbers for Trionic T7

Vehicle Identification Number

|

|

Software version

(obligatory)

|

|

The plate with the engine number is placed on the cylinder block according to WIS - Engine - Base engine, petrol - Technical data - Engine number.

To see the colour of the injectors, remove the upper engine cover.

Engine serial no.

|

|

Fuel injector, colour

|

|

Warning

Warning