Windshield Replacement

| Windshield Replacement |

Special Tools

| • |

BO-641

Suction Holder

|

|

| • |

BO-46974

Glass Removal System

|

|

For equivalent regional tools, refer to Special Tools .

|

|||||||

| Note | ||

|

The following document describes the procedure for removing the windshield using BO-46974 glass removal system. As a supplement to the existing video VT 54, concise steps will be shown for removing the windshield without destroying it. With the introduction of BO-46974 glass removal system , the conventional glass removing methods are no longer used. |

Position the vehicle on level ground and move the front wheels to the straight-ahead position.

BO-46974 glass removal system is recommended for removing glass without destroying it. Further information can be found in video VT 54.

Before cutting out a stationary window, apply a double layer of masking tape around the perimeter of the painted surfaces.

| Removal Procedure |

| 1. |

Open hood.

|

|

| 2. |

Disconnect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 3. |

Remove the plenum water deflector. Refer to

Plenum Water Deflector Replacement

.

|

|

| 4. |

Remove the windshield pillar garnish molding. Refer to

Windshield Side Garnish Molding Replacement

.

|

|

| 5. |

Remove the inside rearview mirror. Refer to

Inside Rearview Mirror Replacement

.

|

|

| 6. |

Remove lower windshield trim strip (1).

Remove from guide.

|

|

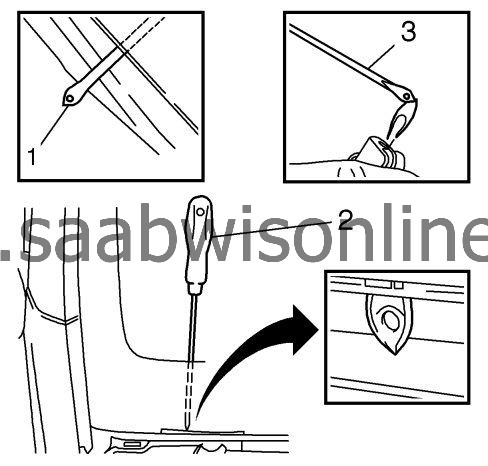

| 8. |

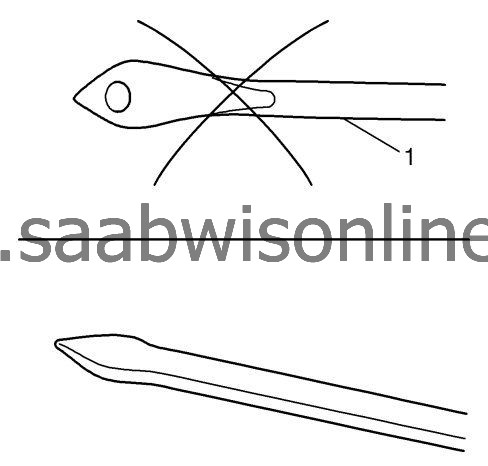

Insert awl through the adhesive bed.

|

|||||||

| • |

Insert the awl (2) (by applying pressure and making slight movements parallel with the adhesive bed).

|

| • |

To make insertion with the awl easier, heat the tip (3) of the awl.

|

| 9. |

Attach cutting wire to the awl.

|

|||||||

| • |

Thread the cutting wire (1) through the hole of the awl.

|

| • |

Bend over the cutting wire.

|

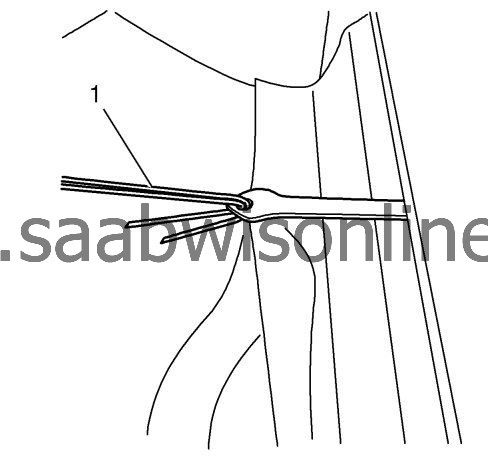

| 10. |

Pull the awl and cutting wire into the vehicle. Pull the cutting wire with awl.

|

|||||||||||||

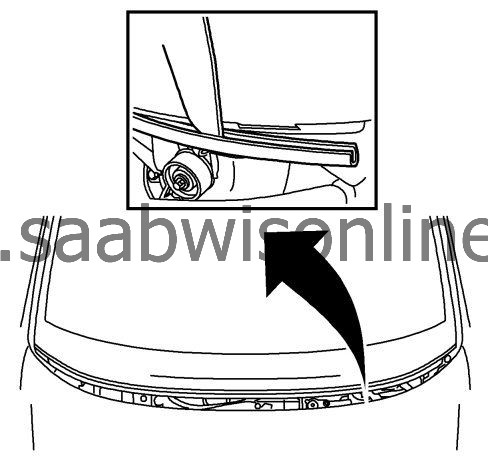

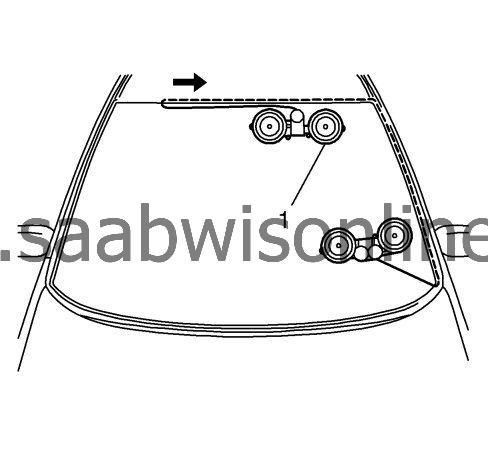

| 11. |

Lay wire below windshield all round.

|

|||||||

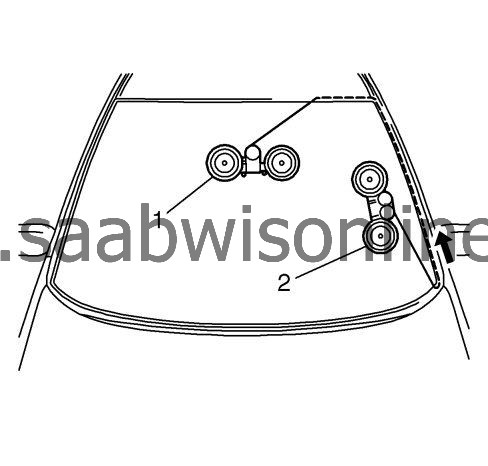

| 12. |

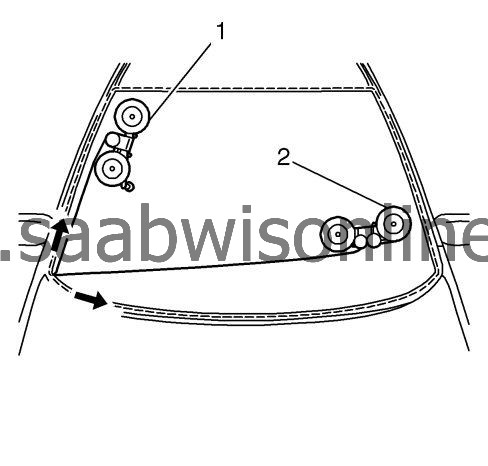

Position winches in the vehicle.

|

|||||||||||||

| • |

Position the winch with one winding head (1) on the right-hand side of the windshield.

|

| • |

Position the winch with two winding heads (2) in the lower left-hand area of the windshield.

|

| • |

Attach 2x cutting wire to winch.

|

| 13. |

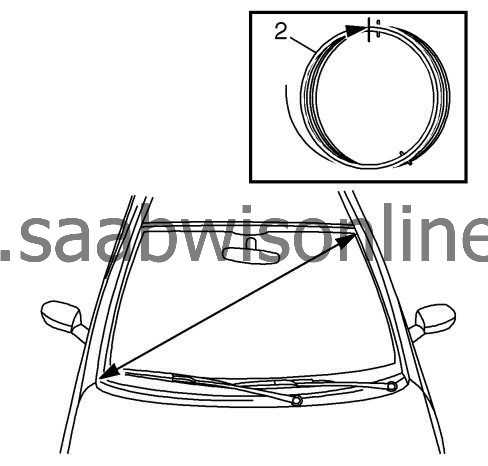

Cut out windshield.

|

|

| • |

Use plastic plate to protect instrument panel padding.

|

| • |

Cut out the windshield using the winch and two winding heads until the cutting wire is level with the winding head.

|

| • |

Arrow shows the path taken by the cutting wire.

|

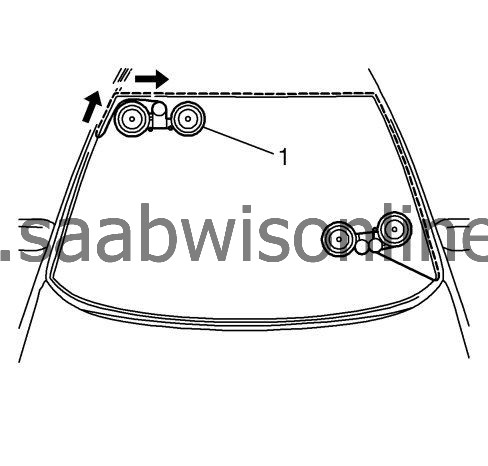

| 14. |

Cut out windshield.

|

|

| • |

Use retainers to protect the A-pillar.

|

| • |

Cut out the windshield using the winch and one winding head until the cutting wire is level with the winding head.

|

| • |

Arrow shows the path taken by the cutting wire.

|

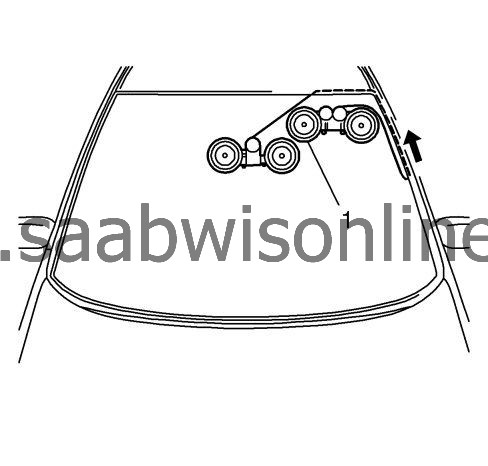

| 15. |

Position winch with one winding head (1) in the vehicle.

|

|||||||||||||

| • |

Attach roof frame in the top right-hand area.

|

| • |

Insert transfer ratchet and pre-tension cutting wire.

|

| 16. |

Cut out windshield.

|

|

| • |

Cut out the windshield using the winch and one winding head until the cutting wire is level with the winding head.

|

| • |

Arrow shows the path taken by the cutting wire.

|

| 17. |

Position winch with one winding head (1) in the vehicle.

|

|||||||||||||

| • |

Attach roof frame in the left area.

|

| • |

Insert transfer ratchet and pre-tension cutting wire.

|

| 18. |

Cut out windshield.

|

|

| • |

Cut out the windshield using the winch and one winding head until the cutting wire is level with the winding head.

|

| • |

Arrow shows the path taken by the cutting wire.

|

| 19. |

Position winch with one winding head (1) in the vehicle.

|

|||||||||||||

| • |

Attach in the centre area of the windshield.

|

| • |

Insert transfer ratchet and pre-tension cutting wire.

|

| 20. |

Position winch with two winding heads (2) in the vehicle.

|

|

| • |

Attach in the lower left area of the A-pillar.

|

| • |

Insert transfer ratchet and pre-tension cutting wire.

|

| 21. |

Cut out windshield.

|

|

| • |

Cut out the windshield using the winch and two winding heads until the cutting wire is level with the winding head.

|

| • |

Arrow shows the path taken by the cutting wire.

|

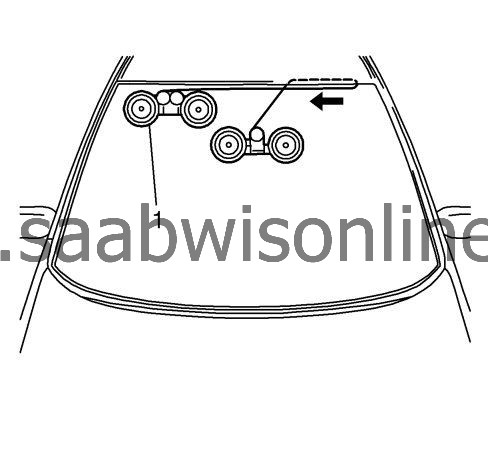

| 22. |

Position winch with two winding heads (1) in the vehicle.

|

|||||||||||||

| • |

Attach roof frame in the left area.

|

| • |

Insert transfer ratchet and pre-tension cutting wire.

|

| 23. |

Cut out windshield.

|

|

| • |

Cut out the windshield until the cutting wire is level with the winch.

|

| • |

Arrow shows the path taken by the cutting wire.

|

| 24. |

Position winch with two winding heads (1) in the vehicle.

|

|||||||||||||||||||

| • |

Attach roof frame in the right-hand area.

|

| • |

Insert transfer ratchet and pre-tension cutting wire.

|

| 25. |

Cut out windshield.

|

|

| • |

Cut out the windshield until the cutting wire has cut through the adhesive bead completely.

|

| • |

Arrow shows the path taken by the cutting wire.

|

| 26. |

Remove both cutting tools.

|

|

| 27. |

Fit

BO-641

suction holder.

|

|

| 28. |

Remove windshield.

|

|

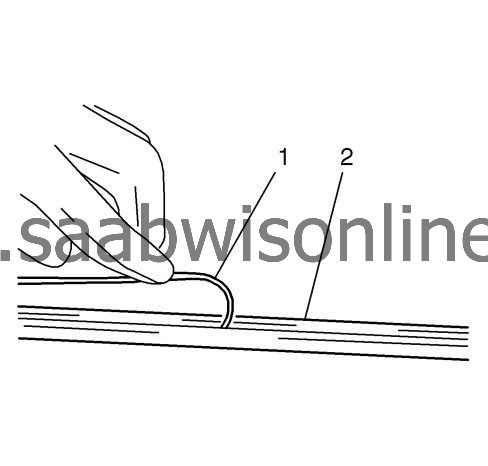

| 29. |

Cut adhesive bead on the vehicle.

Cut the adhesive bead all round using the knife supplied (1) to around 1 mm (0.04 in) thickness.

|

|

| 30. |

Repair any paint damage.

Using a touch-up pen to match the color of the vehicle, repair any paint damage. |

|

| 31. |

Cut adhesive bead on the rear windshield.

Cut the adhesive bead all round using the knife supplied to around 1 mm (0.04 in) thickness. |

|

| Installation Procedure |

| 1. |

Apply primer. |

|||||||

| 2. |

Apply adhesive bead.

Cut into the tip of the cartridge in such a way that a bead of adhesive approximately 13 mm (0.5 in) thick is produced.

|

|

| 3. |

Install windshield into the opening.

|

|

| • |

Second mechanic required.

|

| • |

Insert windshield with

BO-641

suction holder.

|

| • |

Position using fibre tape.

|

| 4. |

Remove

BO-641

suction holder.

|

|

| 5. |

Install lower windshield trim strip.

|

|

| 6. |

Install the plenum water deflector. Refer to

Plenum Water Deflector Replacement

.

|

|

| 7. |

Install the windshield pillar garnish molding. Refer to

Windshield Side Garnish Molding Replacement

.

|

|

| 8. |

Install the inside rearview mirror. Refer to

Inside Rearview Mirror Replacement

.

|

|

| 9. |

Connect the negative battery cable. Refer to

Battery Negative Cable Disconnection and Connection

.

|

|

| 10. |

Close the hood.

|

|

Warning

Warning