Cooling System Draining and Filling (LAU/A28NER)

|

|

Cooling System Draining and Filling (LAU/A28NER)

|

Warning

Warning

|

|

With a pressurized cooling system, the coolant temperature in the radiator can be considerably higher than the boiling point of the solution at atmospheric pressure. Removal of the surge tank cap, while the cooling system is hot and under high pressure, causes the solution to boil instantaneously with explosive force. This will cause the solution to spew out over the engine, the fenders, and the person removing the cap. Serious bodily injury may result.

|

|

|

|

|

|

|

Note

|

|

Use only a GM released anti-freeze mixture and ensure a concentration of 50% water to 50% antifreeze. Antifreeze does not just prevent the cooling system from freezing up, it also protects all the components that are in contact with coolant from rust/limescale deposits. As a result, antifreeze should always be added, even in tropical countries.

|

|

In addition to the anti-freeze mixture, water quality also plays an important role. Potable tap water should normally suffice to fulfil this requirement. The quality of regenerated sea water is not suitable.

|

|

Damage may also be caused to the engine if unauthorized anti-freeze agent is used.

|

|

If radiator, cylinder head or cylinder head seal have been replaced the old coolant must not be re-used.

|

|

1.

|

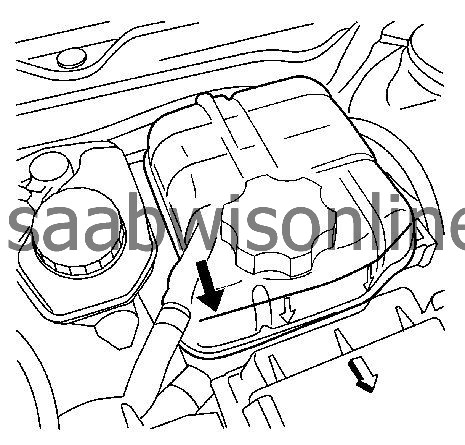

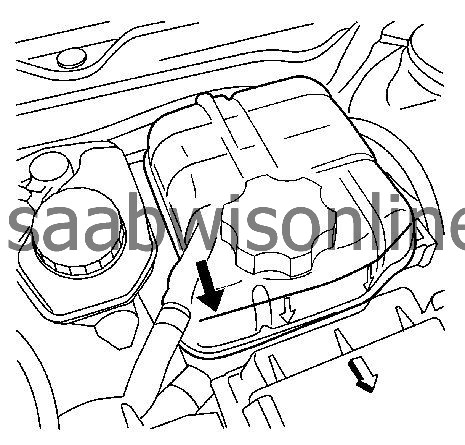

Open cooling system. Unscrew coolant surge tank cap.

|

|

2.

|

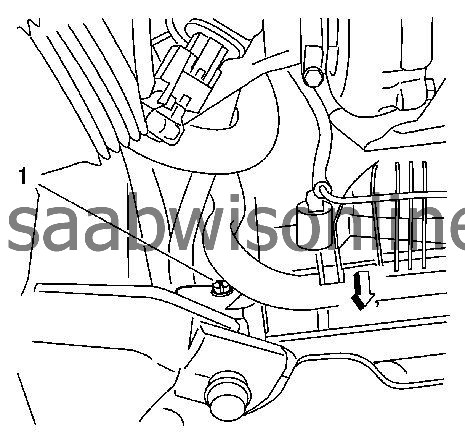

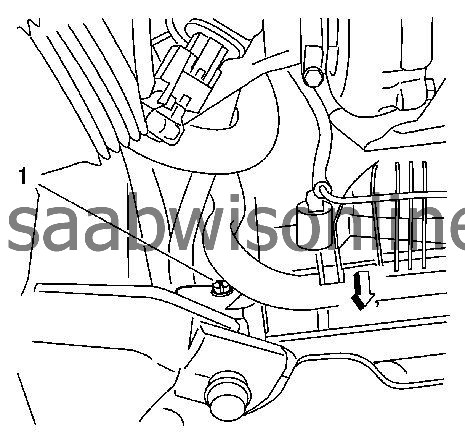

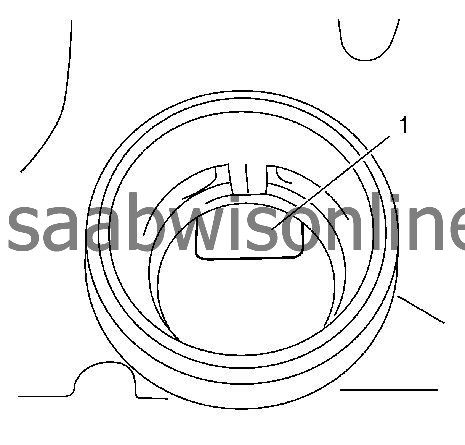

For draining the cooling system, open the drain screw (1) on the radiator.

|

|

1.

|

Vehicles with air conditioning: Switch off the air conditioning.

|

|

2.

|

After draining the system, close the drain screw on the radiator.

|

|

3.

|

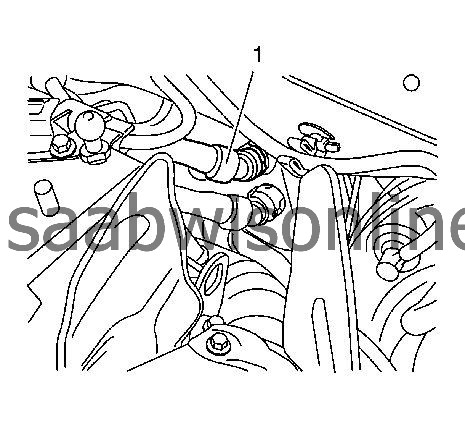

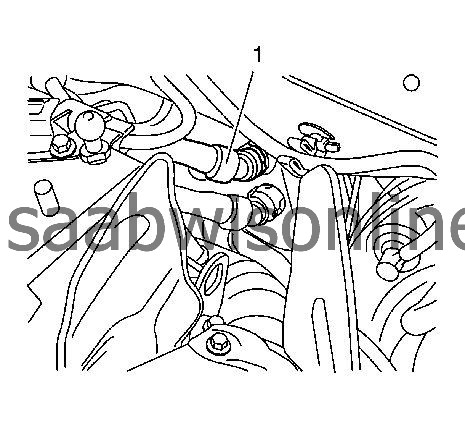

Open vent screw (1) on radiator.

|

|

4.

|

Disconnect the quick connector (1) of the heater core inlet hose.

|

|

5.

|

|

Note

|

|

Connect the quick connector of the heater core inlet hose and close the vent screw when coolant flows out.

|

At first top up coolant until cold level of the coolant expansion tank. When the coolant has stopped dropping top up the coolant until the bottom line of the down pipe hole. (black arrow).

|

|

6.

|

Cap the cooling system screw in coolant expansion tank cap.

|

|

7.

|

|

Note

|

|

After removing the heater core (located in passenger room) the following additional work has to be done:

|

|

Immediately after the engine starts kick the accelerator pedal 3 times - thereby the engine speed should not exceed 2500 RPM.

|

Start and warm up the engine.

Warm up engine at idle speed up to 2500 RPM until first radiator fan setting switches on.

|

|

8.

|

|

Note

|

|

After removing the heater core (located in passenger room) let the engine run for 2 minutes at 2000 to 2500 RPM. This ensures complete venting of the cooling system.

|

Vent cooling system.

Kick the accelerator pedal 3 times - thereby the engine speed should not exceed 2500 RPM.

|

|

9.

|

Switch the engine off and let the engine cool down.

|

|

10.

|

|

Note

|

|

After a test drive let the engine cool down and check the coolant level again.

|

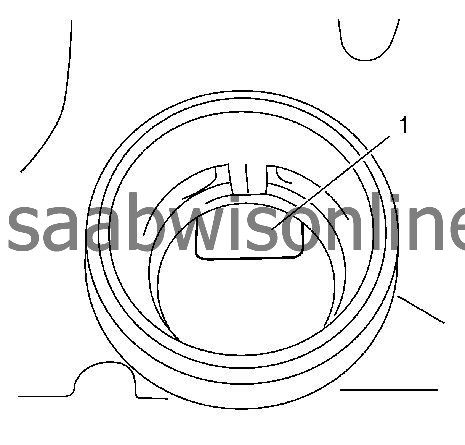

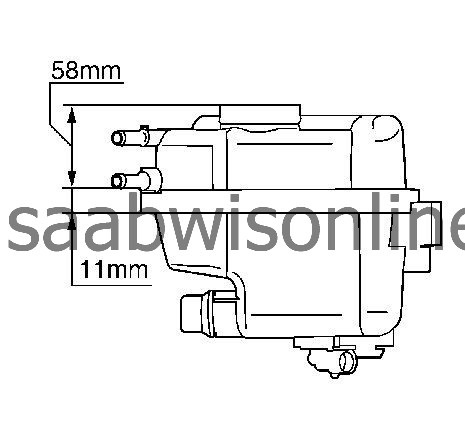

Check coolant level and correct if necessary. The correct cold mark (fill-level) of the degassed system is the existing internal cold mark (1) plus 11 mm (0.43 in), which is an additional amount of 200 ml (6.76 oz).

|

|

11.

|

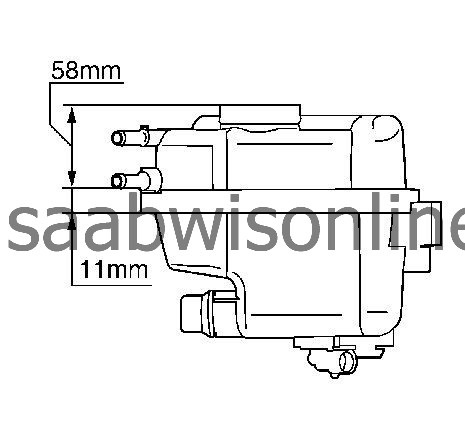

With an own making calliper check the fill-level again. The distance among the fill stud and the fill-level must be 58 mm (2.2 in).

|

|

12.

|

Close cooling system. Screw in coolant surge tank cap.

|

Warning

Warning