Transmission Adaptive Functions

|

|

Transmission Adaptive Functions

|

The changing duration is calculated in real time by comparing the speeds of the input shaft and output shaft. The control module knows the gear ratio for the current gear and the target gear and can follow the change in gear ratio until the changing process is complete. The time it took to change gear is then compared with the desired value for the gear change and an adaptation is made.

The adaptation is done by correcting the requested pressure for the applied friction element solenoid and the correction is then used the next time a change is made between these gears. The adaptation value is saved in a non-volatile memory and must be zeroed using a scan tool each time the TCM, transmission or valve housing is changed and after SPS programming.

After zeroing with a scan tool, it will usually only require a road test, see below, for the TCM to be able to adapt itself to the new conditions.

After changing or updating automatic transmission, TCM or software, the old adaptation data must be removed and a new adaptation performed as described below.

|

1.

|

Drive the vehicle slowly. Stop the vehicle by shifting the shift lever to P range and chock the vehicle. Stop the engine then turn ignition on again.

|

Note

|

|

Check that the vehicle does not move before operation.

|

|

|

2.

|

Release the shift lock, and shift the lever to N range.

|

|

3.

|

Check that the N position mark of the TCM is correct.

|

|

4.

|

Use a scan tool to input the command of the N position.

|

Note

|

|

It is not possible to input the command, unless the ignition is on, the shift lever is in N range, the engine is stopped, and the vehicle speed is 0 km/h.

|

|

|

5.

|

Shift the shift lever from P to D range, then check that the indicator displays the correct position. If the display is incorrect check DTCs.

|

|

6.

|

Reset adaptation using a scan tool.

|

|

7.

|

|

Note

|

|

The automatic transmission must not be warmed up by a stall test.

|

|

Note

|

|

Adaptation can be carried out only when the transmission has attained working temperature

|

Operate the transmission to working temperature (65-110°C). Read from the scan tool.

|

|

8.

|

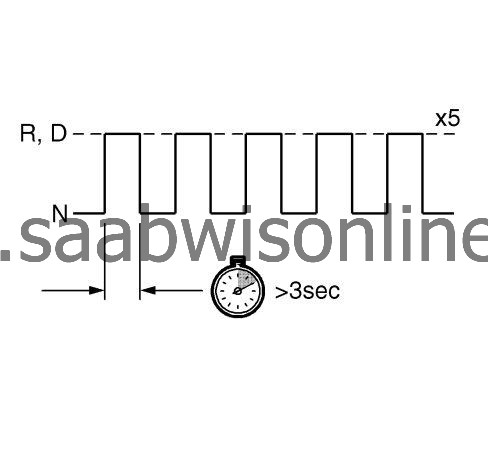

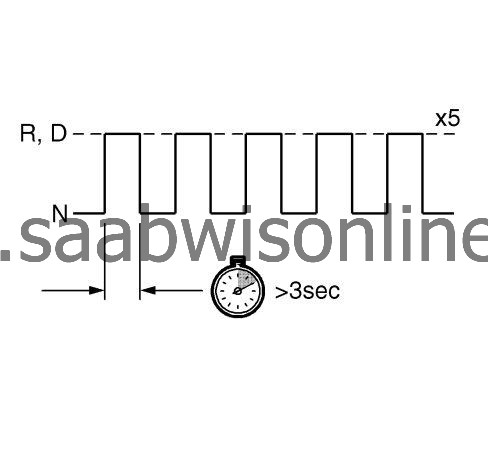

Adaptation for shifting N-D and N-R is carried out with the handbrake applied. If the procedure is done in the workshop, connect an exhaust ventilator, start the car and run at idling speed. Shift from N to R. Keep R engaged for more than three seconds, then shift back to N. Repeat the procedure 5 times. Then shift from N to D the same as above, repeating the steps 5 times.

|

|

9.

|

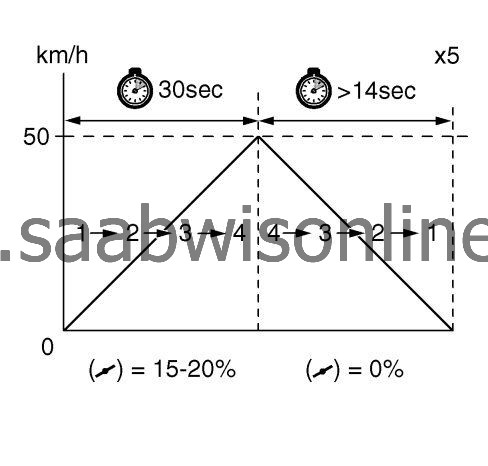

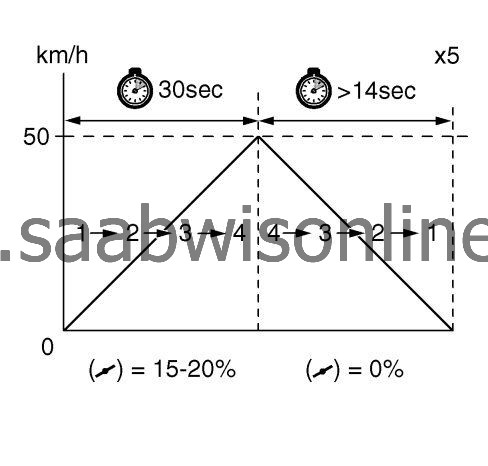

(1) First Gear

(2) Second Gear

(3) Third Gear

(4) Fourth Gear

Adaptation for shifting up and down is done by driving on a road. Engage D and accelerate up to just over 50 km/h with the accelerator pedal at a constant position (approx. 15-20% depressed) until 4th gear has engaged. Brake until the car is stopped. Acceleration up to 50 km/h must take more than 30 sec. and braking must take more than 14 sec. Repeat the above 5 times.

|

|

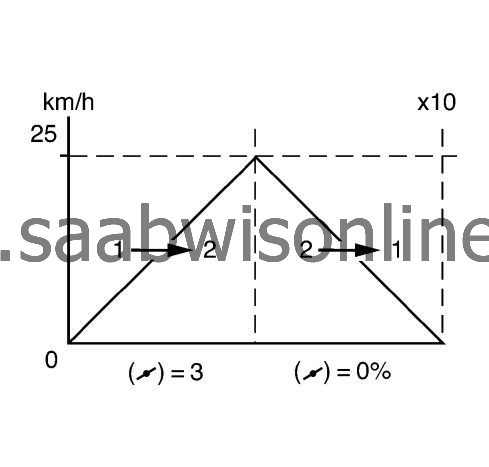

10.

|

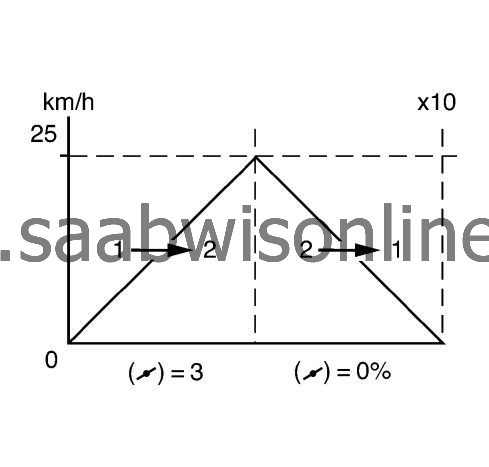

Adaptation of manual shifting from second to first gear is done on the road. Engage M2 with the shift lever. Accelerate to 25 km/h. Engage M1 and brake smoothly until the car is stationary. Repeat this procedure 10 times.

|

|

11.

|

(1) First Gear

(2) Second Gear

(3) Accelerator Pedal Positon (Pedal applied)

Check that adaptation has had the desired effect and that shifting performance has improved.

|