Lower Crankcase Installation (LDK, LHU)

|

|

Lower Crankcase Installation (LDK, LHU)

|

Special Tools

EN-45059

Angle Meter

For equivalent regional tools, refer to

Special Tools (LDK, LHU)

.

|

1.

|

Install the upper crankshaft bearings (1) in the engine block (2) and lubricate bearing surfaces with engine oil.

|

|

2.

|

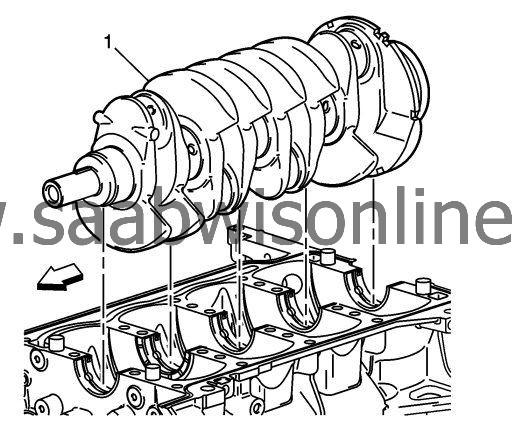

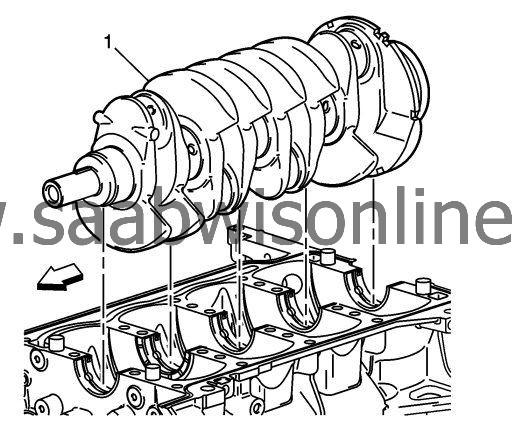

Install the crankshaft (1) on the journals.

|

|

3.

|

Install the lower bearing halves (1), without grooves, into the lower crankcase (2). Apply oil to bearing surfaces.

|

|

4.

|

|

Note

|

|

•

|

The block assembly surface must be free of contamination prior to applying the sealer.

|

|

•

|

Install and align the bedplate to block within 20 minutes of applying the sealer.

|

|

•

|

The bedplate must be fastened to final torque specification within 60 minutes of applying the sealer.

|

Apply a 4.25 mm bead of sealer, dimension a, directly in the groove of the block to bedplate mating surfaces. Refer to

Adhesives, Fluids, Lubricants, and Sealers (LDK, LHU)

.

|

|

5.

|

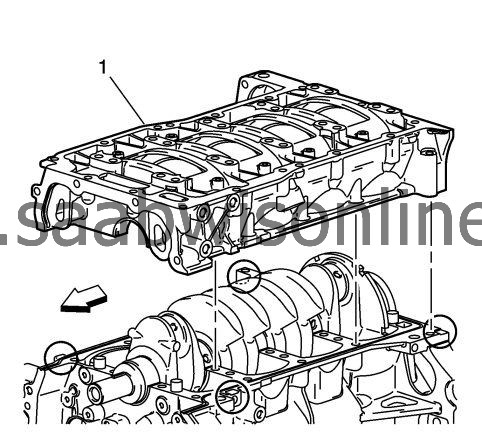

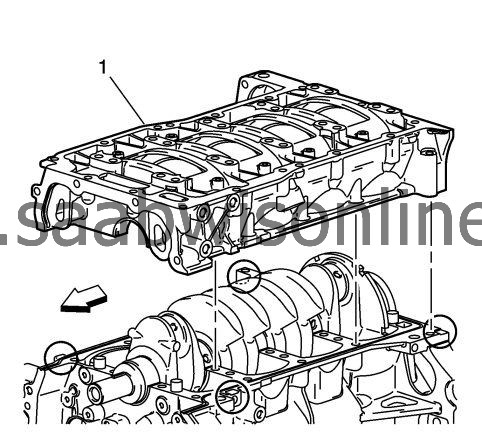

Install the lower crankcase (1). Tap gently into place with a suitable tool, if necessary. Ensure the lower crankcase is aligned properly on the dowels.

|

|

6.

|

Refer to

Fastener Caution

.

Install the NEW crankshaft bearing bolts in sequence finger tight.

|

|

7.

|

Tighten the crankshaft bearing bolts:

|

|

|

7.1.

|

Tighten the crankshaft bearing bolts a first pass in sequence to

20 Nm (15 lb ft)

.

|

|

|

7.2.

|

Using the

EN-45059

angle meter , tighten the crankshaft bearing bolts a final pass in sequence to

70 degrees

.

|

|

8.

|

|

Note

|

|

Do not forget the 2 rear outer bolts.

|

Install the lower crankcase perimeter bolts (1-10) and tighten to

25 Nm (18 lb ft)

.

|