Tyco/AMP Connectors (102-Way Inline)

|

|

Tyco/AMP Connectors (102-Way Inline)

|

Special Tools

For equivalent regional tools, refer to Special Tools

Special Tools

.

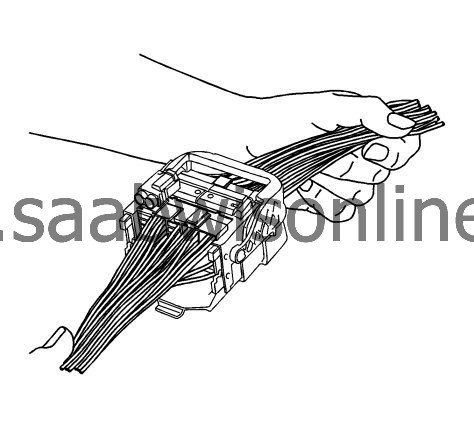

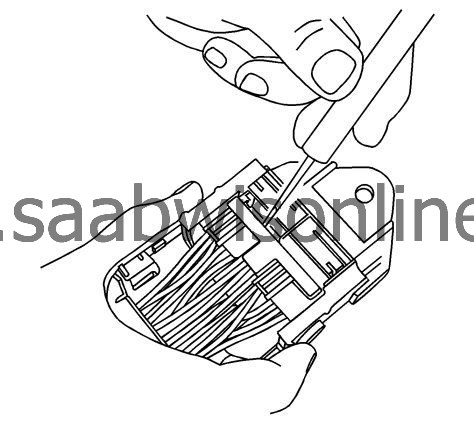

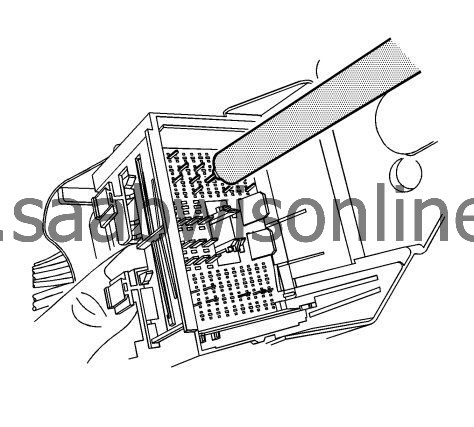

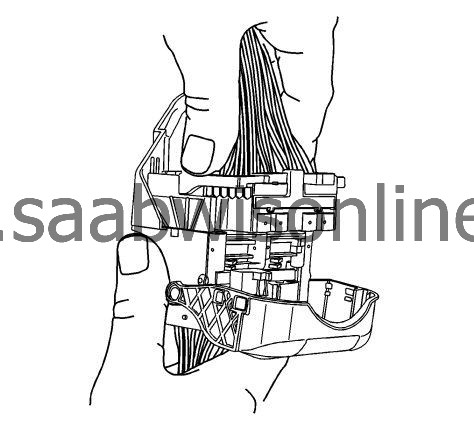

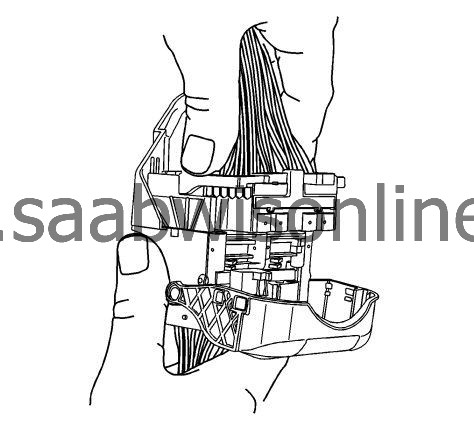

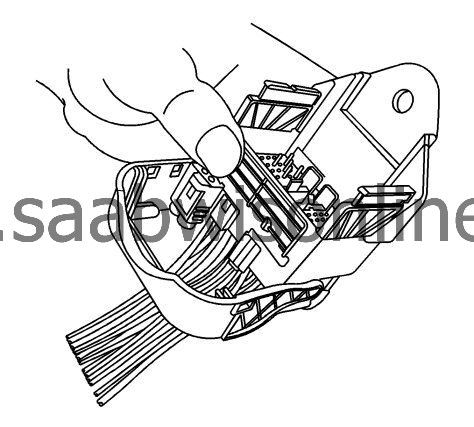

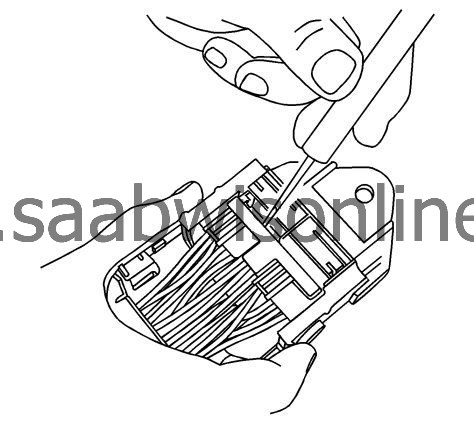

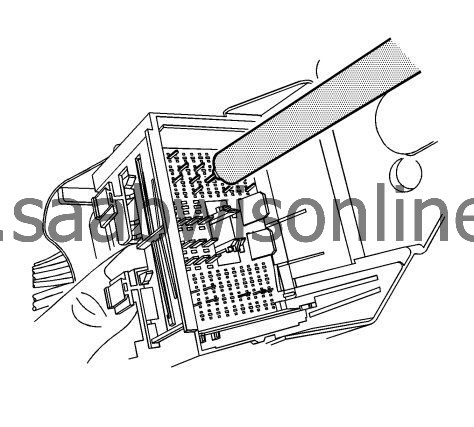

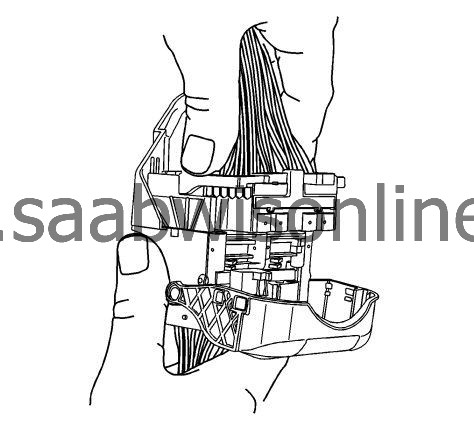

View of a typical connector in the assembled position.

|

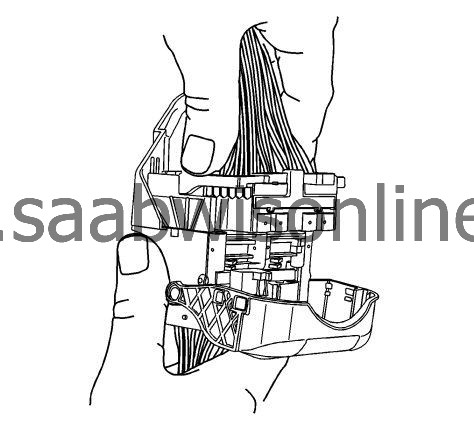

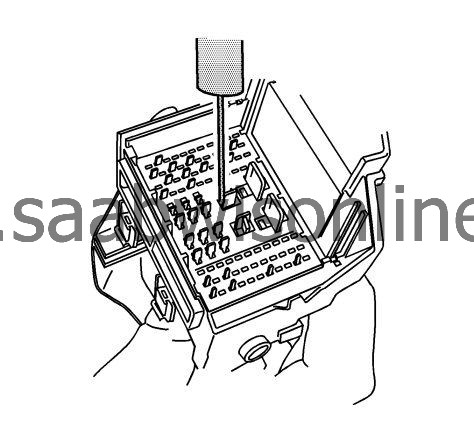

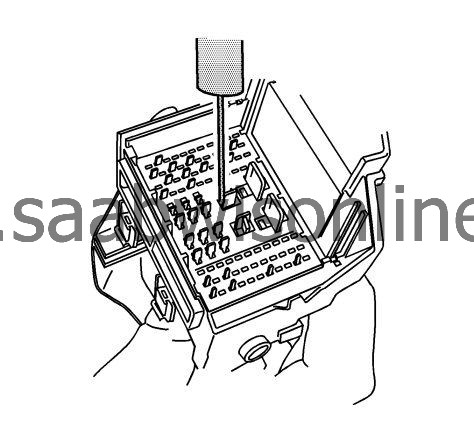

1.

|

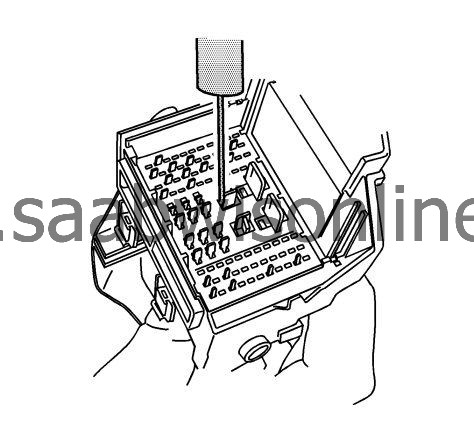

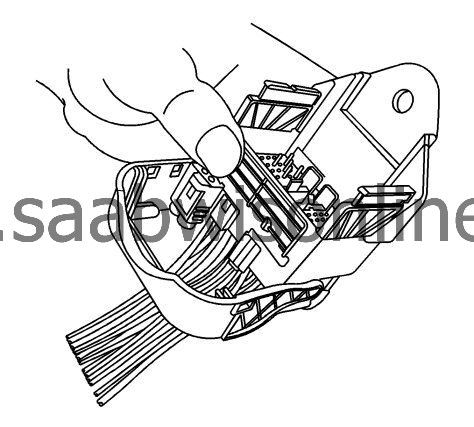

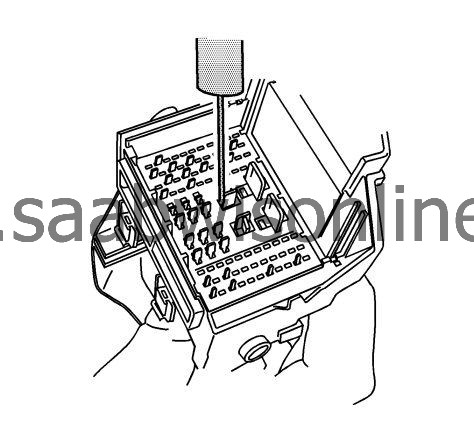

Pull the locking lever to the 90 degree position from the connector body.

|

|

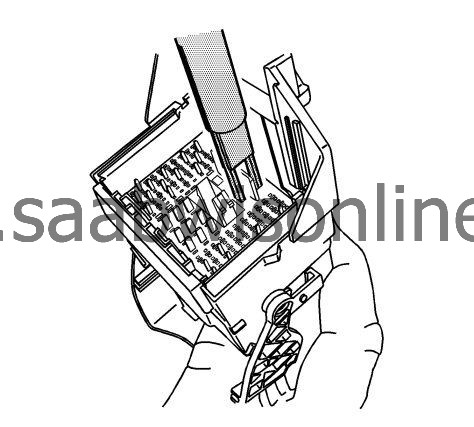

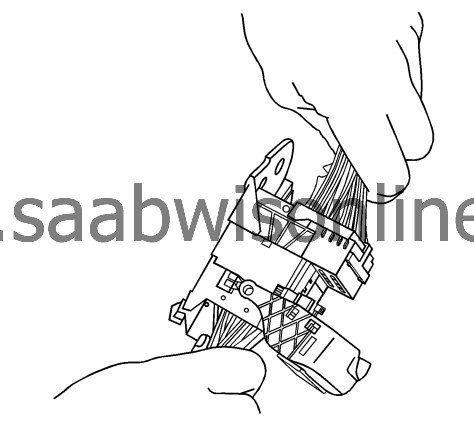

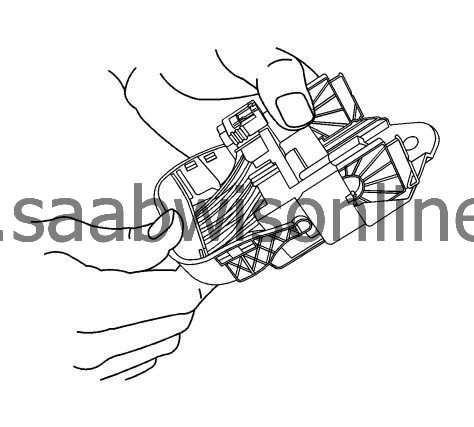

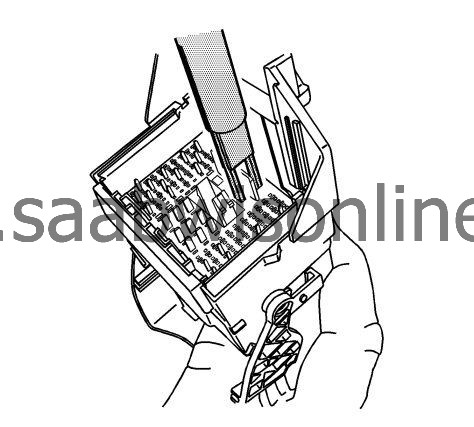

2.

|

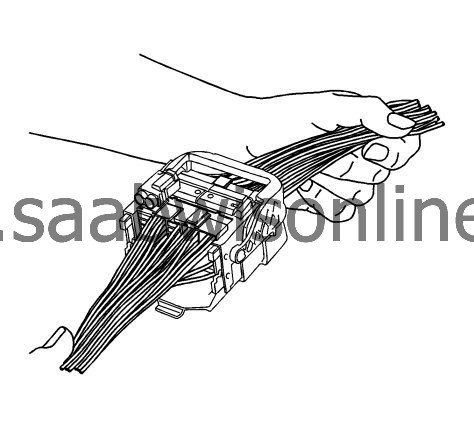

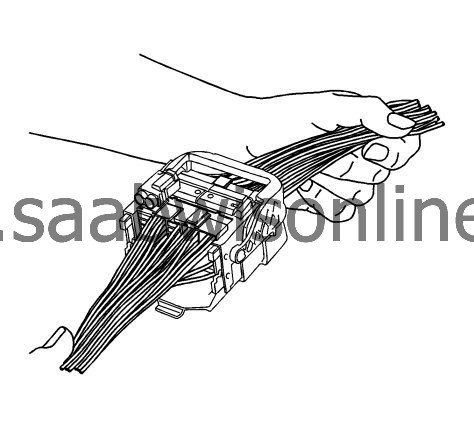

With the locking lever in the 90 degree position and the male connector body separated, it can be slid outward for removal.

|

|

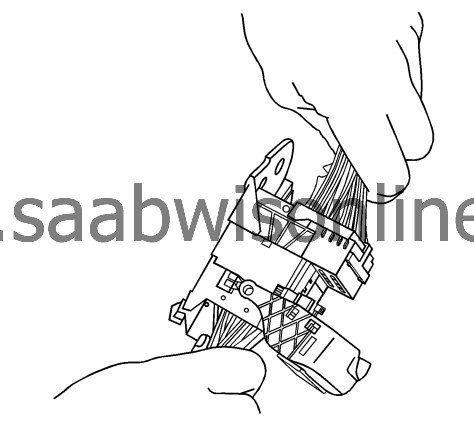

3.

|

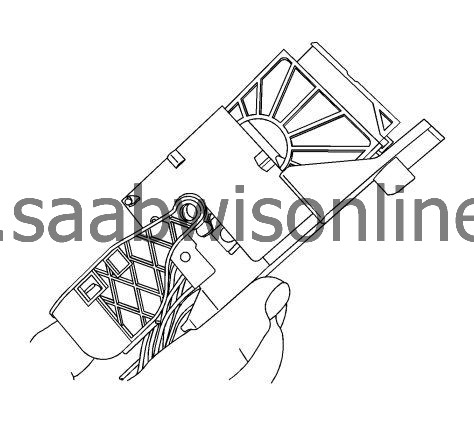

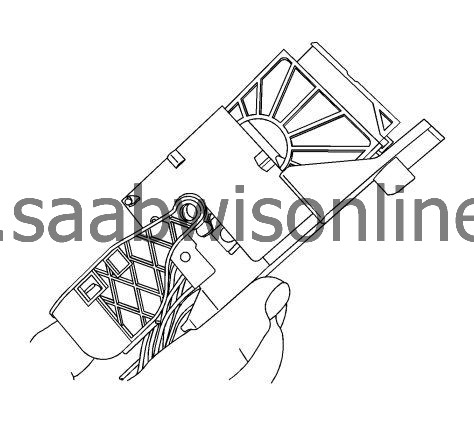

Slide the male connector body out away from the guide plates.

|

|

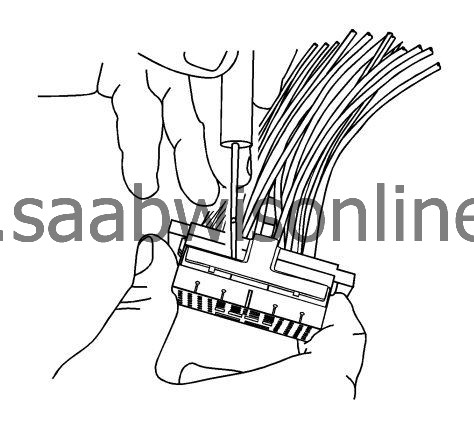

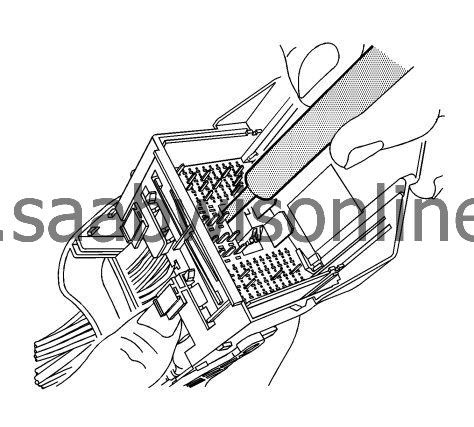

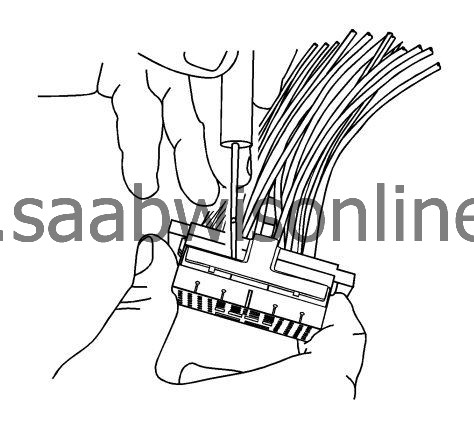

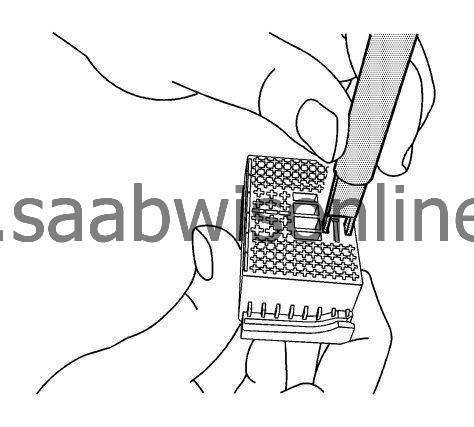

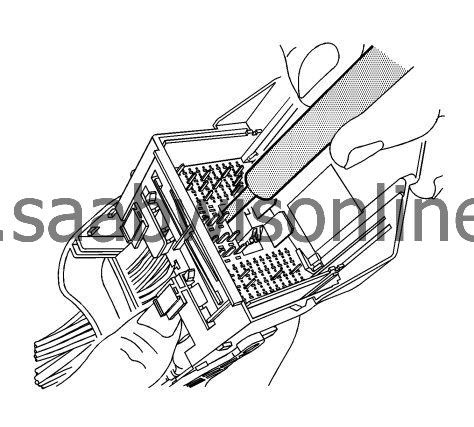

4.

|

|

Note

|

|

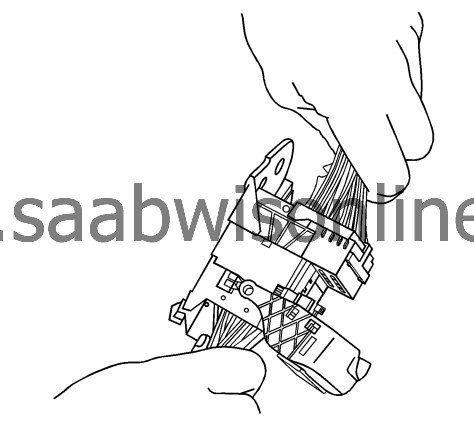

During assembly the TPA will not fully seat if any terminal is not fully seated.

|

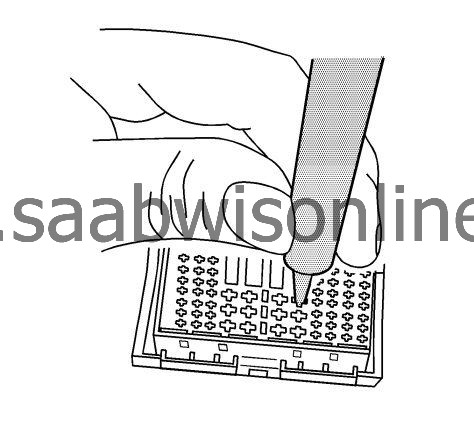

Using terminal release tool J-38125-11A or equivalent, remove the TPA from the connector body.

|

|

5.

|

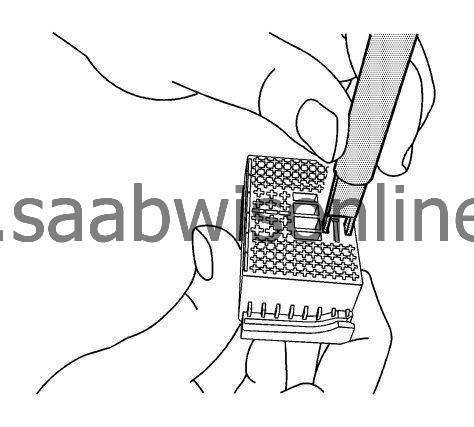

Using terminal release tool J 38125-566, press the prongs into the holes on each side of the terminal to be removed to release the lock tabs and pull the terminal out of the connector body.

|

|

6.

|

Using terminal release tool J 38125-560, press the prongs into the holes on each side of the terminal to be removed to release the lock tabs and pull the terminal out of the connector body.

|

|

7.

|

Using terminal release tool J 38125-221, press the prongs into the holes on each side of the terminal to be removed to release the lock tabs and pull the terminal out of the connector body.

|

|

8.

|

The female connector body may have an additional connector hooked to the edge of the body. Use terminal release tool J-38125-11A or equivalent to release the locking tab and slide the connector off the female body.

|

|

9.

|

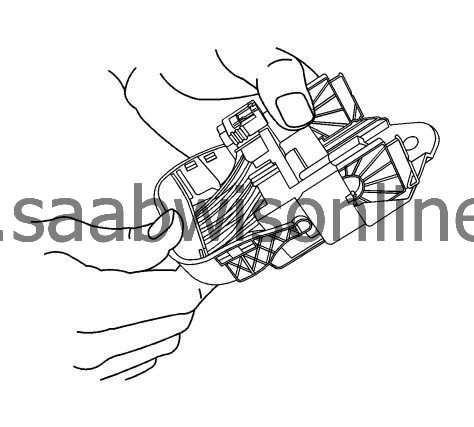

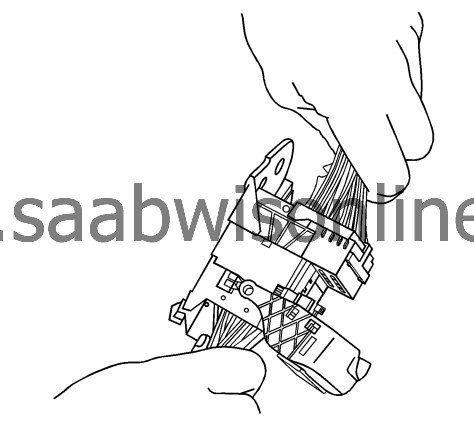

Move the locking lever 180 degrees from the connected position.

|

|

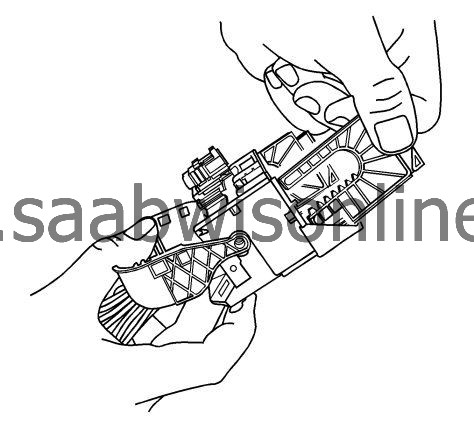

10.

|

With the locking lever in the 180 degree position the guide plates can be removed from the connector body.

|

|

11.

|

|

Note

|

|

During assembly the TPA will not fully seat if any terminal is not fully seated.

|

Using terminal release tool J 38125-11A or equivalent, remove the TPA from the connector body.

|

|

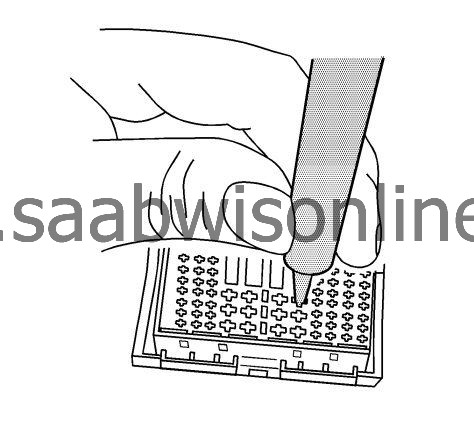

12.

|

Using terminal release tool J 38125-216, lift the terminal plate past the terminals and out of the connector body cavity.

|

|

13.

|

Terminal plate will bind slightly on each corner.

|

|

14.

|

Using terminal release tool J 38125-221, press the prongs into the holes on each side of the terminal to be removed to release the lock tabs and pull the terminal out of the connector body.

|

|

15.

|

Using terminal release tool J 38125-212, press the prongs into the holes on each side of the terminal to be removed to release the lock tabs and pull the terminal out of the connector body.

|

|

16.

|

Using terminal release tool J 38125-560, press the prongs into the holes on each side of the terminal to be removed to release the lock tabs and pull the terminal out of the connector body.

|

|

17.

|

Press the terminal plate back into the female connector to the preset position. The plate will bind slightly on each corner.

|

|

18.

|

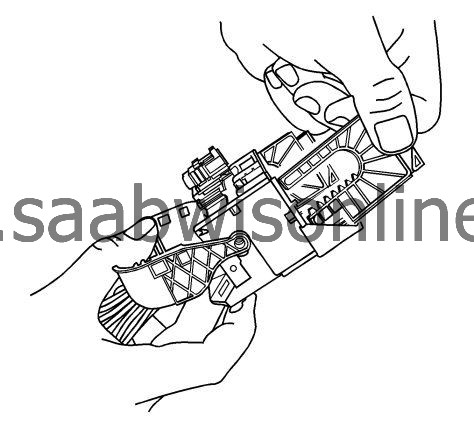

With the locking lever in the 180 degree position, align the guide plates to mesh with the gears on the locking lever.

|

|

19.

|

Slide the male connector body back inward toward the guide plates.

|

|

20.

|

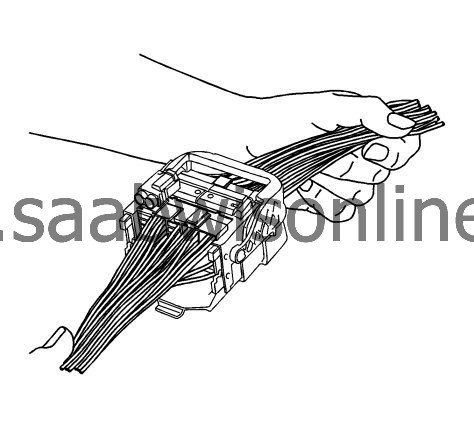

With the locking lever in the 90 degree position and the male connector body connected, it can be slid inward for assembly.

|

|

21.

|

Move the lever into the locked position or in the assembled position. This will pull the male connector down into the female connector.

|

|

2.

|

Find the appropriate terminated lead.

|

|

3.

|

Use the appropriate splice sleeves depending on the gauge size.

|