Crankshaft Balancer Installation (LDK, LHU)

|

|

Crankshaft Balancer Installation (LDK, LHU)

|

Special Tools

|

•

|

EN-38122-A

Crankshaft Balancer Holder

|

|

•

|

EN-43653

Flywheel Holding Tool

|

|

•

|

EN-48585

Crankshaft Balancer Guide

|

|

•

|

EN-48953

Camshaft Actuator Locking Tool

|

For equivalent regional tools, refer to

Special Tools (LDK, LHU)

.

|

1.

|

Warning

Warning

|

|

Ensure both components are aligned correctly or serious engine damage will occur.

|

|

|

|

|

|

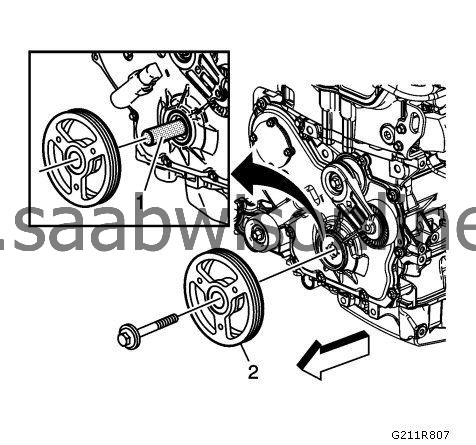

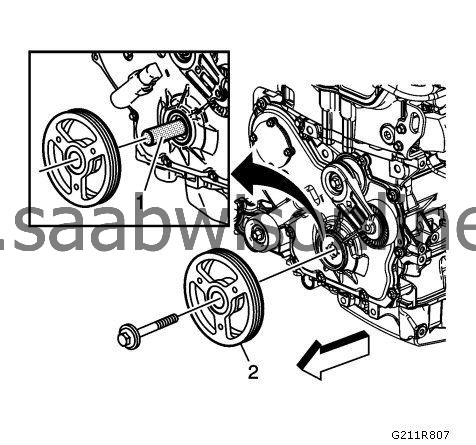

Install the balancer (2) onto the

EN-48585

guide (1). Use care to properly align the keyway and flats on the balancer with the oil pump drive.

|

|

2.

|

Install the crankshaft balancer into the end of the crankshaft.

|

|

3.

|

Refer to

Fastener Caution

.

|

Note

|

|

EN-43653

flywheel holding tool may be used instead of

EN-38122-A

crankshaft balancer holder to prevent crankshaft rotation.

|

|

Note

|

|

Always install a NEW crankshaft balancer retaining bolt.

|

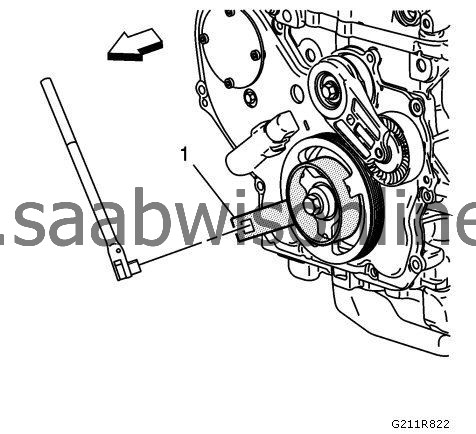

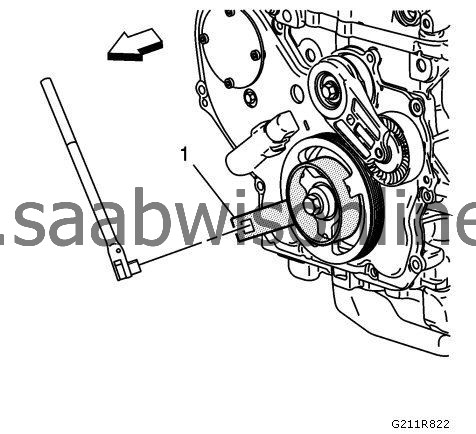

Install a NEW retaining bolt. Use

EN-38122-A

holder (1) and a breaker bar to prevent the crankshaft from rotating, and tighten the bolt to

100 Nm (74 lb ft) plus 125 degrees

using the

EN-45059

angle meter.

|

|

4.

|

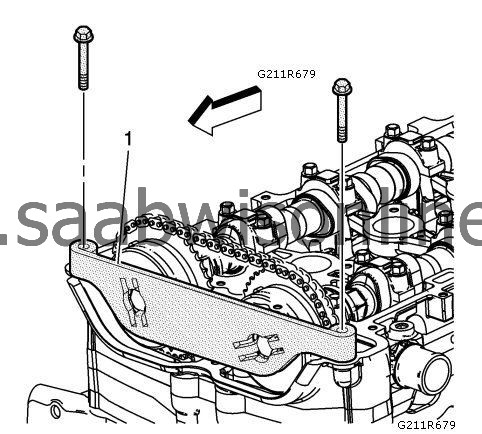

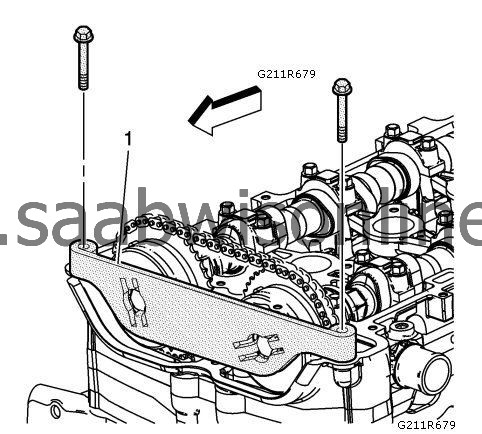

Install

EN-48953

locking tool (1) and tighten the bolts into the cylinder head to

10 Nm (89 lb in)

.

|

|

5.

|

Release the timing chain tensioner by applying

45 Nm (33 lb ft)

counterclockwise torque to the crankshaft balancer bolt.

|

|

6.

|

Remove

EN-48953

locking tool.

|

Warning

Warning