Oil Pump Cleaning and Inspection

|

|

Oil Pump Cleaning and Inspection

|

|

1.

|

Clean the oil pump components with non-corrosive solvent.

|

|

2.

|

Warning

Warning

|

|

Wear safety glasses when using compressed air, as flying dirt particles may cause eye injury.

|

|

|

|

|

|

Dry the oil pump components with compressed air.

|

|

1.

|

|

Note

|

|

There are no serviceable components within the oil pump. Disassemble the pump only to diagnose an oiling concern. A disassembled oil pump must not be reused. A disassembled oil pump must be replaced.

|

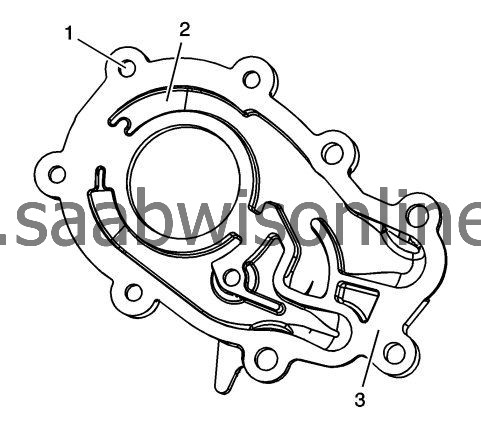

Inspect the oil pump housing for the following:

|

|

|

•

|

Damage, scoring, or debris on the housing surface for the driven gear (1)

|

|

|

•

|

Damage to the oil pump mounting bosses (2)

|

|

|

•

|

Damage, scoring, or debris on the housing surface for the drive gear (3)

|

|

|

•

|

Damage, scoring, or debris in the oil pump relief valve port (4)

|

|

|

•

|

Damage, scoring, or debris in the oil pump intake port (5)

|

|

|

•

|

Damage, scoring, or debris in the oil pump relief valve bore (6)

|

|

|

•

|

Damage, scoring, or debris in the oil pump output port (7)

|

|

|

•

|

Damage to the threads in the oil pump housing for the oil pump cover bolts (8)

|

|

2.

|

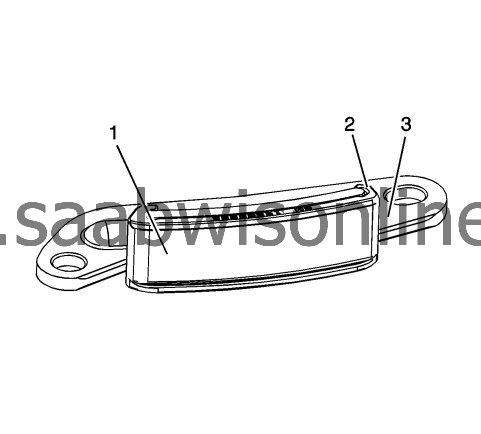

Inspect the oil pump cover for the following conditions:

|

|

|

•

|

Damage to the oil pump cover mounting bosses (1)

|

|

|

•

|

Damage, scoring, or debris in the oil pump cover oil passages (2)

|

|

|

•

|

Damage to the sealing surface between the oil pump cover and the oil pump housing (3)

|

|

3.

|

Inspect the inner drive gear for damage. If inner diameter damage is found, ensure the crankshaft is also inspected.

|

|

4.

|

Inspect the outer driven gear for damage.

|

|

5.

|

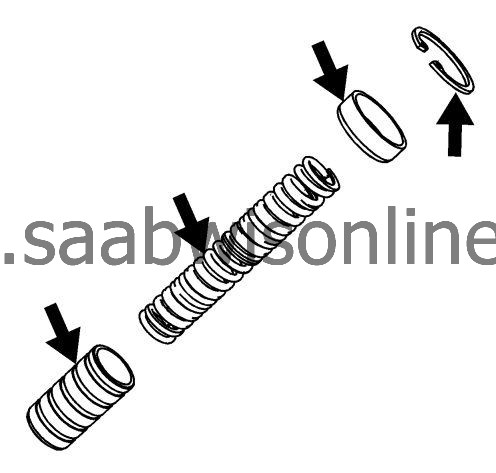

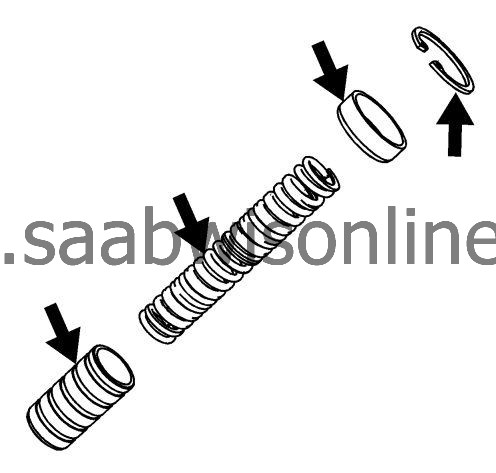

Inspect the oil pump relief valve components for debris or damage.

|

|

6.

|

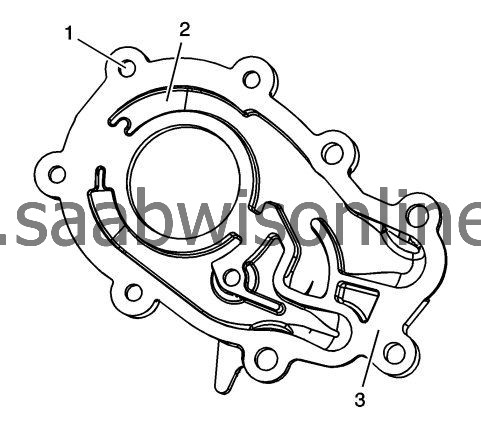

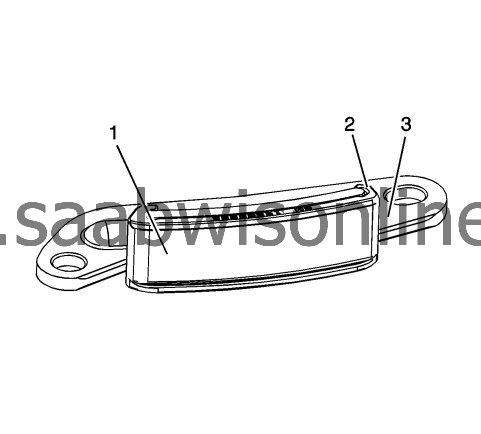

Inspect the primary camshaft drive chain lower guide for damage (1-3).

|

|

7.

|

If debris or damage is present within the oil pump, further inspection of all of the engine components is necessary.

|

Warning

Warning