Anti-Corrosion Treatment and Repair (Corrosion Protection)

| Anti-Corrosion Treatment and Repair (Corrosion Protection) |

| General |

The high demands with regard to process reliability, functionality, environment mean that high demands are also made in the area of the corrosion protection of the vehicles. A distinction must be made between the measures taken in production and the corrosion protection undertaken when repairing the body, for example, if damaged or involved in an accident.

Our customer expects that his motor vehicle receives this high quality corrosion protection as a new vehicle. Similar expectations are also to be found regarding the protective effect within the scope of body repair work.

During the development of new vehicles, the use of structural adhesives which can be resistance spot-welded and have a high level of corrosion protection is gaining in importance. Service has implemented these new processes in body repair operations within an economically viable framework.

You will find more detailed information about the newly developed repair systems in our publications.

| • |

VT-41 Reliable and economical body repairs

|

|

| • |

VT-52 New Method of Body Repairs

|

|

| • |

VT-54 New Adhesive Systems

|

|

| • |

VT 60 New Working Methods

|

|

| Corrosion Protection on Sheet Metal and Aluminium Parts for Service |

Cataphoretic Dip-Coating

All parts requiring body repair are provided with a high quality cataphoretic dip-coat (CDC) on the exterior and interior. This CDC is already provided at the paint shop. Where service parts have to be repaired because of transport damage, areas previously rubbed down must be insulated using a primer.| Bonding of Folded Edges with Adhesive/Sealing Folded Edges |

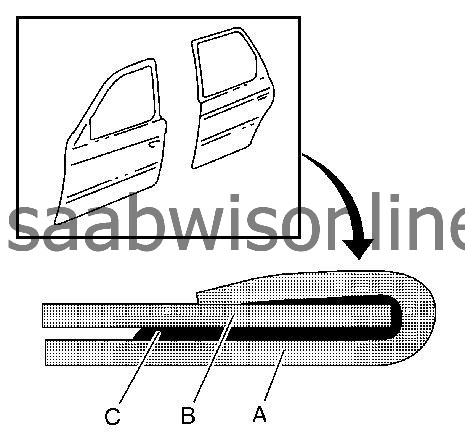

On the majority of bonnets, doors and tailgates, the folded-in flanges of the external panelling are attached to the frame with adhesive. The edges of the flanges are also sealed.

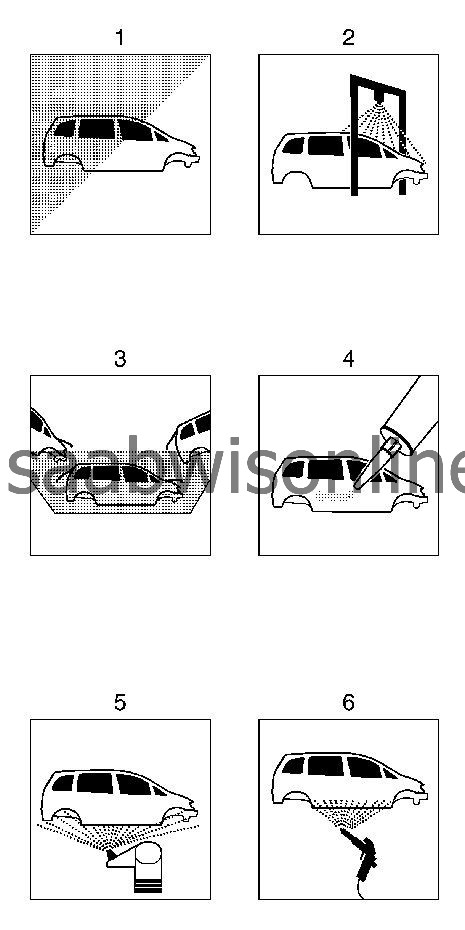

| Corrosion Protection Measures - Typical Production Cycle |

Typical cycle plan, corrosion protection stages.

| Note | ||

|

The illustrations below clarify the individual stages of the process in vehicle production. |

(1) Body-In-White

(2) Spray/Dip-Phosphating

(3) Cataphoretic Electro-Dip-Priming - CDC

(4) Seam Sealer

(5) PVC Underbody Protection

(6) PVC Chipping Protection

(7) Solid Color Primer

(8) Top Coat

(9) Cavity Protection Wax

(10) Underbody protection wax

(11) Protective Wax For Transportation

| Corrosion Protection Measures - Body Repairs |

General

The sections below show a number of the different labour operations with illustrations, views of body sections to provide a better understanding. The sequence is arbitrary. The operations are to be used in accordance with the descriptions in TIS 2000.| Sealing Seams When Undertaking Body Repairs |

| Note | ||

|

Always apply seam sealant to clean, primed or painted base surfaces. Application to bright sheet metal components leads to significant loss of adhesion and qualitative defects in durability. |

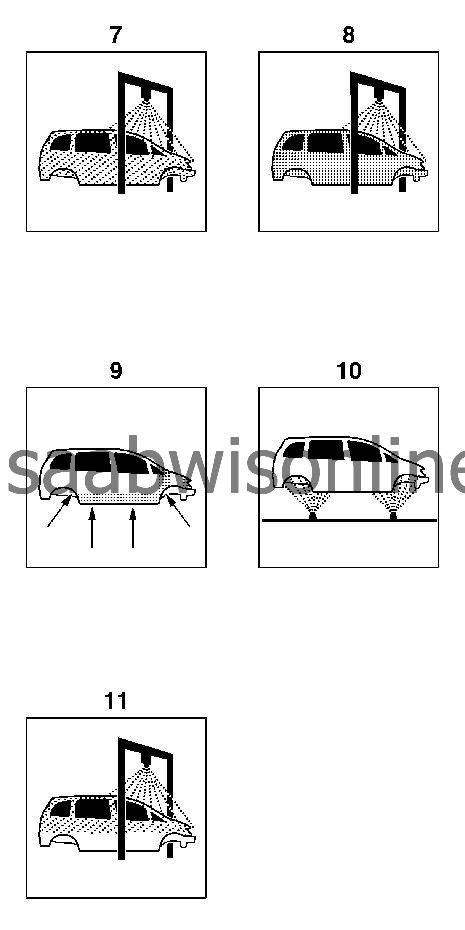

The sealing operations on the body are shown below as a sectional drawing.

(a) Seal Cut Edges of the Flanges

(b) Fill the Molding

(c) Fill Fillet Smooth Sealed Seams in the Visible Area with a Flat Brush

| Chipping Protection When Undertaking Body Repairs |

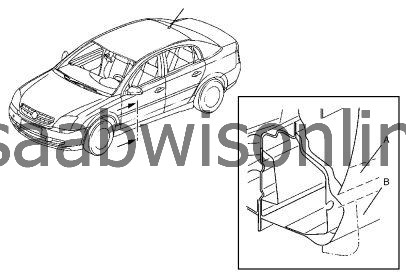

The illustration shows the standard PVC protection in the area of the sills and doors.

(a) Area of Door Sills

(b) Area of Door, Wings, Rear Quarter Panels

| Note | ||

|

Substitute materials should be processed which do not trigger any phenomena caused by dissolving if in contact with the standard PVC protection. As a matter of principle, the substitute materials must be applied to clean, primed base surfaces. Heat standard PVC protection with a hot air blower and remove with a spatula. Do not use any thinners with a high solvent content for washing off. |

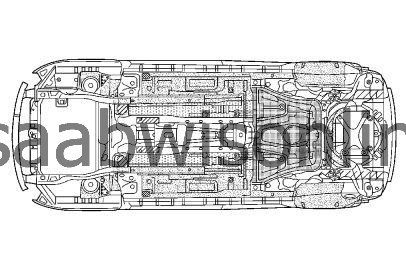

The standard PVC protection must be replaced after dents have been removed or components have been welded in. The areas provided with standard PVC protection are generally on the body.

| • |

Areas in the wheel housing (front, rear of vehicle).

|

|

| • |

Areas in the door sill, lower area of the doors, wings, rear quarter panels.

|

|

| • |

Areas on the vehicle floor, exterior.

|

|

| • |

Areas of the frame side member.

|

|

| Underbody Protection When Undertaking Body Repairs |

| Note | ||

|

Underbody protection materials must be applied to clean, primed or painted base surfaces. The products are less suited to painting over. |

Underbody protection material is used for repairs or maintenance in most cases. When undertaking body repairs, seam sealant which can be sprayed on is preferable.

Advantage:

Universal use, can be painted over if necessary.

| Underbody Protection Wax |

The catalytic converter and exhaust system areas are not coated.

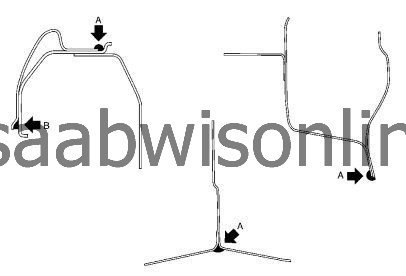

| Cavity Protection When Undertaking Body Repairs |

It is not possible to dispense with subsequent treatment with wax in areas which have been welded or brazed because corrosion protection with paint materials is not possible here.

Areas for subsequent treatment are:

| 1. |

Frame side member

|

|

| 2. |

Doors

|

|

| 3. |

Door pillars

|

|

| 4. |

Sill areas

|

|

| 5. |

Floor/rear end panel

|

|

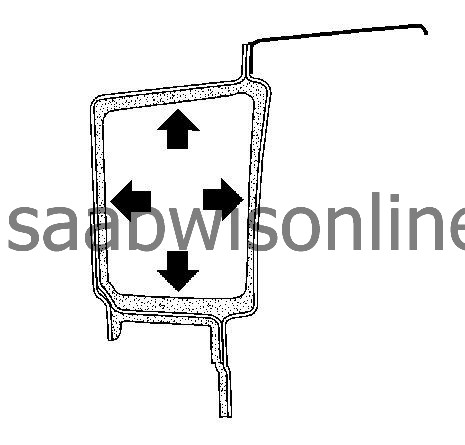

Illustration shows body section with the cavity treatment, using the frame side member as an example.

Illustration shows body section with the cavity treatment, using the door as an example.

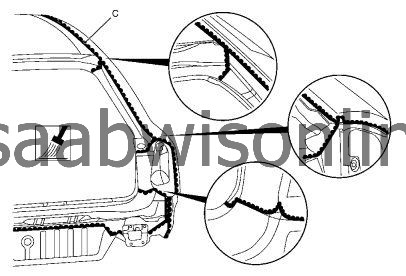

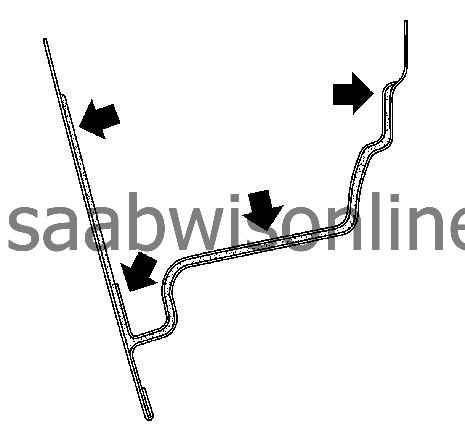

| Bonding the Folded Edge with Adhesive When Undertaking Body Repairs |

| Note | ||

|

The adhesive is most frequently used in one operation to seal the folded joint edges. |

When replacing the outer panelling on doors and tailgate components, the folded edge is bonded using the 2-component adhesive, part no. 93 160 535, catalogue no. 15 05 000.

(a) Outer Panel

(b) Frame

(c) Adhesive

| Body Protection Materials When Undertaking Body Repairs |

For technical process reasons, Aftersales has a separate, harmonised range of materials for adjustment to the corrosion protection materials used in production which meet the high demands if used correctly.

The products in our range have a high quality, long life and are compatible with the materials in our range used in final paint repairs, for further processing of the repaired areas. All the materials used for seam sealing and as protection from chippings can be painted over. Painting over can already be undertaken whilst the sealant materials are still wet.

| Product | Part No. | Catalogue Number | Quantity | Purpose |

|

Chipping protection spray

|

09 121 538

|

15 00 367

|

500 ml

|

Protective coating, body, exterior

|

|

Spray-on seam sealant

|

90 543 279

|

15 03 176

|

300 ml

|

Protective coating, universal, Technical Information TI-C-32 02/1997, telescopic gun MKM-950

|

|

Seam Sealer

|

09 200 244

|

15 06 802

|

310 ml

|

Joints, folded seams

|

|

Sealing Compound

|

90 093 639

|

15 04 520

|

310 ml

|

Folded edges

|

|

Body sealing compound

|

90 273 919

|

15 04 521

|

310 ml

|

Sealing covers, plugs

|

|

Underbody protection spray

|

09 121 545

|

15 00 368

|

500 ml

|

Repair material

|

|

Underbody protection - can

|

09 163 309

|

15 00 371

|

1 liter

|

Repair material

|

|

Underbody Protection Wax

|

09 163 308

|

15 00 370

|

1 liter

|

Repair material

|

|

Cavity Spray Wax

|

09 196 462

|

15 06 801

|

1 liter

|

-

|

|

Corrosion adhesive/sealing system

|

93 160 535

|

15 05 000

|

200 ml

|

Spot-weldable structural adhesive

|

| Body Sealing Plug and Cover |

In addition to the conventional components, plugs with an integrated hot-melt adhesive are mainly used as an annular seam.

Removal of a sealing plug with adhesive:

| • |

Heat the body area around the plug evenly until the adhesive is soft.

|

|

| • |

Unclip the plug with a screwdriver.

|

|

Installation of a new sealing plug with hot-melt adhesive

| • |

Warm body area (hot air blower)

|

|

| • |

Insert plug. During this the hot-melt adhesive will run and form a seal immediately.

|

|

Installation of a new sealing plug without hot-melt adhesive:

Install plug with adhesive sealing compound cold (part no. 93 160 951. catalogue no. 15 03 303).

Paint Repair - TIS 2000, Issue KTA-2207/4