Knock control

| Knock control |

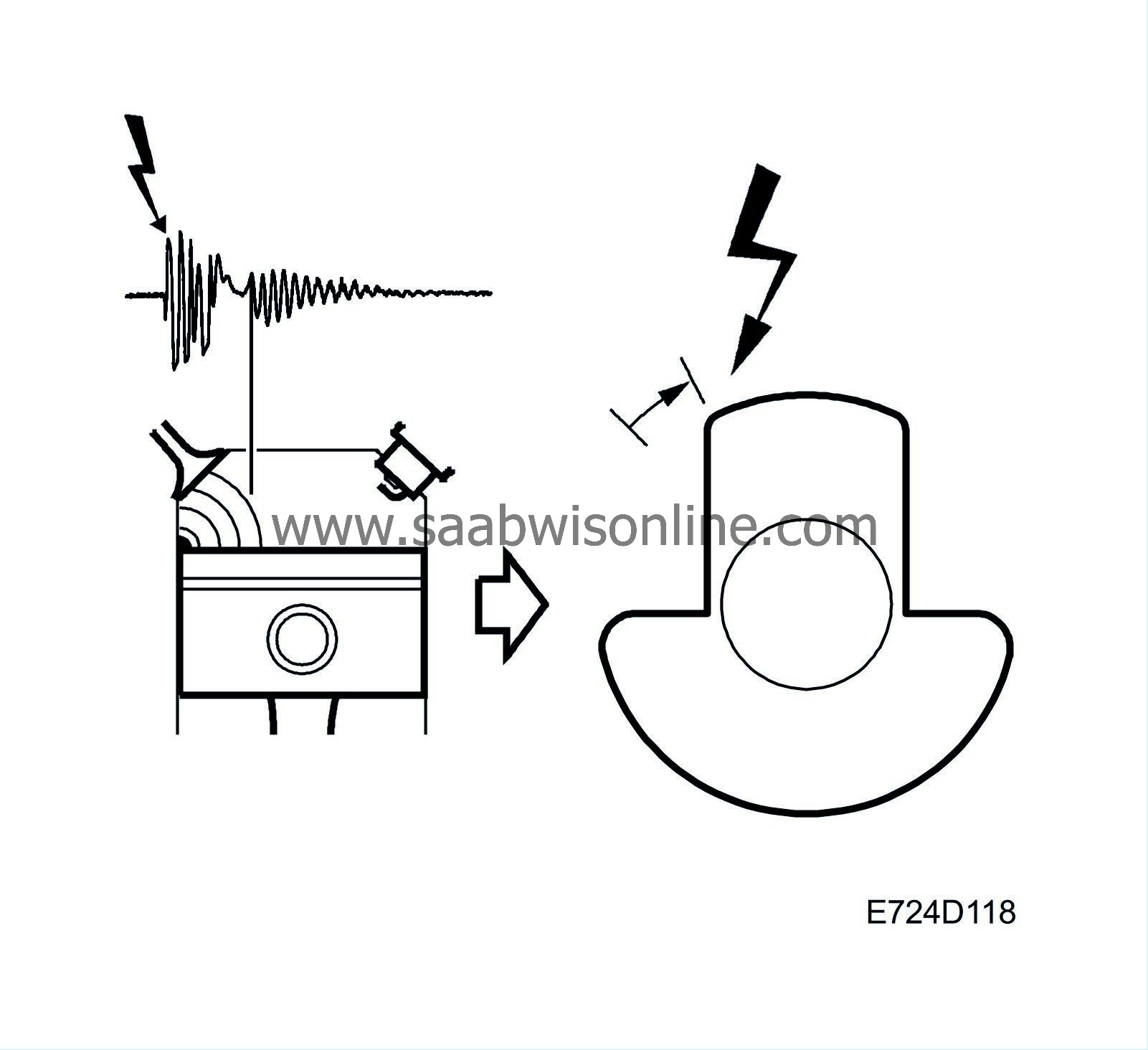

Trionic T7 does not have a conventional knock sensor. Instead, the ignition discharge module analyses the ionization current across the spark plug gap on all cylinders and sends a knock signal from each cylinder to control module pin 38.

From the combustion signals, the control module will be aware of which cylinder has fired and if a knock signal above a certain level is registered at the same time by the control module, it will gradually retard the ignition for the cylinder in question until the knocking ceases. Timing correction then returns slowly to zero.

| Note | ||

|

To ensure optimal engine performance, the correct spark plug should be used for each respective engine type. See Technical data, Spark plugs (157) . |

||

|

Knock control on modern engines is not a safety function but a normal function. Consequently, it is considered normal when knock control reduces engine torque in certain cases. The engine knock control increases for e.g. high intake air temperatures or high coolant temperatures. Further influencing factors are driving at high altitudes and low octane fuel. Certain engine variants require petrol with an octane rating of 98 RON in order to provide the specified engine torque/power. |

If the mean value of the ignition retardation on all cylinder exceeds a certain level, fuel enrichment will take place. If the mean value of the ignition retardation on all cylinders increases further despite fuel enrichment, the maximum permissible air mass/combustion will be limited.

The control module expects the knock signal to be at a certain level as the spark is produced, so it will therefore start the actual knock detection in the respective cylinder only after the spark has been produced.

| Diagnostics |

| • |

If there is an open circuit or a short circuit on the knock lead between the ignition discharge module and the control module, diagnostic trouble code P0327 will be generated.

|

|