Delphi Connectors (Pull To Seat)

|

|

Delphi Connectors (Pull To Seat)

|

Special Tools

For equivalent regional tools, refer to

Special Tools

.

If the terminal is visibly damaged or is suspected of having a faulty connection, the terminal should be replaced.

Follow the steps below in order to repair pull-to-seat connectors:

|

1.

|

Remove the connector position assurance (CPA) device and/or the secondary lock.

|

|

2.

|

Disconnect the connector from the component or separate the connectors for in-line connectors.

|

|

3.

|

Remove the terminal position assurance (TPA) device.

|

|

4.

|

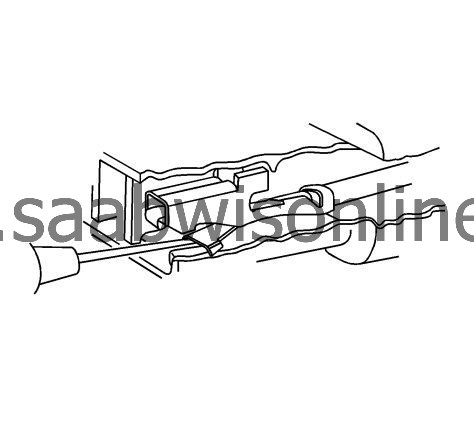

Insert the proper pick or removal tool into the front of the connector body.

|

|

5.

|

|

Note

|

|

On connectors with more than one terminal the service loop may not be large enough to remove the terminal and crimp on a new one. If the terminal wire does not have a large enough service loop for removal, cut the wire 5 cm (2 in) behind the connector before removal.

|

Grasp the wire at the back of the connector body and gently push the terminal out the front of the connector body.

|

|

1.

|

If the wire needed to be cut in order to remove the terminal, gently push a small length of the same size wire through the back of the connector cavity until there is enough wire exposed in order to crimp on a new terminal. If the wire was not cut, cut the existing wire as close to the old terminal as possible.

|

|

2.

|

Strip 5 mm (3/16 in) of insulation from the wire.

|

|

3.

|

Crimp a new terminal to the wire.

|

|

4.

|

Solder the crimp with rosin core solder.

|

|

1.

|

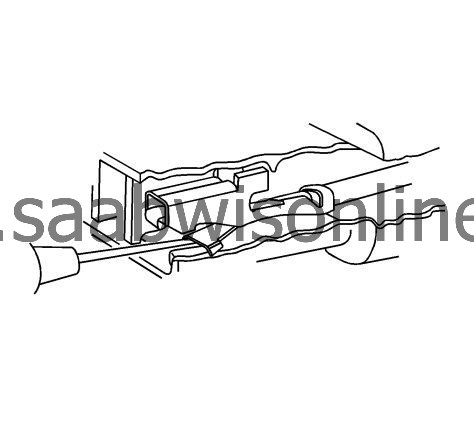

Align the terminal and pull the wire from the back of the connector in order to seat the terminal.

|

|

3.

|

If the connector is outside of the passenger compartment, apply dielectric grease to the connector.

|

|

4.

|

Install the TPA, CPA, and/or the secondary locks.

|

|

2.

|

Find the appropriate terminated lead.

|

|

3.

|

Use the appropriate splice sleeves depending on the gauge size.

|