Spark Plug Inspection

| Spark Plug Inspection |

| Spark Plug Usage |

| 1. |

Ensure that the correct spark plug is installed. An incorrect spark plug causes driveability conditions. Refer to

Ignition System Specifications (LDK with Turbocharger)

for the correct spark plug.

|

|

| 2. |

Ensure that the spark plug has the correct heat range. An incorrect heat range causes the following conditions:

|

|

| • |

Spark plug fouling-Colder plug

|

| • |

Pre-ignition causing spark plug and/or engine damage-Hotter plug

|

| Spark Plug Inspection |

| 1. |

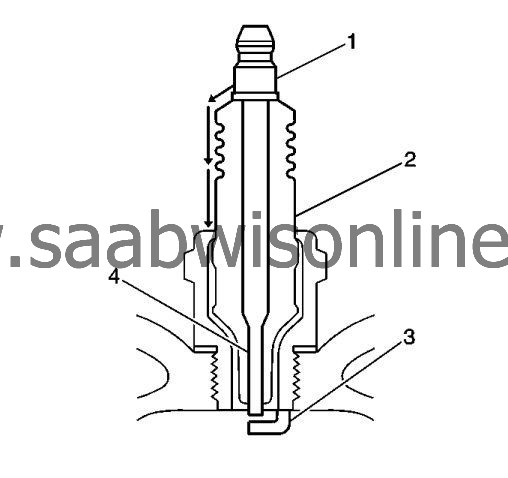

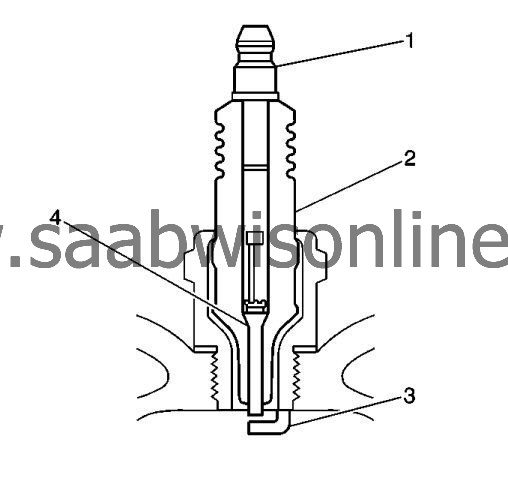

Inspect the terminal post (1) for damage.

|

|

| • |

Inspect for a bent or broken terminal post (1).

|

| • |

Test for a loose terminal post (1) by twisting and pulling the post. The terminal post (1) should NOT move.

|

| • |

Inspect the spark plug boot for damage.

|

| • |

Inspect the spark plug recess area of the cylinder head for moisture, such as oil, coolant, or water. A spark plug boot that is saturated causes arcing to ground.

|

| 3. |

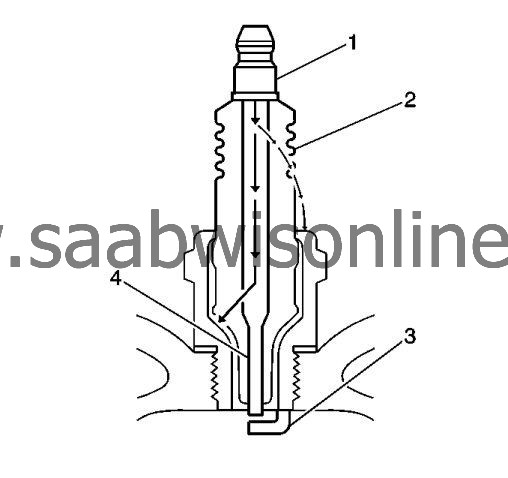

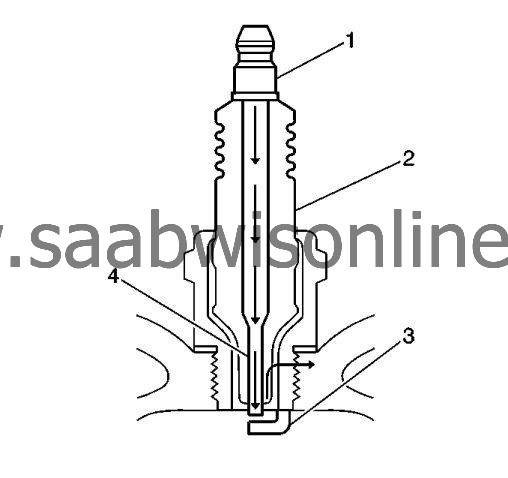

Inspect the insulator (2) for cracks. All or part of the electrical charge may arc through the crack instead of the electrodes (3, 4).

|

|

| 4. |

Inspect for evidence of improper arcing.

|

|

| • |

Measure the gap between the center electrode (4) and the side electrode (3) terminals. Refer to

Ignition System Specifications (LDK with Turbocharger)

. An excessively wide electrode gap can prevent correct spark plug operation.

|

| • |

Inspect for the correct spark plug torque. Refer to

Ignition System Specifications (LDK with Turbocharger)

. Insufficient torque can prevent correct spark plug operation. An over torqued spark plug, causes the insulator (2) to crack.

|

| • |

Inspect for signs of tracking that occurred near the insulator tip instead of the center electrode (4).

|

| • |

Inspect for a broken or worn side electrode (3).

|

| • |

Inspect for a broken, worn, or loose center electrode (4) by shaking the spark plug.

|

| 5. |

A rattling sound indicates internal damage.

|

|

| 6. |

A loose center electrode (4) reduces the spark intensity.

|

|

| • |

Inspect for bridged electrodes (3, 4). Deposits on the electrodes (3, 4) reduce or eliminates the gap.

|

| • |

Inspect for worn or missing platinum pads on the electrodes (3, 4) If equipped.

|

| • |

Inspect for excessive fouling.

|

| • |

Inspect the spark plug recess area of the cylinder head for debris. Dirty or damaged threads can cause the spark plug not to seat correctly during installation.

|

| Spark Plug Visual Inspection |

| 1. |

Normal: Brown to grayish-tan with small amounts of white powdery deposits are normal combustion by-products from fuels with additives.

|

|

| 2. |

Carbon Fouled: Dry, fluffy black carbon, or soot caused by the following conditions

|

|

| • |

Rich fuel mixtures

|

| • |

Leaking fuel injectors

|

| • |

Excessive fuel pressure

|

| • |

Restricted air filter element

|

| • |

Incorrect combustion

|

| • |

Reduced ignition system voltage output

|

| • |

Weak coils

|

| • |

Worn ignition wires

|

| • |

Incorrect spark plug gap

|

| • |

Excessive idling or slow speeds under light loads can keep spark plug temperatures so low that normal combustion deposits may not burn off.

|

| • |

Deposit Fouling-Oil, coolant, or additives that include substances such as silicone, very white coating, reduces the spark intensity. Most powdery deposits will not effect spark intensity unless they form into a glazing over the electrode.

|