Camshaft Cleaning and Inspection

|

|

Camshaft Cleaning and Inspection

|

Special Tools

EN-49474

Magnetic Base Dial Indicator

For equivalent regional tools, refer to

Special Tools

.

|

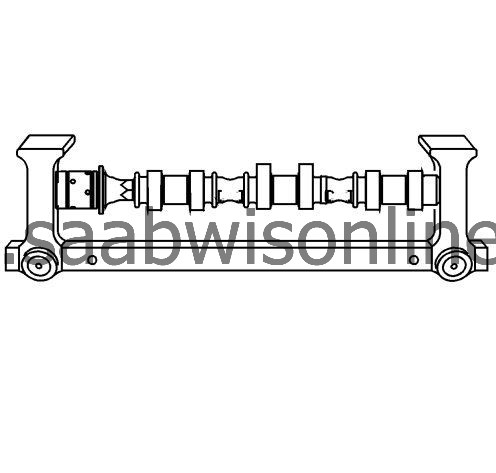

1.

|

Clean the camshaft in solvent.

|

|

2.

|

Warning

Warning

|

|

Wear safety glasses when using compressed air, as flying dirt particles may cause eye injury.

|

|

|

|

|

|

Dry the camshaft with compressed air.

|

|

1.

|

Inspect the camshaft oil feed holes (1) to the camshaft position actuator for dirt, debris or blockage.

|

|

2.

|

Inspect the threaded hole (2) for damage.

|

|

3.

|

Inspect the camshaft position actuator locating notch (3) for damage or wear.

|

|

4.

|

Inspect the camshaft sealing grooves (4) for damage.

|

|

5.

|

Inspect the camshaft thrust surface (5) for damage.

|

|

6.

|

Inspect the camshaft lobes (6) and journals (7) for the following conditions:

|

|

|

•

|

Excessive scoring or pitting

|

|

|

•

|

Discoloration from overheating

|

|

|

•

|

Deformation from excessive wear, especially the camshaft lobes

|

|

7.

|

If any of the above conditions exist on the camshaft, replace the camshaft.

|

|

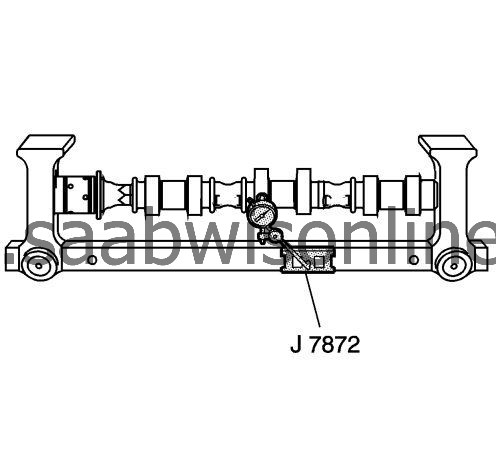

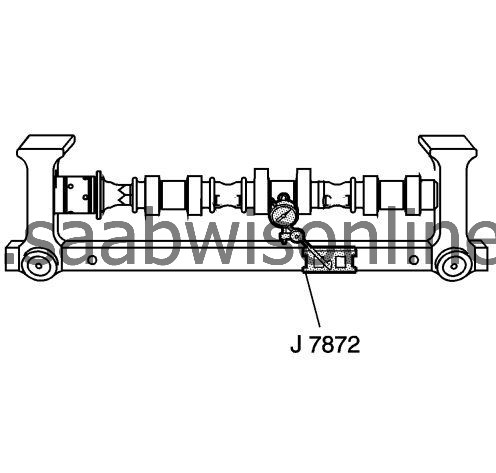

1.

|

With the camshaft in a suitable fixture, measure the camshaft for wear.

|

|

|

•

|

If the diameter is smaller than specifications, replace the camshaft.

|

|

|

•

|

If the out-of-round exceeds specifications, replace the camshaft.

|

|

6.

|

If the camshaft is damaged or worn beyond specifications, replace the camshaft. No machining of the camshaft is allowed.

|

|

7.

|

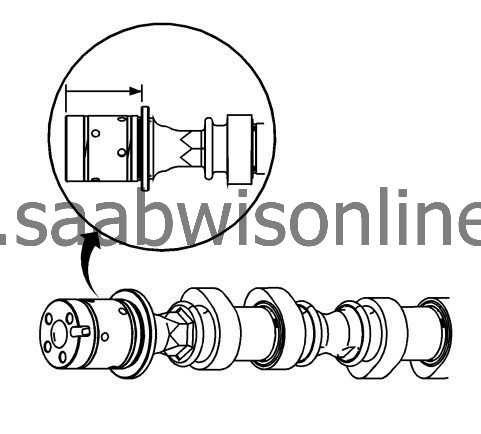

Measure the camshaft lobes for wear using the

EN 49474

indicator.

|

|

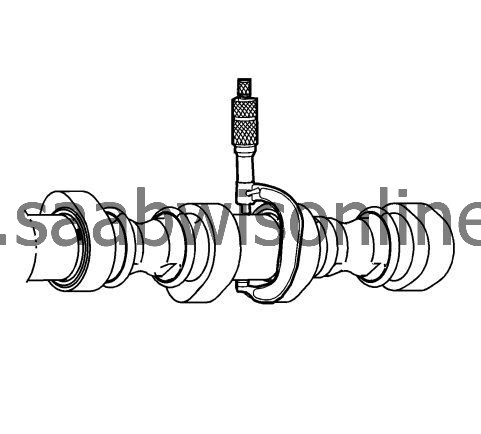

8.

|

Place the

EN 49474

indicator with the indicator tip on the base circle (1) of the camshaft lobe.

|

|

|

8.1.

|

Place the

EN 49474

indicator at zero .

|

|

|

8.2.

|

Rotate the camshaft until the indicator tip is at the highest point (3) on the lobe. This reading is the lift of the camshaft lobe. Refer to

Engine Mechanical Specifications

.

|

|

|

8.3.

|

If the indicated measurement is significantly lower than these specifications, replace the camshaft or engine performance will be reduced.

|

Warning

Warning