Piston, Connecting Rod, and Bearing Installation (LDK, LHU)

|

|

Piston, Connecting Rod, and Bearing Installation (LDK, LHU)

|

Special Tools

|

•

|

EN-43953

Piston Ring Compressor

|

|

•

|

EN-43966-1

Connecting Rod Guides

|

For equivalent regional tools, refer to

Special Tools (LDK, LHU)

.

|

1.

|

Install the NEW connecting rod bearings.

|

|

|

1.1.

|

Install the bearing inserts into the connecting rod and the connecting rod cap.

|

|

|

1.2.

|

Lubricate the connecting rod bearings with engine oil.

|

|

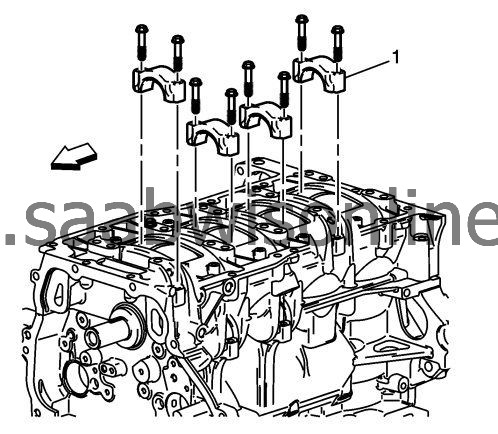

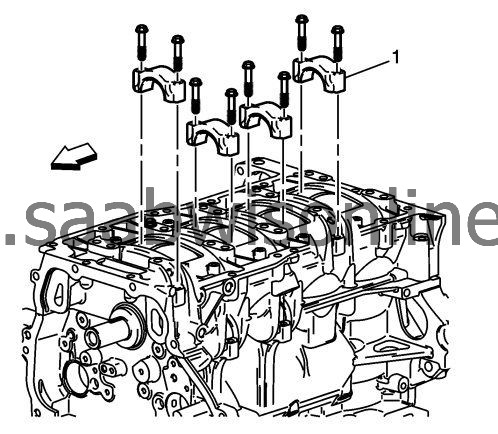

2.

|

Install the

EN-43966-1

guides (1) into the connecting rod bolt holes. This protects the crankshaft journal during piston and connecting rod installation.

|

|

3.

|

Install the

EN-43953

compressor , the piston (2), and the connecting rod to the correct bore.

|

|

|

3.1.

|

Stagger each piston ring end gap equally around the piston.

|

|

|

3.2.

|

Lubricate the piston and the piston rings with engine oil.

|

|

|

3.3.

|

Do not disturb the piston ring end gap location.

|

|

|

3.4.

|

The piston must be installed so that the mark on the top of the piston faces the front of the engine.

|

|

|

3.5.

|

Place the piston in its matching bore.

|

|

|

3.6.

|

Tap the piston into its bore with a hammer handle. Guide the connecting rod to the connecting rod journal while tapping the piston into place.

|

|

|

3.7.

|

Hold the

EN-43953

compressor against the engine block until all the rings have entered the cylinder bore.

|

|

|

3.8.

|

Remove the connecting rod guides from the connecting rod bolt holes.

|

|

4.

|

|

Note

|

|

Ensure that the connecting rod cap is properly oriented on the connecting rod.

|

Install the connecting rod cap (1).

|

|

5.

|

Refer to

Fastener Caution

.

|

Note

|

|

Always use NEW bolts.

|

Install NEW connecting rod bolts and tighten to

25 Nm (18 lb ft)

plus

100 degrees

using the

EN-45059

angle meter .

|

|

6.

|

Install the remaining connecting rods and piston assemblies.

|

|

7.

|

Measure the connecting rod side clearance with a feeler gauge (1).

The correct clearance is 0.07-0.37 mm (0.0027-0.0145 in).

|